Cost Breakdown of Knit Products of Different European Buyers

Authors:

Md. Sirajul Islam1

Md. Mosharaf Hossen Nahid

Dept. of Textile Engineering

Daffodil International University, Dhaka, Bangladesh

Email: sirajul.te@gmail.com1

ABSTRACT

Textile industry is a fast growing industry. The development and the strategy of making garments are now very challenging. Its sustainability is now a big issue over the world. Increasing sustainability practice making this industry in a tremendous form.

Day by day it’s going very harder to flow with customer demand. Consumer are now very much cost conscious and entrepreneurial spiritual. They understand the current market and current trends. To having customer’s attention it is very important fact for buyer to deal with cost. Different kinds of cost are making a total cost over the cost breaking system.

This study is all about cost breakdown of different European buyer. It consist of different parameter over the study to understand the cost and where it actually being increasing and slowing down with the all existing section like Yarn to Garments making.

Cost breakdown is the systematic process of identifying the individual elements that comprise the total cost of a good, service or package. It assigns a specific value to each element. Alternately, the value of the individual elements are expressed as a percentage of the total cost.

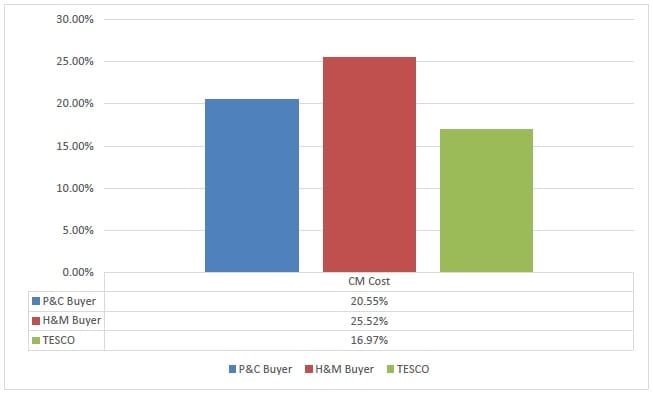

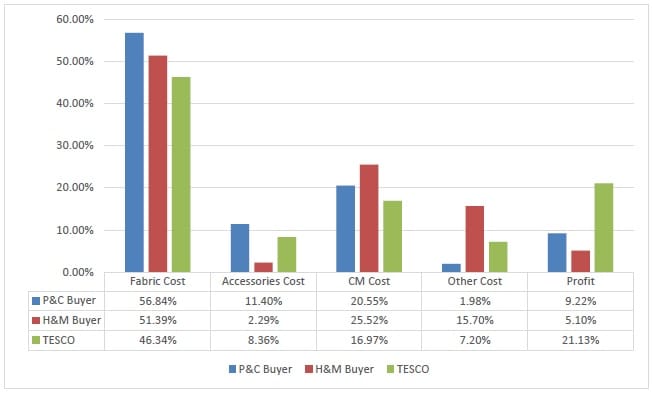

It comply with that solution of cost is different buyer have its different identical point and it’s more close to one another. The study lie with P&C, H&M and TESCO. This three buyer comply in a same point that there fabric cost are in between 46-57% of the total cost. The cost of making is the second highest cost over the cost breakdown. The making cost of garments of H&M buyer takes 25.52% TESCO takes 16.97% and whereas P&C taking 20.55%.

1. INTRODUCTION

1.1 Introduction:

Cost breakdowns are useful in justifying the price charged to the client and keeping sellers and providers accountable. If the client doesn’t know exactly what the total for a good, service or package will be, he can estimate the total by looking at the individual elemental costs. Knowing how the total price breaks down is also a benefit in comparing prices and negotiating better rates. Sellers and providers also can use cost breakdown to verify that they charged the client for everything. And cost breakdowns allow both companies and consumers to identify specific reasons for fluctuations in price.

Only if it can identify all of the elements that contribute to the total are cost breakdowns useful. Sometimes this is fairly difficult. For example, suppose a vendor charged a manufacturer $50 for some lumber. The manufacturer could state on the breakdown of the finished product that lumber cost the manufacturer $50, but this doesn’t show why the vendor charged $50. To figure that out, the client would have to request an additional cost breakdown from the vendor. Each element can be analyzed to a significant degree, and at some point, a decision has to be made about where the breakdown will stop. Additionally, sometimes value is difficult to quantify. For instance, labor is a highly subjective cost. One manufacturer may view the labor of employees as worth $25 per hour while another may view it as only worth $2.50. To explain costs that are not as quantifiable, companies usually have to talk about cultural or corporate values, not manufacturing processes or basic economics.

The price of a product or service is defined as cost plus profit, whereas cost can be broken down further into direct cost and indirect cost. As a business has virtually no influence on indirect cost, a cost reduction oriented cost breakdown analysis focuses rather on factors contributing to direct cost. The most common factors among direct cost are labor, raw materials and subcontracting. These are aspects of a business, over which it has direct control and which, in turn, enables the business to identify ways to save expenditure by the proper application of a cost breakdown analysis. Businesses can also combine this strategy with a value chain analysis, which allows price forecasts and hence, quicker responses to changes in the market.

Breaking down the costs associated with a good, package or service is a four-step process, as described by the European Institute of Purchasing Management. The first step is to establish the cost structure — that is, to gather all the information you need to understand the elements involved and what drives the costs of those elements. Second, check that the offers received for the elements are consistent — that is, do some price comparisons and try to figure out the reasons for variance. Third, negotiate based on your findings, and follow up with additional negotiations, analyses and management of the factors that impact cost fluctuation.

2. LITERATURE REVIEW

2.1 Definition of Costing:

Costing includes all the activities like purchase of raw materials and accessories, knitting fabrics, processing and finishing of fabrics, sewing and packing of garments, transport and conveyance, shipping, over heads, banking charges and commissions, etc.

To do perfect garment costing, one must know about all these activities thoroughly about their costs, procedures, advantages and risk factors. Also he must know how to solve the problems when occurred and to take suitable alternate decision immediately in time.

We must be aware that there are always fluctuations in the costs of raw materials and accessories, charges of knitting, processing, finishing, sewing and packing, charges of transport and conveyance. Hence we must have update knowledge about the latest prices and charges, latest procedures, methods and quality systems, market prices and availability, transportation (road, sea, air) and freight charges, etc.

We must remember that the quality depends on price; price depends on quality. Each product will have different price according to its quality. We do not manufacture only one quality of garments. Also we manufacture the garments not only for one customer. While we do the garment costing, the customer’s price level, quality & quantity and payment terms, to be taken into consideration.

There are two types of garments, namely woven and knitted garments. Shirt, trouser, saris, bedspreads, blankets, towels and made ups are woven. T-shirts, sweaters, undergarments, pajamas and socks are knits. Costing is the deciding factor for fixing of prices and the important thing to follow in all stages like purchase, production, marketing, sales, etc. Also update knowledge about everything related to garments, is essential to make perfect costing. Costing includes all the activities like purchase of fabrics and accessories, processing and finishing of fabrics, sewing and packing of garments, transport and conveyance, shipping, over heads, banking charges and commissions etc. We must be aware that there are always fluctuations in the costs of raw materials and accessories, charges of knitting, processing, finishing, sewing and packing, charges of transport and conveyance. The method of making costing will vary from style to style. As there are many different styles in garments.

2.2 Types of Cost:

- Direct Cost

- Indirect Cost

1. Direct Cost:

A price that can be completely attributed to the production of specific goods or services is called direct cost. Direct costs refer to materials, labor and expenses related to the production of a product.

Example:

- Project staff

- Consultants

- Project supplies

- Labor

- Material

- Directors Salary

2. Indirect Cost:

Indirect costs are costs that are not directly accountable to a cost of an object. These are those costs which are not directly related to production

Example:

- Utilities

- Rent

- Audit and legal

- Administrative staff

- Equipment rental

- Fuel

- Maintenance

- Generator

- Security

- Telephone

- Business travel expenditure

2.3 Profit:

Profit percentage depend on order quantity. If the order quantity is high then profit percentage are kept less and if the order quantity is less than profit percentage are kept higher.

Garment Costing:

For garments costing a merchandiser needs to have clear conception on some important terms. They are-

- Fabric Consumption

- Fabric Cost

- Accessories Cost

- Print/Embroidery/Washing Charge

- M.

- FOB

- Payment mode (at sight deferred payment 60days or 90 days or 120 days, TT, Sales Contract)

- Test Cost

- Commercial Cost

- Profit percentage

2.4 Consumption & Costing:

This is a primary and important job for a merchandiser to know how to do fabric consumption and costing of any garments. The most important factor is the costing which will be done by a merchandiser must commensurate with the prevailing market price, otherwise the costing will not be accepted by the buyer as such he will inclined to such factory to place order who’s costing is more realistic and at par with the prevailing market price. Now to do a reasonable garment costing a merchandiser need to equip him with certain tools and techniques to do reasonable costing.

Before Consumption & Costing, merchandiser should check this parameter:

- Fabrication: There are clear ideas regarding the fabrication before taking the order from the buyer / buying house. After then, surety that strong source of the followings fabric.

- Size spec: Make sure that; get the correct/ latest size spec with the measurement of all the sizes, which will be ordered. Many times it is seen that, PO sheet has come with new bigger size which was not during the costing.

- Fabric color: Try to know that, how many colors the style has & also try to know that, color wise order quantity ratio.

- Quantity: Take information regarding approximate order quantity.

- Shipment date: Asked buyer for the shipment date & check with the production department that, they have enough space for shipped out the followings quantity within the require ship date or tell your possible date.

- Test requirement: Let know that, the order has any test or not.

- L/C payments term: Take a previous L/C copy from them & discuss with commercial people regarding all the terms along with payment term.

- Inspection: Get a confirmation from buyer that, who will inspected the goods. If third party then who will pay their charges.

- GSP: Confirm that, buyer has need GSP or not.

- Body consumption: Calculate the body fabric consumption at first. If possible calculate it after the pattern. Be confirmed regarding the dais. calculate the consumption with adding +5 GSM extra which fabric is sells in kg (s/j ,pique ,rib etc ) .or reduce 2” (in width ) from the both side which are in yards (tricot , taffeta etc ) . Moreover, if the garments are wash garments then make sure that, the pattern has the wash allowance.

- Rib: Calculate the rib consumption carefully because something the garments have rib at cuff opening & bottom hem. Some people mistakenly do the consumption considering one cuff.

- Neck tape: Calculate the consumption of neck tape.

- Appliqué & other fabric: Make sure that, you are not missing any appliqué & any other fabric.

- Labels: Take the quotation from your supplier for the entire woven & satin / paper labels.

- Tape: Calculate the consumption of tape if it has, such as velvet, herringbone or canvas etc.

- Elastic: Make sure which denier & width it need. Then take the quotation from supplier.

- Zipper: If the garments have zippers then confirm that, from where you will purchase that. Many time the logo zipper quality, such metal, and nylon or vision zipper. Check the zipper measurement from production department and get prices from zipper supplier.

- Button: Take the button price from your supplier if the garments have it.

- Inter lining: Calculate the inter lignin price if the garments need.

- Patch or badge: Calculate the patch or badge or others metals item if the garments have.

- Finishing item: Tissue paper, silica gel, hang tag, barcode sticker, back board, h/tag string, scotch tape, security tag calculate the prices of these item.

- Print: If the garments have print then make sure that, the sample have a clear art work of it. Check that clearly mentioned the print quality, dimension & placement. Send the art work to your printers for a better price idea. Many times it is seen that, buyer has asked for so many type /kind prints in same body which is as difficult for production .such as, if buyer asked for flock + discharge & foil print in the same artwork then it is not possible for production.

- Embroidery: Discuss with embroidery supplier regarding the embroidery & take price quotation.

- Wash: Take the wash price quotation from washing factory.

- Test: Confirm the charge of test from the testing company.

2.5 Factors Affecting Consumption & Costing:

- Yarn /Fiber content

- Yarn Count and type (carded or combed)

- Knitting pattern

- Knitting Of fabric

- Lab test requirement

- Type of dyes and chemicals to be used

- Tolerance in dye lot and shade variation

- Any restriction on use of dyes and chemicals

- Packing type and assortment

- Design and pattern of garments

- Matching instruction in case of Y/D and printed Fabrics

- Number of garments to be packed per poly, blister and carton

- Ply of carton and type of poly and thickness of poly

- Details of shipping marks and carton marks

2.6 Thread Consumption (Complete body):

| Item | Consumption of Sewing thread/body |

| Basic T-shirt | 125 meter |

| Basic Polo shirt | 180 meter |

| Basic L/sleeve Woven Shirt | 150 meter |

| Basic S/sleeve Woven Shirt | 125 meter |

| Classic L/sleeve Woven Shirt | 175 meter |

| Classic S/sleeve Woven Shirt | 150 meter |

| Basic shorts | 350 meter |

| Classic Shorts | 450 meter |

| Basic L/pants | 350 meter |

| Classic L/pants | 450 meter |

| Basic Nylon Jogging Suit | 500 meter |

| Basic Short all | 350 meter |

| Classic Short all | 400 meter |

| Basic Overall | 400 meter |

| Classic Overall | 500 meter |

| Padded Coverall | 450 meter |

| Basic Romper | 350 meter |

| Classic Romper | 450 meter |

| Night Dress | 200 meter |

| Pajama Set | 450 meter |

| Skirt | 300 meter |

| Panty | 50 meter |

| Brief | 50 meter |

| Brassier | 100 meter |

| Corp set | 150 meter |

| Tank Top | 50 meter |

| Denim 5 Pocket Pants | 400 meter |

| Basic Nylon Padded Jacket | 350 meter |

| Classic Nylon Padded Jacket | 500 meter |

| Denim Jacket | 450 meter |

| Twill Jacket | 450 meter |

2.6.1 Sewing Thread Consumption Calculation

Say,

Order quantity = 4000 pcs

Per complete body required = 150 meter Process lose = 10%

1 Cone = 4000 meter

2.7 Consumption of Basic Knit T shirt

During the consumption please used measurement of middle size for calculation or used the sizes which have most of the qty. If the styles have 6 sizes then used size number 04 for consumption. Here we will consider the size: “L” for calculate the consumption)

- Body length of the garments in cm. Say it is – 73 cm

- Sleeve length of the garments in cm. Say it is – 19.5 cm

- Approximate sewing allowance at body hem, shoulder joint, sleeve hem & armhole joint (in cm). Say it is – 10 cm

- Chest width (1/2) in cm. Say it is – 52 cm

- Approximate sewing allowance at both side seams (in cm). Say it is – 4 cm

- Fabric GSM (finish). Say it is – 160 gsm

- Approximate fabric wastage in various stage. Say it is – 10%

2.8 Costing of T-shirt

Costing includes all the activities like purchase of fabrics and accessories, processing and finishing of fabrics, sewing and packing of garments, transport and conveyance, shipping, over heads, banking charges and commissions, etc. The method of making costing will vary from style to style. As there are many different styles in garments. Hence let us take men’s basic T-shirt style as example which is in regular use. We have used US Dollar as the currency.

Measurements in cm: (Finished garment)

Size – L

½ Chest – 52 cm

Length – 73 cm

Sleeve length – 19.5 cm

Neck rib width – 3 cm

Hem – 3 cm

Patterns are generally made with the seam allowance and cutting allowance. Generally, 10 cm is added with the total of body length and sleeve length.

GSM- 160,

Wastage – 10%

2.8.1 Consumption

{(B/length + S/length + Sewing Allowance) X (1/2 Chest + Sewing Allowance)} X 2 X GSM X 12 / 10000000 + Wastage

= {(73 + 19.5 + 10) X (52 + 4)} X 2 X 160 X 12 / 10000000 + 10%

= 2.43 kg per dozen.

