Experiment Name: Study on Basic Elements of Weaving

Introduction:

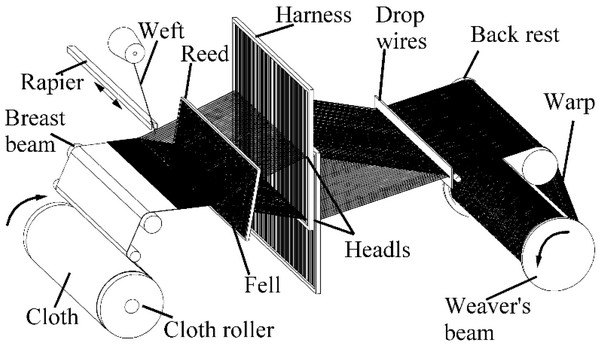

Weaving is one of the most important aspects in the textile industry. Two sets of yarns, namely warp and weft, are needed for the formation of a woven fabric. The process of sequential trapping of weft segments across the warp sheet is known as weaving. There are three actions involved with the weaving process: shedding, picking and beating. Weaving machine is called loom. Weaving has been used to manufacture textile fabrics for more than 5000 years. Today, it is still the predominant technique for the production of fabrics worldwide. The overall production of woven fabrics is about 30 million tons per year.

Objectives:

- To identify the different primary / basic elements of weaving machine.

- To acquire clear conception about the fundamental elements of weaving technology.

Main parts / basic elements of the weaving machine:

- Shuttle

- Pirn

- Drop wire

- Heald wire

- Reed

- Bobbin

- Cone

- Spool

- Jacquard card

1. Sley or lay:

Sley is one of the important element of weaving machine. It is made of wood and consists of the sley race or race board, reed cap and metal swords carried at either ends. The sley mechanism swings to and fro. It is responsible for pushing the last pick of weft to the fell of the cloth by means of the beat up motion. The sley moves faster when moving towards the fell of the cloth and moves slower when moving backwards. This unequal movement is known as ‘eccentricity of the sley’. It is needed in order to perform the beat up and also to give sufficient time for passage of shuttle to pass through the warp shed. The beat up of the lastly laid pick of weft is accomplished through a metal reed attached to the sley.

2. Shuttle:

Shuttle is the basic weaving element of the weaving machine. It is used to pass weft yarn. Shuttle is basically a weft carrier and helps in interlacement of the weft with the warp threads to form cloth. Shuttle is divided mainly two types.

- Ordinary shuttle.

- Automatic shuttle.

i. Ordinary shuttle: This the oldest form of shuttle which is used in hand and taped loom.

ii. Automatic shuttle: This is the moderation of ordinary shuttle which is used in automatic loom.

3. Pirn:

Pirn is placed in the shuttle and carries the yarn during operation. It is the carrier of the weft yarn. There are two types of pirn.

- Automatic pirn

- Ordinary pirn

i. Automatic pirn: Used in automatic shuttle.

ii. Ordinary pirn: Used in ordinary shuttle.

4. Drop wire:

When the yarn has neps , knots or the yarn gets breakage, the wires are dropped. Drop wire is an automatic stopper.

5. Heald wire:

Heald wire used in weaving loom to pass yarn in proper tension by its eye.

6. Picker:

The picker is a piece made either of leather or nylon or plastic material. It may be placed on a spindle or grooves in the shuttle box. It is used to drive the shuttle from one box to another. It also sustains the force of the shuttle while entering the box.

7. Reed:

Reed are used to remove neps, knots, waste etc. reed is like as comb. It combs the yarn separately.

8. Bobbin:

Bobbin is the small package of yarn and used in weaving mainly.

9. Cone:

Cone is the biggest package of yarn. Yarn wound in cone cross sectional wise. Before weaving the cone yarn are in soft winding.

10. Spool:

Spool is small yarn package.

11. Jacquard card:

Jacquard card is used in design fabric in weaving. It consists of punch or outpunches.

12. Warp beam:

This is also known as the weaver’s beam. It is fixed at the back of the loom. The warp sheet is wound onto this beam. The length of warp in the beam may be more than a 1000 m.

Conclusion:

Weaving is the major part in our weaving garments goods. The demand of our woven fabrics as well as weaving is increasing very rapidly day by day. So, it is very much important for us to have a clear idea about the basic weaving elements and it plays a vital role in our studies about weaving technology.

You may also like:

- Features and Working Principle of Air Jet Weaving Machine

- Conversion of Chittaranjan Hand Loom into Power Loom