There are a number of spinning techniques. Ring spinning, the oldest and most popular one, which is still used, rotor spinning which is used on denim yarns but others of wrap, core, air jet and friction spinning have been used but generally have failed to become accepted.

Ring spinning is a continuous spinning action that entails drawing the roving, twisting and winding it onto bobbins in one action to form the yarn. It is used for the cotton system. This system is used by approximately 85% of the market.

The functions of the spinning machines are the preparation of the fibers for the actual spinning process, the organization of the fibers in a coherent, continuous structure, and the production of packages or units suitable for further processing. The basic principle of producing a yarn by organizing, parallelizing, drawing, and twisting of the fibers has not changed since the very beginning of spinning thousands of years ago.

In this article I will give a list of machinery are used in cotton spinning mill.

List of Machinery Used in Spinning Mill

1. Blowroom Machine

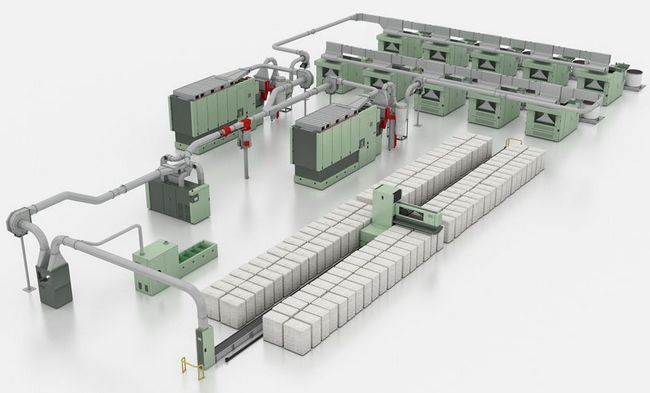

Blowroom is the first section in cotton spinning mill. In blowroom section, opening, cleaning, blending and dust removing are done. So various types of machines are used in blowroom section. They are,

👉Opening Machine:

There are some opening machines used for bale opening in the blow room;

- Bale Opener Machine

- Porcupine Opener Machine

- Crighton Opener Machine

👉Cleaning Machine:

There are some Cleaning machines used for cleaning the fiber in the blow room;

- Axo Flow Cleaner Machine

- Step Cleaner Or Ultra Cleaner Machine

- S.R.L.L Cleaner Machine

👉Blending Machine:

There are some blending and mixing machines used for fiber blending in the blow room;

- Automatic Blending Box Machine

- Double Chamber Blending Box Machine

👉Dust Removing Machine:

There are some dust removing machines used for special fiber cleaning process in the blow room;

- Dustex Dx Machine

- Heavy Part Separator Sp-H Machine

Input & Output Material: Input material of blowroom is raw cotton and output material is Lap / Tufts.

Manufacturers of blowroom machine:

- Rieter, Switzerland

- Trutzschler, Germany

- Saurer, Germany

2. Carding Machine

Input & Output Material: Input material of carding machine is lap / tufts and output material is carded sliver.

Manufacturers of carding machine:

- Rieter, Switzerland

- Trutzschler, Germany

- Saurer, Germany

- Bonino, Italy

3. Drawframe Machine

Input & Output Material: Input material of drawframe machine is carded sliver and output material is drawn sliver.

Manufacturers of drawframe machine:

- Rieter, Switzerland

- Trutzschler, Germany

4. Lap Former Machine

Input & Output Material: Input material of lap former machine is drawn sliver and output material is mini lap.

Manufacturers of lap former machine:

- Rieter, Switzerland

5. Comber Machine

Input & Output Material: Input material of comber machine is mini lap and output material is combed sliver.

Manufacturers of comber machine:

- Rieter, Switzerland

- Trutzschler, Germany

6. Simplex/Roving Frame/Flyer Frame/Speed Frame Machine

Input & Output Material: Input material of simplex machine is combed drawn sliver and output material is roving.

Manufacturers of simplex machine:

- Rieter, Switzerland

- Saurer, Germany

- Toyota, Japan

7. Ring Frame Machine

Input & Output Material: Input material of ring frame machine is roving and output material is yarn.

Manufacturers of ring frame machine:

- Rieter, Switzerland

- Saurer, Germany

- Toyota, Japan

In every Rieter spinning frame machine has 1824 spindles.

For 100,000 spindles need 55 Ring Frame Machine.

8. Auto Winder

Input & Output Material: Input material of auto winder machine is yarn and output material is yarn cone.

Manufacturers of auto winder/auto coner machine:

- Rieter, Switzerland

- Saurer, Germany

9. Open End Rotor Machine

Manufacturers of rotor machine:

- Rieter, Switzerland

- Saurer, Germany

You may also like:

- Applications and Impacts of Automation in Fiber and Yarn Manufacturing

- List of Top 10 Yarn Manufacturers and Exporters in Bangladesh