Introduction:

Various properties of textile products are affected by relative humidity. The marginal utility of fabrics made from that fiber is determined by considering the effect of moisture on textile product properties. Similar to the effect on the fabric that results from weaving in wet weather, a different effect is observed on the fabric in warm weather. As a result, the result of the garment produced by knitting the two types of weather is also different. Hence, relative humidity, whether atmospheric or textile, is considered to be of utmost importance in textile products.

What is relative humility?

The ratio of the amount of water vapor present in a given volume of air at a given temperature to the amount of water vapor required to saturate that volume of air is called relative humidity. It is expressed as a percentage. The humidity of a particular place or system depends on the temperature and pressure of that place or system. The same amount of water vapor creates more relative humidity in cold air than in warm air.

What are textile materials?

Textile materials are materials that contain textile fibers. These materials also include fibers, threads as well as products made from them. Textile fibers are elongated flexible and durable shapes with very small transverse dimensions, limited length, suitable for making yarn and textile products.

Effect of relative humidity on textile materials:

The different properties of textile materials depend on the behavior of different water vapor and weathering conditions. Because most textile fibers are sensitive to relative humidity. Various properties of textile products affected by relative humidity are discussed below:

- Fiber swells due to absorption of water vapor from the weather or absorption of water by the fiber during washing in water. Due to which the width of the ash increases and the length decreases. As a result, the fabric shrinks.

- The penetration of water molecules into the fiber reduces the molecular force of the fiber holding it together, which in turn reduces the strength of the fiber itself. However, plant fiber increases energy. The relationship between relative humidity and strength Relative humidity has a great influence on the strength of fibers, and it can also increase and improve the degree of integration of long chain molecules and increase strength.

- Dry fibers generate static electricity during processing. Excessively wet fiber also interferes with the flow of electricity, both of which are harmful.

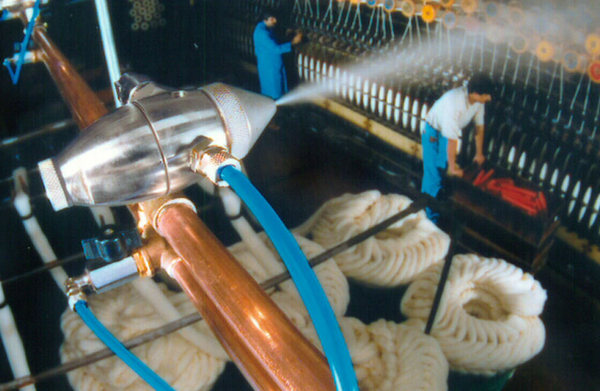

- Without the effect of relative humidity on textile materials or the ability of fibers to absorb water vapor, neither spinning nor weaving would be possible. If the yarn is spun or woven in dry weather, the production is damaged and it is also unusable.

- Due to the effect of relative humidity, the amount of dust and fly is comparatively reduced.

- The strength of the produced yarn is increased, thereby reducing the tendency to tear.

- Besides, under the influence of relative humidity, the fabric has the ability to hold water vapor, thereby providing a lot of comfort and convenience.

- Processing capacity is also reduced if the relative humidity is too low.

- Fiber growth expands with increasing relative humidity. Among them, wool, silk and viscose fibers also absorb moisture very easily compared to natural fibers such as cotton and hemp. As with synthetic fibers (such as polyester), hygroscopicity is poor, so increases in relative humidity have little effect.

Among the various fibers, kapas fiber absorbs water easily, but take time to dry. Wool has the highest water vapor holding capacity. In fact, wool can hold 15-30 percent of its own weight in water vapor. Silk also absorbs water vapor as quickly as wool and does not feel wet even after holding a lot of water vapor. Clothing made from fibers that have high absorbency is comfortable and easily absorbs sweat from the body and prevents the build-up of static electricity.

The relative humidity of the room in which the yarn is spun or woven depends on many factors. The size of the room, the number of appliances located in the room and the heat produced by them, population, outside weather etc. are taken into consideration.

Relative humidity meter:

Since the water vapor is in contact with the textile fibers, it is possible to twist or weave the yarn. Since textile fibers absorb water vapor from the weather, it is also necessary to measure what relative humidity is present in the weather. An instrument that measures relative humidity is called a hygrometer.

The following hygrometers are commonly used in textile mill factories. Example:

- Wet and dry bulb hygrometer

- Hair hygrometer

- Electrolytic hygrometer

- Drew point hygrometer

- Chemical hygrometer

- Gravimetric hygrometer

Conclusion:

A textile mill produces several thousand bobbins of yarn or several thousand yards of cloth in a day. All types of textile fibers have the ability to hold more or less water vapor in any weather, which is a natural religion of fibers. Many physical properties of textile materials such as dimension, tensile strength, elasticity, electrical resistance, rigidity, pliability etc. are affected by relative humidity. So finally it can be said that the effect of relative humidity on textile materials is essential.

References:

- Testing Of Textile By – A.K.M. Faridul Azad

- https://textilelearner.net/moisture-regain-of-textile-materials/

- https://www.condair.com.bd/knowledge-hub/the-importance-of-humidity-control-in-textile-processing

- https://www.researchgate.net/publication/266588415_Textile_Environmental_Conditioning_Effect_of_Relative_Humidity_Variation_on_the_Tensile_Properties_of_Different_Fabrics

- https://www.scirp.org/journal/paperinformation.aspx?paperid=20477

Author of This Article:

Nazifa Tabassum

Dept. of Clothing and Textile

Govt. College of Applied Human Science, Dhaka

Email: nazifa.099@gmail.com