An Overview of Waterproof Breathable Fabrics

Ariful Hasan, Al-amin Sohag, Lutfur Rahman, Uzzal Hossain, NM Walid

Department of Textile Engineering

Daffodil International University

Introduction:

Waterproof breathable fabrics are designed for use in garments that protection from the weather, that is from wind, rain and loss of body heat. Waterproof fabric completely prevents the penetration and absorption of liquid water, in contrast to water-repellent fabric, which only delays the penetration of water. Traditionally, waterproof fabric was made by coating (like animal fat, wax, vegetable oils). Nowadays, uses polyvinylchloride (PVC) polymer. Coated fabrics are, however, considered to be more uncomfortable to wear than water-repellent fabric, as they are relatively stiff and do not allow the escape of perspiration of vapor. Water-repellent fabric is more comfortable to wear but its water-resistant properties are short lived. The ideal fabric should be waterproofed (do not allow water get into the fabric) and breathable (allow water vapor escape from skin). Breathable fabrics allow water vapor (gas) to diffuse through fabric and still prevent the water penetration of liquid water. Production of water vapor by the skin is essential to maintenance of body temperature. The normal body temperature is 37°C, and skin temp is between 33 to 35°C. During physical activity, the body provides cooling by producing perspiration. If the water vapor cannot escape to the surrounding, the relative humidity of the microclimate inside the clothing increase and clothing becomes uncomfortable to wear.

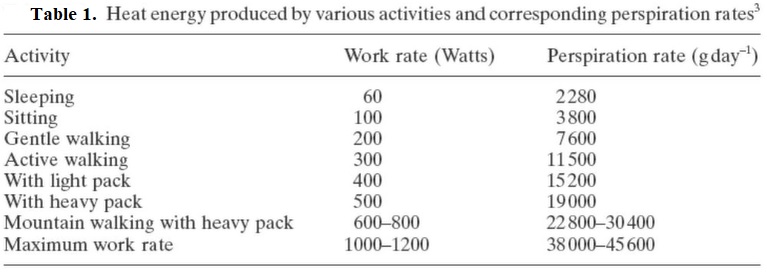

Perspiration rates and activities:

Table 1 shows the perspiration rates and activities from sleeping to max work rate. If the body is to remain at the physiologically required temp. clothing has to permit the passage of water vapor from perspiration rate as shown in Table 1. The ability of fabric to allow water vapor to penetrate is commonly known as breathability. The waterproof breathable fabrics prevent the penetration of liquid water from outside to inside the clothing. It can, however, permits the penetration of water vapor (gas) from inside the clothing to outside atmosphere.

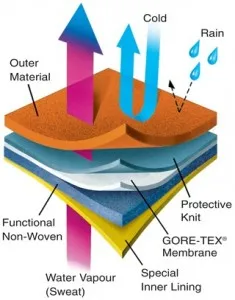

Structure of water proof breathable fabric:

How to make a waterproof and breathable fabric:

We want to prevent water molecule (liquid) to get it the fabric and allow water vapor (gas) to pass from skin to fabric. The size of water droplet (liquid) is 100 μm and the water vapor (gas) is 0.0004 μm and we need to make a fabric with porous space around 10 μm. In this way, it allows water vapor to pass through (from skin to fabric) and prevent water droplet to penetrate (from outside to fabric).

Types of waterproof breathable fabric:

Different types of breathable fabrics can be classified into the following groups:

- Cloosely woven fabrics

- Microporous membranes and coatings

- Hydrophilic membranes and coating

- Combination of microporous and hydrophilic membranes and coating

- Retroreflective microbeads

- Smart breathable fabrics

- Fabrics based on biomimetics

There are several methods which can be used to obtain fabrics which are both breathable and water proof. They are:

- Densely woven fabrics

- Membranes (Gore-tex fabric)

- Coatings

Densely woven fabrics:

