Feed Mechanism in Sewing Machine:

In order to get the good appearance and performance of the seam, produced by sewing, need to produce correct and well balanced length of stitches. In addition to this, need to ensure so that the fabric along the sewing line remains flat that means no gathering is created. But sometimes gathering in fabrics along the sewing line is formed intentionally, which is done as per the requirement or for the interest of the designs. These required matters are maintained during the production of seam by sewing with the feed mechanism of sewing machine. The feed mechanism controls the feeding speed of the fabrics during sewing. Besides feed mechanism, the speed of the fabric can also be controlled by adjusting some more mechanisms or spare parts with the machine, which have been discussed later on. For the purpose of controlling the feeding speed of fabrics in sewing machines, mainly six types of feed mechanism in sewing machine are used which are discussed here with images.

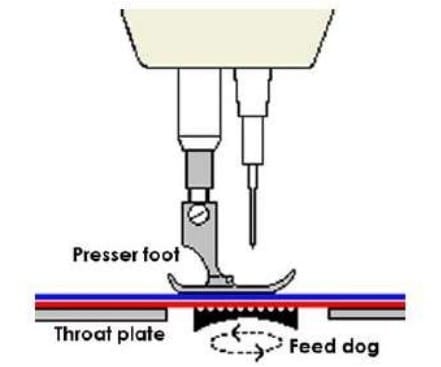

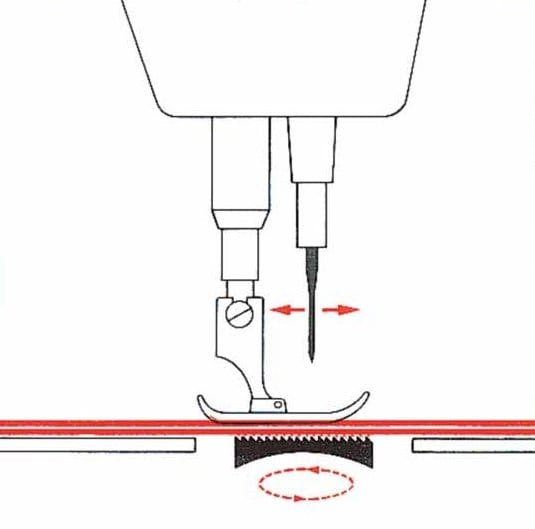

1. Drop feed system:

It is the simplest and most used feed mechanism. The feed mechanism in sewing machine is consist of three parts, they are: a) pressure foot, b) throat plat, and c) feed dog. The throat plate is made of stainless steel and its surface is very smooth. For the reason of smooth surface, fabrics can easily be feed on it. Sometimes throat plate is also called the needle plate. In throat plate, there are one or more than one slots in which feed dog can move forward or backward. There is also a hole through which the needle can move upward or downward. The size of the needle hole should not go beyond more than 30% of the needle size. If the size of the needle hole is more than 30% of the size of the needle, then during penetrating of the fabric by needle, some portion of fabric will also enter into the needle hole, which is called the flagging. Problem can arise in the formation of correct stitch due to the flagging. The drop feed mechanism has been shown in figure-1.

The main function of feed dog is to make the fabric pass the pre-settled distance for the formation of each stitch. The speed of the feed dog or the stitch length is controlled by stitch length regulator. The upper end of the feed dog is slotted or toothed which goes through the slot of the throat plate and comes a little upper to the plate and comes in touch of the fabric from the downside of the fabric and takes the fabric a step forward into the machine. Then the feed dog comes down from the surface of the throat plate, as a result, it is separated from the touch of the fabric. Because, at this stage only the throat plate remains in touch of the fabric. Again, the feed dog comes backward a step, comes through the slot of the throat plate and finally come a little above the surface of the plate and from the down side of the fabric, it comes in touch with the fabric. This way in cyclic order, for each of the stitch, it helps in making to a pre-settled distance. The speed of the feed dog and the needle is so adjusted that when the fabric gets speed, then the needle stays above the fabric.

