What is Shedding Tappet?

Generally tappets are used for heald shedding. The object of the shedding tappet is to impart a vertical motion to warp ends for allowing passage to the shuttle so the healds must be moved at a varying speed to correspond with the warp tension. There are three distinct types of shedding mechanism.

- Tappet shedding mechanism

- Dobby shedding mechanism

- Jacquard shedding mechanism

The object of all the different mechanisms is the same, but each of them works on different systems, and each kind has its own disadvantage. Tappet shedding mechanism is the simplest shedding mechanism used in the textile industry suitable for high speed looms. It is having the repeat of the pattern only on small number of ends and picks. The tappet shedding mechanism is suitable for simple weaves: but when the patterns consist of large number of ends for producing a particular design, then a dobby shedding mechanism is utilized. The dobby shedding mechanism is complex and the loom can be operated at slow speeds.

Jacquard shedding mechanism is still more complex but has the advantage of controlling large number of ends and suitable for weaving floral designs. Tappets, cams are the names given to those pieces of mechanism which are characterized as irregular in shape. A rotary motion is given to the tappet which produces reciprocating motion in the levers by sliding contact. The positive tappet controls healds in both the directions whereas a negative tappet is used either to pull down or lift up the heald shaft and an additional motion is required in the opposite direction.

Construction of shedding tappet:

In order to design a shedding tappet, the following points and dimensions must be taken in to consideration:

- Pattern to be produced in the fabric, i.e., the number of picks in a repeat of the design and the lifting order.

- Lift or stroke of the tappet

- Distance from the centre of the driving shaft to the nearest point of contact with the treadle bowl

- Dwell of the tappet – Time during which the healds will remain stationary, and

- Diameter of the treadle bowl

Tappet design for plain weave:

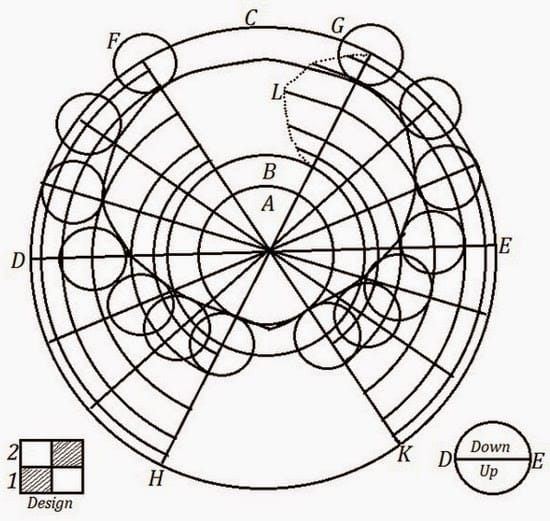

To design a shedding tappet for plain weave, the following particulars have been taken into consideration.

- Lift of tappet = 4 in.

- Distance from the centre of the driving shaft to the nearest point of contact with the treadle bowl = 2 in.

- Dwell of tappet = 1/3 of a pick

- Diameter of the treadle bowl = 2 in.

Design of tappet for twill weave:

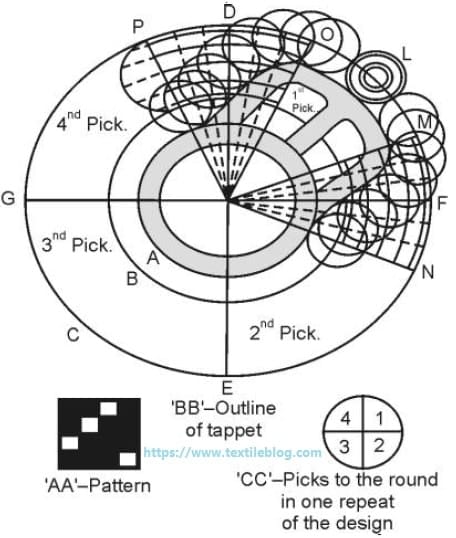

Twill tappet is constructed with the following with the following particulars.

- Pattern or design – 3 up 1 down

- Distance from centre of shaft to the nearest point of contact with treadle bowl – 3 inches

- Lift of tappet – 3 inches

- Diameter of treadle bowl – 2 inches

- Dwell – ½ a pick

For this twill weave there will be four treadle levers, each treadle being operated by a tappet of the same shape; but the tappet operating each succeeding treadle will be placed one quarter of a revolution than the previous one.

References:

- Textile Mechanisms in Spinning and Weaving Machines by Ganapathy Nagarajan

- https://textilemerchandising.com/tappet-dobby-jacquard-shedding/