Fabric Inspection:

Main purpose of fabric inspection is to determine its acceptability from a quality view point. Fabric inspection ensures to minimize the rejected garments due to fabric defects. It is an important aspect followed prior to apparel manufacturing to avoid rejections due to fabric quality & facing with unexpected loss in during manufacturing. Besides, fabric is the main element of garment manufacturing. Local or foreign that means whatever be the country of origin of fabrics, the quality of fabrics. Before purchasing of fabrics should be well judged, because, if not so, both time & money may be wasted. Specially, in case of the low grade fabrics, burden of irreparable loss may have to be borne. Some factories do inspection after reaching the fabrics at their factories. But it is wise to do the fabric inspection at seller’s factory so that in case of excessive defects in fabrics, both opportunity and time are got to change the fabrics. There are many system for fabric inspection but frequently used 4 point system for fabric inspection.

Fabric inspections are generally done by machines. Fabric roll is held or hung at the back of the machine and the fabric from the roll is pulled over the glass of the inspection table and it is wound in another role placed in front of the machine. Fabric unwinding from one roll and wound in another is done by motor or by manually. The speed of the fabric can be controlled that means it can be increased or decreased. Arrangement of light is done from the lower end of the glass of the inspection table. As a result, during passing of the fabrics on the glass, if there are any defects in fabrics, they can easily be detected and they are marked right away so that later on specially, during spreading or cutting of fabrics, necessary steps are taken for those defects. During inspection of fabric in this machine, the total length of the fabric in the roll can automatically be known and also there is system for measuring the width of the fabric in the roll. In the supplied lot of fabrics, the difference of widths in rolls is more important than the difference in lengths of fabrics in the rolls. Because due to the differences in the width of fabric rolls, changing of markers may be required, also wastage of fabrics may happen.

There are different systems for fabric inspection, such as 4 Point System, 10 Point System, 2.5 Point System, Grantville System etc. but in the above mentioned systems, or in any other systems, there are no arrangements until recently, for considering of the shade, bias, handling etc., of fabrics. The Four Point System for fabrics inspection has been described here. Because the system of examining of the quality of fabrics in this system, has been recognized by American Association of Quality Control (AAQC).

4 Point Fabric Inspection System:

4 Point System for fabric inspection is widely used in garment industry for fabric quality inspection. It is a tool for satisfying internal as well as external customer. In this fabric inspection system, the number of defect points in one hundred square yards of fabrics is determined through inspection. If the defect points in each one hundred square yards of fabrics be 40 or above, then that fabric will be considered as rejected. Based on the price and quality of garments, the acceptability of defect points may be determined more than 40 also, but in that case it depends on the understanding of the buyer and the seller. The chart of point determination for the defects in fabrics is given below:

| Both way in warp and weft the length of the defect in fabrics | Distribution of points |

| Defects up to 3” inches | 1 |

| Defects from 3” to 6” inches | 2 |

| Defects from 6” to 9” inches | 3 |

| Defects of more than 9” inches | 4 |

| The volume of Holes and Openings | |

| 1” inch or below | 2 |

| More than 1” inches | 4 |

Note: In each yard of fabrics, the defect points more than 4 cannot be counted.

The defects points and the system of determination of acceptability of a fabric is shown through an example. Let by examining a roll of fabric in 48” width and 120 yards in length, the below defects have been determined or marked:

4 defect below 3” 4 x 1 = 4 points

6 defects between 3” to 6” 6 x 2 = 12 points

2 defects between 6” to 9” 2 x 3 = 6 points

1 defect more than 9” 1 x 4 = 4 points

————————————————————————————-

Total points = 26 points

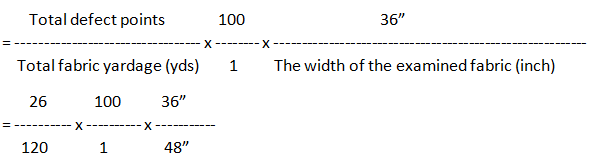

Points/100 square yards,

= 16.25 defect points/100 square yds

The total defect points in each 100 square yards being below 40, this roll of fabric may be accepted. If defects points above 40 in 100 square yds then fabric will be rejected. It may be mentioned here that the limit or level of acceptability of fabric is ascertained by the buyer & seller of the fabric. How much the difference in length & in width in the fabrics rolls will be accepted also depends on the written contract between buyer & seller of the fabric. Inspection sampling plan is also not done by any hard & fast rule. But, 100% inspection is done on the fabrics from which the value of the apparels produced is more than US $20 & 10% inspection is done on those fabrics where the value of the apparels produced from the fabric is less than US $20.