2.8.2 Costing

Here,

Fabric price/kg= $6

Fabric price / dozen = 6 X 2.43 = $ 14.58

Fabric price/ dozen = $ 14.58

Per dozen CM cost = $ 5.5

Per dozen accessories cost = $5.0

Per dozen overhead cost = $1.8 (bank handling, carriage, forwarding)

Commission = $3

—————————————————————–————————————–

Total FOB price = $29.88 (including commission)

Here, total FOB price = $29.88

Per dozen sea freight = $ 1.34

———————————————————————————————————–

Total C&F price (Hamburg)/dozen = $ 31.22

Again, total C&F price / dozen = $ 31.22

Per dozen insurance cost = $ 1.3

Total CIF price / dozen = $ 32.52

Total CIF price/piece = (32.52÷12) = $ 2.677

2.9 Bill of Material

A bill of materials or Product structure (sometimes bill of material’ or BOM) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts and the quantities of each needed to manufacture an end product. A BOM may be used for communication between manufacturing partners, or confined to a single manufacturing plant.

A BOM can define products as they are designed (engineering bill of materials), as they are ordered (sales bill of materials), as they are built (manufacturing bill of materials), or as they are maintained (service bill of materials or pseudo bill of material). The different types of BOMs depend on the business need and use for which they are intended. In process industries, the BOM is also known as the formula, recipe, or ingredients list. In electronics, the BOM represents the list of components used on the printed wiring board or printed circuit board. Once the design of the circuit is completed, the BOM list is passed on to the PCB layout engineer as well as component engineer who will procure the components required for the design.

3. METHODOLOGY

3.1 Introduction

H&M, TESCO, P&C are the three buyer this study lie with. The cost breakdown of the H&M buyer are related with TESCO. However the P&C buyer having some major changes in cost breakdown. Mainly it seems with few cost.

| Fabric Cost | Accessories | CM Cost | Others Cost | Total Cost | Profit | FOB Cost |

The retail supply chain, which includes both retailers and parts of the wholesale sector, accounts for a significant part of Australian economic activity, representing around 7 per cent of GDP and more than 10 per cent of total employment. Purchases of retail goods (such as food and beverages, clothing, household goods and motor vehicles) collectively make up around 30 per cent of the basket of household expenditure covered by the consumer price index (CPI). To better understand the factors that influence trends in retail goods prices, and hence overall inflation, it is helpful to know the various costs incurred and margins applied by distributors (retailers and wholesalers) in the process of getting goods to consumers. For example, it is useful to know how much of final prices is due to the cost of imported goods when assessing the extent to which movements in the exchange rate are likely to be reflected in final consumer prices. Likewise, knowing the cost incurred in employing labor to distribute goods enables an understanding of the impact of changing labor costs on retail prices. More generally, the relative importance of distribution costs in the overall supply chain has important implications for how changes in demand or discounting behavior can affect firms’ profitability.

3.2 Composition wise yarn count price of card and combed yarn

| Composition | Yarn Count | Card | Combed |

| 100% Cotton Conventional (With BCI) (From Bangladesh) For White add $0.10 For Slub add $0.40 For Organic add $0.15 For Compact add $0.10 | 50/1 | $5.70 | |

| 40/1 | $4.10 | $4.40 | |

| 36/1 | $3.80 | $4.10 | |

| 34/1 | $3.65 | $3.95 | |

| 32/1 | $3.55 | $3.85 | |

| 30/1 | $3.40 | $3.70 | |

| 28/1 | $3.40 | $3.70 | |

| 26/1 | $3.35 | $3.65 | |

| 24/1 | $3.35 | $3.65 | |

| 22/1 | $3.30 | $3.60 | |

| 20/1 | $3.30 | $3.60 | |

| 16/1 | $3.30 | $3.60 | |

| 10/1 | $3.10 | $3.55 | |

| 100% Cotton, NON BCI (From Bangladesh) For White add $0.10 For Organic add $0.15 For Compact add $0.10 | 40/1 | $4.10 | $4.35 |

| 36/1 | $3.80 | $4.05 | |

| 34/1 | $3.65 | $3.90 | |

| 30/1 | $3.40 | $3.65 | |

| 28/1 | $3.40 | $3.65 | |

| 26/1 | $3.35 | $3.60 | |

| 24/1 | $3.35 | $3.60 | |

| 22/1 | $3.30 | $3.55 | |

| 20/1 | $3.30 | $3.55 | |

| 100% Cotton, ORGANIC(From Bangladesh) | 40/1 | $4.15 | $4.45 |

| 36/1 | $3.95 | $4.25 | |

| 34/1 | $3.80 | $4.10 | |

| 30/1 | $3.55 | $3.85 | |

| 28/1 | $3.55 | $3.85 | |

| 26/1 | $3.50 | $3.80 | |

| 24/1 | $3.50 | $3.80 | |

| 22/1 | $3.45 | $3.75 | |

| 20/1 | $3.45 | $3.75 |

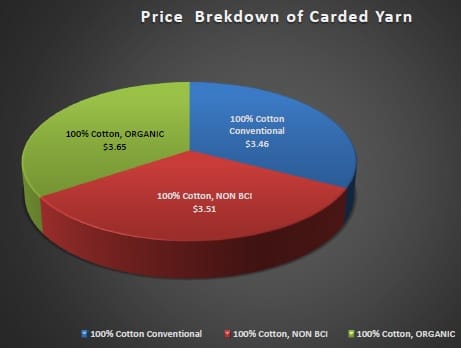

3.2.1 Price Breakdown of Carded Yarn

3.3 Composition wise yarn count and price of PC, CVC

| Composition | Yarn Count | PC 65:35 | CVC 60:40 | CVC 80:20 |

| PC 65/35 CVC 60/40 CVC 80/20 (With BCI) For White add $0.10 For Slub add $0.40 For Vortex add $0.10 | 50/1 | |||

| 40/1 | $3.55 | $3.65 | $3.90 | |

| 36/1 | $3.30 | $3.40 | $3.65 | |

| 34/1 | $3.15 | $3.25 | $3.50 | |

| 32/1 | $3.05 | $3.15 | $3.40 | |

| 30/1 | $2.90 | $3.00 | $3.25 | |

| 28/1 | $2.90 | $3.00 | $3.25 | |

| 26/1 | $2.85 | $2.95 | $3.20 | |

| 24/1 | $2.85 | $2.95 | $3.20 | |

| 22/1 | $2.80 | $2.90 | $3.15 | |

| 20/1 | $2.80 | $2.90 | $3.15 | |

| 16/1 | $2.80 | $2.90 | $3.15 | |

| 10/1 | $2.75 | $2.85 | $3.10 | |

| PC (65/35 Poly/Cotton) & CVC (60/40 or 80/20 Cotton/Poly) Slub (for white add $0.10 Cent) | 34/1 | $3.55 | $3.65 | $3.75 |

| 30/1 | $3.30 | $3.40 | $3.65 | |

| 26/1 | $3.25 | $3.35 | $3.45 | |

| Grey Melange ((1% to 15%) (Cotton+ Black Viscose) For BCI add $0.05 for Organic add $.15 for Slub add $.40 Cent | 40/1 | $4.05 | x | |

| 36/1 | $3.85 | x | ||

| 34/1 | $3.65 | x | ||

| 30/1 | $3.45 | x | ||

| 26/1 | $3.40 | x | ||

| 22/1 | $3.35 | x | ||

| 100% Viscose (add $.10 for white) | 40/1 | $4.00 | x | |

| 34/1 | $3.60 | x | ||

| 32/1 | $3.50 | x | ||

| 30/1 | $3.40 | x | ||

| 50% Cotton 50% Modal (With BCI) (for white add $.10) (for Organic add $.15) | 40/1 | $4.70 | x | |

| 36/1 | $4.50 | x | ||

| 34/1 | $4.35 | x | ||

| 30/1 | $4.10 | x | ||

| 100% Cotton Carded Slub (With BCI)

(for white add $.10) (for Organic add $.15) | 40/1 | $4.15 | x | |

| 36/1 | $3.95 | x | ||

| 34/1 | $3.80 | x | ||

| 30/1 | $3.55 | x | ||

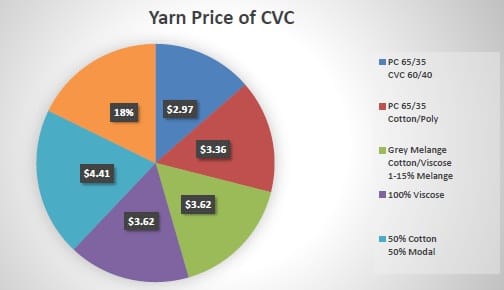

3.3.1 Yarn Cost Breakdown of CVC

3.4 Composition wise yarn count and price of PC, CVC

| Composition | Yarn Count | PC 65:35 | CVC 60:40 | CVC 80:20 |

| ORGANIC PC 65/35 CVC 60/40 CVC 80/20

For White add $0.10 For Slub add $0.40 (For Vortex add $0.10) | 50/1 | |||

| 40/1 | $3.70 | $3.80 | $4.05 | |

| 36/1 | $3.45 | $3.55 | $3.80 | |

| 34/1 | $3.30 | $3.40 | $3.65 | |

| 32/1 | $3.20 | $3.30 | $3.55 | |

| 30/1 | $3.05 | $3.15 | $3.40 | |

| 28/1 | $3.05 | $3.15 | $3.40 | |

| 26/1 | $3.00 | $3.10 | $3.35 |

| 24/1 | $3.00 | $3.10 | $3.35 | |

| 22/1 | $2.95 | $3.05 | $3.30 | |

| 20/1 | $2.95 | $3.05 | $3.30 | |

| 16/1 | $2.95 | $3.05 | $3.30 | |

| 10/1 | $2.90 | $3.00 | $3.25 | |

| Siro 50:50 or 60:40 Cotton/poly (For Slub Add $0.70) | 34/1 | $4.35 | ||

| 30/1 | $4.10 | |||

| 26/1 | $4.05 | |||

|

CVC 60/40 Cotton/Recycle Polyester

For BCI add $0.05 For Organic add $0.15 | 40/1 | $4.05 | x | |

| 34/1 | $3.70 | x | ||

| 30/1 | $3.45 | x | ||

| 28/1 | $3.45 | x | ||

| 26/1 | $3.40 | x | ||

| 22/1 | $3.35 | x | ||

| 36/1 | $3.70 | |||

| 30/1 | $3.30 | |||

| 20/1 | $3.20 | |||

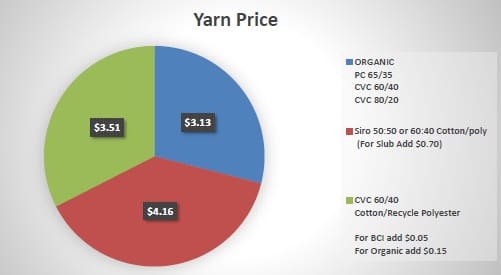

3.4.1 Yarn Cost Breakdown

3.5 Knitting Price

Data Collected from Meghna Knit Composite Ltd.

| Sl. No | Fabrics Type | M/C Gauge | Yarn Count | Current Market Rate / KG. $ | Budget sheet price. Rate / KG. $ | Remarks |

