What is Knitting and Knitted Fabrics?

Knitting is a process of manufacturing of fabric by the intermeshing of loops of yarns. The word knitting has been derived from the Saxon word ‘Cnyttan’, which has its origin from Sanskrit word ‘Nahyati’. Knitting has been associated with human civilization even before 256 AD. Three small pieces of wool-knitted fabric found in Syria by archaeologists have established this fact. In the known history, the credit for developing the knitting machine goes to Reverend William Lee of Calverton near Nottinghamshire, England during 1600 AD. Still, there are fabrics that were found in Egyptian tombs that suggest this method of producing a fabric could date back to the fourth century BC. Also, knitting was not a traditional craft for women but mainly men as they produced their nets for fishing.

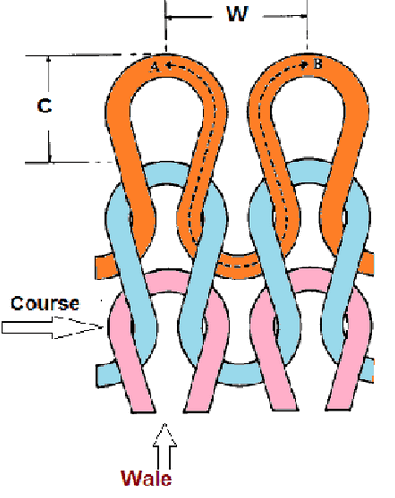

The top of the loop is known as the crown and the two straight sections are the legs; the total length of the loop is known as the Stitch Length. Similar to weaving, the fabric structure has a count that is the number of loops in the courses and wales per two square centimetres. A fabric with a high wale count will be rigid and stable in the width, but a fabric with a high count in the courses will be rigid and stable in the length. Fabrics that have a high count in both course and wale have a much better recovery rate after they have been stretched.

Fabrics with a lower count may be less rigid, have more stretch, and fit one’s body contours better, but they have a lower recovery rate. Fabrics with a higher wale count shrink less in the width; fabrics with a higher course count shrink less in the length.

The basic unit of a knitted structure is called a loop. A stitch is formed when one loop is drawn through another loop. Stitches may be formed in horizontal or in a vertical direction. Weft knitting is a method of forming a fabric by means of interlacement of horizontal loops in a circular or flat form on a course-wise basis. In this method, one or more number of yarns are fed to a group of needles placed in either lateral or circular fashion. The figure of a weft-knitted fabric is illustrated in below Figure.

Warp knitting is a method of forming a fabric by interlacement of loops made in a vertical way from each warp yarn. In this method, a number of end of yarns are fed simultaneously to individual needles placed in lateral fashion.

Features of Knitted Fabrics:

1. Extensibility:

Knitted fabrics (more specifically, weft knits) are highly extensible with incomplete elastic recovery. This semi-permanent deformation left after the partial recovery can be almost removed by agitation, as in washing and tumble drying. This characteristic makes the fabric more comfortable when body movements are made, and it provides better freedom to the wearer. However, the extensibility of knitted fabric is also responsible for creating problems in cutting and sewing the garments. The semi-permanent deformation may generate bagging at knees and elbows.

2. Crease and tear resistant:

The knitted fabrics are highly crease resistant. This is due to the loop arrangement of such fabrics. When bent or folded, the loops act as reversible hinges at the edges. High tear resistance of knitted fabrics is due to the fact that the loops distribute the stress throughout the entire fabric, being extensible.

3. Limpness:

It is the opposite of stiffness. Both the warp and the weft knits have low bending length, which is reflected in their typically soft drape.

4. Softness:

The feel of the fabric is related to its stiffness or flexural rigidity of the material. As the knits have lower flexural rigidity than the wovens of the same weight, they have a softer feel.

5. Fullness:

The fullness or hand of the knitted fabric is dependent on the bending modulus of knitted structure. Bending modulus is directly related to the flexural rigidity and inversely to the cube of thickness of the fabric. Since the weft knits have low flexural rigidity and high thickness, they are fuller than wovens or even warp knits. In addition, the low twist of the yarns also contributes to softness and fullness of the knitted fabrics.

6. Air permeability:

Knitted fabrics are several times more air permeable than the woven fabrics. This attribute is due to the fact that the structure in itself is composed of much airspace generated due to the interlacement of loops. This property is a useful quality for underwear, whereby the garment next to the skin can breathe.

References:

- Fibres to Smart Textiles: Advances in Manufacturing, Technologies, and Applications Edited by Asis Patnaik and Sweta Patnaik

- Fibres to Fabrics by Bev Ashford

- Textile Engineering – An Introduction Edited by Yasir Nawab