What is Fiberglass?

Glass fiber is also often called fiberglass, and they mean the same. Fiberglass has been widely used, mainly in the composite industry, for its cost-effectiveness and good performance. As early as the 18th century, Europeans already realized that glass could be spun into fibers that can be woven. There were already decorative fabrics made of glass fiber in the coffin of the French Emperor Napoleon. There are both filament and staple or floc of glass fiber. The glass filaments are usually used in the composites, rubber goods, conveyor belts, tarpaulin, etc. Short fiber is mainly used in nonwoven felt, engineering plastics, and composites.

Highly attractive physical and mechanical properties of glass fibers, ease of manufacturing, and their comparable low cost to carbon fibers make it a highly preferable material in high-performance composite applications. Glass fibers are composed of oxides of silica. Fiberglass have outstanding mechanical properties, such as less fragility, extreme strength, less stiffness, and lightweight. Glass fiber-reinforcing polymers consist of a large family of different forms of glass fibers such as longitudinal, chopped strand fiber, woven mat, and chopped strand mat used to increase the mechanical and tribological properties of polymer composites. Study has been carried out to investigate the suitability of glass fibers with the polymer such as rubber. It is possible to obtain high initial aspect ratio with fibers of glass, but fragility causes fibers to break during processing.

Different Types of Fiberglass and Composition:

Properties of Fiberglass:

Fiberglass properties are printout below with brief description.

1. Absorbency: Glass fibers are water repellent, which makes them unsuitable for clothing because perspiration will not be absorbed, leaving the wearer feeling clammy. On the plus side, because the material is not affected by water, it will not shrink.

2. Resilience: Because there is no elasticity, there is little extension and recovery inherent to the fabrics. Therefore, they require a finish to make them resistant to creases.

3. Strength: Glass fiber is extremely strong, almost as strong as Kevlar. However, when the fibers rub against each other, they will break and cause the fabric to take on a hairy appearance. This process occurs on curtains that rub against window sills.

4. Insulating: In staple form, glass fibers are excellent insulators because air is trapped between the fibers.

5. Draping: The fibers have excellent draping properties, which makes them highly suitable for curtains.

6. Resistance: Glass fibers are highly resistant to heat – they can withstand temperatures up to 315⁰C before losing their strength or soften at 732⁰C. They are not affected by sunlight, bleaches, bacteria, mildew, insects or alkalis.

7. Susceptible: Glass fibers are affected by hydrofluoric acid and hot phosphoric acids. Because the fibers are glass base products, some raw forms of glass fibers should be handled with care e.g. household insulation, as the ends of the fibers are brittle they can aggravate the skin and can embed into cuts so are potentially harmful; gloves should be worn when handling glass fibers.

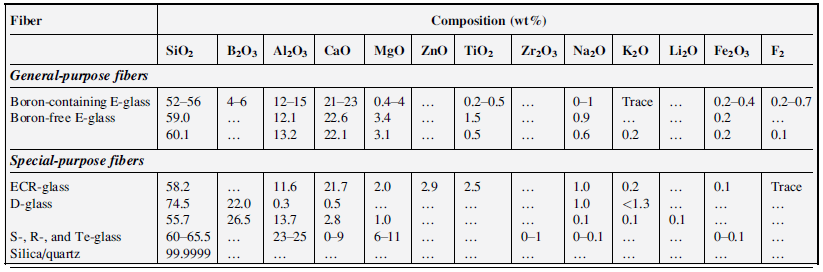

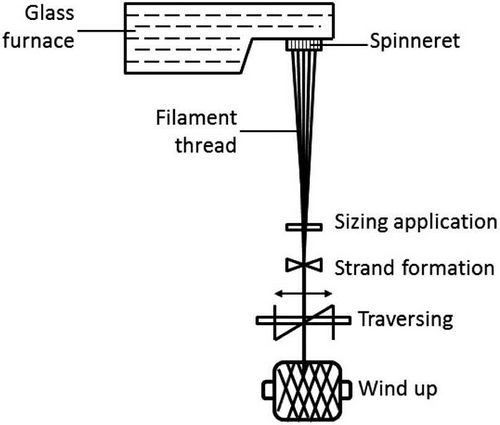

Physical and mechanical properties of commercial glass fibers:

Finishes of Fiberglass:

- Coronizing: Uses a combination of heat setting and resins. The heat setting relaxes the fibers, permanently crimps the yarns and sets the weave. The resins provide good resistance to abrasion, water-resistance and allow for easier laundering.

