What is Dyeing Process?

Dyeing is a process of coloring fibers, yarns, fabrics or garments with either natural or synthetic dyes. Dyeing is a most common word in dyeing industry. Now a days, a cloth without dyeing is not imagine. Different types of dyeing methods are used in dyeing and wet processing industry to dye fiber, yarn, fabric or garments.

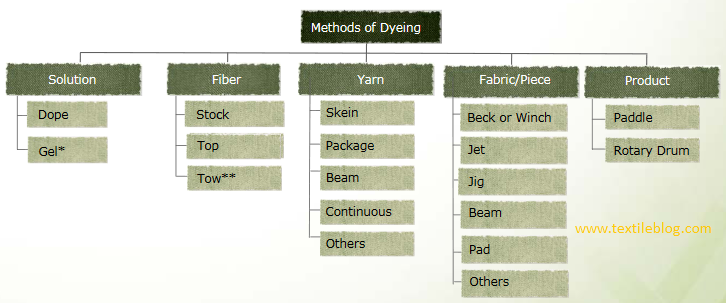

Dyeing of the fiber is carried out by placing the stock in a vat or pressure kettle containing dye solution and providing necessary physical conditions (such as heat, pressure etc.,). After a specified period, the stock is taken out and rinsed. They dyed stock is then processed in to yarn. Dyeing methods have applied according to demand on the optic effect required in the final garment, the following can be dyed: fiber dye, yarn dye, fabric dye, garment dye etc.

Different Types of Dyeing Methods

Fiber dyeing:

Fiber dyeing is also called stock dyeing or top dyeing. In this dyeing methods, fiber are dyed before blending with other colors to give fancy yarns or fabrics. Stock dyeing refers to the dyeing of fibres, or stock, before it is spun into yarn. Top dyeing is also the dyeing of fibre before it is spun into yarn and serves the same purpose as stock dyeing that is to produce soft, heather (mélange) like color effects. In this dyeing methods, fibres are placed in large vats and the dye liquor is forced through the mass at high temperatures. Generally this dyeing methods is used for special purposes only.

Yarn dyeing:

Yarn dyeing is carried out by either one of the following three dyeing methods: 1) Skein dyeing, 2) Package dyeing and 3) Space dyeing. Among these, package dyeing is the most common yarn dyeing process.

Skein dyeing is performed by suspending skeins of yarn in an agitated dye bath with possible additional movement of the skeins during dyeing.

Package dyeing is the most common dyeing process. In this method yarn is wound as packages on perforated spindles or spools and immersed in dye bath. The dye liquor is then circulated into the reaction vessel back and forth through the packages. This type of dyeing is always carried out in closed systems at elevated temperature and pressures. This technique is also employed to dye fabric rolls.

Space dyeing is a special type of yarn dyeing in which dye liquor is applied to yarns by a roller type dye pad, at specified intervals. The dyed yarn is then passed on to hot water steam box for development and fixation of color, after which the yarn is rinsed well with water.

Fabric dyeing:

Fabric dyeing is the most common method used today and preferred over yarn dyeing, as fabric dyeing is a continuous or semi-continuous process. The popular methods of fabric dyeing are beck (winch), jet, jig and continuous range. The method of choice depends upon the nature of fabric (cotton, synthetic or blend) and dyes employed (for synthetic fibers, jet dyeing is the most commonly employed method). The water requirements and quantity of effluents depend on the type of dyeing.

Beck dyeing uses a winch to move a continuous fabric piece through the dye liquor. Jig dyeing involves passage of a fabric piece back and forth from one spindle to another through a dye bath. Jet dyeing is a specialized technique especially employed for applying disperse dyes to polyester. In this method, dye is impinged on to the moving fabric through the use of a venturi jet system. In the application of disperse dyes to polyester fabrics (by jet dyeing) carriers* which aid in dyeing are used along with dyes as they have affinity for polyester. These carriers must be removed after dyeing, and their presence in the effluents poses a problem because of their toxic nature.

In continuous range dyeing, fabric is continuously passed through a dye solution of sufficient length to achieve initial dye penetration. The dye on the fabric is fixed by further steaming. Recently, foamed dye formulations have been applied to fabrics. Application of these dyes are gaining prominence as they reduce the dye liquor to fabric ratio and subsequently effluent treatment costs and energy. Another continuous method of dyeing “Thermosol dyeing” is now carried out at many mills to dye polyester under heat and partial vacuum. The liquid effluent generated in this method is muchless compared to conventional dyeing techniques.

Garment dyeing:

In garments dyeing method, entire garment is placed in the dye-bath, with the resulting color having highs and lows. Generally, non-tailored and simpler forms of garments, such as sweaters, sweat-shirts, T-shirts, hosiery, and pantyhose are dyed in this method. However, the penetration of the dye solution may not be completely passed to the fibers such as between the seams, buttons, zippers etc.