The textile and apparel industry are one of the most polluting industries in the world. These industry’s Carbon Di-Oxide emissions are increased by more than 60% toper year nearly 2.8 billion tons by 2030. Consequently, many multinationals have inhabited the business concept ‘fast-fashion,’ producing clothing continuously and control the waste emission. It seems obvious that textile and apparel industry are moved away from our current linear model to a new circular model. Circular economy is a new approach that alters the production process. It could reduce the use of resources and waste. Many governments, multinationals, and start-ups are working with the concept of circular economy in textile and apparel industry.

Before we discussed about details, we have to know about the concept of the circular economy.

What is Circular Economy?

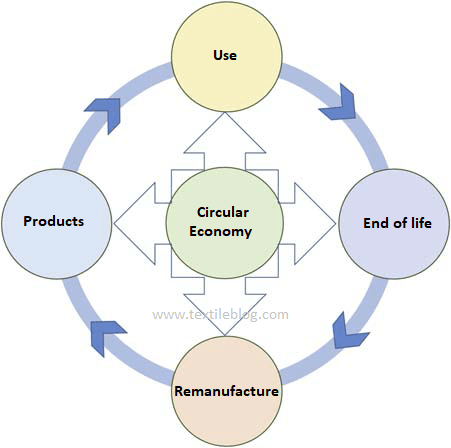

Circular economy is a systemic approach to economic development in several industry. It is mainly designed to benefit businesses, society, and also the environments. On the contrary linear model concept: ‘take-make-waste’. Circular economy is resurgent by design and aims to serially decouple growth from the consumption of finite resources.

Concept of Circular Economy Principle:

Technically the concept of circular economy is driven by five principles. Five pillars of circular economy are:

- Design for reuse

- Resilience through diversity

- Energy use from infinite sources

- System thinking

- Bio-based basis

Principles of circular economy are discussed below:

| SL No. | Principle | Description |

| 01. | Design for reuse | If the technical and biological products are created for reuse again in a new cycle, the waste will not exist in the product life cycle. The material can be reassembled and reused. Therefore, the value of the product will be upcycled. This ultimately will benefit prosperity in terms of new product combinations, new services, lower environmental impact toxicity and so on. |

| 02. | Resilience through diversity | The business or economy should be resilient in terms of unexpected external influences. It means the practical business strategy should be heterogeneous. The business models should have enough diversity with sufficient mutual connections along with alternative suppliers of resources and end-users like the natural ecosystem |

| 03. | Energy use from infinite sources | During upcycling process, the additional energy could be renewable. The circular economy basically focuses on renewable energy not on the labour. |

| 04. | System thinking | Back-feed loops play a vital role in the main principle focuses on the nonlinear system. It requires huge time focus at various levels of the production system. Feedback loops contribute to the resilience of the circular economy at different scales of industry in, the dependencies, systems influence. |

| 05. | Bio-based basis | Goods for consumption ispopularly made from biological materials. Natural scoured goods are most preferable. |

Needs Circular Economy to Reduce Alarming Treands of Textile and Apparel Industry:

The global textile and apparel industry are believed to account for 1/20 of the world’s annual carbon emissions which also described at the above. In addition, with consumer demand for new fashionable apparel are growing exponentially. Experts have predicted that the fashion industry could account for a quarter of global emissions by 2040 without ambitious action.

Current system for producing, distributing, and consuming apparel is mainly depends on “take-make-dispose” linear model. High volumes of non-renewable resources are used to produce apparels. Which apparels products are often used for only a short period, after which the materials are largely lost to landfill or incineration.

This linear model, puts pressure on resources, pollutes and degrades ecosystems, and creates significant societal impacts at local, regional, and global scales, while leaving out economic opportunities untapped. The following sections provide a synthetic overview of the main issues at stake.

