Finishing cost calculation:

Finishing is the process in which some special feel or properties are imparted to the fabric. This is done to make the fabric more suitable for intended end use and it is usually the final processing of cloth before it is being cut into apparel or some other products. Most of fabrics will have been subject to finishing treatment before being offered to sale. Some fabrics may have two or more finishing treatments to make them suitable for their intended end use. In this article I will discuss how to calculate finishing cost of fabric.

Most finishing process is performed in the same plants as dyeing and printing. Most dyers and printers are also finishers, with finishing being considered as a separate but integrated department of the dyeing printing industry.

Textile finishing and finishers are classified in several ways, the most common classifications being: (i) Aesthetic finishes and (ii) Functional finishes. Aesthetic finishes modify the appearance or feel or drape of fabrics, while functional finishes improve the performance properties of fabrics.

Finishes are also categorized as: (i) Chemical or wet finish and (ii) Mechanical or dry finish. Chemical or wet finishes are usually applied to fabric by padding followed by curing or drying. Mechanical or dry finishes usually involve specific physical treatment to a fabric surface to cause change in fabric appearance. The examples various finishes are calendaring, raising, shearing, softening, stiffening, antiseptic, crease resistant, flame resistant, water proof, soil release, durable press etc.

Generally, production merchandiser is responsible for doing complete costing of garment, such as dyeing costing, printing and finishing costing. So merchandiser must have knowledge of costing. Hence merchandiser must be aware of fluctuation of cost of different components of fabric, garment, time to time. Total fabric cost can be estimated by following way:

Yarn cost + fabric manufacturing cost (knitting or woven) + dyeing cost + finishing cost = Total fabric manufacturing cost

The process sequence involved in the finishing process is as follows:

↓

Hydro extraction

↓

Balloon padding (finishing)

↓

Drying

↓

Compacting

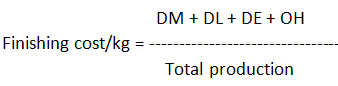

Formula:

The formula to find out the finishing cost is as follows:

Cost elements:

The cost elements in the finishing process are as follows:

Direct Material (DM) = Finishing chemicals

Direct Labor (DL) = Operators and helpers for specific job

Direct Expenses (DE) = Cost of re-finishing, compacting, raising etc.

Over Heads (OH) = Rent, power, steam, salary, etc.

Cost factors:

The factors which influence finishing cost are as follows:

- Finishing chemicals

- Type of finishing – soft, stiff, anti-bacterial, water repellent etc.

- Method of finishing – chemical finishing or mechanical finishing

- Production capacity

Cost examples:

The approximate cost examples of various finishing are as follows:

Soft finish = BDT30 – 40/kg

Anti-bacterial = BDT90-100/kg

Water-proof = BDT60-80/kg

Compacting = BDT10-12/kg

Heat setting = BDT10-12/kg

If you have any confusion about finishing cost of fabric in apparel industry then don’t hesitate to comment here. I will try to give answer.