The number of feed dog, their placement and the shape of the slotted tooth and the numbers may vary. In case of a single row feed dog, during the time of feeding the fabric, the sewing line may bend left or right instead of going straight. Generally, the sewing line becomes straight in two rows or three rows feed dog sewing machines, because fabric cannot easily move to the left or to the right.

The number and shape of slotted tooth on the surface of the feed dog may be of various types, but the direction of the tooth will be kept slanted to the direction at which the fabric will be fed. For the light to medium weight fabric, the pitch of tooth is used between 1.3 and 1.6 mm and the front part of the tooth is kept to some extent rounded so that fabric is not damaged. For very light weight fabric, feed dog of 1 to 1.25 mm pitch tooth is used. For some complicated fabrics, feed dog with rubber covered tooth is used so that fabric is not damaged or marked by the tooth of the feed dog. During the formation of the seam, if the pitch of the stitch and the pitch of the tooth of the feed dog becomes equal, then fabric may be damaged due to the reason of repeated striking of the tooth of the feed dog to the same place of the fabric.

The pressure foot is used to create pressure on the fabric with the help of spring pressure, so that during the up and down word movement of the needle, fabric also may not move up and down. In drop feed process, the pressure foot remains static and fabric is fed under the lower surface of it. The lower surface of the pressure foot is generally kept very smooth so that the friction between the pressure foot and the fabric becomes less. There are various types of pressure foot.

In drop feed process, when two ply fabric is sewn, the feed dog makes the lower layer of fabric to move forward from the lower side of the fabric and the upper layer fabric gets speed due to touch with the lower layer of fabric and the pressure. The pressure foot always exerts pressure on the fabric with the help of pressure spring and during the moving forward of the fabric by feed dog, the movement of the upper layer of fabric in the same speed is obstructed due to the friction with the pressure foot. As a result, it is seen that the lower layer of fabric becomes greater feed than the upper layer, which is called the ply shifting or differential feed pucker or feeding pucker. For the same reason, ropping is created during hemming. In drop feed sewing machine, ply shifting and ropping are very common. This problem can be avoided by very skilled operator, but the speed of the sewing becomes much slower.

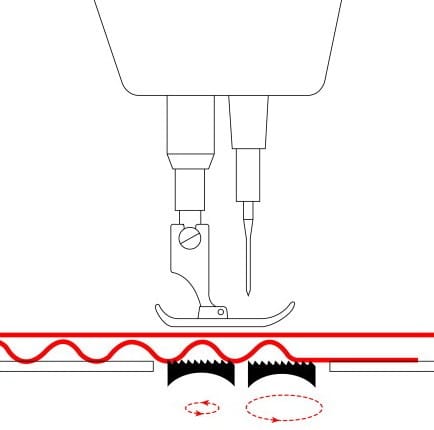

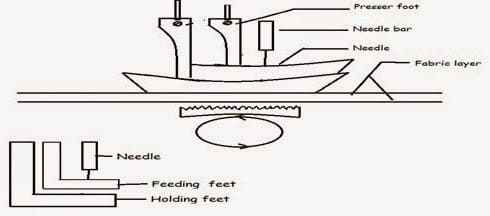

2. Differential bottom feed:

The feed dog used in this system is divided in two different parts, this means in one part, the needle remains in the front and in the other part the needle remains in the back. Like the mentioned feed dogs of the drop feed system, the feed dogs of this system get speed. But the two parts can be operated in the same speed or in different speeds. The differential bottom feed mechanism has been shown in figure-2.

Operating the front feed dog in higher or lower speed than the back feed dog, the lower layer of the fabric can be stretched or gathered. As a result, in this process, the problem of differential puckering can easily be controlled. Differential bottom feed system is available also in machines of making chain stitch, lockstitch and ever edge stitch.