Probably the first effective waterproof breathable fabric was developed in the 1940s for military purposes and is known as Ventile. Ventile fabric uses the finest cotton yarn, combed and piled together. The yarn is woven using Oxford weave, which is a plain weave with two threads acting together in the warp. When the fabric surface is wetted by water, the cotton fibers swell reducing the size of the pores in the fabric and requiring very high pressure to cause penetration. The fabric is thus rendered waterproof without the need for any water repellent finishing treatment. The densely woven waterproof breathable fabrics consist of cotton or synthetic microfilament yarns with compacted weave structure. One of the famous waterproof breathable fabrics known as VENTILE was manufactured by using long staple cotton with minimum of spaces between the fibers1. Usually combed yarns are weaved parallel to each other with no pores for water to penetrate. Usually oxford weave is used. When fabric surface is wetted by water the cotton fibers swell transversely reducing the size of pores in the fabric and requiring very high pressure to cause penetration. Therefore waterproof is provided without the application of any water repellent finishing treatment. Densely woven fabrics can also be produced from micro-denier synthetic filament yarns. The individual filaments in these yarns are of less than 10 micron in diameter, so that fabrics with very small pores can be engineered.

Highly dense fabric results:

The use of very fine fibers and filaments and dense construction (setts) results in fabrics with very small pore size compared with conventional fabrics. Typical pore size for waterproof fabric is about 10 μm compared with 60 μm for conventional fabric. Ventile fabric has a pore size of about 10 μm when dry and 3-4 μm when wet. Fabric made from micro-filaments is claimed to have 7000 filaments per cm.

Breathable Fabric by Monofilament Fibers:

Membranes:

Membranes are extremely thin films made from polymeric material and engineered in such a way that they have a very high resistance to liquid water penetration, yet allow the passage of water vapor. A typical membranes is only 10 μm thick and is laminated to a conventional textile fabric to provide the necessary mechanical strength.

Designing waterproof breathable fabrics:

Waterproof breathable fabrics are designed for use in garments that provide protection from the environmental factors like wind, rain and loss of body heat. Waterproof fabric completely prevents the penetration and absorption of liquid water. The term breathable implies that the fabric is actively ventilated. Breathable fabrics passively allow water vapor to diffuse through them yet prevents the penetration of liquid water. High functional fabrics support active sportswear with importance placed on high functions as well as comfort. Finally, materials with heating and/or cooling property have newly attracted the interest of the market. All these materials do not pursue a single function, but different functional properties combined on a higher level. Fabrics that can convey water vapor from body perspiration out through the material while remaining impervious to external liquids such as rainwater are widely used in sportswear and similar applications. Water-resistant and moisture-permeable materials may be divided into three main categories high-density fabrics, resin-coated materials and film-laminated materials – which are selected by manufacturers according to the finished garment requirements in casual, athletics, ski or outdoor apparel.

Laminated waterproof breathable fabrics:

Laminated waterproof breathable fabrics made by application of membranes into textile product. These are thin membrane made from polymeric materials. They offer high resistance to water penetration but allow water vapor at the same time. The maximum thickness of the membrane is 10 micron

They are of two types:

- Micro porous membranes

- Hydrophilic membranes.

The micro porous membranes have tiny holes on their surface smaller than a rain drops but larger than water vapor molecule. Some of the membranes are made from Polytetrafluoroethylene PTFE polymer, Polyvinylidene fluoride PVDF. The hydrophilic membranes are thin films of chemically modified polyester or polyurethane. These polymers are modified by the incorporation of poly. The poly (ethylene oxide) 4 constitutes the hydrophilic part of the membrane by forming amorphous region in the main polymer system. This amorphous region acts as intermolecular pores allowing water vapor molecules to pass through but preventing the penetration of liquid water due to the solid nature of the membrane.

Coated waterproof breathable fabrics:

Coated fabrics with waterproof breathable fabrics consist of polymeric material applied to one surface of fabric. Polyurethane is used as the coating material. The coatings are of two types:

- Micro porous membranes

- Hydrophilic membranes.

In microporous membrane the coating contains very fine interconnected channels much smaller than finest raindrop but larger than water vapor molecules. Hydrophilic coatings is same as hydrophilic membrane but the difference between the microporous and hydrophilic material is the former water vapor passes through the permanent air-permeable structure whereas the later transmits vapor through mechanism involving adsorption-diffusion and de-sorption. The desirable attributes of functional sportswear and leisurewear are as follows:

- Optimum heat and moisture regulation.