| 01 | S/Jersey- 100% Cotton | 24 | 20/s-30/s | $ 0.16 | $0.15 | |

| 24 | 32/s-40/s | $ 0.20 | ||||

| 28 | 34/s-40/s | $ 0.25 | ||||

| 2 | S/Jersey- 100% Viscose | 24 | 26/s-40/s | $ 0.25 | $0.15 | |

| 28 | 30/s-40/s | $ 0.30 | ||||

| 3 | Slub-S/Jersey- 100%Cotton | 20 | 16/s-30/s | $ 0.25 | $0.15 | |

| 24 | 32/s-40/s | $ 0.20 | ||||

| 28 | 34/s-40/s | $ 0.30 | ||||

| 04 | S/Jersey D/Y F/Stripe 100%Cotton | 24 | 24/s-32/s | $ 0.28 | $0.20 | |

| 24 | 34/s-40/s | $ 0.32 | ||||

| 20 | 20/s-30/s | $ 0.35 | ||||

| 5 | S/Jersey 100% Polyster | 28 | 75D | $ 0.45 | $0.20 | |

| 6 | Heavy Jersey- 100%Cotton | 20 | 16/s-30/s | $ 0.28 | $0.15 | |

| Heavy Jersey (2ply) – 100%Cotton | 20 | 32/2-40/2 | $ 0.28 | |||

| 7 | F/F.Lycra- S/Jersey | 24 | 30/s-40/s | $ 0.40 | $0.35 | |

| 28 | 36/s-40/s | $ 0.46 | ||||

| 8 | F/F.Lycra-Viscos- S/Jersey | 24 | 30/s-40/s | $ 0.40 | ||

| 28 | 36/s-40/s | $ 0.50 | ||||

| 9 | H/F.Ly- S/Jersey- D/Y Stripe | 24 | 30/s-40/s | $ 0.40 | $0.35 | |

| 10 | F/F.Ly- S/Jersey-D/Y Stripe | 24 | 30/s-40/s | $ 0.50 | ||

| 11 | F/F.Lycra- S/Jersey Polyster | 24 | 150D | $ 0.50 | ||

| 12 | 1X1 Normal Rib- 100%Cotton | 18 | 20/s-30/s | $ 0.22 | $0.20 | |

| 18 | 32/s-36/s | $ 0.25 | ||||

| 13 | Slub-1X1 Rib- 100%Cotton | 18 | 24/s-40/s | $ 0.28 | $0.20 | |

| 14 | 1X1 Rib D/Y Stripe- 100%Cotton | 18 | 20/s-30/s | $ 0.28 | $0.20 | |

| 15 | H/F.Lycra- 1X1 Rib | 18 | 26/s-30/s | $ 0.28 | ||

| 18 | 32/s-40/s | $ 0.30 | $0.25 | |||

| 16 | F/F.Lycra- 1X1 Rib | 18 | 26/s-40/s | $ 0.40 | ||

| 17 | 2X1 Normal Rib- 100%Cotton | 18 | 20/s-30/s | $ 0.30 | ||

| 18 | 32/s-40/s | $ 0.35 | $0.30 |

| 18 | 2X1 Rib D/Y Stripe- 100%Cotton | 18 | 20/s-30/s | $ 0.40 | ||

| 19 | H/F.Lycra- 2X1 Rib | 18 | 24/s-30/s | $ 0.40 | ||

| 18 | 32/s-40/s | $ 0.45 | $0.35 | |||

| 20 | F/F.Lycra- 2X1 Rib | 18 | 32/s-40/s | $ 0.50 | ||

| 21 | Lycar 2X1 Rib D/Y Stripe | 18 | 20/s-40s | $ 0.50 | ||

| 22 | P.K/Lacost- 100%Cotton | 24 | 20/s-30/s | $ 0.25 | $0.20 | |

| 24 | 32/s-40/s | $ 0.30 | ||||

| 28 | 32/s-40/s | $ 0.35 | ||||

| 23 | P.K/Lacost- F/Stripe- 100%Cotton | 24 | 24/s-34/s | $ 0.40 | $0.30 | |

| 20 | 20/s-30/s | $ 0.45 | ||||

| 24 | Lycra- P.K/Lacost | 24 | 30/s-40/s | $ 0.50 | ||

| 25 | Plain Interlock- 100%Cotton | 22/24 | Up to 40/s | $ 0.30 | $0.20 | |

| 28 | 40/s-50/s | $ 0.50 | ||||

| 26 | Interlock D/Y Stripe- 100%Cotton | 24 | 30/s-40/s | $ 0.45 | ||

| 27 | H/F.Lycra- Interlock | 22/24 | 30/s-40/s | $ 0.55 | ||

| 28 | Interlock/Needle Drope | 24 | 30/s-40/s | $ 0.50 | ||

| 29 | 2-Thread Terry-100% cotton | 24 | 20/s-34/s | $ 0.30 | $0.25 | |

| 30 | 3-Thread Fleece- 100% cotton | 20 | 20/s-34/s | $ 0.30 | ||

| 31 | Diagonal 3-T.F | 20 | 20/s-34/s | $ 0.35 | ||

| 32 | Lycra- Fleece/Terry | 24 | 30/s-40/s | $ 0.45 | ||

| 20 | 30/s-34/s | $ 0.50 | ||||

| 33 | Mash 100%Cotton | 24 | 30/s-40/s | $ 0.65 | ||

| 34 | Mash 100%Polyster | 24 | 75D-150D | $ 0.80 | ||

| 35 | Thermal | 18 | 26/s-34/s | $ 0.55 | $0.35 | |

| 36 | Flat Back Rib | 18 | 30/s-34/s | $ 0.55 | $0.40 | |

| 37 | Pointel Rib (normal) | 24/18 | 30/s-34/s | $ 0.80 | ||

| 38 | Verigated Rib | 18 | 26/s-34/s | $ 0.60 | ||

| 39 | Waffel | 18 | 26/s-34/s | $ 0.50 | $0.35 | |

| 40 | Pointe De-Roma | 24 | 30s-75s | $ 0.80 | ||

| 41 | Electronic Jacquard- S/Jersey | 24 | 26/s-34/s | $ 2.20 | ||

| 42 | Eng. Stripe (4 Colour) S/Jersey | 24 | 20/s-34/s | $ 1.40 | ||

| 43 | Eng. Stripe (6 Colour) S/Jersey | 24 | 20/s-34/s | $ 1.50 | ||

| 44 | Eng. Stripe (4 Colour) PK/Lacost | 24 | 22/s-34/s | $ 1.55 |

| 45 | Eng. Stripe (6 Colour) PK/Lacost | 24 | 22/s-34/s | $ 1.60 | ||

| 46 | Eng. Stripe (4&6 Colour) H/F.S/J- PK/Lacost | 24 | 30/s-34/s | $ 2.80 | ||

| 47 | Eng. Stripe (4&6 Colour) F/F.S/J- PK/Lacost | 24 | 30/s-34/s | $ 3.00 | ||

| 48 | Eng. Stripe (6 Colour) Rib | 18 | 26/s-32/s | $ 2.10 | ||

| 49 | Eng. Stripe (6 Colour) Interlock | 24 | 30/s-40/s | $ 2.80 | ||

| 50 | Eng. Stripe (6 Colour) Ly- Rib/Interlock | 24/18 | 30/s-34/s | $ 3.50 | ||

| 51 | Eng. Stripe 2X1 H/F Ly-Rib | 18 | 30/s-34/s | $ 3.50 | ||

| 52 | Eng. Stripe 2X1 F/F Ly-Rib | 18 | 30/s-34/s | $ 4.00 | ||

| 53 | Eng. Stripe Flat Back Rib | 18 | 26/s-34/s | $ 3.80 | ||

| 54 | Eng. Stripe Fleece/Terry | 24 | 20/s-24/s | $ 2.60 | ||

| 55 | Plane Collar & Cuff 1set | 12 | 26/s-40/s | $ 0.08 | ||

| 56 | Tpping Collar & Cuff 1set | 12 | 20/s-40s | $ 0.10 | ||

| 57 | Raising Collar & Cuff 1set (2part/2Color) | 12 | 20/s-40s | $ 0.45 |

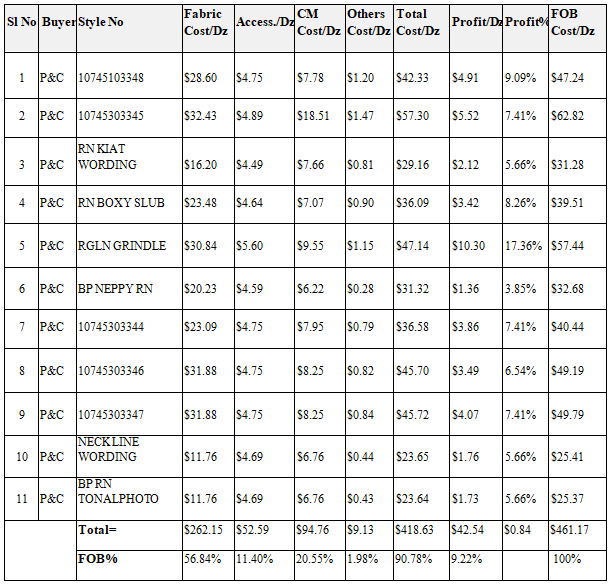

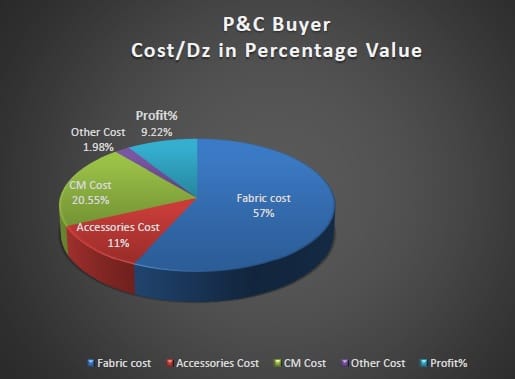

3.6 Cost breakdown of Knit Garments of P&C Buyer

3.6.1 Cost breakdown of P&C Buyer of Knit Products

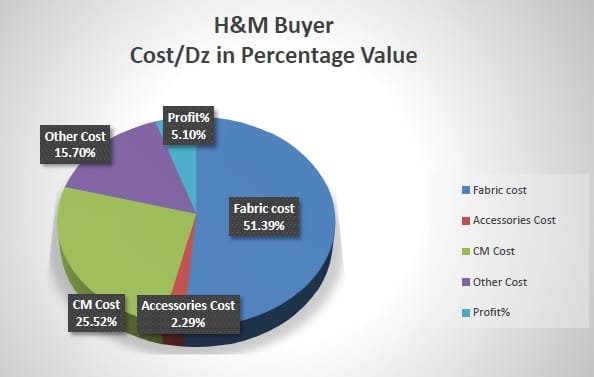

3.6.2 P&C Buyer Cost Breakdown of Knit Products

3.6.3 H&M Buyer Cost Breakdown of Knit Products

| Sl No | Buyer | Style No | Fabric Cost/Dz | Access./ Dz | CM Cost/Dz | Others Cost/Dz | Total Cost/Dz | Profit/ Dz | FOB Cost/Pc |

| 1 | H&M | MAUI S/L | $19.68 | $2.28 | $4.56 | $1.80 | $28.32 | $0.60 | $28.92 |

| 2 | H&M | VIGOT HOOD | $20.28 | $1.56 | $10.80 | $5.64 | $38.28 | $3.36 | $41.64 |

| 3 | H&M | RAPHIE | $31.80 | $0.00 | $12.00 | $2.40 | $46.20 | $1.68 | $47.88 |

| 4 | H&M | NILS | $12.60 | $0.84 | $22.20 | $3.60 | $39.24 | $0.60 | $39.84 |

| 5 | H&M | SIRPA | $11.04 | $0.36 | $17.88 | $1.92 | $31.20 | $0.48 | $31.68 |

| 7 | H&M | LICCENSE TEE | $10.20 | $0.36 | $1.80 | $8.64 | $21.00 | $2.64 | $23.64 |

| 8 | H&M | SS TEE | $14.72 | $0.48 | $3.12 | $7.84 | $26.16 | $1.92 | $28.08 |

| 9 | H&M | CUP SS TEE | $14.72 | $0.48 | $3.12 | $6.64 | $24.96 | $1.68 | $26.64 |

| 10 | H&M | 6700538 | $14.72 | $0.48 | $3.12 | $5.80 | $24.12 | $1.68 | $25.80 |

| 11 | H&M | 6700538 | $14.76 | $0.48 | $3.12 | $6.00 | $24.36 | $1.68 | $26.04 |

| Total | $164.52 | $7.32 | $81.72 | $50.28 | $303.84 | $16.32 | $320.16 | ||

| FOB% | 51.39% | 2.29% | 25.52% | 15.70% | 94.90% | 5.10% | 100% | ||

3.6.4 H&M Buyer Cost Breakdown of Knit Products

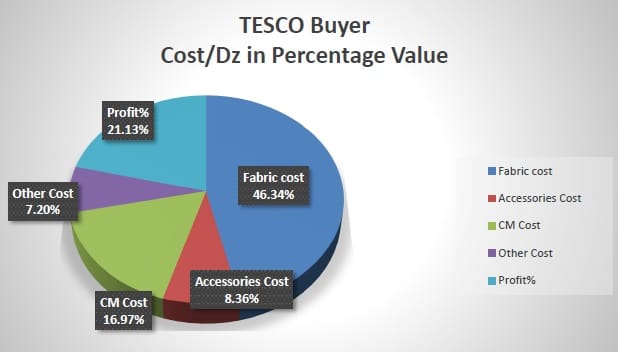

3.6.5 Cost breakdown of TESCO buyer of Knit

| Sl No | Buyer | Style No | Fabric Cost/Pc | Access./ Pc | CM Cost/Pc | Others Cost/Pc | Total Cost/Pc | Profit/ Pc | FOB Cost/Pc |

