What is Flame Retardant Fabric?

A flame retardant fabric is a special kind of technical fabric that avoids fire spreading. The special feature is that its flame-retardant features reside in its composition materials and don’t depend in any case from a finish. It can be chemically insert into the polymer molecule or physically blend in the polymers after polymerization to suppression, reduce, or modify the propagation of flame.

Maximum fire accidents are associated with the burning of fabrics. Cellulosic that is generally used in apparel are comfortable. But, it has more prone to in flammability. The weight and weave decide of the fabrics its inflammability. Loosely woven fabrics burn fast but heavy and tight woven fabrics burn slowly compare with.

Types of Flame Retardants:

| Types of Flame Retardants | Details |

| 1. Halogenated Hydrocarbons | The most well-known are Bromine Flame Retardants (BRFs). BFRs are commonly used in the electronics industry, textiles and construction products. Halogenate releases active molecular atoms into the gas phase before the material reaches its ignition temperature. It can be prevented the burning process or slow the fire flame. |

| 2. Inorganic flame retardants | Inorganic compounds are used as flame retardants or as a catalyst within a flame-retardant system. In these system antimony-oxides does not have flame retardant properties. But when it combines with halogen-based flame retardants it serves as synergist. It means the antimony oxides act as a catalyst causing the halogen to break down even faster. Thus, releasing active halogen atoms into the gas phase at a more rapid rate. It removes the high energy radicals that feed the gas phase of the fire. These compounds interfere with the burning process through the release of inert gasses and creating a protective char layer, or energy absorption. |

| 3. Nitrogen Flame Retardants | Melamine-based retardants are the most commonly used type of nitrogen flame retardants. When it is in the condensed phase, the molecular structures of melamine transform into cross-linked structures. These changes promote the formation of char, which inhibits oxygen supply in the fire. |

| 4. Intumescent Coatings | The aim of systems intumescent coatings is to protect materials from fire by preventing burning. When exposed to heat these coatings expand to create a fire-resistant and insulating layer on the material. This layer protects the material from high temperatures and prevents or slow the structural damage. |

| 5. Phosphorous containing Compounds | These compounds are both chemically bound to materials and are also physically incorporated as an additive. Char forms when the phosphorous compound is heated. As a result, inhibiting the formation of combustible gas and the pyrolysis process. The interesting things about the formation of char are: it hinders the release of combustible gasses while forming the protective layer that shields the polymer from the heat of the flame. |

There are different types of retardants, as below:

- Brominated flame retardants.

- Carbon Based flame retardants.

- Chlorinated flame retardants.

- Minerals flame retardants.

- Phosphorous-containing flame retardants.

- Nitrogen-containing flame retardants.

- Inorganic flame retardants.

- Phosphorous flame retardants.

- Silicon Based flame retardants.

- Synergists flame retardants, etc.

Treatment of Flame Retardant Fabric:

Flammability is important, particularly for fabric. A retardant finish is allowed to fabrics to prevent it from getting burnt. Some treatment applied to the fabric to create a flame-retardant fabric. They are discussed below:

1. Textile treatments:

Flame retardant materials can effectively apply to both natural textile fibre and synthetic fibres. The textile fiber treated with the chemical which can minimize the flammability of the fabric. When a fire occurs, the flame-retardant fabric reacts with the gases and tars generated. It converts the gases and tars into carbon char. This ultimately slows down the burning speed of the fabric.

Various fire-retardant materials used in textile treatment:

- Kevlar

- Twaron

- Indura fr cotton

- M5 fiber

- Nomex

- Coated nylon

- Carbon Foam

- Proban fr cotton

- PYROMEX

- Pyrovatex fr cotton

- Dale Antiflame

- Technora

- Teijinconex

- Lenzing FR

- PBI

- Carbon X

- Kanox

- Mazic

- Modacrylic

- Kermel, etc.

2. Non-permanent & semi-permanent treatment:

Non-permanent & Semi-permanent treatments are used for substrates that are not exposed to water without being soaked. In this treatment, the principle consists of dissolving a salt in water and impregnating the fibre or fabric with this solution and then drying the fabric. The salt remains on the fabric. It helps system to delay the appearance or spread of fire.