- Good air and water vapor permeability

- Rapid moisture absorption and conveyance capacity

- Absence of dampness

- Rapid drying to prevent catching cold

- Low water absorption of the layer of clothing just positioned to the skin

- Dimensionally stable even when wet

- Durable

- Easy care

- Lightweight

- Soft and pleasant touch

It is not possible to achieve all of these properties in a simple structure of any single fiber or their blend. The two layer structure has layer close to skin of the wicking type comprised of synthetic fibers e.g. micro-denier polyester and the outer layer usually cotton or rayon that absorbs and evaporates. Micro denier polyester is ideal for wicking perspiration away from the skin. The use of superfine or microfiber yarn enables production of dense fabrics leading to capillary action that gives the best wicking properties. No single fiber or blend of different fibers can give ideal sportswear. The right type of fiber should be in the right place. Blending of fibers does not give the same effect as that of multi-layer fabric. The wicking behavior of the fabric is mainly depending on its base fibers moisture properties.

Moisture transport mechanism:

The mechanism by which moisture is transported in textiles is similar to the wicking of a liquid in capillaries. Capillary action is determined by two fundamental properties of the capillary:

- Its diameter; and

- Surface energy of its inside face.

The smaller the diameter or the greater the surface energy, the greater the tendency of a liquid to move up the capillary. In textile structures, the spaces between the fibers effectively form capillaries. Hence, the narrower the spaces between these fibers, the greater the ability of the textile to wick moisture. Fabric constructions, which effectively form narrow capillaries, pick up moisture easily. Such constructions include fabrics made from micro fibers, which are packed closely together. However, capillary action ceases when all parts of a garment are equally wet. The surface energy in a textile structure is determined largely by the chemical structure of the exposed surface of the fiber, as follows.

Hydrophilic fibers have a high surface energy. Consequently, they pick up moisture more readily than hydrophobic fibers-Hydrophobic fibers, by contrast, have low surface energy and repel moisture. Special finishing processes can be used to increase the difference in surface energy between the face of a fabric and the back of the fabric to enhance its ability to wick.

Factors affecting moisture transport:

There are several factors, which affect moisture transport in a fabric. The most important are:

- Fiber type;

- Cloth construction or weave;

- Weight or thickness of the material; and

- Presence of chemical treatments.

Synthetic fibers can have either hydrophilic (wetting) surfaces or hydrophobic (nonwetting) surfaces. They also have a range of bulk absorbencies, usually reported by suppliers and testing organizations as the percentage moisture regain1 by weight. Synthetic fabrics are generally considered to be the best choice for garments worn as a base layer. This is because they are able to provide a good combination of moisture management, softness and insulation. While most fabrics, both natural and synthetic, have the ability to wick moisture away from the skin, not all of these are fast-drying and air permeable-two factors, which have a direct influence on cooling and perceived comfort. High-tech synthetic fabrics are lightweight, are capable of transporting moisture efficiently, and dry relatively quickly. It is generally agreed that fabrics with moisture wicking properties can regulate body temperature, improve muscle performance and delay exhaustion. While natural fibers such as cotton may be suitable for clothing worn for low levels of activity, synthetic fabrics made of nylon or polyester are better suited for high levels of activity. They absorb much less water than cotton, but can still wick moisture rapidly through the fabric. The main parameters for comfort and functionality are:

- Water and wind proof, breathability and comfort.

- Moisture/Sweat management

- Warmth/temperature control

- Easy-care performance

- Smart and functional design.

Water Proof Fabric Made from Different Fibers:

Polyester:

Polyester has outstanding dimensional stability and offer excellent resistance to dirt, alkalis, decay, mold and most common organic solvents. Being durable, yet lightweight, polyester has elasticity and a comfortable smooth feel or “soft hand”. These are all important qualities to consumers for a wide variety outerwear and recreational applications. Excellent heat resistance or thermal stability is also an attribute of polyester. It is the fiber used most commonly in base fabrics for active wear because of its low moisture absorption, easy care properties and low cost. Polyester is essentially hydrophobic and does not absorb moisture. However, most polyester used in base layer clothing is chemically treated so that they are able to wick moisture. This can be done by:

- Coating the polyester with a hydrophilic finish; or

- Changing its surface chemistry to improve its wetting by moisture.

