Computer-aided design, also known as CAD, has extended the media choices for des thanks to a wide range of vector and bitmap graphics programs. Some are generic, while others have been specifically developed for the fashion industry. CAM works with the CAD system. Once the design is completed, it can be imported as a digital file to the CAM system. CAM has become an integral part of the design and production systems that exist in fashion and textiles. CAD/CAM is a term often used to cover three areas of activity controlled by a linked computerized system: design, analysis, and manufacture in textile and garment industry.

CAD/CAM systems assist in automating tasks within design and manufacturing. CAD helps in design and product development and CAM helps in controlling the operations steps of production and equipment. The analysis of design and their translation for the manufacturing system is carried out by equipment that is part of computer-aided engineering (CAE). It is the combination of CAD, CAE, and CAM that make up computer-integrated manufacture (CIM) – otherwise referred to as CAD/CAM.

A CAD/CAM system may also link the production stages to orders, sales, production planning and scheduling and sales analysis, etc., via a secure server through an electronic data interchange (EDI) system. All CAD/CAM systems can create, save, store, retrieve, amend, and correct designs created on the CAD system used.

Functions of CAD/CAM in Textile and Garment Industry:

Functions of the CAD/CAM process in the textile and garment industry are described below:

1. Connectivity:

The need for companies in design (buyers, designers, suppliers), production (manufacturers) and retailing (e-commerce/e-tailing) in the design and production chain to communicate in a global market.

2. Design creation/ideation:

Through image/mood boards, designs, virtual fabrics/clothing, flats.

3. Production data management:

The ability to use product data management (PDM) software to control the whole production cycle of a garment. This type of software allows tracking of the workflow and identification of the status of an individual garment at any one time.

4. Pattern design:

This is divided into two areas, one being the specification drawings, the second at PDS (pattern design systems). It is in these systems that the pattern is generated for a garment.

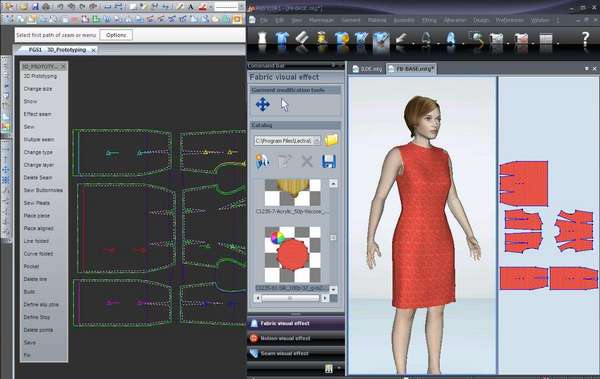

5. Garment sampling:

At this stage, the pattern created in the PDS can be modelled in both physical patterns and 3D virtual systems. In these systems, garments can be virtually stitched together, tested for fit in a virtual environment, and then even visualized on virtual runways. It is also at this stage that patterns can be exported to digital textile printing machines, and prototype garments produced.

6. Sizing:

The advent of body scanners had led to an increase in made-to-measure clothing, leading companies to develop mass customization as a process for ensuring better customer fit, style, and options.

7. Pattern grading:

Pattern grading systems now mean that the processing of patterns is leading to more streamlined process for pattern making. Pattern grading is done by inputting pattern data, creating the grading criteria, grading the pattern, and then sending this data to the production planner.

8. Production:

Here the data created at the pattern grading stage is converted into a production pattern, known as production lay planning and marker making. Using the software the pattern can be specifically laid to create the best efficiency for cutting out, and lower costs especially related to material waste.

9. Plotting and cutting:

Companies now utilize CAM systems to enable the accurate cutting out of garments and production pieces. These systems also enable companies to review waste management in terms of fabrics.

10. Product life cycle:

Product lifecycle management (PLM) software that can be accessed on a global basis is database software enabling companies to view all aspects of a product from design to finish. It is usually integrated with PDM system software. This allows companies to monitor the styles to market, the workflow and the sales, from design inception to completion.

Besides, CAD software becomes essential in this field as geometric modelling of yarn is necessary; “solid volumes representing the approximate bounds of the fibers contained within them” for the application in composite textiles is important because it enables:

- Determination of the mechanical properties of the fabric forming behavior,

- Prediction of the permeability of fabrics for processing of composites, and

- Modelling of the mechanical properties of composite parts and their damage behavior for use in engineering applications.

Importance of CAD/CAM Software in Textile and Apparel Industry:

CAD is a computer-aided design and drafting software implemented on a computer. CAD uses a large number of hardware and software devices. The software available in the market is installed on the system with their drivers. The hardware devices mostly in use are Flat bed plotter, Digitizer, Printer, video display boards and zip driver for backup purpose. Earlier, the manual process of body measurement is not so effective and time consuming. Body scanners have significant advantages in measuring the human body compared with traditional tape measurement methods. The 3D body scanning technique captures the three coordinates to cover the complete body measurement. This scanned data is converted into accurate body dimension with the help of software.

The garment is draped on their 3D scan image, and the consumer can see how the garment looks and fits before the purchase is made. The virtual fit models reduce the cost and time involved in the creation of physical samples. The virtual fit models can help the customers to visualize the mass-customized product before making the purchase. The right type of fabrics can be selected as per the customer’s choice with virtual dressing rooms; consumers are also able to virtually try-on selected garments and preview fit and appearance before purchase.

The virtual fit model is used by many online retail businesses. The universities, research institutions and software producers apply new technologies nowadays to create advanced computer solutions that will in the future support the whole cycle starting from the virtual design of fabric and garments through automated production up to virtual merchandising.

CAD supports 2D drafting and 3D wireframe models. The system is designed as a single-user CAD package. The drawing elements are lines, polylines of any width, arcs, circles, faces and solids. There are many ways to define a drawing element. For example, a circle can be defined by center and its radius, three points and two end points of its diameter. The system always prompts the user for all options. Annotation and dimensioning are also supported. Text and dimension symbols can be placed anywhere on the drawing, at any angle and at any size. A variety of fonts and styles are also available.

CAD/CAM plays a major role in the textile and apparel industry. CAD is one of the technologies being used in the fashion industry for mass customization, develop more design, frequent changing styles and production, making work easier through efficient and better quality products. CAD/CAM is more favorable in quick changes for any design and possible to use more application on garments and textile industry.

In pattern making of main size patterns, when we discuss about the simple patterns, there are no major differences, but as the complexity of style patterns increases, CAD system gives good results. It is not only the CAD system that is responsible for fast, accurate, efficient and better quality of products to produce but it also depends on the personal skills and creativity. A CAD system is very useful for creating a virtual sample that saves time. The virtual sample made by CAD can be shared with buyer immediately without physical designing of the sample which saves time and cost of the industry.

It is creating more job opportunity for students. It has created more study opportunities for aspiring professionals, especially fashion design students and CAD learners as well. Nowadays, many institutions presented different types of short-term and long-term courses, which examine the importance of CAD knowledge for the industry.

References:

- Fibers to Smart Textiles: Advances in Manufacturing, Technologies, and Applications Edited by Asis Patnaik and Sweta Patnaik

- Textiles and Fashion: Materials, Design and Technology Edited by Rose Sinclair

- Woven Textiles: Principles, Developments and Applications, Second Edition Edited by K. L. Gandhi

- Fashion Design: The Complete Guide by John Hopkins

- Structural Textile Design: Interlacing and Interlooping By Yasir Nawab, Syed Talha Ali Hamdani, and Khubab Shaker

- Textile Engineering – An Introduction Edited by Yasir Nawab

- https://textilelearner.net/cam-in-textile-industry/

You may also like: