Different Types of Acid Wash Operation against Some Specific Buyer Order

Authors:

Md. Zahidul Islam1

Md. Shamiul Islam

Dept. of Textile Engineering

Daffodil International University, Dhaka, Bangladesh

Email: zahidabdullah3680@gmail.com1

ABSTRACT

This report represents different types of acid wash operation against some specific buyer order. This assessment is done on different types of fabric like black denim, indigo blue denim and some other denim where fabric width were different. We have collected data from R&D section, Production section and also from lab test report for specific order. As a result we have found some different shade variation , different chemical consumption and also different working procedure maintained by skilled operator. We assessed on different types of acid wash like towel,ball,cokset,stone etc. During the process we faced some managerial problem which was solved from HR department. This industry has good image on washing filed as they work for some famous buyer like H&M, ZARA , NEXT , S.OLIVIER and so on. We also assessed top buyer of acid wash in this industry.

INTRODUCTION

1.1 Objectives

- To know about the types of ACID WASH.

- To know about the machines used in ACID WASH process.

- To know about the chemical consumption.

- To know about the function the chemicals used in ACID WASH.

- To know the time and temperature maintained in ACID WASH.

- To know the buyer requirement for shade variation.

- To know the allowance % from buyers.

- To know how to match the shades.

- To know about test requirement and test processes.

- To observe the appearance of ACID WASH and their variety for different types.

1.2 Limitations

- As we are not well trained so we faced some problem during the work.

- Due to limitations of some theoretical knowledge we faced some problem.

- Due to short time internship we couldn’t collect healthy data for this assessment.

- Due to some managerial problem we had some restrictions to collect data.

- Sometimes we had no work because there was no order of acid wash.

LITERATURE REVIEW

2.1 Garment Wash:

The process which is used to transform the outlook appearance, warmness & fashion appeal of the garments is called garment washing. Garment pre- wash became popular especially since 1978 when jeans garments started pre- washing and got instant popularity. It gave different a look to the clothes. Garments washing are mainly done after stitching. Wash types usually depend on the product natures and usages. Based on consumer demand and fashion trend, buyer will fix the washing type of any product. For example, stone enzyme wash is required for denim item, but light softener wash is perfect for knitted item.

2.2 Objectives of Garment Wash:

Garment wash here refers to garment pre- wash performed after production of garment’s before using it for the consumers. Garment washing is utilized for the following reasons:

- Usually, some Garment shows up hard, feeling rough, stiff and not responsive enough for wearing if not pre- washed.

- Garment is often made bigger and larger. Pre- wash returns those to the right size and dimensional instability.

- After pre- wash garment becomes fit as they get rid of shrinkage; as a result, the garment becomes soft hand feels and become size free.

- After wash some garment’s become more attractive, lucrative and lively, such as jeans, twill, cotton, gabardine etc.

- Different washing methods are being used to make an additional appeal for customers/Buyers.

- During manufacturing dirt, spot or oil mark may add with the garment’s what may eliminate by washing process.

- To eliminate starch and chemicals what used during fabric manufacturing and dyeing process.

2.3 Types of Garment Wash:

There are different varieties of garment wash used nowadays:

- Normal wash

- Pigment wash

- Bleach wash

- Stone wash with or without bleach

- Acid wash

- Enzyme wash

- Caustic wash

- Garment wash and over-dye

- Whitening

A simple outline about different garment wash has given here:

1) Normal Wash:

Normal wash consists of washing garments in hot water with adequate detergent and softener, rinse with plain water and dry in tumble dryer until it is 100% dry. Some sodium is added to lend the garment a prominent washed look. Water temperature, proportion of components of wash is adjusted as per requirement of wash and types of fabric; the garment is made of. The softener makes the fiber soft and tumble-drying makes the fabric fluffier. An expert technician can handle washing by an expedient way to solve many problems arising out during washing. Washing can also affect different garment parts differently. Shell fabric may be solid color while pocket may be white pocketing piece. After washing, it may appear that pocketing piece has been stained.

It may happen because maybe too much softener has been used or the fabric bleeding color is of weak color quality. Though softener makes the fiber soft, it also breaks the dye loose and may stain the fabric. Too much use of softener makes the fabric waxy. So, one should cut a balance in using softener and other components in regular wash. In such cases, garment should be washed with less softener and check if the staining problem is got rid of or eliminated. If use of less softener cannot solve the problem of staining indicates poor color quality of fabric. In this case, the garment will not pass U.S. standard on possibly the following aspects:

Color change, Color staining, Crooking (rubbing), One way of improving staining problem or dye quality of fabric may be the following:

- Have 40 degree C hot water in a tumble washer.

- Put 1% color fixing agent and mix with hot water.

- Put the dry garment into the tumble washer and let them soak in the solution for 5 minutes and then lift them up for drying.

- Run the tumble washer a few times and stop.

- Do not run the washer too much; it may lead the dye to come off and stain.

- Just let the garments soak and absorb the chemicals. Move the garments inside the washer as gently as possible; when the garments are dried, the color quality substantially improves. After treating the garments in the mentioned way, they can simply be imposed to normal wash to give it the washed look.

2) Pigment Wash:

Pigment Wash is similar to normal wash but a bit costlier. The garment is solid color pigment dye. The requirement is that the color should fade evenly to lend the garment a prominent washed look. Pigment wash requires a higher temperature of water than a normal wash.

- Use hot water 50-60 degree C.

- Load the tumble washer not more than 70 % of its capacity. It enables garment to move inside smoothly. If fully loaded with garments due to the friction of the garments with tumble body.

3) Bleach Wash:

Bleach wash means that bleach chemical is used in water while washing in a tumble washer. Strict washing time is a requirement with such wash because otherwise the garment may be over bleached and the color cannot be reversed.

4) Stone Wash:

Stone wash means washing garments with special stones so that garments achieve a very strong washed effect. Volcanic stones are used in such wash abrade exposed parts of the garments, this idea of washing with porous volcanic stones is to give the garment a strong and rough wash to achieve the pronounced washed effect through abrasion on the exposed areas, such as the seams and pocket corners.

Sometimes, bleach is added to the wash so that the color fades in a more pronounced manner. This is done to make navy blue jeans into a more faded light blue. Such wash requires a lot of skill, experience; workmanship and expertise so that desired results are achieved. In stone wash the following points should be carefully checked:

- Size of the stones: Stone size is very important in stone wash. They have various effects on the garment being washed. Large stones may give tough abrasion, and small stones may lead less abrasion. Stone should be selected based on the required abrasion effect as well as the type of fabric of the garments. However, larger stones may damage comparatively light-weight fabric. Small stones may give softer abrasion.

- Garment-Stone ratio: (Weight of stones relative to the weight of garment) Wash with more stones may lead to more apparent blue/white contrast on the fabric.

- Washing time: Washing time also much important in stone wash.

- Quantity of Bleach: Use of more bleach can shorten wash time and leads to more productivity. Bleach, however, cannot be used indiscriminately. Disproportionate amount of bleach may lead to lose of the desired blue/white contrast on the fabric. In order to achieve a better result, one should cut a balance between quantity of bleach, stone size and amount of stone. Sometimes one needs to use the normal quantity of stone and longer washing time to achieve the color standard requirements.

5) Acid Wash:

It is a patented process and can be used only by permission. It is also a kind of stone wash. The wash is performed in two steps: in the first step, garment is washed without water and in the 2nd step with water.

- Soak volcanic stones in potassium permanganate solution. Stones absorb chemicals and become saturated. The stones are then dried in normal air or sun. The stones are ready for work.

- Denim garments are now made ready for wash. They are desized/detached in water in a tumble washer and dried in a spin dryer.

- The garments are put in a separate tumble washer filled with treated stones. Water is not added. Now run the tumble dryer wash the garments without water. Tumble washer is run to wash the garments without water. Stone will abrade the garments, especially, the exposed parts. Hidden parts will not be abraded.

- After that, the garments are taken out of the tumble and transferred to another tumbler filled with water for washing and rinsing. After rinsing is over, the prominent acid wash effect will show up.

The treated stones carry the chemical to bleach the exposed parts and bleach them to white. But the hidden parts remain untouched. Whitening agents are often added to water during rinse to make the white color in the blue jeans whiter to display acid wash.

6) Enzyme Wash:

Enzyme wash is performed with a kind of live cell. Enzyme can break some fibers of fabric and gives the fabric special effect desired on the garment. Enzyme wash provides the fabric a soft, sanded or “peached” effect very desirable on many garments. Enzyme wash is also useful for indigo denim.

In this case, enzyme can replace stone but gives denim a stone wash look, with better and nicer blue and white contrast on the fabric. Enzyme wash is, however, costlier than stone wash.

