What is Plant Fibre?

Plant fibre is a type of natural fibre that is obtained from various plants. These fibres are made of cellulose, a complex carbohydrate, and are strong, durable, and versatile. They are commonly used in the production of textiles, paper, and other products. Some examples of plant fibres include cotton, flax, hemp, jute, bamboo, and others. These fibres can be processed in different ways to produce different types of products, such as soft and absorbent cotton fibres for clothing or strong and durable jute fibres for bags and ropes. Plant fibres are renewable and biodegradable, making them an environmentally friendly alternative to synthetic fibres.

Fibres from plants can be in the form of hairs (cotton, kapok), hard fibres (coir, sisal), and fibre sheaves (flax, hemp, jute). The plant fibres are classified depending on their utility such as primary and secondary. Plants to be used as fibres for primary utilities include hemp, jute, kenaf, etc., while the by-products of plants such as coir, pineapple, etc., belong to the secondary group. Fibres extracted from plants are a type of renewable sources and a new generation of reinforcements and supplements for polymer-based materials. These fibres are renewable, cheap, completely or partially recyclable, biodegradable, and environmentally-friendly materials. Their availability, low density, price, and satisfactory mechanical properties make them attractive alternative reinforcements to glass, carbon, and other artificial fibres

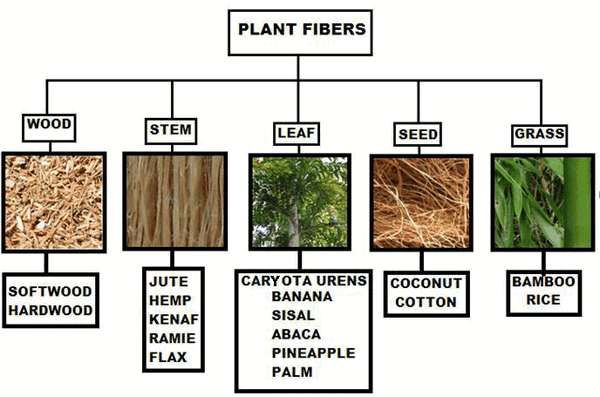

Types and Classification of Plant Fibres:

Plant fibres composed of single cells are hollow and cylindrical and relatively short (up to 65 mm) with tapering ends. Cotton, kapok fiber and akund, all seed fibres, are examples and the single cells are termed ‘ultimate fibres’. The majority of plant fibres are multicellular, containing close-packed arrays of ultimate fibres rather like the longitudinal cells in wood, and these plant fibres should strictly be termed ‘fibre bundles’. Mechanical fibre bundles (i.e., with significant mechanical strength) are extracted from either plant stems (e.g., hemp, jute, flax, kenaf, ramie, also known as ‘bast’ fibre bundles), leaves (e.g., sisal, henequen, pineapple) or fruiting bodies (e.g., coir and palm empty fruit bunch) and are up to 300 mm in length. Once extracted from the plant and processed, fibre bundles are usually irregular in cross-section, with considerable variations in the number of ultimate cells often depending on the severity of the extraction process. Plant fibres are classified in terms of their fibre type, botanical name, family, origin and approximate level of production.

There are many different types of plant fibres, each with its own unique characteristics, that can be used for various purposes, including textiles, paper, rope, and more. But basically plant fibres can be classified in 5 categories. They are listed below:

- Bast fibres

- Leaf fibres

- Seed fibres

- Wood fibres

- Fruit fibres

Above fibres are discussed below:

A. Bast fibres:

Bast fibres are long fibres that are obtained from the phloem, or the outer layer of the stem of certain plants. These fibres are usually stronger and have a greater length-to-width ratio compared to other plant fibres. Some examples of bast fibres include:

- Flax (Linen): A strong, fine fibre obtained from the stem of the flax plant, also known as linen. This fibre is used to make a wide range of products, including textiles, paper, and twine.

- Hemp fiber: A strong, durable fibre obtained from the stem of the hemp plant. It is often used in the production of rope, twine, paper, and clothing.

- Jute: A coarser fibre obtained from the stem of the jute plant. It is often used in the production of burlap, hessian, and sacks.

- Kenaf: A versatile fibre obtained from the stem of the kenaf plant. It is often used in the production of paper, textiles, and insulation materials.

B. Leaf fibres:

Leaf fibres are short fibres that are obtained from the leaf sheaths of certain grasses. These fibres are usually softer and more flexible compared to bast fibres. Some examples of leaf fibres include:

- Sisal fiber: A strong, stiff fibre obtained from the leaves of the sisal plant. It is often used in the production of twine, rope, and floor mats.

- Abaca: A strong, durable fibre obtained from the leaves of the abaca plant. It is often used in the production of paper, cordage, and textiles.

C. Seed fibres:

Seed fibres are obtained from the seeds of certain plants. The most well-known seed fibre is cotton, which is a soft, fluffy fibre that grows in a protective capsule around the seeds of the cotton plant. Cotton is the most widely used fibre in the world and is used to make a wide range of products, including clothing, towels, and bedsheets.

D. Wood fibres:

Wood fibres are obtained from the wood of certain trees, such as bamboo and some species of conifers. These fibres are often used in the production of paper, flooring, and furniture.