Table: Impacts of the unsustainable practices in the textile and apparel industry

| Types of Impacts | Category |

| Wastage Issues | Low recycling |

| Low reuse rate | |

| Environmental | Contribution to climate change |

| Toxic chemicals | |

| Waste volumes | |

| Water consumption | |

| Non-renewable resources | |

| Space consumption | |

| Economic and social | Low wages |

| Low labour standards | |

| Low collective bargaining | |

| Lack of fair trade |

These impact only can be reduced by transformation of the textile and apparel industry.

Steps for Achieving Circular Economy:

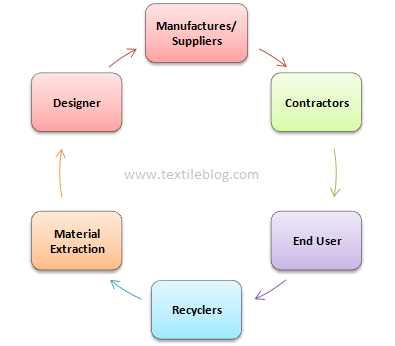

In past few years, circular economy become a much-discussed topic in textile and apparel industry. Its dependents on the four loops. These are: prolongation of product life, reuse or redistribution of product, remanufacturing to enhance the performance, recycling to make sustainable for reuse purposes. To obtain these goals, the textile and apparel industry needs to put effort in total product design to supply chain management.

Today re-manufactured fashion products are rising in textile and apparel industry. But it is an important point that the remanufactured fashion is the initial point of sustainability in circular economy concept. Merchandising those remanufactured products to the consumers are increasedby selling at a low price, which stimulates high consumption.

The availability of remanufactured fashionable products in the market with the standard fabric would raise the utilization of those products and reflect the basic of circular economy.

The marketing of re-manufactured fashion must be aware of the remanufacturing aspects and costs. Cause the mass consumers to need to be satisfied with the cost they expected. At the same time, the apparel designers might not create nonstandard products at a high price. They need to create the products in such a way that standardizes simple apparel designs. In this way, the industry can move forward to achieve a circular economy. The circular economy is mainly aimed to dominate the linear model’s take, make, disposal of waste.

Circular Economy: New opportunities to transform the textile industry and apparel industry

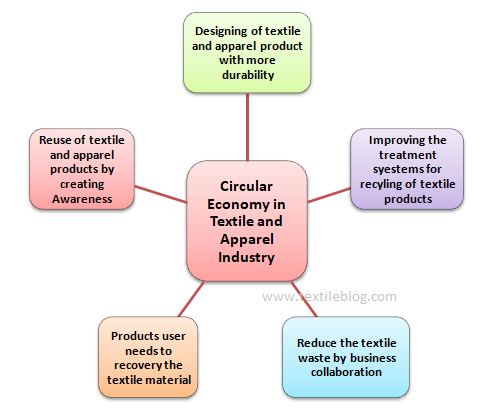

Several circular principles could be applied throughout the life cycle of textile and apparel products. A circular economy can facilitate by the development of right choices in the design of products, selection of resources, production, retailing and consumption phases and ultimately in the end of life of the products.

Circular principals for textile industry:

- Design out waste: In textile sector, circular economy aims to design out the negative impacts of economic activity. CE reduce the damage to human health and natural systems also. This includes the discharge of greenhouse gases, carbon emission, hazardous substances, the pollution of air, land, and water.

- Keep products and materials in use: Circular economy in textile industry favours activities that preserve more value within the variety of energy, labour, and materials. It preferred to create an economy for durability, remanufacturing, reuse, and recycling to keep products, components, and materials circulating in the economy. CE systems helps to make the effective use of biologically-based materials by encouraging various uses before nutrients are returned to natural systems.

- Regenerate natural systems: Circular economy in textile avoids the utilization of non-renewable resources. It mainly wants to preserve renewable resources for example by returning valuable nutrients to the soil to support regeneration. It is also using renewable energy as opposed to relying on fossil fuels.