7) Caustic Wash:

Caustic wash is a pre- printing wash. Caustic is a strong chemical with highly corrosive features. Prior to printing on cotton fabrics, gray goods are treated in boiling water with caustic, which also has strong cleaning power, especially for grease. This wash can remove all soil, dirt, grease, fine particles of cotton seeds as well as all foreign materials. As a result, only pure cotton fiber in the fabric for printing is left. It leads to stability of printing and well-cleaned fabric. However, when we want to do caustic wash on garments, we just do the opposite of the above; prior to printing, fabric is not treated with caustic wash for cleaning.

Printing is done on the row & unclean fabric so that about 30% of the printing done on the surface may eventually fade away. Finally, printed garments are caustic washed. It leads to, about 30% of the printing washed away along with the foreign materials- leaving about 70% of the printing on the fabric. It eventually makes the design or stripe of the desired look. For this type of wash, the printing must be pigment print with a binder. Baking treatment should also be performed so that

The color will stay on the fabric more or less securely to coincide with the caustic wash to be done later.

8) Garment Wash And Over-Dye:

This type of wash is also used for denim garments to give them an exclusive look. This is performed in the following way:

- Wash the denim garments with stone so that the double needle seams, pocket flaps, and exposed parts get washed down to light blue color or white.

- Put into dye the tumble to dye the garments to get the desired color.

- A coat of new color will appear on to the garment, especially, in areas where the garment has been washed to a light shade. It creates a unique but different look. In this process of wash, the lining or pocketing will pick up the color too. By this wash, direct dye or reactive dye same as dyeing fabrics or yarn may be used. Direct dye is cheap. So, direct dye may be utilized with the concomitant use of color fixing agent, after dying to make the color more stable. In case of solid color fabric staining within the garment is not a problem. However, if garments of different colors are washed together by the consumers, color may transfer to other garments. Reactive dye is always preferable in this case.

9) Whitening:

Whitening agents are used to create a super white look. (Unless the garments you wash is all colored namely no white color at all in the fabric, you should use whitening powder in the rinsing process to make the white part more white) In denim where there are colored warp threads and white weft threads. If such garments undergo “stone wash and bleach” whitening powder is used for the final rinsing. It makes the white threads in the fabric whiter and generates a stronger contrast between blue and white on the surface of the fabric.

After washing, denim checks the reverse side of the fabric to evaluate if adequate whitening agent has been used during rinsing. It is a common practice that garments having white parts should be washed with whitening powder at the time of rinse. It generates a quick and desired look. [1]

2.4 Acid Wash

Acid wash is again becoming popular on denim jeans and we are going to see more of acid washes in the coming seasons. Here, let’s have a quick look at the acid washing process. An acid wash finish treatment creates significant contrasts in the color of the denim material. It can be done on Indigo & Sulphur base fabric garments. As the randomly faded, acid washed style came into vogue in 1980s, the process of treating denim in such a way began to become increasingly refined. Some tried to use a method similar to the stonewashing, yet the fading did not occur as dramatically or throughout the material. During acid wash thermocol ball , pumic stone, towel , cokset are used. Basically acid wash is done on heavy fabric like denim, twill/thick canvas or sweater. To produce irregular fading effects or old looking effect according to the buyer standard, acid wash is done.

Acid wash can be carried on Indigo & Sulphar base fabric garments. Acid wash is a chemical wash on denim which stripped the top layer of color and makes a white surface while the color remained in the lower layers of the material, giving it a faded look. This wash is being carried out by pre soaking stones in bleach and then followed by neutralization. Acid wash of denim garment normally carried out by tumbling the garments with pumice stones presoaked in a solution which contains sodium hypochlorite (5 to 10%) or potassium permanganate (3 to 6%). [2]

2.5 Basic Process Flow Chart of Acid Wash:

Desizing

↓

Enzyme

↓

Bleach

↓

Neutral

↓

Acid wash

↓

Neutral

↓

Tint (if necessary)

↓

Softening

↓

Hydro extract

↓

Drying

↓

Finishing

2.6 Basic Chemicals Used In Acid Wash:

- Desizing agent

- Detergent

- Potassium permanganate

- Sodium Matabisulphite

- Phosphoric acid

- Acetic acid

- Softener etc. [3]

2.7 Test Requirements:

| NO | TEST NAME | STANDARD | Requirement | |

| Dry | Wet | |||

| 1 | Color Fastness To Rubbing | ISO 105*12 | ||

| 2 | Color Fastness To Houshold Laundering | H&M TM CF:3 | ||

| 3 | Dimension Stability To Household Laundering | H&M TM LA:03 | ||

| 4 | Appearance Area 1&5 Time Washes | ‘’ ‘’ LA:02 | ||

| 5 | Tursting | ‘’ LA:04 | ||

| 6 | Color Fastness To Water | ISO 105 EO1 | ||

| 7 | Color Fastness To Perspiration | ISO 105 E04 | ||

| 8 | Color Fastness To Saliva | GB/T 18886 | ||

| 9 | pH | ISO 13937-2 | ||

| 10 | Nickel Test | EN 12471 | ||

| 11 | Pull Force Test | EN 71-1 | ||

| 12 | Tear Strength | ISO 13937-2 | ||

| 13 | Slim Slippage | ISO 1936-2 | ||

| 14 | Tensile Strength | ISO 13934-1 | ||

| 15 | Fabric Weight | ISO 13934-1 | ||

| 16 | Color Fastness To Washing | ISO 105 CO6 | ||

2.8 Fault Of Acid Wash:

- Spot mark.

- More effect.

- Less effect.

- Shade light.

- Uneven shade.

- Garment tear

2.9 Causes Of The Faults Occur In Acid Wash:

# Sopt Mark:

- RPM of the machine.

- Improper chemical mixing in the solution.

- Improper swelling of towel with potassium permanganate.

- Presence of water in the machine.

# More Effect:

- Improper chemical mixing.

- Improper chemical dosing.

- Careless operating.

- Presence of potash.

# Uneven Shade:

- Percentage of potash.

- Amount of activator.

- Improper time maintaining

- Improper temperature maintaining

- Lack of checking.

# Shade Light:

- More percentage of potash.

- Presence of phosphoric acid in a high percentage.

# Garment Tear:

- Strength loss due to chemical effect.

- GSM reduce due to chemical effect.

- Careless operating.

EXPERIMENTAL DETAILS

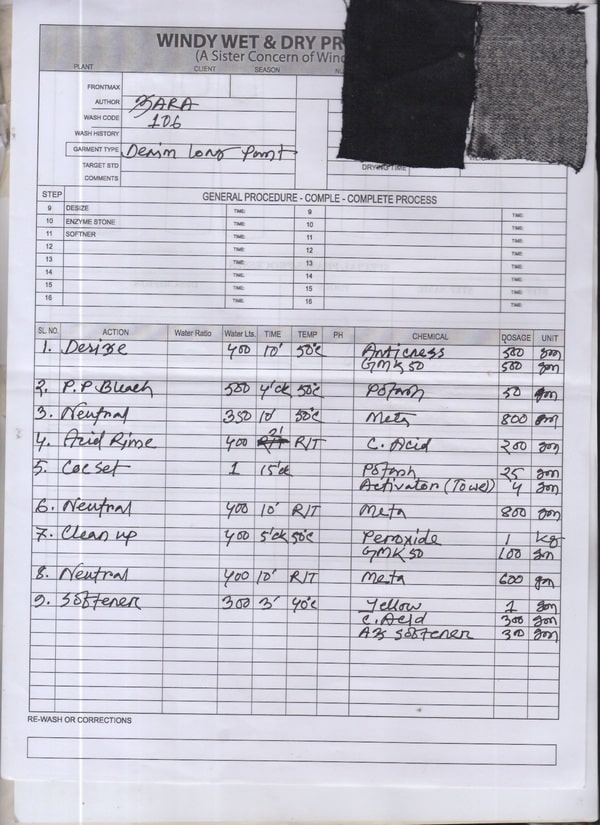

3.1: Buyer Name: Zara

Style:106

Garments Type: Denim Long Pant

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: | ||||||||||||||||

| FRONTMAX | ||||||||||||||||||||

| AUTHOR | ZARA | FABRIC NO. | ||||||||||||||||||

| WASH CODE | 106 | ESTIMATE COST | ||||||||||||||||||

| WASH HISTORY | MACHINE TYPE | Belly machine | ||||||||||||||||||

| GARMENT TYPE | LOAD SIZE UNIT | |||||||||||||||||||

| TARGET STD | DRYING TIME | |||||||||||||||||||

| COMMENTS | Black | |||||||||||||||||||

| STEP | GENERAL PROCEDURE-COMPLE-COMPLETE PROCESS | |||||||||||||||||||

| 1 | TIME: | 9 | TIME: | |||||||||||||||||

| 2 | TIME: | 10 | TIME: | |||||||||||||||||

| 3 | TIME: | 11 | TIME: | |||||||||||||||||

| 4 | TIME: | 12 | TIME: | |||||||||||||||||

| 5 | TIME: | 13 | TIME: | |||||||||||||||||

| SL NO. | ACTION | WASH RATIO | WATER Lts. | TIME | TEMP | PH | CHEMICLE | DOSAGE | UNIT | |||||||||||

| 1 | DESIZE

| 400L | 10’ | 50C | Anticress | 500 | gm | |||||||||||||

| GMK50 | 500 | ‘’ | ||||||||||||||||||

| STONE | ||||||||||||||||||||

| 2 | P.P bleach | 500l | 4’ck | Potash | 50 | “ | ||||||||||||||

| 3 | Neutral | 350L | 10’ | 50C | Meta | 800 | ‘’

| |||||||||||||

| 4 | Acid Rinse | 400L | 2’ | R/T | C.Acid | 200 | ‘’ | |||||||||||||

| 5 | Cocset | 1bag | 15’ | Potash | 25 | “ | ||||||||||||||

| 6 | Neutral | 400 | 10’ | R/T | Meta | 800 | ‘’ | |||||||||||||

| 7 | Cleanup | 400 | 5’ ck | R/T | Peroxide | 1 | Kg | |||||||||||||

| GMK50 | 100 | gm | ||||||||||||||||||

| 8 | Nutral | 400 | 10’ R/T Meta | 600 | “ | |||||||||||||||

| 9 | Softener | 300 | 3’ | 40c | Yellow | 1 | Gm | |||||||||||||

| C.Acid | 300 | “ | ||||||||||||||||||

Fig 3.1.2: R&D Recipe Of Acid Wash (Cokset; Zara)

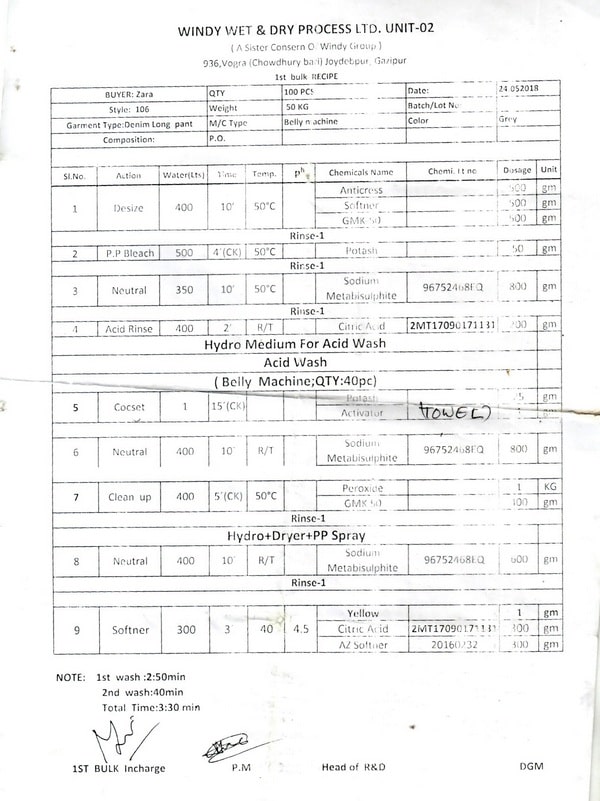

3.2: Bulk Recipe:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 24-05-18 | |

| Buyer | ZARA | 100 pcs | |||

| Style | 106 | 50kg | Batch no | ||

| Type | Denim long pant | Color | Grey | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

| SL No | Action | Water | Time | Temp | pH | Chemical | Chemi.lt No | Dosage | Unit |

| 1 | Desize | 400 | 10’ | 50c | Anticress Softner GMK-50 | 500 500 500 | Gm Gm Gm

| ||

| 2 | P.P bleach | 500 | 4’ | 50c | Potash | 50 | Gm | ||

| 3 | Neutral | 350 | 10’ | 50c | Meta | 800 | Gm | ||

| 4 | Acid Rinse | 400 | 2’ | R/T | C.Acid | 200 | Gm | ||

Acid Wash

| 5 | Cocset | 1 | 15’ck | Potash | 25 | Gm | |||

| Activator | towel | 1 | Bag | ||||||

| 6 | Neutral | 400 | 10’ | Meta | 800 | Gm | |||

| 7 | Cleanup | 400 | 5’ck | 50c | Peroxide | 1 | KG | ||

| 8 | Neutral | 400 | 10’ | R/T | Meta | 600 | Gm

| ||

| 9 | Softener | 300 | 3’ | 40 | Yellow C.Acid AZ Softener | 1 300 300 | Gm Gm Gm |

FIG 3.2.2: RECIPE

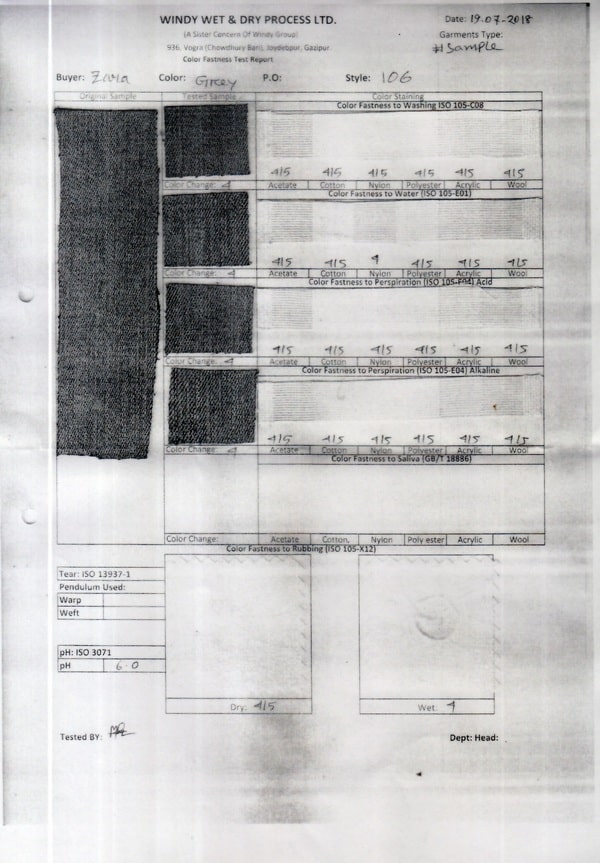

3.3: Lab Test Report:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 24-05-18 | |

| Buyer | ZARA | 100 pcs | |||

| Style | 106 | 50kg | Batch no | ||

| Type | Denim long pant | Color | Grey | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

Color Fastness:

| Test Name | Method | Grade | ||

| 1.Color Fastness to washing | ISO 105-C08 | 4 | ||

| 2.Color Fastness to Water | ISO 105-E01 | 4 | ||

| 3.Color Fastness to Perspiration(Acid) | ISO 105-E04 | 4 | ||

| 4.Color Fastness to Perspiration(Alkali) | ISO 105-E04 | 4 | ||

| 5.Color Fastness to Saliva | GB/T 18886 | 4 | ||

Color Fastness to Rubbing: ISO 105-X12

| Object | Grade |

| DRY | 4/5 |

| WET | 4 |

pH Test: ISO 3071

| pH | 6.0 |

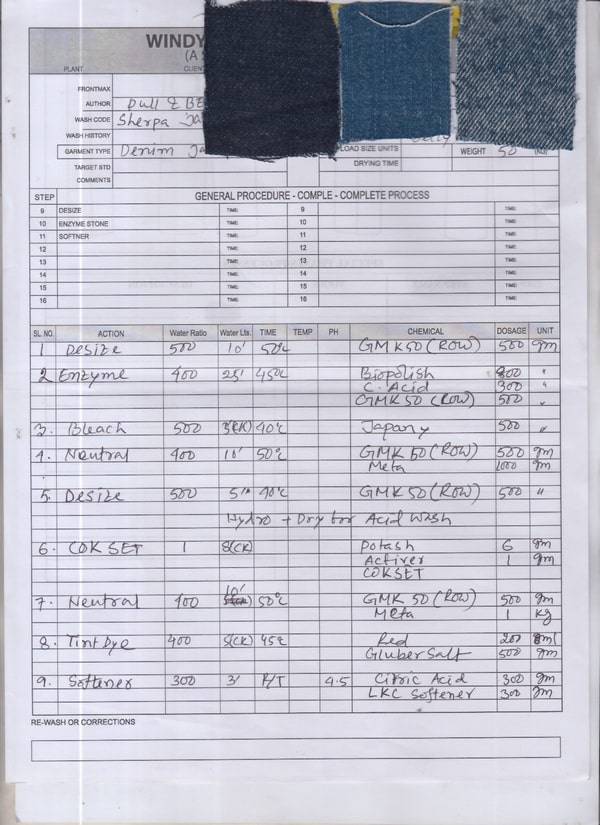

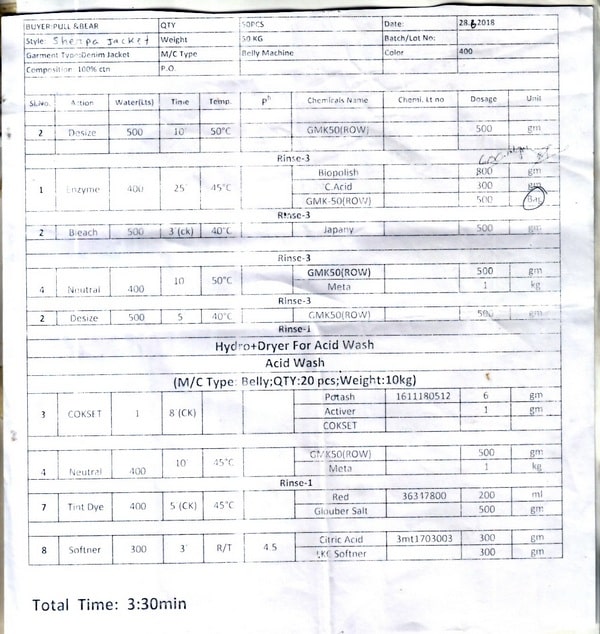

3.4: Buyer: Pull & Bear

Style: Sherpa Jacket

Garments Type: Denim Jacket

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: | |||||||

| FRONTMAX | |||||||||||

| AUTHOR | Pull & Bear | FABRIC NO. | |||||||||

| WASH CODE | Sherpa | ESTIMATE COST | |||||||||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||||||||

| GARMENT TYPE | Denim Jacket | LOAD SIZE UNIT | |||||||||

| TARGET STD | DRYING TIME | ||||||||||

| COMMENTS | Black | ||||||||||

| STEP | GENERAL PROCEDURE-COMPLE-COMPLETE PROCESS | ||||||||||

| 1 | TIME: | 9 | TIME: | ||||||||

| 2 | TIME: | 10 | TIME: | ||||||||

| 3 | TIME: | 11 | TIME: | ||||||||

| 4 | TIME: | 12 | TIME: | ||||||||

| SL NO. | ACTION | WASH RATIO | WATER Lts. | TIME | TEMP | PH | CHEMICLE | DOSAGE | UNIT |

| 1 | DESIZE

| 500L | 10’ | 50C | Raw GMK50 | 500 | gm | ||

| 2 | Enzyme | 500l | 25’ | 45c | Lavacel NHC C.Acid GMK50 | 800 300 500 | “ “ “ | ||

| 3 | Bleach | 600l | 5ck | 40C | Japany Bleach | 500 | ‘’

| ||

| 4 | Neutral | 500L | 10’ | 45c | Meta | 1 | Kg | ||

| 5 | Cleanup | 500 | 5’ | 50c | GMK50 | 500 | Gm | ||

| 6 | Acid Wash | 1 | 5’ck | KMnO4 C.Acid | 6 1 | Gm Gm | |||

| 7 | Neutral | 500 | 10’ | 45c | LP30 Max | 500 600 | ‘’ “ | ||

| 8 | Cleanup | 600 | 5’ ck | 50c | LP30 | 500 | gm | ||

| 9 | Tint | 400 | 5’ 45c Red | 300 | Ml | ||||

| Brown | 500 | gm | |||||||

| 9 | Softener | 400 | 5’ | R/T | C.Acid | 100 | Gm | ||

3.5: Bulk Recipe:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 24-05-18 | |

| Buyer | Pull & Bear | 100 pcs | |||

| Style | Sherpa | 50kg | Batch no | ||

| Type | Denim Jacket | Color | 400 | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

| SL No | Action | Water | Time | Temp | Ph | Chemical | Chemi.lt No | Dosage | Unit |

| 1 | Desize | 500 | 10’ | 50c | GMK-50 | 500 | Gm | ||

| 2 | Enzyme | 500 | 25’ | 45c | NHC C.Acid GMK-50 | 800 300 500 | Gm Gm gm | ||

| 3 | Bleach | 600 | 5’ | 40c | Japani BleaCH | 500 | Gm | ||

| 4 | Neutral | 500 | 10’ | 45c | Meta GMK-50 | 1 500 | Kg gm | ||

| 5 | Cleanup | 500 | 5’ | 50c | GMK-50 | 500 | gm |

Acid Wash

| 5 | Acid wash | 1 | 5’ck | Potash C.Acid | 06 01 | Gm Bag | |||

| 6 | Neutral | 500 | 10’ | 45c | Meta GMK-50 | 600 500 | Gm gm | ||

| 7 | Cleanup | 600 | 5’ck | 50c | GMK-50 | 500 | gm | ||

| 8 | Tint | 500 | 5’ | 45c | Red Brown | 300 500 | Gm Gm

| ||

| 9 | Softener | 400 | 5’ | R/T | C.Acid GMK-50 | 400 500 | Gm Gm |

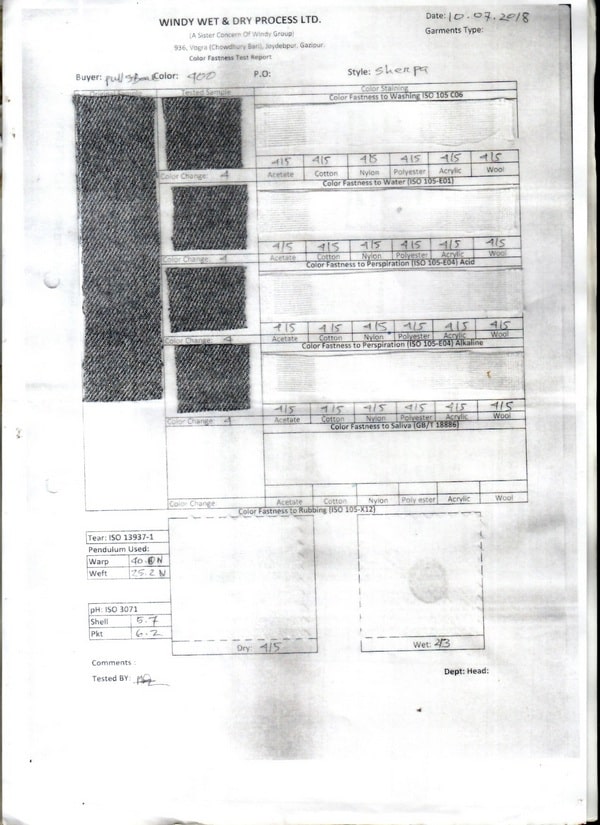

3.6: Lab Test Report:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 24-05-18 | |

| Buyer | Pull & Bear | 100 pcs | |||

| Style | Sherpa | 50kg | Batch no | ||

| Type | Jacket | Color | 400 | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

Color Fastness:

| Test Name | Method | Grade | ||

| 1.Color Fastness to washing | ISO 105-C08 | 4 | ||

| 2.Color Fastness to Water | ISO 105-E01 | 4 | ||

| 3.Color Fastness to Perspiration(Acid) | ISO 105-E04 | 4 | ||

| 4.Color Fastness to Perspiration(Alkali) | ISO 105-E04 | 4 | ||

| 5.Color Fastness to Saliva | GB/T 18886 | 4 | ||

Color Fastness to Rubbing: ISO 105-X12

| Object | Grade |

| DRY | 4/5 |

| WET | 2/3 |

pH Test: ISO 3071

| Shell | 5.7 |

| PKT | 6.2 |

Tear Test: ISO 13937-1

| WARP | 40.0 N |

| WEFT | 25.2 N |

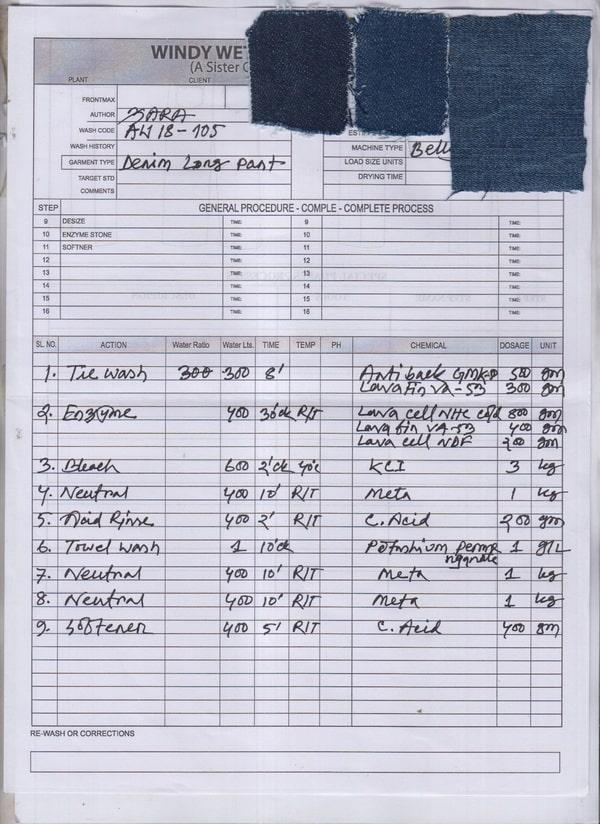

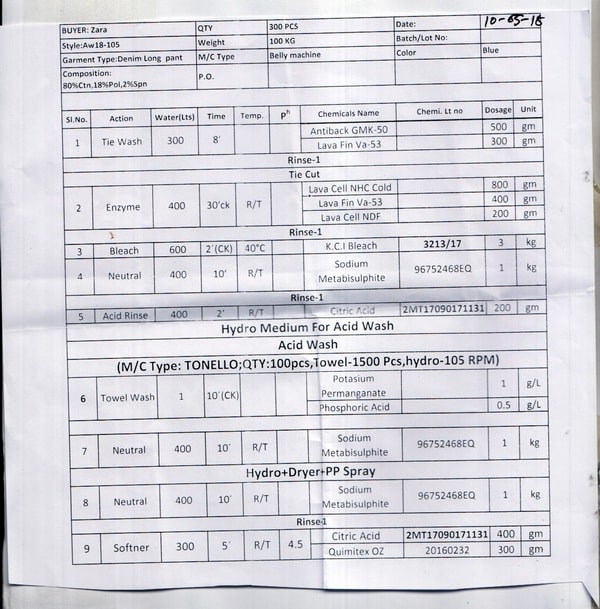

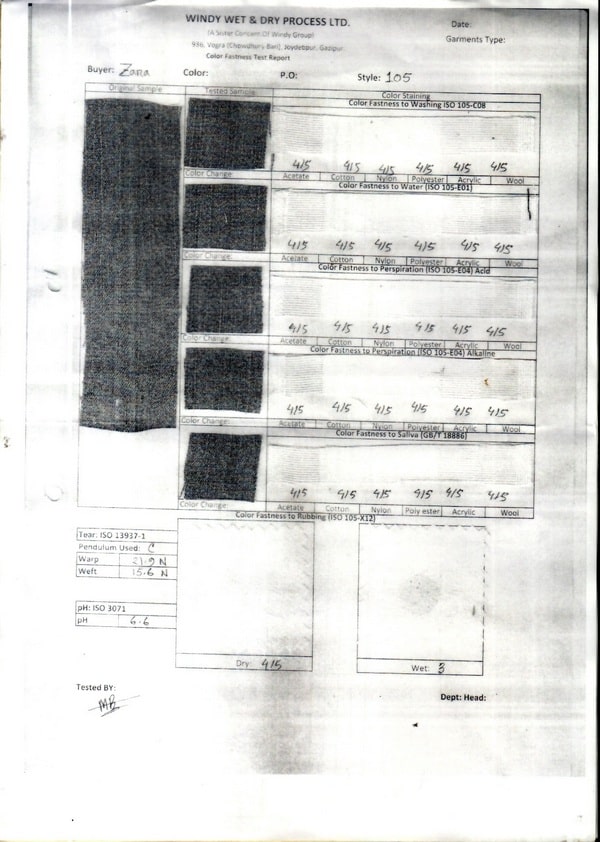

3.7 Buyer: ZARA

Style:105

Garments type: Denim Long Pant

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: | |||||||

| FRONTMAX | |||||||||||

| AUTHOR | Zara | FABRIC NO. | |||||||||

| WASH CODE | 105 | ESTIMATE COST | |||||||||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||||||||

| GARMENT TYPE | Denim Long Pant | LOAD SIZE UNIT | |||||||||

| TARGET STD | DRYING TIME | ||||||||||

| COMMENTS | Black | ||||||||||

| STEP | GENERAL PROCEDURE-COMPLE-COMPLETE PROCESS | ||||||||||

| 1 | TIME: | 9 | TIME: | ||||||||

| 2 | TIME: | 10 | TIME: | ||||||||

| 3 | TIME: | 11 | TIME: | ||||||||

| 4 | TIME: | 12 | TIME: | ||||||||

| SL NO. | ACTION | WASH RATIO | WATER Lts. | TIME | TEMP | pH | CHEMICLE | DOSAGE | UNIT |

| 1 | Tie wash

| 300L | 8’ | Antiback GMK50 VA-53 | 500 300 | Gm Gm | |||

| 2 | Enzyme | 400l | 30’ck | R/T | Lavacel NHC cold VA -53 Lavacel NDF | 800 400 200 | “ “ “ | ||

| 3 | Bleach | 600l | 2’ck | 40C | KCI | 500 | ‘’ | ||

| 4 | Neutral | 400L | 10’ | R/T | Meta | 1 | Kg | ||

| 5 | Acid Rinse | 400l | 2’ | R/T | C.Acid | 200 | Gm | ||

| 6 | Towel Wash | 1l | 10’ck | KMnO4 | 6 | Gm | |||

| 7 | Neutral | 400 | 10’ | R/T | Meta | 1 | Kg | ||

| 8 | Neutral | 400 | 10’ ck | R/T | Meta | 1 | Kg | ||

| 9 | Softener | 400 | 5’ | R/T | C.Acid | 400 | Gm | ||

3.8: Bulk Recipe:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 24-05-18 | |

| Buyer | Zara | 100 pcs | |||

| Style | AW 18-105 | 50kg | Batch no | ||

| Type | Denim long pant | Color | 400 | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

| SL NO. | ACTION | WASH RATIO | WATER Lts. | TIME | TEMP | PH | CHEMICLE | DOSAGE | UNIT |

| 1 | Tie wash

| 300L | 8’ | Antiback GMK50 VA-53 | 500 300 | Gm Gm |

Rinse 1 And Tie cut

| 2 | Enzyme | 400l | 30’ck | R/T | Lavacel NHC cold VA -53 Lavacel NDF | 800 400 200 | “ “ “ | ||

| 3 | Bleach | 600l | 2’ck | 40C | KCI | 500 | ‘’

| ||

| 4 | Neutral | 400L | 10’ | R/T | Meta | 1 | Kg | ||

| 5 | Acid Rinse | 400l | 2’ | R/T | C.Acid | 200 | Gm | ||

Hydro Medium for Acid wash

| 6 | Towel Wash | 1l | 10’ck | KMnO4 | 6 | Gm | |||

| 7 | Neutral | 400 | 10’ | R/T | Meta | 1 | Kg | ||

Hydro+Dryer+PP spray

| 8 | Neutral | 400 | 10’ ck | R/T | Meta | 1 | Kg | ||

| 9 | Softener | 300 | 5’ | R/T | C.Acid | 400 | Gm | ||

3.9: Lab Test Report:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 24-05-18 | |

| Buyer | Zara | 100 pcs | |||

| Style | Aw18-105 | 50kg | Batch no | ||

| Type | Denim Long pant | Color | 400 | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

Color Fastness:

| Test Name | Method | Grade | ||

| 1.Color Fastness to washing | ISO 105-C08 | 4 | ||

| 2.Color Fastness to Water | ISO 105-E01 | 4 | ||

| 3.Color Fastness to Perspiration(Acid) | ISO 105-E04 | 4 | ||

| 4.Color Fastness to Perspiration(Alkali) | ISO 105-E04 | 4 | ||

| 5.Color Fastness to Saliva | GB/T 18886 | 4 | ||

Color Fastness to Rubbing: ISO 105-X12

| Object | Grade |

| DRY | 4/5 |

| WET | 3 |

pH Test: ISO 3071

| pH | 6.6 |

Tear Test: ISO 13937-1

| WARP | 21.9 N |

| WEFT | 15.6 N |

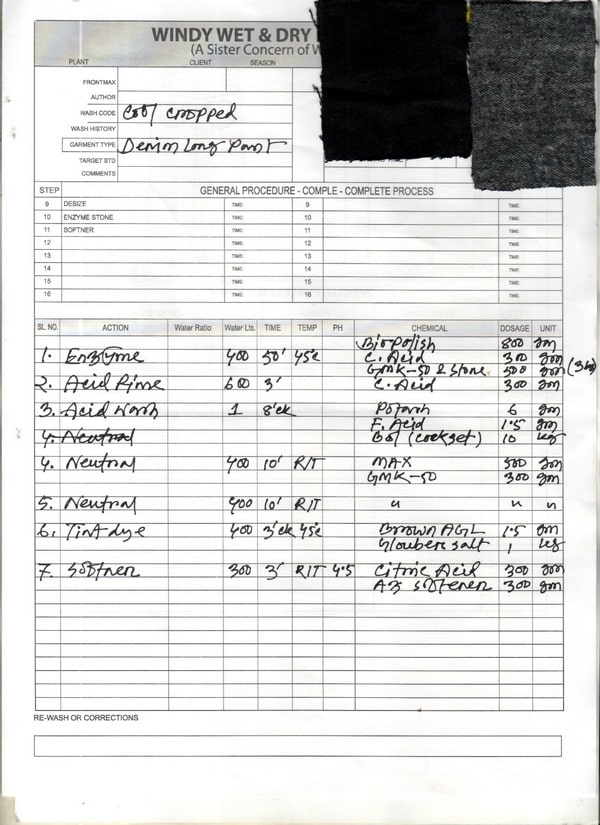

3.10: Buyer Name: H&M

Style: Cool Cropped

Garments type: Denim long pant

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: | |||||||

| FRONTMAX | |||||||||||

| AUTHOR | Zara | FABRIC NO. | |||||||||

| WASH CODE | 105 | ESTIMATE COST | |||||||||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||||||||

| GARMENT TYPE | Denim Long Pant | LOAD SIZE UNIT | |||||||||

| TARGET STD | DRYING TIME | ||||||||||

| COMMENTS | Black | ||||||||||

| STEP | GENERAL PROCEDURE-COMPLE-COMPLETE PROCESS | ||||||||||

| 1 | TIME: | 9 | TIME: | ||||||||

| 2 | TIME: | 10 | TIME: | ||||||||

| 3 | TIME: | 11 | TIME: | ||||||||

| 4 | TIME: | 12 | TIME: | ||||||||

| SL NO. | ACTION | WASH RATIO | WATER Lts. | TIME | TEMP | PH | CHEMICLE | DOSAGE | UNIT |

| 1 | Enzyme | 400l | 50’ | 45c | Biopolish C.Acid GMK-50 Pumic Stone | 800 300 500 3 | “ “ “ Bag | ||

| 2 | Acid Rinse | 600l | 3’ | C.Acid | 300 | Gm | |||

| 3 | Acid wash | 1 | 8’ck | 40C | Potas F,acid Cockset | 6 1.5 10 | ‘’ “ kg

| ||

| 4 | Neutral | 400L | 10’ | R/T | Max GMK 50 | 500 300 | Kg | ||

| 5 | Neutral | 400 | 10’ ck | R/T | Max GMK 50 | 500 300 | Kg | ||

| 6 | Tint dye | 400 | 3’ck | 45c | Brown AGL Glouber salt | 1.5 1 | Gn Kg | ||

| 9 | Softener | 300 | 3’ | R/T | 4.5 | C.Acid | 300 | Gm | |

| AZ softener | 300 | Gm | |||||||

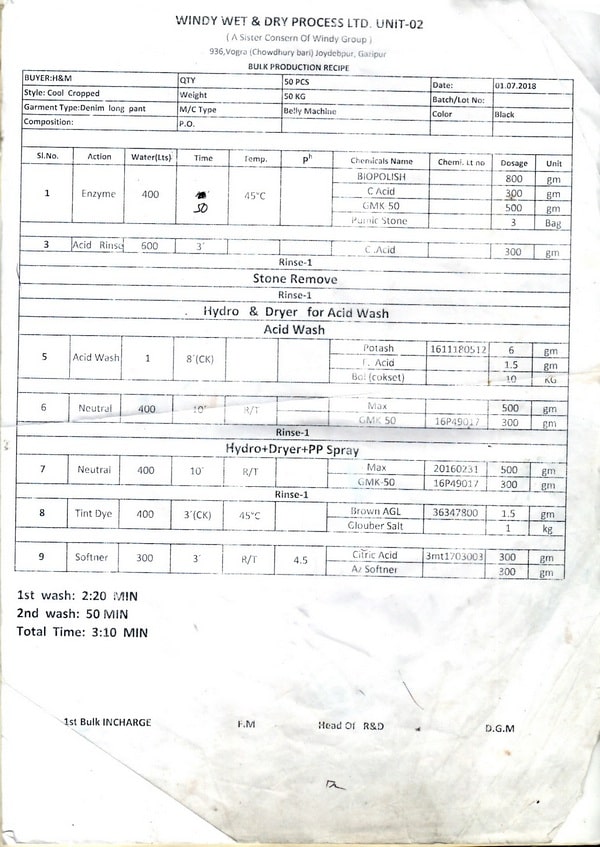

3.11: Bulk Recipe:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 24-05-18 | |

| Buyer | H&M | 100 pcs | |||

| Style | Cool cropped | 50kg | Batch no | ||

| Type | Denim long pant | Color | 400 | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

| 1 | Enzyme | 400l | 50’ | 45c | Biopolish C.Acid GMK-50 Pumic Stone | 800 300 500 3 | “ “ “ Bag | ||

| 2 | Acid Rinse | 600l | 3’ | C.Acid | 300 | Gm |

Rinse 1

Stone remove

Hydro and dryer for acid wash

| 3 | Acid wash | 1 | 8’ck | 40C | Potas F,acid Cockset | 6 1.5 10 | ‘’ “ kg | ||

| 4 | Neutral | 400L | 10’ | R/T | Max GMK 50 | 500 300 | Kg |

Hydro+Dryer+PP spray

| 5 | Neutral | 400 | 10’ ck | R/T | Max GMK 50 | 500 300 | Kg | ||

| 6 | Tint dye | 400 | 3’ck | 45c | Brown AGL Glouber salt | 1.5 1 | Gn Kg | ||

| 9 | Softener | 300 | 3’ | R/T | 4.5 | C.Acid | 300 | Gm | |

| AZ softener | 300 | Gm | |||||||

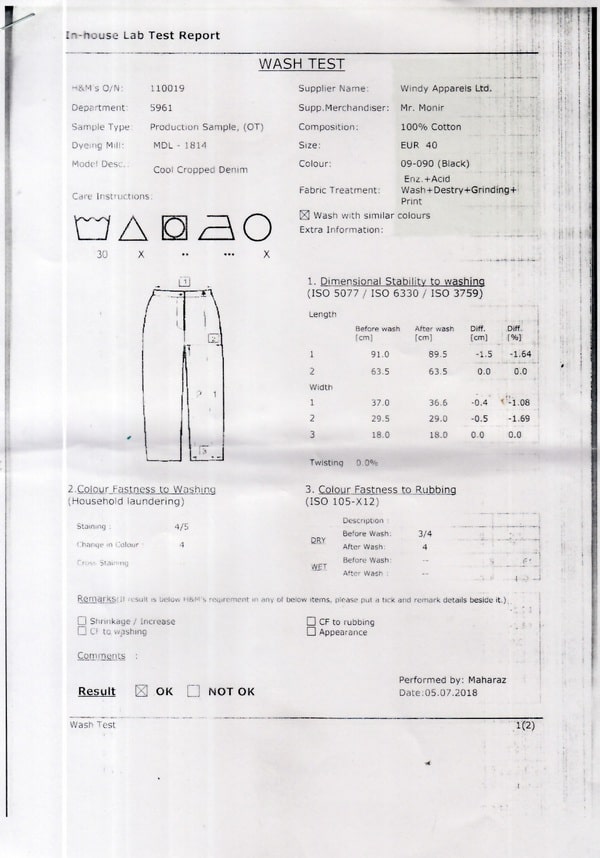

3.12: Lab test report:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 24-05-18 | |

| Buyer | H&M | 100 pcs | |||

| Style | Cool cropped | 50kg | Batch no | ||

| Type | Denim Long pant | Color | 400 | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

Color Fastness:

| Test Name | Method | Grade | ||

| 1.Color Fastness to washing | ISO 105-C08 | 4/5 | ||

| 2.Color Fastness to Water | ISO 105-E01 | 4 | ||

| 3.Color Fastness to Perspiration(Acid) | ISO 105-E04 | 4 | ||

| 4.Color Fastness to Perspiration(Alkali) | ISO 105-E04 | 4 | ||

| 5.Color Fastness to Saliva | GB/T 18886 | 4 | ||

Color Fastness to Rubbing: ISO 105-X12

| Object | Grade |

| DRY | ¾ |

| WET | 4 |

pH Test: ISO 3071

| pH | 6.6 |

Tear Test: ISO 13937-1

| WARP | 29.63 N |

| WEFT | 20.71 N |

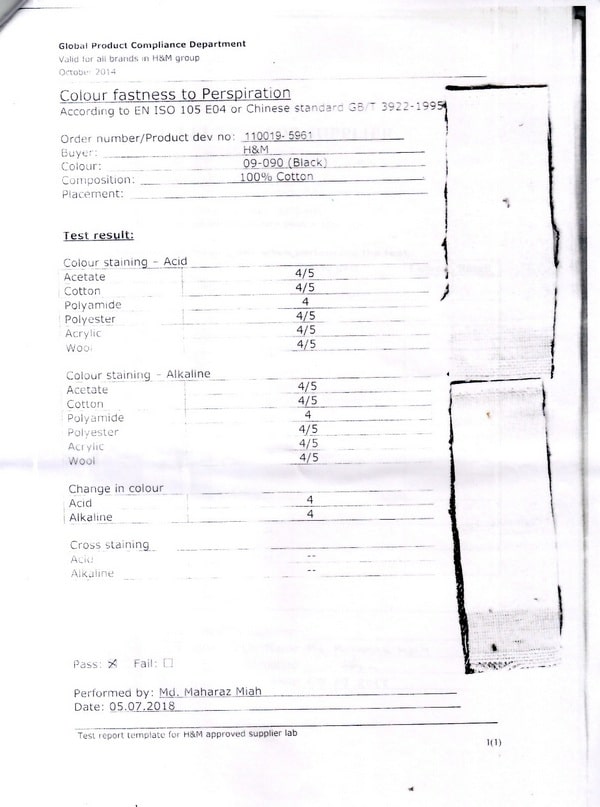

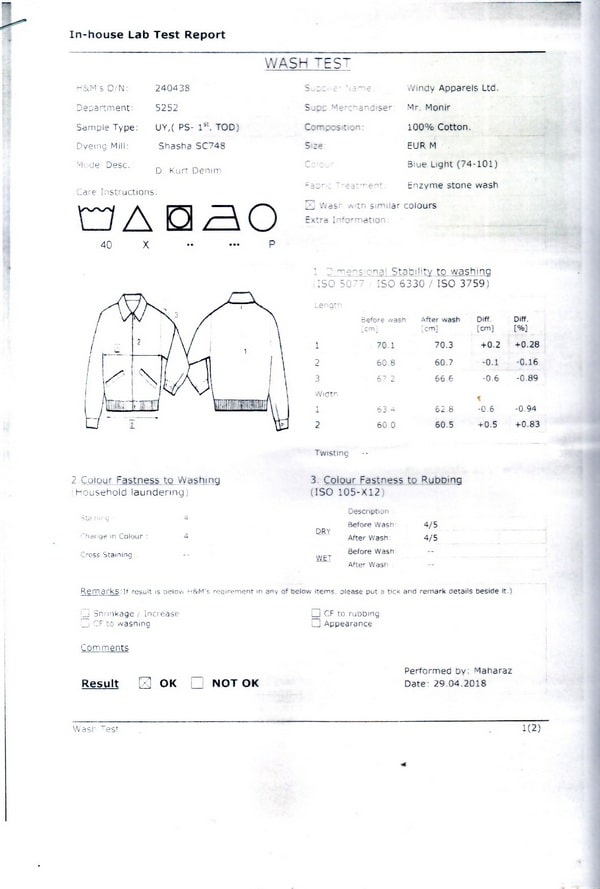

3.13: Buyer Name: H&M

Style: D.Curt Denim

Garments type: Denim jacket

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 19-07-18 | |||||||

| FRONTMAX | |||||||||||

| AUTHOR | H&M | FABRIC NO. | |||||||||

| WASH CODE | D.Curt denim | ESTIMATE COST | |||||||||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||||||||

| GARMENT TYPE | Denim Long Pant | LOAD SIZE UNIT | |||||||||

| TARGET STD | DRYING TIME | ||||||||||

| COMMENTS | Black | ||||||||||

| STEP | GENERAL PROCEDURE-COMPLE-COMPLETE PROCESS | ||||||||||

| 1 | TIME: | 9 | TIME: | ||||||||

| 2 | TIME: | 10 | TIME: | ||||||||

| 3 | TIME: | 11 | TIME: | ||||||||

| 4 | TIME: | 12 | TIME: | ||||||||

| SL NO. | ACTION | WASH RATIO | WATER Lts. | TIME | TEMP | PH | CHEMICLE | DOSAGE | UNIT |

| 1 | Enzyme | 500l | 40’ | 45c | JQA -38 GMK-50 Pumic Stone | 1 1 3 | kg “ bag | ||

| 2 | Enzyme | 500l | 10’ck | 45c | JQA -38 GMK-50 Stone more use | 600 800 1 | Gm “ bag | ||

| 3 | Acid wash | 1 | 3’ck | Potas Activator Cockset | 4 5 1 | gm “ bag

| |||

| 4 | Neutral | 400L | 10’ | R/T | Meta | 1 | Kg | ||

| 5 | Acid rinse | 500l | 2’ | R/T | C.Acid | 200 | gm | ||

| 6 | Neutral | 400 | 10’ | R/T | Max | 400 | gm | ||

| 7 | Cleanup | 400 | 5’ | 45c | Soda ash GMK -50 | 500 300 | Gm “ | ||

| 6 | Tint dye | 400 | 5’ck | 45c | Brown AGL GMK-50 | 500 300 | Gm gm | ||

| 9 | Softener | 300 | 3’ | R/T | 4.5 | C.Acid | 400 | Gm | |

| softener | 300 | gm | |||||||

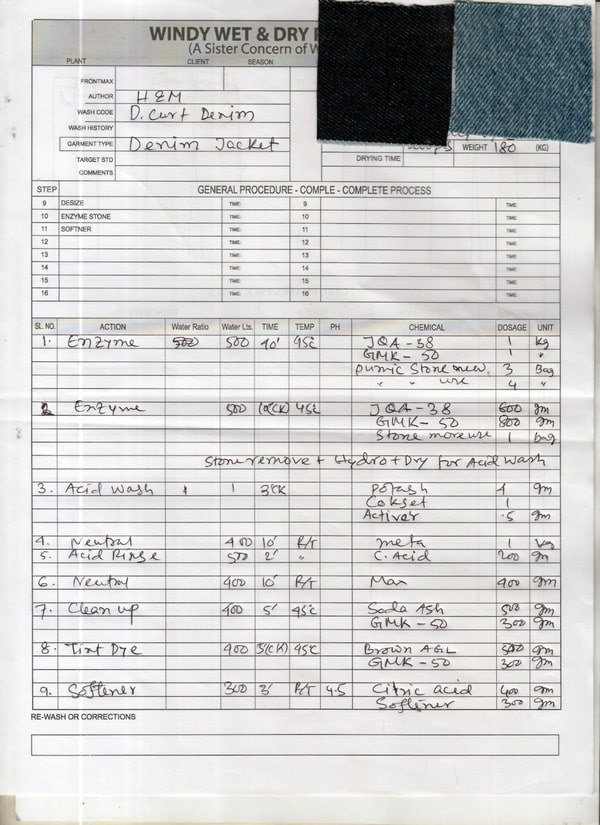

3.14: Bulk Recipe:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 19-07-18 | |

| Buyer | H&M | 100 pcs | |||

| Style | D.curt denim | 50kg | Batch no | ||

| Type | Denim long pant | Color | 400 | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

| 1 | Enzyme | 500l | 40’ | 45c | JQA -38 GMK-50 Pumic Stone | 1 1 3 | kg “ bag | ||

| 2 | Enzyme | 500l | 10’ck | 45c | JQA -38 GMK-50 Stone more use | 600 800 1 | Gm “ bag |

