Sample Garment Making:

In garments industry, garments of any design are made commercially. As a result, thousands of garments for each style are made at a time. Before starting of production of each style, a sample of that style is made which is called sample garments. For maintaining interests of both buyer and seller, the sample garment is made approved by buyer before the bulk production of the style. Garment sample making is the 2nd step after designing in garment manufacturing process.

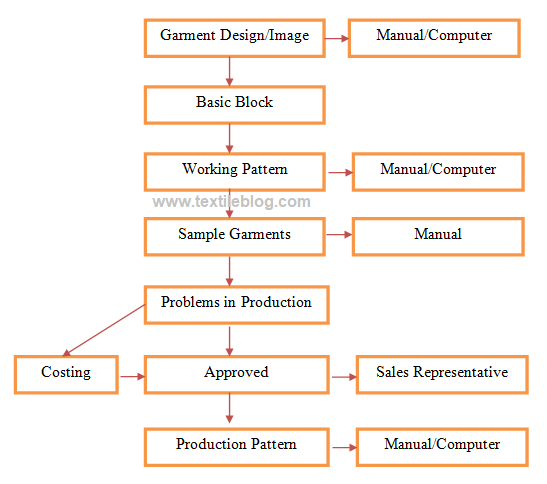

Flow Chart of Sample Garments Making:

The systematic processes of sample garments making is shown below:

For making sample garments, first of all an image of the sample garment is to be drawn and for drawing the image of the garments, a design is to be determined.

Mainly there are three ways to develop the designs of garments by a designer. For example,

- With self thinking and study.

- To copy any existing design exactly.

- To create a new design by adding or subtracting on any design.

After selecting any design, its image is to be drawn clearly on paper. Drawing of images manually is very time consuming and laborious job. This job can also be done by computer very easily and within a very short time. If it is done through computer, more additional facilities are available. For example, use of colors, use of check or stripes, changing of styles very quickly, printing out of designs in paper and even the design of the garments can be seen moving in various directions in computer.

After drawing the design, for making garments of that design, the job starts from the basic block means a sample or a pattern, which expresses the shape of the parts of a body but it does not express any specialty or design. The basic blocks of various sizes of male or female are available. The standard size for men’s shirt is 40 and the standard size for ladies blouse is taken as 12. The basic block can be bought from the market or we can make them ourselves also.

The basic block is kept on white coarse drawing sheet and the image of the block is made on the paper by marking around the block with pencil and then the basic block is removed from the paper. Then with the sketch of the basic block, various types of allowances and special characteristics or samples, for example, seam allowance, trimming allowance, special designs, folding etc. are added. Finally a changed and extended pattern of the basic pattern is obtained which is called the working pattern. Working patterns for all the components (parts) of a garment have to be made. Working patterns can be made manually or by computer. Marker is made with the working patterns and fabrics for garments are cut with the help of marker. Then the sample garment is made by a skilled operator. The designer and the garments sample making technician are different persons. The persons involved with these jobs are required to have much skill and experience. But if both the jobs are done efficiently by the same people, then sample making job can be done quickly and easily.

You may also like: Pattern Making Process in Garment Industry

After making the sample garments, thorough study and checking is done, first of all that whether the garment has become like the planned and drawn garments and if there is any faults in the garments or there will be any problem to produce the garment on a large scale or will any change be required by which minimum time will be required to make the garment and it will be possible to make the garment easily. If any change is required anywhere, then the job will have to be restarted from the design. When sample garment is produced in this way, then it is sent to the costing department for the fixation of its price. After estimating the total production cost of the proposed garments plus determining proposed sales price, the costing department submit it to the higher authority. The costing list of the sample garment is very important and secret information.

After approval of the sample garment and its price by concerned authority, production pattern is made. Generally a sample garment is made one size. But for bulk production pattern is made based on the working pattern of the sample garment.

References:

- Garments & Technology by Prof. M. A. Kashem

- Apparel Manufacturing Technology by T. Karthik, P. Ganesan, D. Gopalakrishnan

- Garment Manufacturing Technology Edited by Rajkishore Nayak and Rajiv Padhye

- Garment Manufacturing Technology by Md. Shafiul Azam, Md. Abu Saleh & Khondokar Abu Nafiz

- https://textilelearner.net/sequence-of-garment-sample-development/