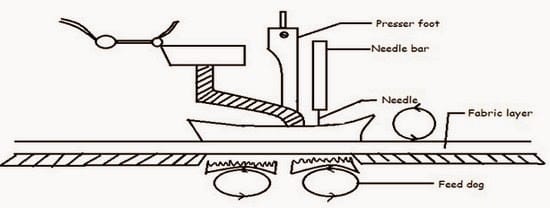

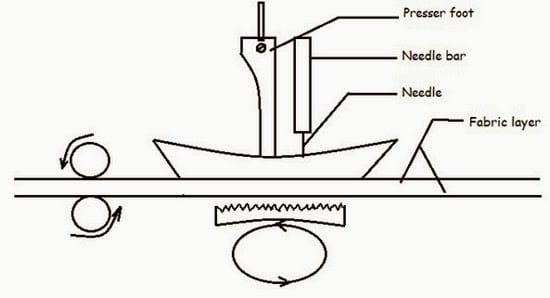

3. Adjustable top feed system:

In this system, when fabrics of a number of layers are sewn together, then speed is given directly to the top layer of the fabric. As a result, the top layer can be fed in the same speed or in higher or lower speed than the lower layers. The Adjustable top feed mechanism has been shown in figure-3.

Figure-3: Adjustable top feed system

There are two sections of the pressure foot used in this process. When the needle penetrate the fabric, then a section keeps holding of the fabric and the pressure foot of the other section moving a step forward is placed and pressed on the fabric and with the help of tooth speed of the lower end it gives speed to the top layer of the fabric that means feed it. Sewing machine adjustable with top feed system and ordinary drop feed system is available also the sewing machine adjustable with differential bottom feed and adjustable top feed system is available. The gathering of the top ply can be done on the lower ply and also the gathering of the lower ply can be done on the lower side of the top ply by the machines available with adjustable top feed and differential bottom feed. Over edge stitching machine in combination with adjustable top feed and differential bottom feed is also available.

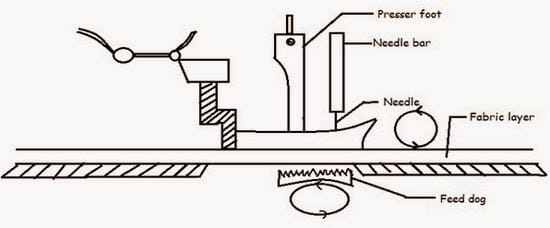

4. Needle (Compound) feed system:

In this system the needle itself goes forward and backward. After the penetration of the needle into the fabric it gets speed resulting the possibility of tendency of being the bigger hole in the fabric made by the needle. In order to avoid this problem, the needle feed mechanism is adjustable with the drop feed mechanism which is called the compound feed. After penetrating the fabric the needle enters into the hole of the feed dog and for making the advancement of the fabric for a step of one stitch length, both the feed dog and the needle pass the same distance at the same time. Then the needle coming out of the fabric goes upward and coming forward a step, gets speed for making of the next stitch. This system is very much suitable for sewing thick or hollow fabric. For changing the stitch length, the strokes of both needle and feed dog are required to change. The needle feed or compound feed mechanism in sewing machine has been shown in figure-4.

5. Unison feed:

The unison feed has been made by adjusting the needle feed mechanism with positive top and bottom feed. Here, the two pressure foot, one stays at the middle of the other and they get speed in different times. Due to needle feeding, the maximum activities of the top and bottom feed are kept stop. But for the fabric whose sewing is very difficult like sewing of adhesive surfaced fabric, this type of feed mechanism is very much suitable. There is no possibility of ply shifting during the sewing of the fabric. This type of feeding system is not used very much in normal situation except some special aspects. The unison feed mechanism has been shown in figure-5.

6. Puller feed:

In this system, a pair of roller is used with ordinary drop feed mechanism that means just behind the pressure foot which keeps the fabric layers pulling. Speed is given to the upper roller directly from the machine and the lower roller gets speed due to be in touch and pressure of the upper roller. The puller roller is operated at a little higher speed than the speed of the drop feed and for this reason there is no possibility of being ply shifting or roping. This mechanism is very much suitable for sewing in multiple needled machine, specially for making of waist band. The puller feed mechanism has been shown in figure-6.

Without this, there are various arrangements for ruffling of one fabric to another at specific distances. For ruffling of fabrics, special type of blades and pressure foot are used.