Circular principals for apparel industry:

A. Design principles:

- Zero Waste Strategy: Waste is considered as a product of bad designin a circular economy. Traditionally, waste has always contaminated with evil of production. Today, industryis seeing a shift from this point of view. The strategical view is that, waste is intended out and everything that was ever made should return either to nature or the industry without damaging the environment. This strategy is encouraged designers to minimize and even eliminate the waste that’s created at both pre- and post-consumer levels in the apparel industry. This concept includes zero-waste pattern cutting by using the robot, recycling, or reusing leftovers.

- Design for Circularity: All products should be designed to be biodegradable and recyclable in a circular economy. All materials and components in a product could be recovered for using in new products or processesthrough recycling.

- Design for Zero Toxicity: It is important to design a product which are 100 percent safe and biodegrade to be released into our environment. For this all components of a product must be non-toxic and effective to biodegrade. Natural fibers, such as cotton, flax, hemp, wool, silk, bamboo, viscose, and wood should be prioritised to minimize the threat for any harmful compounds. Trimmings and accessories such as thread, buttons and laces should also be made out of natural materials, such as cotton or silk and wood, respectivelyfor safe and effective biodegradation.

- Energy and Resource Efficiency: Energy consumption and water usage in the apparel industry are extremely high and occur at each stage of the lifecycle of textiles such as at the production stage, use phase and end stage. In this strategy, design choices are made to reduce energy and resource consumption. Production phase could use of dry patterning systems andair-dyeing system. Alternatives such as design for no and technical coatings to reduce washing could be privileged.

- Design inspired by Nature: This strategy is followed by scientistto find inspiration and information for future sustainable design to end use. Shape-memory polymers to mimic natural movement, ‘Lotus effect’ nano-coatings, Velcro are the perfect example of design inspired from nature.

B. Resources principles:

- Choose low impact materials: Each material has its own strengths and weaknesses. It is difficult to assess the overall environmental impact of a material throughout its life cycle. When trying to establish which has the lowest impact, the following principles should be pursued. Resources should be derived from natural products, biodegradable, renewable.

- Choose recycled or recyclable fibres: Using recycled fabrics scores well in terms of environmental impact. Cause, recycled fiber requires less energy, resources and chemical products than the production of new textile. Turning to existing yarn and textile. It prefers reducing the need to make fabrics from virgin (raw) materials like cotton, wool or synthetic yarn. Recycling saves energy and avoids the pollution which is take place during current dyeing, printing, washing and harvesting process.

C. Production principles:

- Ethical production: Ethical production supports and values workers’ rights. It is also for sourcing of fair-trade materials. It includes sourcing fair trade materials, engaging suppliers who abide by codes of conduct, vertical supply chains, consideration of local resources.

- Clean technologies production: New technologies are developing rapidly. That allows rethinking traditional production processes. thereby helping to reduce the ecological footprint associated with production. The aim of this strategy is to replace systems of production with less energy consuming and smarter technologies to reduce environmental impacts.

D. Retail and consumption:

- Leasing models: Leasing model simply based on demand of the consumer. Consumer simply pay a small fee up front. Then a regular fee for each month have to paidif they wanted to lease the clothes. When consumer grew tired of their rental clothes, they can easily just send them back properly and stop paying to authority. This leasing model are successfully used in marriage ceremony.

- Clothing libraries: Clothing libraries strategy is adopted from the concept of book libraries to clothing items. In this model, various subscription options are available as like you can lend apparel that you simply swap for others again after a while.

- Swapping: Swapping is created a space where you can leave your clothes behind in exchange for coupons. By usingthese coupons, you can be used to buy someone else’s clothes. Swapping issuccessfully applied at various charity foundation to help humanity.

- Online second-hand marketplace: Internet is a huge facilitator to providevarious possibilities such as giving away, swapping and selling or, buying second-hand clothing’s. Different sites and apps have already brought suppliers and demanders together. When apparelsare shared or sold on, industry doesn’t have to make as much new stuff, and fewer resources are used.