- Anti-Static: To reduce electrostatic build-up.

- Corrosion-Resistance: Is used for industrial purposes.

- Resinophobic treatment: Is used to prevent resins from adhering to the fabric’s surface. It is then treated with a resin that does not stick to the surface; instead, it coagulates in the gaps within the fabric. This treatment vastly increases the tear and burst strength of the fabric.

Variations:

- Hollow Fiber: Possesses excellent insulating properties and is lightweight.

- Spun Yarns: Are used mainly for industrial purposes.

- Multifilament: Are used for furnishings.

- Textured Materials: Use air bulking to produce a rough texture.

Fiberglass Manufacturing Process:

Glass is a non-metallic fiber, widely used as industrial material these days. Generally the glass state is defined as the frozen state of a super cooled and thus solidified liquid. The basic raw materials for glass fiber include a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Silica sand is used as the glass former, while soda ash and limestone help to lower the melting temperature. A low coefficient of thermal expansion combined with low thermal conductivity properties make glass fiber a dimensionally stable material that rapidly dissipates heat as compared to asbestos and organic fibers.

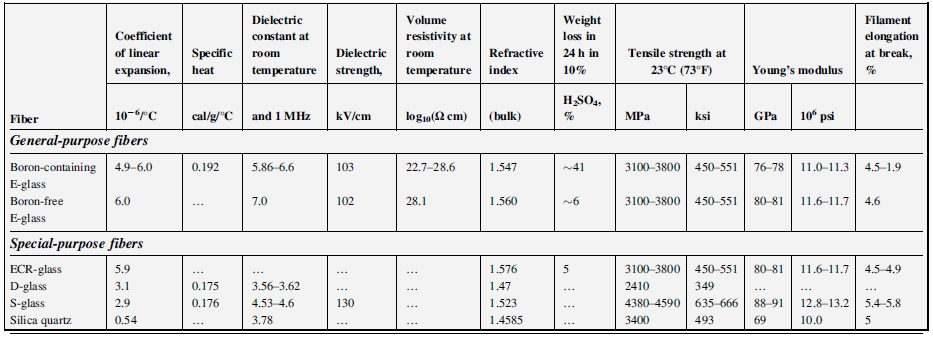

Flow Chart of Fiberglass Manufacturing Process:

