Defects in Fabrics:

There are various types of defects in fabrics which may be created during weaving of fabrics or may be created during dyeing, finishing after weaving. Fabric defects may also be caused due to the yarn faults. By 4 point inspection system we can know about fabric defects. Quality fabrics demand increasing day by day, high quality requirements are today greater since customer has become more aware of poor quality problems. One some common fabric defects are discussed below:

Common Woven Fabric Defects with Pictures

Bad selvedge:

The selvedge of a fabric may be marked as bad it is wavy, corded, thick and thin and has broken weft yarn etc. If the selvedge is bad, whatever precious fabric it is, it will look bad. The finishing of fabric is troublesome, if the selvedge is bad.

Broken ends:

For any reason if the warp yarn is broken, then it creates a defect in fabric in the direction of length.

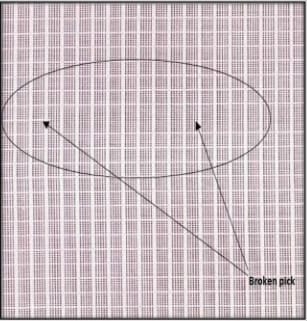

Broken picks:

During weaving, if the weft yarn is broken and it is not rectified, then fabric defect happens in width of the fabric. If it is a design fabric then the designs is also hampered.

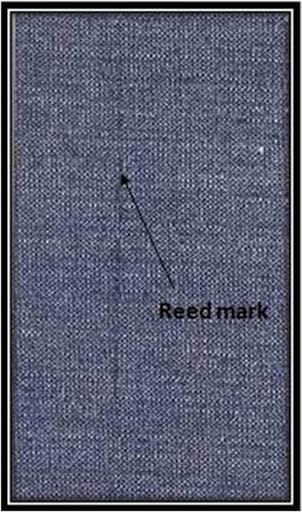

Reed marks:

If any visible line or mark is created in warp yarn then it is called the reed mark. If there is defect in reed mark, denting is not done properly, beam setting is not done correctly or the selection of reed is wrong, then this types of problems happen.

Broken pattern:

During weaving of design fabrics, if the warp yarn is broken and not rectified then in any designs like dobby, jacquard or in ordinary looms, the patterns are broken. In order to avoid such defects, care should be taken for lifting, peg plan or jacquard card.

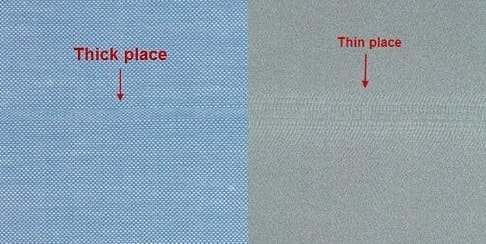

Thick and thin places:

If the yarns in fabric is thick in some places and thin in other places, then thick-thin places are created in fabrics. These defects are more visible after finishing of fabrics. Also if the fabric is woven with uneven warp yarn weft or yarn, then this type of problem may appear.

Rough surface cloth:

During weaving of fabrics, if uneven tension or excessive tension is applied or weaving is done with unsteamed yarn then the surface of the fabric becomes rough.

Mixed weft:

For any reason if different types of weft yarns are used, then visible stains are created in fabrics which become more visible after finishing. Generally, such type of defect happens due to weaver’s mistake.

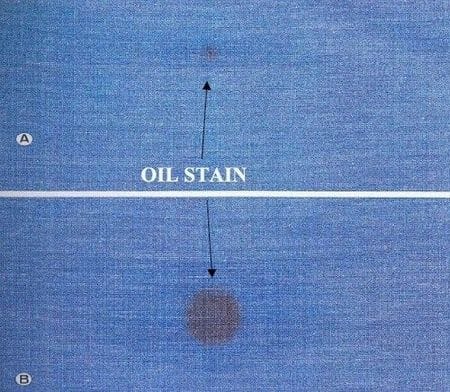

Stain:

Oil stains are frequently seen in fabrics. Such type of stains may happen during the time of spinning, weaving or finishing.

Iron stain:

Sometimes stains of iron are found. If any age old device with rust is used in any stage of fabric making, then this type of problem may happen from rust.

Sometimes iron stains are visible in layers of fabrics. The drops of water coming out from the rusted pipe and falling on the fabrics may cause such type of defect.

During finishing of fabrics, if the wet fabric is kept in any place where rusts are present then stains of iron will occur in that fabric.

Mildew:

If gray fabrics or colored fabrics or wet fabrics are kept in wet or damp weather or kept in the store, then mildew occurs in fabrics. If mil-dew happens in fabrics, it is very difficult to remove it. Fabrics may be done separate finishing treatment so that mildew cannot happen easily.

Holes in the cloth:

Sometimes small holes or cut marks are found in fabrics. Due to the faults in roll handling or due to the defects in sand roller, such types of defects are found in fabrics.

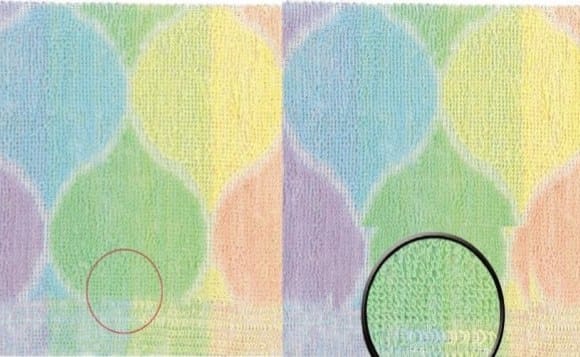

Shading:

If there is difference in depth of colors in fabrics then it is called shading. Shading is seen frequently mainly in colored fabrics. Shading may happen in the same bundle or roll of fabric or it may be found from one roll to the other. Mainly due to the defects in dyeing, the shading problem occurs but shading problem may happen also for other reasons like the defects in fibers or in yarns or in weaving.

Shuttle marks:

Sometimes stains are found in the warp yarns parallel to the weft yarns which are caused due to the friction of warp yarn with the shuttle. This type of defects may happen due to the alignment fault of shuttle box, the uneven tension on warp yarn or for any other reasons.