Changing the surface chemistry of the polyester involves introducing free hydroxyl groups into molecules on the surface of the filament. The result is a de structuring of water, causing wetting. The combination of opposing properties-a hydrophobic core and a hydrophilic surface-creates a fabric in which the fibers encourage moisture to migrate through the fabric along the outer surface of the filament while the hydrophobic core does not absorb moisture. The main disadvantage of chemical or molecular modification is that it is more costly for the fabric manufacturer. However, the effect on the fabric is “permanent”. To be classified as permanent, it has to have the capability to withstand at least 50 home washings. Most coatings, by contrast, have an average lifespan of five home washings. Toray develops airfine Fieldsensor which is made from a polyester filament yarn which has the grooves help the fabric absorb sweat quickly and disperse it along the surface. Company claims that the moisture absorbing and dispersing property of the new material is twice a great as its former Fieldsensor fabric. Polyester coolmax has been claimed to increase wearer comfort through rapid removal of perspiration by capillary. Also it has good wicking properties and nonabsorbency. Coolmax and thermostat polyester fibers used in two fold garments claimed to wick moisture away from the skin (the former) and to maintain warmth (the later).

Polypropylene:

Polypropylene cannot wick liquid moisture. However, moisture vapor can still be forced through polypropylene fabric by body heat. Polypropylene has the advantage of providing insulation when wet But it can melt at medium heat in home dryers. Also, polypropylene is more oleophilic (oil absorbing) than polyester Consequently, it has a greater tendency to attract and hold oily bod) odors even more. Polypropylene is claimed to be a proved performer in moisture management due to its hydrophobic nature and has very good thermal characteristics, keeping the wearer warm in cold weather and cold in warm weather.

Nylon:

Nylon fiber characteristic include lightweight, high strength and softness with good durability. Nylon also quickly when wet. Nylon is good fabric choice when combined with PU coatings. Nylon has a much higher moisture regain than polyester and therefore has better wicking behaviour. It is most often used in tightly woven outerwear, which can trap heat because of low air permeability. It is also used in more breathable knitted fabrics, where it can perform well. However, it is much more expensive than polyester and is therefore only used in premium applications such as swimwear and cycling wear. Also, because of its higher moisture regain, it dries more slowly than equivalent fabrics made from polyester. Teijin DuPont Nylon has developed a waterproof fabric, polus-Ex that is permeable to moisture. The material is made by laminating a multiporous film to a nylon fabric and a moisture permeability of 8000 g/m2/24 hours, as well as 20 m head of water.

Silk:

Because of its hollow structure, silk breathes well. It is soft strong and has natural wicking properties. However, it dries slowly and requires care in cleaning.

Wool:

Not all grades of wool are appropriate for a base layer. First, since it’s next to skin, it shouldn’t itch. The “itch” so commonly noticed in wool garment results from the fiber ends tickling. Consequently, short fibers will cause more itch than long fibers because there will be more fiber ends touching your skin. Second, the fiber should be very fine. This allows for a fabric of high fiber density to be made, which increases strength and abrasion resistance in addition to increasing the air movement between and adjacent to pockets of dead air space in the fabric (thus, increasing warmth). Finally, fine fibers absorb less water weight per cross-sectional area, so they are more resilient than coarse fibers. The efficiency of wicking is also greater with a fine fibered fabric because more fibers (and correspondingly, more cross-sectional surface area) can be packed into a given space than an equal volume of coarse fibers. Wool has good, natural wicking properties and will provide insulation even when wet. However, it is slow to dry. However the use of fine chlorinated merino wool is employed in Sport wool as a base layer. Wearing a Merino wool undergarment will result in the garment staying dryer for longer during periods of exertion. Wool fibers have micropores in them (a characteristic not unique to Merino wool) that readily allow for the absorption of water vapor-up to 1/3 the fiber weight. Consequently, it takes longer for a wool garment to reach the high relative humidity required for condensation to occur (synthetic fibers typically absorb less than 5% of their own weight in moisture vapor before feeling wet). A wool fabric (manufactured into long-sleeved T- shirt form) has been shown to absorb significantly more sweat than a polyester fabric (of comparable structure) during a period of exercise followed by rest. The amount of moisture desorbed from the wool fabric was significantly higher than that from the polyester fabric, and the skin temperature decreased faster and recovered more slowly after contact with the wool fabric compared with polyester fabric.

