Milk or Casein Fiber: An Overview

Abdul Aziz

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Email: abdulaziz1998tex@gmail.com

What is milk or casein fiber?

Unbelievable but it is true. Nowadays regenerated fiber is made from milk to make very comfortable wearables. This fabric made from pasteurized milk contains about 16 types of amino acids which are very beneficial for human health.

Milk fiber is basically a combination of casein protein and acrylonitrile. This milk or casein fiber is prepared in the same process as viscose / rayon. Since it is a regenerated protein fiber, it usually exhibits the same properties as wool fiber.

The superior physical properties of wool have for long been the subject of investigation by scientists, and therefore it is not unexpected that at this particular period of civilization a fiber aiming at the chemical constitution and physical properties of wool should have been developed and made available commercially. This fiber is one which we are here called “Casein Fiber.”

History of milk fiber:

During the First World War, when the Germans were looking for a new source of fabric, they discovered the properties of making fabric in milk. Then in 1930, the Italian chemist Antonio Feretti discovered a successful method of making milk or casein fiber so that he could overcome the shortcomings of this fibre. Since then mass production of milk fibre started and in 1939 about 10,000 tons of milk fibre was produced. It then competes with wool fibre in the global market.

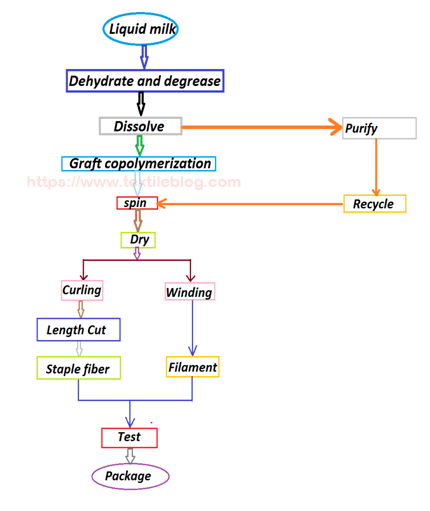

How milk or casein fiber is prepared:

Casein is mainly obtained from pasteurized milk through acid treatment. The casein is first frozen and then dried. At one stage it dries and takes the form of a fine powder. It is then dissolved in caustic soda and the solution is left until it acquires the appropriate viscosity.

The solution is then left in a bath by wet spinning by spinneret containing a mixture of sulfuric acid, formaldehyde, glucose and water. In this way it takes the shape of a filament. It is then hardened by formaldehyde treatment. At this stage it is sent to the drawing stage. After this chemical treatment the filaments are washed and dried and crimp is provided mechanically. This is how milk / casein fiber is made.

Various names in different countries:

- Lanital in Belgium and France.

- Fibrolane in Britain.

- Merinova in Italy.

- Wipolan in Poland.

- Aralic in America.

Characteristics of milk or casein fiber:

- This fiber is thermal insulation. So the fabric made with this fiber can easily hold the body temperature.

- It has elasticity religion.

- Milk fiber cannot be separated from wool fiber by chemical test or burning test, it is only possible with a microscope.

- It is quite smooth fiber.

- Its natural color is bright white.

- Can easily absorb moisture.

- The fabric made of this fiber is quite comfortable.

- This fiber can be easily dyed.

Main technical indexes of milk protein fiber:

| No | Item Name | Index |

| 1 | Fibre tenacity (dtex) | 0.8-3 |

| 2 | Breaking tenacity (cN/dtex) | 2.5-3.5 |

| 3 | Breaking elongation rate (%) | 25-35 |

| 4 | Modulus (cN/dtex) | 60-80 |

| 5 | Standard moisture regain (%) | 5.5 |

| 6 | Specific resistance | 1.5×104 |

| 7 | Static friction coefficient | 0.187 |

| 8 | Dynamic friction coefficient | 0.214 |

| 9 | Color fastness to washing | 4-5 grade |

| 10 | Fastness to crocking | 4-5 grade |

| 11 | Fastness to perspiration | 4-5 grade |

| 12 | Color fastness to light | 4 grade |

| 13 | Pilling resistance | 3 grade |

Advantages of milk fiber:

- It is environmentally friendly.