E. End of life:

- Biodegradability: Making sure a product has been designed with biodegradability is important aspect to allow for the material to disappear back safely into the planet. Selecting natural textile fibers which break downeasily (such as: cotton, silk, wool, hemp, etc). Because, synthetic fabrics such as polyester, spandex, nylon will eventually break down in a very long period. It can take timebetween 20 to 200 years depending on the material.

- Upcycling: Upcycling strategy focuses on reusing discarded pieces of fabric to create new products. It has an additional value. Discarded textile is creatively reused. Generally, it can re-enter the market as a new and upcycled product. The process of upcycling is preferred making new clothes from old pieces or fabrics.

- Take back systems: Many manufacturers and brands have already started the strategy to collect clothes to encourage consumers to return unwanted items. It helps to increase the brand value. They often offer a discount on the next purchase by exchanging with old one.

- Recycling: Recycling natural materials such as cottonis done by mechanically. It is a process of stripping and shredding fabrics into smaller particles of fibres. Theses fibres emerge from this process have been broken and torn. It’s making fiber very short. But, using these kinds of fibres would threaten the quality of the fabric. Cause, the product made from this process would not be strong enough and would disintegrate quickly. To solve this problem and achieve a better quality, the short fibres are mixed with new long and less fragile fibres. It also matters that fabric is dark or light. The fabrics have to be decolorized for making dark or light fabric. Obviously darker fabrics needs more bleach.

Advantages of Circular Economy:

Economic Advantages:

- Material cost savings and reduced exposure to resource price volatility.

- Reduce the use of raw virgin materials and promoting the use of recycled materials.

- Additional profit opportunities for new services as like: rental or subscription services.

- Improved brand image.

Environmental Advantages:

- Less carbon emissions forusing lowcarbon materials.

- Renewable energy and energy-efficiency measures can reduce the GHG emissions of the sector.

- Less leakage of hazardous substances discharge into the environment.

- Reduced consumption of virgin, and non-renewable materials.

- improved recycling, and reduced waste in production.

Social Advantages:

- Reduced obsolescence through longer lasting and higher quality products.

- Increase positive health impacts through the reduction of hazardous substances.

- Better working conditions for employees.

Current Challenges of Circular Economy:

- To replace conventional business modeling in terms to delivery system.

- Lack of policy management in textile industries about collection and processing.

- Infrastructure disabilities for operation.

- Improper disposal system.

- Some clothes are not designed to recycle.

- It is a complex problem to disintegrate the polyester cotton blends individually, while this combination is the major player in the market.

- National-level implementation possibilities and technology availability.

- Skill requirements to process the circular fashion concept at all levels.

- Limited access to natural resources.

- Lack of textile supply chain.

- Product quality and sustainability.

- Unawareness of recycling across global standard, etc.

Circular Economy: A Revolution for Future

Slogan of linear model is “Take, make, and dispose”. In consumptive society, it does not seem to be sustainable. But, long-lasting design, repair-communities, and recycling are becoming a trend of the modern society. Textile and apparel industries now attempt to reconcile industrial production with the protection of the physical and human resources available today. From various point of view, great importance is given to reducing the consumption of raw materials, waste during production, and waste at the end of life of products. In this way, circular economy implementation right now is playing the vital role in the whole textile and apparel industry.

References:

- Circular Economy in Textiles and Apparel, Edited by Subramanian Senthilkannan Muthu, Head of Sustainability, SgT Group & API, Hong Kong

- Circular Economy — Challenges for The Textile and Clothing Industry by MałgorzataKoszewska, Lodz University of Technology, Faculty of Management and Production

- https://design4circle.eu/wp-content/uploads/2019/06/Report%20Design4circle%20-%20IO1%20A3%20ECORES.pdf

- https://www.ellenmacarthurfoundation.org/explore/the-circular-economy-in-detail

- https://edepot.wur.nl/425277

- https://conversableeconomist.blogspot.com/2018/01/textiles-your-clothes-are-pollutants.html

Author of this Article:

Md. Mahedi Hasan.

B.Sc. in Textile Engineering

Textile Engineering College, Noakhali.

Email: mh18.bd@gmail.com