| 1 | TESCO | DMF 81488 | $23.92 | $4.42 | $7.78 | $12.04 | $48.16 | $10.12 | $58.28 |

| 2 | TESCO | EARL | $26.73 | $6.78 | $17.01 | $1.45 | $ 51.97 | $15.59 | $67.56 |

| 3 | TESCO | M-SH-115-107 | $23.47 | $3.21 | $6.02 | $1.76 | $34.46 | $9.99 | $44.45 |

| 4 | TESCO | M-SH-214-111 | $18.72 | $2.90 | $5.40 | $1.75 | $28.77 | $6.33 | $35.10 |

| 5 | TESCO | M-SH-214-130 | $17.12 | $2.63 | $5.12 | $1.75 | $26.62 | $13.05 | $39.67 |

| 6 | TESCO | M-SH-214-132 | $23.60 | $2.57 | $6.65 | $2.20 | $35.02 | $11.90 | $46.92 |

| 7 | TESCO | RN IKAT AOP | $16.73 | $4.59 | $7.07 | $2.40 | $30.79 | $1.54 | $32.33 |

| Total | $150.29 | $27.10 | $55.05 | $23.35 | $255.79 | $68.52 | $324.31 | ||

| FOB% | 46.34% | 8.36% | 16.97% | 7.20% | 78.87% | 21.13% | 100.00% | ||

3.6.6 Cost breakdown of TESCO buyer of Knit Products

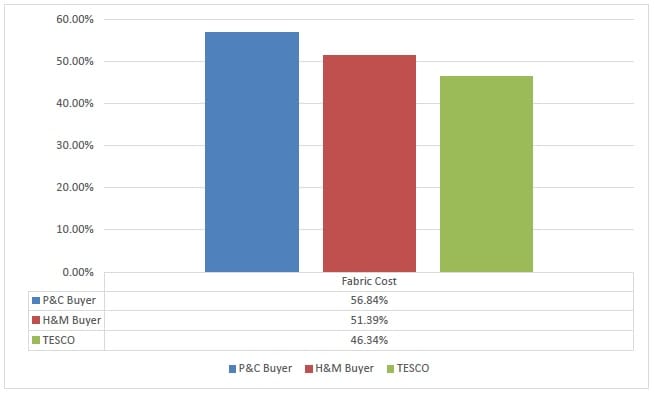

3.7 Comparison among All the Cost of P&C, H&M, TESCO

3.7.1 Fabric Cost of P&C, H&M, TESCO

- P&C Buyer Fabric Cost: 56.84%

- H&M Buyer Fabric Cost: 51.39%

- TESCO Buyer Fabric Cost: 46.34%

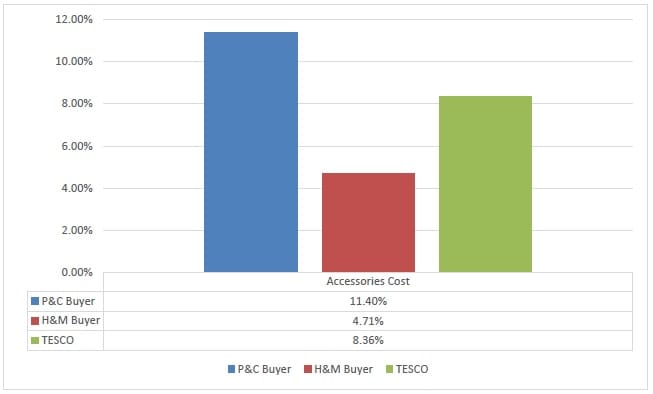

3.7.2 Accessories Cost of P&C, H&M, TESCO.

- P&C Buyer Accessories Cost: 11.40%

- H&M Buyer Accessories Cost: 4.71%

- TESCO Buyer Accessories Cost: 8.36%

3.7.3 Cost of Making (CM) of P&C, H&M & TESCO

- P&C Buyer CM Cost: 20.55%

- H&M Buyer CM Cost: 25.52%

- TESCO Buyer CM Cost: 16.97%

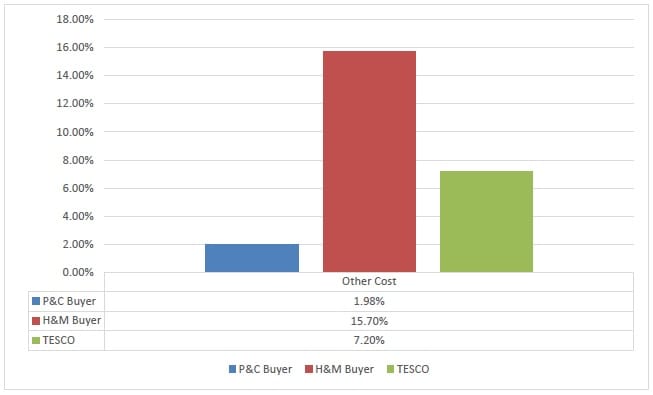

3.7.4 Other Cost of P&C, H&M & TESCO Buyer

- P&C Buyer Other Cost: 1.98%

- H&M Buyer Fabric Cost: 15.70%

- TESCO Buyer Fabric Cost: 7.20%

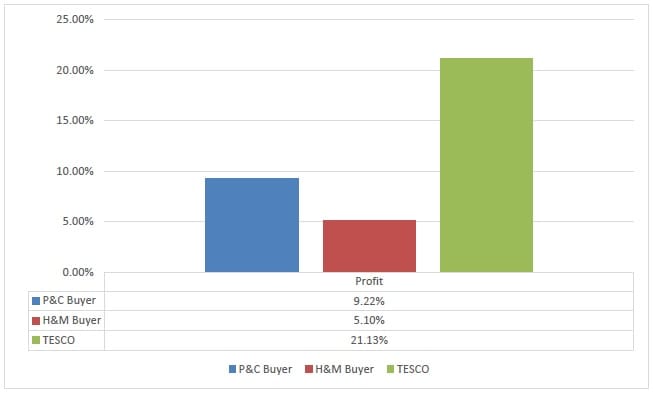

3.7.5 Profit of P&C, H&M & TESCO Buyer

- P&C Buyer Profit: 9.22%

- H&M Buyer Profit: 5.10%

- TESCO Buyer Profit: 21.13%

4. RESULT & DISCUSSION

Cost breakdown is the systematic process of identifying the individual elements that comprise the total cost of a good, service or package. It assigns a specific value to each element. Alternately, the value of the individual elements are expressed as a percentage of the total cost.

It comply with that solution of cost is different buyer have its different identical point and it’s more close to one another. The study lie with P&C, H&M & TESCO. This three buyer comply in a same point that there fabric cost are in between 46-57% of the total cost. The cost of making is the second highest cost over the cost breakdown. The making cost of garments of H&M buyer takes 25.52% from the total cost, TESCO takes 16.97% and whereas P&C taking 20.55%.

The fabric cost of H&M buyer are higher than any buyer and due to this cost P&C fabric quality are much better whereas the H&M takes 51.39% which is almost 5% lower than P&C and 5% higher than the TESCO.

Accessories cost of the P&C buyer are higher than any other buyer. P&C takes 11.40% whereas H&M takes 2.29% and TESCO takes 8.36%. On that fact H&M and TESCO are using a little bit of money in accessories but P&C are using a higher amount of cost in accessories. It defines that the product of P&C are more decorative.

4. CONCLUSION

Cost breakdown of different European buyer are different. The study runs with one of the major three buyer of the world like- P&C, H&M and TESCO. The analysis makes a decision over the study in the topic of cost breakdown is fabric cost is the major cost of the product. As compared in the study is different buyer remains different kinds of cost and mesurements. P&C is takes 56% of the total FOB, H&M takes 51.39% and TESCO takes 46.34%.

Cost of making (CM) is another big issue of the FOB whereas H&M is providing higher amount of CM within 25.52% of the total cost, P&C takes 20.55% & TESCO takes 16.97%.