The impregnation is often performed by padding. The operation refers to dipping the fabric in a bath. Then a passage between two superimposed rollers applied high pressure. This device used in this process is called ‘mangle’. This is a very simple technique to implement. It’s cheap and applicable to many fibres. The ‘mangle’ device makes it possible to standardize the impregnation, to get the salt deeply into the fabric and to recover the excess. Thus, facilitating the drying that follows.

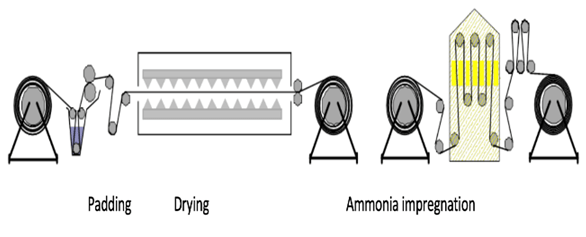

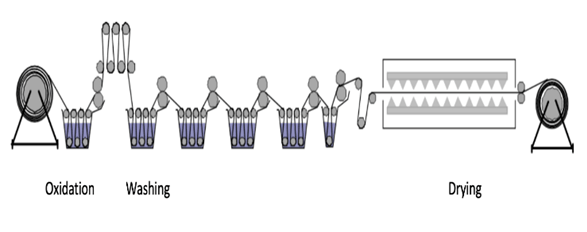

3. Permanent treatment:

In this permanent treatment, two types of treatment exist for cellulose. The first treatment is chemically binding a molecule to the cellulose, by using one of its own OH- groups. Another is based on a polymerization of product with itself, which forming a network in and around the fibre, without creating chemical bonding. In both treatments, fabric used is a phosphorus derivative.

In the treatment, it is important to work in an acidic environment. This causes a loss of fibre strength, typically 15- 30%. Another solution makes to maintain almost unchanged mechanical strengths. It can also be used on cellulose or, synthetic fibre mixtures. It gives a better resistance to fire. It is applied as follows:

- Padding in a bath containing the flame-retardant product. It is a pre-condensate of Tetrakis Hydroxymethyl phosphonium chloride (THPC)

- Drying according to well-defined criteria.

- Washing and oxidation to remove unbound products and to stabilize phosphorus at a five-fold bonds.

- Finally drying.

In this process machine filled with gaseous ammonia that allows a polycondensation chemical reaction to take place. The ammonia group serves as a link among the different molecules.

This permanent treatment, allows obtaining excellent fireproof results, up to M1 & B1classifications. Permanent mainly used for the production of protective clothing for trades exposed to fire risks: fire fighters, military, electricians, etc.

Applications of Fire Retardant Fabrics:

Fire retardant fabrics are usually used in industrial worker wears, uniforms for firefighters, military pilots’ suit, war-combat dress, tent fabric, parachute fabric, professional motor racing apparel etc. Materials like ‘Twaron’ are mostly used to withstand high temperature in industry like firefighting. A fire-retardant fabric protects the wearer against fires, and electrical arcs etc. It is mostly used in interior materials like curtains, in hotels, hospitals, theatres, etc.

In this modern era, the presence with flammable materials in our homes (curtains, carpets, decorations, plastics etc.), a typical room in a house can reach 600°C in 3 minutes. The flame retardant materials in consumer goods and furnishing help us to avoid the fires. Sometimes it adds few life-saving minutes to escape from danger. Flame retardants fabrics save lives and protect property by helping to prevent fires from starting and spreading.

References:

- https://textilelearner.net/flame-retardant-finishes/

- https://www.technicaltextile.net/articles/flame-retardant-finishes-2686

- https://www.life-farbioty.eu/flame-retardant-finish-on-textiles/

- http://www.polymersolutions.com/blog/major-categories-flame-retardants

- https://texfire.net/blog/en/what-is-a-permanent-flame-retardant-fabric

- http://fr.polymerinsights.com/fr-types

- https://technicaltextile.net/articles/fire-retardant-fabrics-3131

Author of this Article:

Md. Mahedi Hasan

B.Sc. in Textile Engineering

Textile Engineering College, Noakhali.

Email: mh18.bd@gmail.com