What is hemp fiber?

Hemp is also one of the bast fibers known from ancient times. It has been conducted over many centuries, for end uses from textiles, ropes and sail cloth, to matrices for industrial products in the modern age. It is one of the fastest growing biomasses. Hemp fiber is cultivated from the plants belonging to the Cannabis genus. Cannabis sativa has two varieties named industrial hemp and marijuana typically contains 3-15% of the psychoactive ingredient called tetra hydro cannabinol (THC) on a dry-weight basis, while industrial hemp generally have less than 1% of THC. However, the two varieties are very identical by appearance and are often cause confusion.

Hemp has been widely cultivated as a source of bast fibers. Hemp is an annual plant and can grow on a wide spectrum of soils. Well drained, nitrogen rich and non-acidic soil are essential for hemp cultivation. Hemp favors a mild climate, humid atmosphere and a rainfall of at least 25-30 inches (64-76) per year. Soil temperatures must reach a minimum of 42-460F (5.5-7.70C) before seeds can be planted. The fibers are removed from hemp plant is similar to the process flax fiber production.

Types of hemp fiber:

Hemp fibers are three types. They are following:

- Primary bast fiber-long and low in lignin

- Secondary bast fiber-intermediate and high in lignin

- Libriform-short and high in lignin

Chemical composition of hemp:

The distribution of chemical constituents of hemp stems varies remarkably between the outer bast and the woody core. Chemical composition of outer bast is given below:

- Cellulose: 60-70%

- Hemi-cellulose: 15-20%

- Lignin: 2-4%

- Pectin: 2-4%

- Fat and wax : 1-2%

The chemical composition of hemp woody core is similar to that of hardwood with approximately 40% cellulose, 20% hemicelluloses and 20% lignin.

Physical properties of hemp fiber:

Length and diameter of hemp fiber are 1-5 meters and 16-50 microns respectively. Hemp fiber is a good conductor of heat. It dyes well, resists mildew, obstructs ultra violet (UV) and has natural anti-bacterial properties.

Hemp fiber processing:

Harvesting:

The fiber is ready around the time, when the plant starts developing its first seeds.

Retting:

Retting is process to separate fibers from bark tissue. It can be done through various methods.

Dew/Snow retting:

Hemp stems are left in open, where rain, dew, irrigation or snow can keep the stems moist. This process may take up to 5 weeks and gives a coarse fiber which is light brown in colour.

Water retting:

Stem bundles are submerged in water for bacterial break down of pectin. It takes 70-10 days and produces better quality fiber.

Enzyme retting:

Many research has been focused on retting hemp with enzymes by attempting to replace the bacteria which facilitate fermentation in water retting with enzymes in tanks. The main objective of this technique is to ultimately produce a fiber quality equivalent to that achieved with water retting but without the problems of effluent waste and malodour. In case of enzyme retting, field retting is not required. Specially this method is attractive because it allows retting to take place all year around and eliminates the risks associated with field retting.

Chemical retting:

In this process, chemicals are used to dissolve the pectin. This process takes approximately 48 hrs and produces a very high quality product.

Fibre extraction:

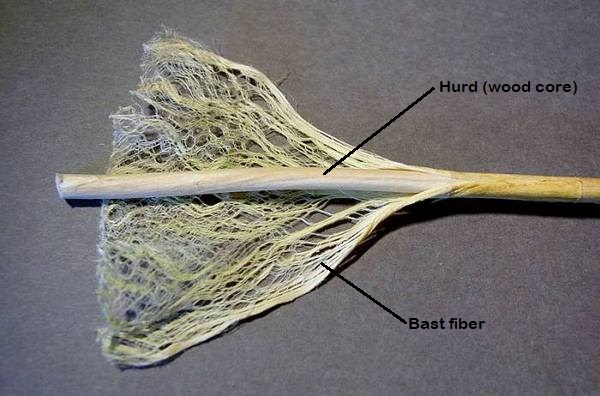

Fiber extraction from hemp stems is commonly achieved by the mechanical processing of the straw, although historically manual decortication has been widely practiced.

After extraction, the fiber is degummed, dried, decorticated, scotched, hackled and combed processes that separate and clean the component parts. Each part can be used for various purposes. Tows are derived from the scotching and hackling process. Optimum yield of hemp fiber is more than 2 tonnes per hectare. Fiber from the stems, oil from the seeds and narcotic from the leaves and flowers are found for various purposes.

End uses of hemp fiber:

Hemp fiber has many applications in industrial sector including paper, textiles, biodegradable plastics, health food and fuel. It is stronger than jute and linen fiber. Besides, it is ideal for making ropes, twine, cables, carpets, sail cloth, canvas, ship cordage etc. Hemp is used for wide varieties of purposes, specially the manufacture of cordage of varying tensile strength, clothing and nutritional products.

Hemp has been used for centuries to make rope, canvas and paper. Long hemp fibers can be spun and woven to fine quality fabric used in clothing, home furnishing textiles and floor coverings. Hemp is primarily used for paper manufacturing in Europe due to low lignin content. Hemp fibers are also used in automobile industry for reinforcing molded thermoplastics. The short fibers (tow) are used for manufacturing insulation products, fiber board and erosion control mats. The fibrous core can be blended with lime to make strong and lightweight concrete.

Long fiber makes long and strong strands (superior to cotton) suitable for textiles. Hemp is used for making variety of textile products, such as bedspreads, blankets, backpacks, carpets, clothing, draperies, hats, luggage, mattresses, sails, sheets, shoes, shirts, tents, towels and upholstery. Hemp textiles have a number of exclusive advantages over other fabrics like hemp textiles are longer, stronger, more lustrous and absorbent and more mildew resistant than cotton textiles.

References:

- Handbook of natural fibres, Volume 1: Types, properties and factors affecting breeding and cultivation Edited by Ryszard M. Kozłowski

- Natural Fibers by Dr. Abu Bakr Siddique & Dr. Hosne Ara Begum

- Introduction to Textile Fibres by H. V. Sreenivasa Murthy