Cotton:

Cotton garments provide a good combination of softness and comfort. However, cotton is not recommended for use in base layer clothing because of its tendency to absorb and retain moisture. When wet, cotton garments cling to the skin. Causing discomfort. Wearing jeans on the ski slopes, for instance, will not only weigh down the skier but will also cause chilling if the jeans become wet.

The slow-to-dry and cold-when-wet characteristics of cotton make this material unsuitable in conditions in which there are high levels of moisture-either perspiration or precipitation-and where the ambient temperature is low. During SASMIRA’s trials for wicking of cotton treated with hydrophobic finishes showed good wicking properties.

Viscose Rayon:

The viscose rayon is not preferred next to skin as it holds water (13% moisture regains) in sportswear. The outer layer of knitted hydrophilic portion of the twin layer sportswear can be of viscose rayon, which absorbs 2-3 times more moisture than cotton. The wicking behavior improves by incorporation of some hydrophobic finishes.

Application of Water Proof Breathable Fabric:

Development in active sportswear:

The 1980s was a period of highly fruitful innovation in sportswear garments. Some reasonably simple microfibers and coated fabrics were developed; variants of which have met the needs of many sports garments. The innovation of new materials and garments was so successful that in many sports the fundamental performance requirements have been identified and largely satisfied. Nowadays, from very simple microfibers to much more complex fabrics are effectively used in active sportswear. The latest textile materials are much more function specific for fulfilling specific needs in different sports activities.

Sweat absorption and fast drying property:

Moisture handling properties of textiles during intense physical activities have been regarded as major factor in the comfort performance. Actually the comfort perceptions of clothing are influenced by the wetness or dryness of the fabric and thermal feelings resulting from the interactions of fabric moisture and heat transfer related properties. For the garment that is worn next to skin should have:

- Good sweat absorption and sweat releasing property to the atmosphere, and

- Fast drying property for getting more tactile comfort.

It has been found that frictional force required for fabric to move against sweating skin (resulting from physical activities, high temperature and humidity of surroundings) is much higher than that for movement against dry skin. Which means, the wet fabric, due to its clinging tendency, will give an additional stress to the wearer. In removing the liquid sweat from the skin, some textile manufacturers claim that moisture absorbency of the fiber is important and hence cotton or viscose is a necessary component for the sportswear, which is next to skin. While others say that fibers in these garments should not absorb moisture, so that moisture or perspiration is wicked away from the skin to outer layers of clothing from whence it can evaporate into atmosphere. However, a lot will depend on the degree of activity contemplated. In fact, so far as cotton is concerned, the synthetics should be preferred in clothing of active sports as they do not retain moisture and this has the advantage of keeping garments lighter than the cotton when it is wet. Also synthetic fibers have some added advantage of quick dry and good shape retention property. Most of the modern textile materials use the basic idea of capillary action for sweat absorption and fast drying.

Conclusion:

In this modern world, water proof breathable fabric is the greatest invention among the most useful invention for human being. Once upon a time, textile world face some limitation in their textile product inventory but nowadays it can be said to tell undoubtedly, there is no restrictions in the textile world. When water proof breathable fabric was discovered, textile word seemed there is no restriction is the textile world. Water proof breathable fabric is very important because of playing vital role in sportswear.

References:

- “Waterproof Breathable Active Sports Wear Fabrics” Sanjay S. Chaudhari, Rupali S. Chitnis and Dr. Rekha Ramkrishnan ,The Synthetic & Art Silk Mills Research Association, Mumbai

- ASTM D3393-Standard Specification for Coated FabricsWaterproofness

- “Breathability” comparison of commercial outerwear shell layers

- Rupp, J., “Architectural Textiles: Economical And Ecological Roofing”,

- Multi-layered Breathable Fabric Structures with Enhanced Water Resistance Ilhan Ozen, Ph.D. Erciyes University, Melikgazi, Kayseri TURKEY