Rinse 1

Hydro+Dryer for Acid wash

| 3 | Acid wash | 1 | 3’ck | Potas Activator Cockset | 4 5 1 | gm “ bag | |||

| 4 | Neutral | 400L | 10’ | R/T | Meta | 1 | Kg | ||

| 5 | Acid rinse | 500l | 2’ | R/T | C.Acid | 200 | gm |

Hydro+Dryer+PP spray

| 6 | Neutral | 400 | 10’ | R/T | Max | 400 | gm | ||

| 7 | Cleanup | 400 | 5’ | 45c | Soda ash GMK -50 | 500 300 | Gm “ | ||

| 6 | Tint dye | 400 | 5’ck | 45c | Brown AGL GMK-50 | 500 300 | Gm gm | ||

| 9 | Softener | 300 | 3’ | R/T | 4.5 | C.Acid | 400 | Gm | |

| softener | 300 | gm | |||||||

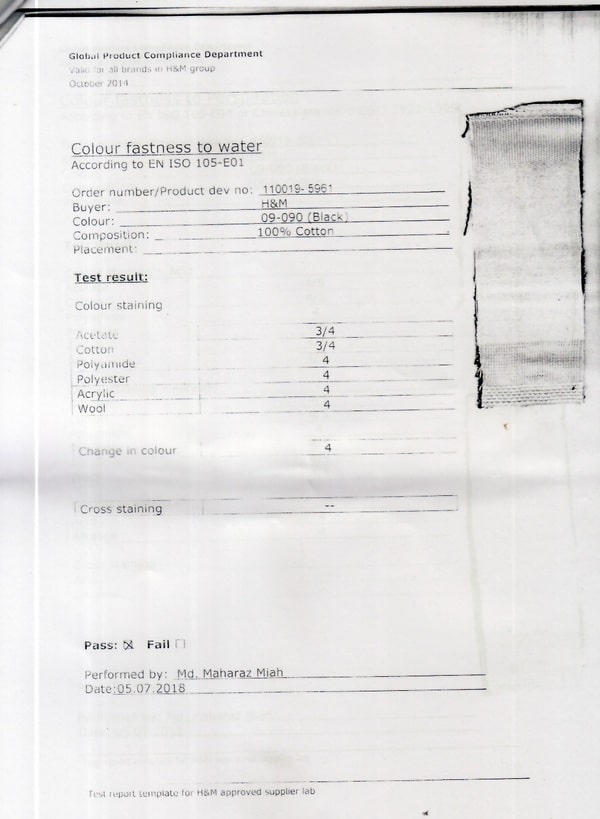

3.15: Lab test report:

WINDY WET AND DRY PROCESS LTD.

(A Sister Concern Of Windy Group)

| Plant | Client | Season | Number | Date: 19-07-18 | |

| Buyer | H&M | 100 pcs | |||

| Style | D.curt denim | 50kg | Batch no | ||

| Type | Denim Long pant | Color | 400 | ||

| WASH HISTORY | MACHINE TYPE | Belly machine | |||

Color Fastness:

| Test Name | Method | Grade | ||

| 1.Color Fastness to washing | ISO 105-C08 | 4 | ||

| 2.Color Fastness to Water | ISO 105-E01 | 4 | ||

| 3.Color Fastness to Perspiration(Acid) | ISO 105-E04 | 4 | ||

| 4.Color Fastness to Perspiration(Alkali) | ISO 105-E04 | 4 | ||

| 5.Color Fastness to Saliva | GB/T 18886 | 4 | ||

Color Fastness to Rubbing: ISO 105-X12

| Object | Grade |

| DRY | 4/5 |

| WET | 4/5 |

pH Test: ISO 3071

| pH | 6.0 |

Tear Test: ISO 13937-1

| WARP | 31.38 N |

| WEFT | 31.36 N |

DISCUSSION AND RESULT

4.1 Analysis Of Chemical Consumption For Different Types Of Acid Wash

| Wash name | Main chemical | Special chemical | Time | Temp |

| Acid wash (towel) | Antibac lavacel nhc lavafix va53 kci meta | KMnO4 | 10mins(ck) | r/t |

| Acid wash cokset | Biopolish c.acid japany meta | Potash activator | 8mins(ck) | r/t |

| Acid wash ( stone+cokset) | JQA 53 LP30 c.acid sodium metabisulphite soda ash citric acid | Potash | 3’(ck) | r/t |

| Acid wash( ball ) | Biopolish c.acid glubar salt brown AGL | Potash a.acid | 8’(ck) | r/t |

| Acid wash (towel) | Anticress c.acid peroxide meta | Potash activator | 15’(ck) | r/t |

FIG 4.1: Chemcal Consumption For Different Types Of Acid Wash.

From this table we can see basic chemicals (main) for different types of acid wash is used according to the fabric type for same operation like desize, enzyme, bleach , neutral , cleanup , softening. But special chemical, time , temperature is maintained according to the shade appearance. we also can see the difference between the time maintaining during the special operation like towel, cokset, ball ,stone etc.

4.2 Analysis Of Test Report For Different Types Of Acid Wash Based On Buyer Requirement.

| Wash type

| Test name | Requirement | Buyer | |

| Dry | Wet | |||

| Acid wash ( towel) | Color fastness to washing | 3 | 3 | ZARA |

| ‘’ ‘’ ‘’ water | 3 | 3 | ||

| ‘’ ‘’ ‘’ perspiration( acid and alkali) | 4/5 | 4/5 | ||

| ‘’ ‘’ ‘’ saliva | 3 | 3 | ||

| ‘’ ‘’ ‘’ rubbing | 3/4 | 2/3 | ||

| Acid wash ( cokset+ball ) | Color fastness to washing | 3 | 3 | H&M |

| Color fastness to rubbing | 3 | 2/3 | ||

| Color fastness to water | 4 | 4 | ||

| Color fastness to perspiration (acid and alkali) | 3/4 | 3/4 | ||

| Nickel test | Pink-not ok Not pink-ok | |||

| Tear test | 22daN | 22DaN | ||

| Acid wash (cokset) | Color fastness to washing | 3/4 | 3/ | PULL AND BEAR |

| Color fastness to rubbing | 3/4 | 2/3 | ||

| Color fastness to water | 3 | 4 | ||

| Color fastness to perspiration( acid and alkali) | 4 | 4 | ||

| color fastness to saliva | 4 | 3 | ||

Fig 4.2: Analysis Of Test Report For Different Types Of Acid Wash Based On Buyer Requirement.

In this table we can see types of tests and test requirement are not same against the specific buyer. ZARA & PULL AND BEAR buyer don’t want nickel and tear test. But H&M buyer require these two. On the other hand H&M buyer don’t require color fastness to saliva test. Requirements are not same against specific test for all buyers.

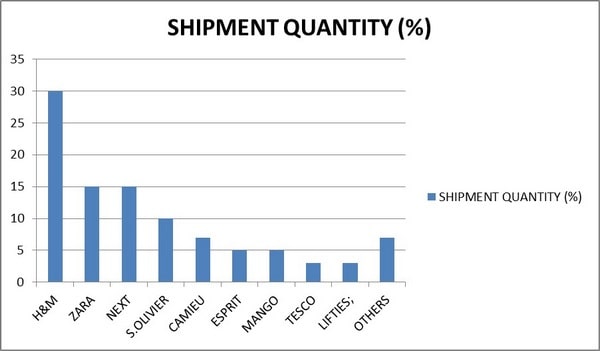

4.3 Analysis of Buyer and Their Shipment Quantity

| Buyer Name | Shipment quantity (%) |

| H&M | 30 |

| ZARA | 15 |

| NEXT | 15 |

| S.OLIVIER | 10 |

| CAMIEU | 7 |

| ESPRIT | 5 |

| MANGO | 5 |

| TESCO | 3 |

| LIFTIES | 3 |

| OTHERS | 7 |

Fig 4.3: Analysis of Buyer and Their Shipment Quantity

In this table we can see the top buyer of this industry is H&M. They order 30% of total production of windy wet and dry process limited(unit-2). ZARA AND NEXT are also top buyer.

4.4 Graphical Analysis of Buyers and Their Shipment Quantity

By this chart we can see the shipment contribution from buyers.as a result we can easily see that who are the major buyers of windy wet and dry process limited and the top buyer is H&M.

CONCLUSION

5.1 CONCLUSION

This report represents different types of acid wash and their recipe. Total four types of acid wash is done here in this report. They were acid wash (towel), acid wash(ball), acid wash (cokset), acid wash (stone+cokset). Data collection and sample collection was done against shipment orders. As a result we are able to see strong difference between working process , chemical consumption , time and temperature maintaining . we also analysis on the lab test report against those orders. We saw lab tests , test requirements from different buyer are different. Analysis on monthly production and leading buyers of windy wet and dry process limited ( unit-2). We saw 30% of total monthly production is ordered by H&M buyer. We have done the whole working process which has guided by some human resources connected to the processes. They were very helpful and active. They helped us to collect data and understand the processes carefully and sensitively. As a result it was easier to complete the thesis.

References:

- Denim : Manufacture, Finishing and Applications Edited by Roshan Paul

- Sustainability in Denim Edited by Subramanian Muthu

- https://clothingindustry.blogspot.com/2018/01/denim-jeans-washing.html

- http://www.goldnfiber.com/2013/04/different-types-of-garments-wash.html

- https://textilelearner.net/effect-of-random-wash-on-denim-fabrics/ (1.5.2.2)