- It can be called a “green product” because it does not contain any formaldehyde.

- This fiber has a pH of 7.8, which is close to human skin. So products made with this fiber are more suitable for people.

- It is more comfortable, water transportable and air permeability is good.

Some disadvantages of milk fiber:

- The clothes made by it are folded after washing and have to be ironed every day.

- It should not be machine washed, as it is not too hard.

- It’s a bit expensive.

- It is less durable.

The blending of milk fiber:

The blending of milk fibre is done in the following manner:

- Cotton method: Blend viscose and casein (milk fibre).

- Woollen method: casein and wool blend.

- Worsted method: Blend casein and wool or viscose.

Care of milk protein fiber:

The physical and chemical structure of milk protein fiber is different from that of natural protein fiber. Therefore, care is taken in the following ways:

Desizing: Enzyme products can be used between pH 4 to 6.

Scouring: If you use synthetic detergent, you have to keep it within pH 8.

Bleaching: Milk or casein fiber is usually white, so bleaching is not necessary. If bleaching is required, bleaching can be done with sodium pyrophosphate and hydrogen peroxide at pH 7.

Dyeing: Acid, basic, direct and disperse dyes can be used. Dye liqueur should have a pH of 4-6 and a dyeing temperature of 90-95 degrees Celsius.

Printing: Block, screen and roller printing can be used. Acid, Basic, Direct, Aggregate Pigment Dye can be used.

Uses of milk / casein fabric:

- T-Shirts

- Ladies outwear

- Sports-wear

- Undergarments

- Sweaters

- Children’s garments

- Bedding

Milk / casein fibre is renewable, bio-degradable and eco-friendly. It is also possible to make more high quality fiber by blending wool, cotton and other fibres with this fibre. This milk fibre has much more quality than other man made fibers made so far. Also, since this fibre is antibacterial, it is now being used in many textile applications.

You may also like: Fabric Made with Milk: An Ecological Revolution

Technical uses of Milk/Casein fiber:

Commercial casein is generally two types.

- Rennet Casein

- Acid casein

The technical uses of these two types of casein fiber are discussed below.

| Acid casein | Rennet casein |

| Adhesive for wood, e.g. plywood; adhesive for foil laminates and paper | Plastics in the form of buttons, buckles, imitation tortoiseshell, imitation ivory, fountain pen barrels, shoehorns, dominoes novelties |

| Coating for paper and cardboard | |

| Horticultural spreader | |

| Joint cements in wallboard | |

| Leather tanning | |

| Paints | |

| Photo-resist | |

| Stock foods | |

| Synthetic fibres | |

| Textiles sizing |

Manufacturers of milk fibre:

- Cyarn Textile Co., Ltd. •Contact: info@cyarn.com

- Fabman Fabrics and Manufacture •Contact: info@fabmanindia.com in India

- Euroflax Industries (Imports of Textiles) •Contact: euroflax@euroflax.com

- Shanghai Zhaokai Import & Export Co •Contact: http://zhaokai.en.made-in-china.com

- China Xhmart Textile Co., Ltd.

- Ningbo Guang Yuang Fabric Co, Ltd. •Contact: http://www.new-fabric.com

Conclusion:

All through the years, experts have been devoted to the researches on improved fibres and at present they have succeeded in the development of the globally advanced milk protein fibre, a milestone in the international textile industry.

Milk fabrics are so skin-friendly that it itself makes us feel better. The milk protein fibre is a fresh product as a superior green, healthy and comfortable fibre, which will certainly become popular goods in the market.

Resources:

- https://textilelearner.blogspot.com/2011/07/introduction-of-milk-or-casein-fiber_3419.html

- https://www.fibre2fashion.com/industry-article/5279/an-introduction-to-milk-fiber-a-review

- https://bunon.info/fibertofabric/

- https://textilelab.blogspot.com/2017/12/blog-post_79.html

- https://www.slideshare.net/monaverma1/casin-fibres