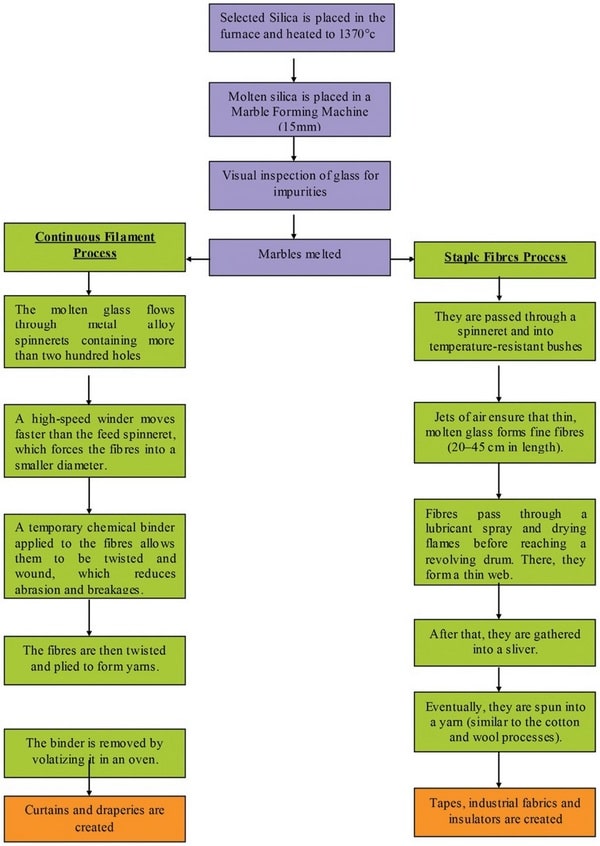

They are produced by direct melting, involving processes of batching, melting, spinning, coating, drying, and packaging. Batching is the initial state of glass manufacture, material quantities are thoroughly mixed at this stage. The mixture is then taken to furnace at a high temperature of 1400°C for melting. This temperature is high enough to convert the sand and other ingredients into molten state. The molten glass then flows into the refiner, where its temperature is reduced to 1370°C.

Spinning of glass fiber involves a combination of extrusion and attenuation. During this process the molten glass passes out through a bushing with very fine orifices. Bushing plates are heated electronically, and their temperature is controlled to maintain a constant viscosity. Water jets are used to cool the filaments as they exit the bushing at roughly 1204°C.

Attenuation is the process of mechanically drawing the extruded streams of molten glass into filaments, with a diameter ranging from 4 μm to 34 μm. A high speed winder is used to provide tension, and draw the molten stream into thin filaments. In the final stage, a chemical coating of lubricants, binders and/or coupling agents is applied to the filaments. The lubrication will help to protect the filaments from abrasion when collected and wound into packages. The packages, still wet from water cooling and sizing, are then dried in an oven. Afterwards, the filaments are ready for further processing into chopped fiber, roving, or yarn.

It is an inorganic material and does not burn or support combustion, retaining approximately 25% of its initial strength at 540°C. Most chemicals have little or no effect on glass fiber. The inorganic glass textile fibers will not mildew or deteriorate. Glass fibers are affected by hydrofluoric, hot phosphoric acids and strong alkaline substances. It is an excellent material for electrical insulation. The combination of properties such as low moisture absorption, high strength, heat resistance and low dielectric constant makes fiber glass fabrics ideal as reinforcement for printed circuit boards and insulating varnishes.

Application of Fiberglass:

The high strength-to-weight ratio of fiberglass makes it a superior material in applications where high strength and minimum weight are required. In textile form, this strength can be unidirectional or bidirectional, allowing flexibility in design and cost. It is extensively used in automotive market, civil construction, sporting goods, aviation and aerospace, boats and marine, electronics, home and wind energy. They are also used in the manufacture of structural composites, printed circuit boards and a wide range of special-purpose products. The world production of glass fibers is around 4.5 million ton annually. Major producers are China (60% market share), the United States, and the European Union.

References:

- Fibers to Fabrics by Bev Ashford

- Textile Engineering – An Introduction Edited by Yasir Nawab

- Cut Protective Textiles By Daniel (Xuedong) Li

- High-Performance Fibers by J W S Hearle

- Introduction to Textile Fibers by V. Sreenivasa Murthy

- Hybrid Fiber Composites: Materials, Manufacturing, Process Engineering By Anish Khan, Sanjay Mavinkere Rangappa, Mohammad Jawaid, Suchart Siengchin and Abdullah M. Asiri

- Fiber Technology for Fiber-Reinforced Composites Edited by Ozgur Seydibeyoglu, Amar Mohanty, Manjusri Misra

- Glass Fiber: Types, Properties, Manufacturing Process and Uses (https://textilelearner.net/glass-fiber-types-properties)

- Flow Chart of Glass Fiber Manufacturing Process (https://www.textileflowchart.com/2021/08/glass-fiber-manufacturing.html)

You may also like:

- Kevlar: A Fiber has changed the War Industry

- Ceramic Fiber: Properties, Production and Applications

- Aerospace Textiles: Applications of Textiles in Space Technology