Accessories cost of the product are much higher of the P&C buyer and that is because of the decorative purpose. H&M buyer are taking less decorative in that sense of cost.

Most importantly profit are very crusial and turing fact of the FOB. TESCO is the buyer who is giving much profit to the supplier and this is really matters with the FOB%.

APPENDICES

P&C Buyer Cost Breakdown Detail Sheet

1. P&C 10745103348

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $28.60 | $2.384 | 53.01% |

| SEWING ACC COST | $2.19 | $0.183 | 4.07% | |

| FINISHING ACC COST | $2.56 | $0.213 | 4.74% | |

| PRINT COST | $1.50 | $0.125 | 2.78% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $4.50 | $0.375 | 8.34% | |

| TESTING COST | $0.72 | $0.060 | 1.33% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $1.20 | $0.100 | 2.23% | |

| CM | $7.78 | $0.648 | 14.41% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $4.91 | $0.409 | 9.09% | |

| TOTAL | $53.96 | $4.50 | 100% |

2. P&C 10745303345

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $32.43 | $2.702 | 43.50% |

| SEWING ACC COST | $2.33 | $0.194 | 3.13% | |

| FINISHING ACC COST | $2.56 | $0.213 | 3.43% | |

| PRINT COST | $0.00 | $0.000 | 0.00% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $11.00 | $0.917 | 14.76% | |

| TESTING COST | $0.72 | $0.060 | 0.97% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $1.47 | $0.123 | 1.97% | |

| CM | $18.51 | $1.543 | 24.84% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $5.52 | $0.460 | 7.41% | |

| TOTAL | $74.54 | $6.21 | 100% |

3. P&C RN KIAT WORDING

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $16.20 | $1.350 | 43.16% |

| SEWING ACC COST | $1.93 | $0.161 | 5.14% | |

| FINISHING ACC COST | $2.56 | $0.213 | 6.81% | |

| PRINT COST | $4.65 | $0.388 | 12.39% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $1.00 | $0.083 | 2.66% | |

| TESTING COST | $0.60 | $0.050 | 1.60% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.81 | $0.067 | 2.15% | |

| CM | $7.66 | $0.638 | 20.41% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $2.12 | $0.177 | 5.66% | |

| TOTAL | $37.52 | $3.13 | 100% |

4. P&C RN BOXY SLUB

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $23.48 | $1.957 | 56.70% |

| SEWING ACC COST | $2.09 | $0.174 | 5.04% | |

| FINISHING ACC COST | $2.56 | $0.213 | 6.17% | |

| PRINT COST | $0.00 | $0.000 | 0.00% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $1.00 | $0.083 | 2.41% | |

| TESTING COST | $0.90 | $0.075 | 2.17% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.90 | $0.075 | 2.17% | |

| CM | $7.07 | $0.589 | 17.07% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $3.42 | $0.285 | 8.26% | |

| TOTAL | $41.41 | $3.45 | 100% |

5. P&C RGLN GRINDLE

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $30.84 | $2.570 | 51.97% |

| SEWING ACC COST | $3.05 | $0.254 | 5.14% | |

| FINISHING ACC COST | $2.56 | $0.213 | 4.31% | |

| PRINT COST | $0.00 | $0.000 | 0.00% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $1.00 | $0.083 | 1.69% | |

| TESTING COST | $0.90 | $0.075 | 1.52% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $1.15 | $0.096 | 1.94% | |

| CM | $9.55 | $0.796 | 16.09% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $10.30 | $0.858 | 17.36% | |

| TOTAL | $59.35 | $4.95 | 100% |

6. P&C BP NEPPY RN

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $20.23 | $1.686 | 57.16% |

| SEWING ACC COST | $2.26 | $0.189 | 6.39% | |

| FINISHING ACC COST | $2.32 | $0.194 | 6.57% | |

| PRINT COST | $1.00 | $0.083 | 2.83% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $1.00 | $0.083 | 2.83% | |

| TESTING COST | $0.72 | $0.060 | 2.03% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.28 | $0.023 | 0.78% | |

| CM | $6.22 | $0.518 | 17.58% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $1.36 | $0.113 | 3.85% | |

| TOTAL | $35.40 | $2.95 | 100% |

7. P&C 10745303344

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $23.09 | $1.924 | 44.26% |

| SEWING ACC COST | $2.19 | $0.183 | 4.21% | |

| FINISHING ACC COST | $2.56 | $0.213 | 4.90% | |

| PRINT COST | $0.00 | $0.000 | 0.00% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $11.00 | $0.917 | 21.09% | |

| TESTING COST | $0.72 | $0.060 | 1.38% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.79 | $0.066 | 1.52% | |

| CM | $7.95 | $0.663 | 15.24% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $3.86 | $0.322 | 7.41% | |

| TOTAL | $52.17 | $4.35 | 100% |

8. P&C 10745303346

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $31.88 | $2.657 | 59.69% |

| SEWING ACC COST | $2.19 | $0.183 | 4.11% | |

| FINISHING ACC COST | $2.56 | $0.213 | 4.79% | |

| PRINT COST | $1.50 | $0.125 | 2.81% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $2.00 | $0.167 | 3.74% | |

| TESTING COST | $0.72 | $0.060 | 1.35% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.82 | $0.068 | 1.53% | |

| CM | $8.25 | $0.687 | 15.44% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $3.49 | $0.291 | 6.54% | |

| TOTAL | $53.41 | $4.45 | 100% |

9. P&C 10745303347

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $31.88 | $2.657 | 57.95% |

| SEWING ACC COST | $2.19 | $0.183 | 3.99% | |

| FINISHING ACC COST | $2.56 | $0.213 | 4.65% | |

| PRINT COST | $1.50 | $0.125 | 2.73% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $3.00 | $0.250 | 5.45% | |

| TESTING COST | $0.72 | $0.060 | 1.31% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.84 | $0.070 | 1.52% | |

| CM | $8.25 | $0.687 | 14.99% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $4.07 | $0.340 | 7.41% | |

| TOTAL | $55.01 | $4.58 | 100% |

10. P&C NECK LINE WORDING

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $11.76 | $0.980 | 37.78% |

| SEWING ACC COST | $2.13 | $0.178 | 6.84% | |

| FINISHING ACC COST | $2.56 | $0.213 | 8.21% | |

| PRINT COST | $4.00 | $0.333 | 12.85% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $1.00 | $0.083 | 3.21% | |

| TESTING COST | $0.72 | $0.060 | 2.31% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.44 | $0.037 | 1.42% | |

| CM | $6.76 | $0.563 | 21.71% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $1.76 | $0.147 | 5.66% | |

| TOTAL | $31.14 | $2.59 | 100% |

11. P&C BP RN TONALPHOTO

| /DZN | /PC | |||

| COST BREAKDOWN % | FABRIC COST | $11.76 | $0.980 | 38.44% |

| SEWING ACC COST | $2.13 | $0.178 | 6.96% | |

| FINISHING ACC COST | $2.56 | $0.213 | 8.36% | |

| PRINT COST | $3.50 | $0.292 | 11.44% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $1.00 | $0.083 | 3.27% | |

| TESTING COST | $0.72 | $0.060 | 2.35% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.43 | $0.036 | 1.42% | |

| CM | $6.76 | $0.563 | 22.10% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $1.73 | $0.144 | 5.66% | |

| TOTAL | $30.60 | $2.55 | 100% |

H&M Buyer Cost Breakdown Detail Sheet

Reference NO: 01

OPD: 26

Valid From: 30 Jun 2017

Valid To: 30 Jun 2017

Production Unit: Fakir Knitwear ltd.

| Cost Blocks | Cost/Pc |

| Material | $1.64 |

| Trim | $0.19 |

| CMT | $0.38 |

| Finishing | $0 |

| Labels | $0.15 |

| Overhead | $0.05 |

| Total USD | $2.41 |

Reference NO: 02

OPD: 34

Valid From:

Valid To:

Production Unit: Knit Concern Ltd.

| Cost Blocks | Cost/Pc |

| Material | $1.69 |

| Trim | $0.13 |

| CMT | $0.9 |

| Finishing | $0.35 |

| Labels | $0.12 |

| Overhead | $0.28 |

| Total USD | $3.47 |

Reference NO: 03

OPD: 34

Valid From:

Valid To:

Production Unit: Koush Moda Ltd

| Cost Blocks | Cost/Pc |

| Material | $2.65 |

| Trim | $0 |

| CMT | $1 |

| Finishing | $0 |

| Labels | $0.2 |

| Overhead | $0.14 |

| Total USD | $3.99 |

Reference NO: 04

OPD: 38

Valid From:

Valid To:

Production Unit: Pioneer Knitwear Ltd.

| Cost Blocks | Cost/Pc |

| Material | $1.05 |

| Trim | $0.07 |

| CMT | $1.85 |

| Finishing | $0.14 |

| Labels | $0.16 |

| Overhead | $0.5 |

| Total USD | $3.77 |

Reference NO: 05

OPD: 32

Valid From:

Valid To:

Production Unit: Target Fine Knit Ind. Ltd.

| Cost Blocks | Cost/Pc |

| Material | $0.92 |

| Trim | $0.03 |

| CMT | $1.49 |

| Finishing | $0.1 |

| Labels | $0.15 |

| Overhead | $0.4 |

| Total USD | $3.09 |

Reference NO: 06

OPD: 38

Valid From:

Valid To:

Production Unit: Karooni Knit Composite Ltd.

| Cost Blocks | Cost/Pc |

| Material | $0.85 |

| Trim | $0.03 |

| CMT | $0.15 |

| Finishing | $0.61 |

| Labels | $0.11 |

| Overhead | $0.22 |

| Total USD | $1.97 |

Reference NO: 07

OPD: 9-13

Valid From:

Valid To:

Production Unit: Comfit Composite Knit Ltd.

| Cost Blocks | Cost/Pc |

| Material | $1.2272 |

| Trim | $0.04 |

| CMT | $0.26 |

| Finishing | $0.55 |

| Labels | $0.1 |

| Overhead | $0.16 |

| Total USD | $2.34 |

Reference NO: 08

OPD: 7-9

Valid From:

Valid To:

Production Unit: Comfit Composite Knit Ltd.

| Cost Blocks | Cost/Pc |

| Material | $1.2272 |

| Trim | $0.04 |

| CMT | $0.26 |

| Finishing | $0.45 |

| Labels | $0.1 |

| Overhead | $0.14 |

| Total USD | $2.22 |

Reference NO: 09

OPD: 7-9

Valid From:

Valid To:

Production Unit: Comfit Composite Knit Ltd.

| Cost Blocks | Cost/Pc |

| Material | $1.2272 |

| Trim | $0.04 |

| CMT | $0.26 |

| Finishing | $0.385 |

| Labels | $0.1 |

| Overhead | $0.14 |

| Total USD | $2.15 |

Reference NO: 10

OPD: 47-50

Valid From:

Valid To:

Production Unit: Comfit Composite Knit Ltd.

| Cost Blocks | Cost/Pc |

| Material | $1.23 |

| Trim | $0.04 |

| CMT | $0.26 |

| Finishing | $0.44 |

| Labels | $0.09 |

| Overhead | $0.14 |

| Total USD | $2.20 |

Cost Breakdown Detail Sheet of TESCO Buyer

Reference 01

| /DZN | /PC | |||

| COST BREAKDOWN% | FABRIC COST | $16.73 | $1.394 | 51.73% |

| SEWING ACC COST | $2.26 | $0.189 | 7.00% | |

| FINISHING ACC COST | $2.32 | $0.194 | 7.19% | |

| PRINT COST | $0.00 | $0.000 | 0.00% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $1.00 | $0.083 | 3.09% | |

| TESTING COST | $0.72 | $0.060 | 2.23% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.69 | $0.058 | 2.14% | |

| CM | $7.07 | $0.589 | 21.86% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $1.54 | $0.128 | 4.76% | |

| TOTAL | $32.33 | $2.69 | 100% |

Reference 02

| COST BREAKDOWN% | FABRIC COST | $23.92 | $1.994 | 41.05% |

| SEWING ACC COST | $2.12 | $0.177 | 3.64% | |

| FINISHING ACC COST | $2.30 | $0.192 | 3.95% | |

| PRINT COST | $5.50 | $0.458 | 9.44% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $1.50 | $0.125 | 2.57% | |

| TESTING COST | $0.72 | $0.060 | 1.24% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $4.33 | $0.361 | 7.43% | |

| CM | $7.78 | $0.648 | 13.34% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $10.12 | $0.843 | 17.36% | |

| TOTAL | $58.28 | $4.86 | 100% |

Reference 03

| COST BREAKDOWN% | FABRIC COST | $26.73 | $2.227 | 39.56% |

| SEWING ACC COST | $3.54 | $0.295 | 5.24% | |

| FINISHING ACC COST | $3.24 | $0.270 | 4.79% | |

| PRINT COST | $0.00 | $0.000 | 0.00% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $0.00 | $0.000 | 0.00% | |

| TESTING COST | $0.43 | $0.036 | 0.64% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $1.02 | $0.085 | 1.51% | |

| CM | $17.01 | $1.418 | 25.18% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $15.59 | $1.299 | 23.08% | |

| TOTAL | $67.56 | $5.63 | 100% |

Reference 04

| COST BREAKDOWN% | FABRIC COST | $23.47 | $1.955 | 52.79% |

| SEWING ACC COST | $1.93 | $0.161 | 4.34% | |

| FINISHING ACC COST | $1.28 | $0.106 | 2.87% | |

| PRINT COST | $0.65 | $0.054 | 1.46% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $0.00 | $0.000 | 0.00% | |

| TESTING COST | $0.29 | $0.024 | 0.65% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.83 | $0.069 | 1.86% | |

| CM | $6.02 | $0.501 | 13.54% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $9.99 | $0.833 | 22.48% | |

| TOTAL | $44.45 | $3.70 | 100% |

Reference 05

|

COST BREAKDOWN% | FABRIC COST | $18.72 | $1.560 | 53.35% |

| SEWING ACC COST | $1.77 | $0.148 | 5.05% | |

| FINISHING ACC COST | $1.13 | $0.094 | 3.23% | |

| PRINT COST | $0.65 | $0.054 | 1.85% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $0.00 | $0.000 | 0.00% | |

| TESTING COST | $0.41 | $0.034 | 1.17% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.68 | $0.057 | 1.94% | |

| CM | $5.40 | $0.450 | 15.38% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $6.33 | $0.527 | 18.03% | |

| TOTAL | $35.10 | $2.92 | 100% |

Reference 06

| COST BREAKDOWN% | FABRIC COST | $17.12 | $1.427 | 43.16% |

| SEWING ACC COST | $1.55 | $0.129 | 3.90% | |

| FINISHING ACC COST | $1.08 | $0.090 | 2.73% | |

| PRINT COST | $0.65 | $0.054 | 1.64% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $0.00 | $0.000 | 0.00% | |

| TESTING COST | $0.48 | $0.040 | 1.21% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.63 | $0.052 | 1.58% | |

| CM | $5.12 | $0.426 | 12.90% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $13.05 | $1.087 | 32.89% | |

| TOTAL | $39.67 | $3.31 | 100% |

Reference 07

| COST BREAKDOWN% | FABRIC COST | $23.60 | $1.967 | 50.30% |

| SEWING ACC COST | $1.51 | $0.126 | 3.22% | |

| FINISHING ACC COST | $1.06 | $0.088 | 2.26% | |

| PRINT COST | $0.65 | $0.054 | 1.39% | |

| EMBROIDERY COST | $0.00 | $0.000 | 0.00% | |

| AOP COST | $0.00 | $0.000 | 0.00% | |

| TESTING COST | $0.72 | $0.060 | 1.53% | |

| COURIER COST | $0.00 | $0.000 | 0.00% | |

| COMMERCIAL COST | $0.83 | $0.069 | 1.76% | |

| CM | $6.65 | $0.554 | 14.17% | |

| L/C FINANCE COST | $0.00 | $0.000 | 0.00% | |

| B/COMM | $0.00 | $0.000 | 0.00% | |

| MARGIN | $11.90 | $0.992 | 25.37% | |

| TOTAL | $46.92 | $3.91 | 100% |