E. Fruit fibres:

Fruit fibres are obtained from the husks of certain fruits, such as coconut fiber. Coir, for example, is obtained from the husks of coconuts and is often used in the production of mats, brushes, and rope.

Components of Plant Fibre:

The basic components of plant fibre is cellulose, hemicellulose, lignin, pectin, and waxes. These components make up the structure of the plant fibres and contribute to their unique properties:

- Cellulose: Cellulose is a linear polysaccharide and is the main component of plant fibre. It makes up the cell walls of plant fibres and provides strength and rigidity.

- Hemicellulose: Hemicellulose is a branched polysaccharide that is found in the matrix between the cellulose fibres. It acts as a filler and helps to absorb moisture.

- Lignin: Lignin is a complex polymer that provides additional strength and rigidity to the plant fibre. It helps to protect the fibres from environmental damage and decay.

- Pectin: Pectin is a polysaccharide that helps to hold the cell walls together and provides a gel-like structure. It also helps to absorb moisture.

- Waxes: Waxes are lipophilic substances that provide a barrier against moisture and protect the plant fibres from environmental damage. They also contribute to the durability and strength of the fibres.

The exact composition of plant fibers can vary greatly depending on the species of plant, the conditions under which the fibres were grown and processed, and the intended use of the fibres.

Characteristics / Properties of Plant Fibres:

The properties of plant fibres vary depending on the type of fibre and the species of plant it is obtained from. However, some of the common properties of plant fibres include:

a) Strength: Plant fibres can have a high tensile strength, meaning they are resistant to breaking under tension. This makes them suitable for use in various applications, such as rope and twine.

b) Elasticity: Some plant fibres have a certain amount of elasticity, which allows them to stretch and then return to their original shape. This property is important in applications such as clothing and textiles.

c) Softness: Some fibres are soft and smooth to the touch, making them suitable for use in clothing and bedding.

d) Absorption: Plant fibres can absorb moisture, which makes them suitable for use in applications such as towels and napkins.

e) Durability: These fibres can be durable and resistant to wear and tear, which makes them suitable for use in applications such as flooring and furniture.

f) Length: The length of plant fibres can vary, with some fibres being very short and others being very long. This property is important in applications such as textiles, where the length of the fibre affects the strength and the softness of the final product.

g) Density: The density of plant fiber can vary, affecting their overall weight and the amount of space they occupy.

h) Chemical resistance: Some plant fibres are resistant to certain chemicals, making them suitable for use in applications where they will be exposed to chemicals.

i) Biodegradability: They are biodegradable, which means they can break down into natural substances over time. This makes them an environmentally friendly alternative to synthetic fibres.

Application / Uses of Plant Fibres:

Plant fibres have a wide range of uses, due to their unique properties and versatility. Here are some of the most common uses of plant fibres:

- Textiles: Cotton, linen, and hemp are commonly used to make clothing, bedding, and towels.

- Cordage: Fibres like hemp and jute are used to make rope, twine, and cord.

- Paper production: Fibre from trees like bamboo and kenaf fiber can be processed into paper.

- Building materials: Bamboo fibres are used in construction, such as flooring and paneling.

- Biodegradable products: Natural plant fibres can be made into biodegradable products like bags, plates, and cutlery.

- Automotive parts: Hemp fibres are used to make car parts like door panels, dashboards, and trunk liners.

- Packaging: Flax and sisal fibres are used in the production of biodegradable packaging material.

- Home décor: Natural fibres like sisal, jute, and abaca are used in making mats, rugs, and other decorative items.

Conclusion:

Plant fibres are an important resource with a wide range of uses across different industries. They are known for their sustainability, versatility, and biodegradability. From textiles to building materials, from paper products to biodegradable packaging, plant fibres play a crucial role in many aspects of our lives. Their ability to be transformed into a variety of products, combined with their eco-friendliness, makes them a valuable resource for the future. Additionally, the growing demand for sustainable products has led to increased research and development in the use of plant fibres, ensuring that they will continue to be an important part of our world for years to come.

References:

- Handbook of Properties of Textile and Technical Fibres, Second Edition Edited by Anthony R. Bunsell

- Bast and Other Plant Fibres Edited by Robert R Franck

- Handbook of Textile Fibre Structure | Volume 2: Natural, Regenerated, Inorganic and Specialist Fibres Edited by S.J. Eichhorn, J.W.S. Hearle, M. Jaffe and T. Kikutani

- Fibre Technology for Fibre-Reinforced Composites Edited by Ozgur Seydibeyoglu, Amar Mohanty, Manjusri Misra

- Industrial Applications of Natural Fibres: Structure, Properties and Technical Applications Edited by Jürg Müssig

- https://www.britannica.com/topic/list-of-plant-fibres-2076241

- https://byjus.com/chemistry/plant-fibers/

Author of This Article:

Nazifa Tabassum

Clothing and Textile

Govt. College of Applied Human Science, Dhaka

Email: nazifa.099@gmail.com

You may also like:

- Properties, Production and Uses of Viscose Fiber

- Properties, Manufacturing and Application of Fiberglass

- Sisal Fiber: Properties, Production Process and Uses