Trimmings in Garments:

For making and decorative garments which materials (without fabric) are used, those are called trimmings. Generally trimmings are attached in garments by sewing. Some trimmings are visible from outside of garment and some are not visible such as interlining. Trimmings and accessories are used in garments for decorative and functional purposes. There are various types of garment trimmings are used in making garments, such as label and motif, zipper, button, sewing thread, interlining, lining, hook and loop fastening, lace braid and elastic, wadding, and shoulder pad etc. In this article I will discuss about functions and importance of different trimmings in garments, how to add trimmings in garment, advantages by using trimmings in garments etc.

Label and Motif:

Garments cannot be sold without using labels of its one or more kinds, specially in garments exporting, the presence of labels is mandatory. Labels mean a component used in the garment where some essential information is written, such as, the size of the garment, the types of fiber, caring instructions, the country of origin, the company of the make, trade mark etc. All the information mentioned or a part of it may be in the label of a garment. Specially the size labels are present in almost all the garments. Labels are generally used in garments by sewing. Labels, expensive labels are used in garments of high price and cheap labels are used in garments of low price.

Generally the most expensive labels are made in narrow looms with jacquard and the information is woven. The cut ends of his type of labels are folded inside and are used in garments stitched by plain machines or by zig-zag stitched machines.

The cheapest labels are generally made by printing the information on the wide woven fabric containing thermoplastic fibers. Then cutting in the shape of a narrow long tape and heat sealing the ends, they are supplied in rolls in the garments factories. The labels are used in garments by cutting and sewing in pieces from the roll manually or with the help of automatic label attaching machine. As the ends of the labels are made heat seal, during using the garments, they may prickle the body for which the ends are folded into the sewing.

One or more than one labels are used in a garment. Labels are attached in various places based on the different garments. The process of attaching the labels sewing in garments.

For increasing the beauty of the garments, the special component which are attached to the outer side of the garments are called motif. Sometimes there may be company name, trade mark or various types of symbols in motifs and in such situations; it may seems difficult to some extent to separate the label and the motif. But generally motifs remain in the outer side of the garment and labels remain inside.

Motifs may be of various sizes and types and the processes of joining in garments may also be different. In most of the motifs, the designs are made in embroidery and in some cases there are printed designs also. In making some motifs, a few thermoplastic threads are used and those motifs are attached in garments by ultrasonic welding. Motifs can be attached in garments be sewing also.

Zipper:

In garments production, specially in making of trousers, jacket and skirt chain or zipper is an essential component trimmings in garments. Zippers are used for opening and closing of some specific parts of garments. It is a functional component of a garment and sometimes it is used for increasing beauty of a garment. Metal or plastic teethed or spiraled row and similar two rows placed on narrow tapes and joining with a slider is used to close the open parts of a garment. The narrow two tapes are attached to two edges of the garment by sewing properly.

Generally, the zipper tapes are made of cotton, polyester, nylon or of their mixed fabrics and the zipper teeth are generally made of brass but sometimes aluminum and plastic teeth are also used. A slider is used for closing and opening of teeth and three is a small pin in the slider by which the unwanted movement of the slider is kept stopped. Zippers can be joined in the garments in various ways and in various processes. But for joining of zipper, very skilled operator is required because if not so, that means, if the zipper is not joined properly, the garment may be bad looking.

You may also like: Essential Qualities of Garment Trimmings

There are various types of zippers in various lengths. Each type of zipper is used for each type of task. Concealed zippers are widely used for ladies skirts. Continuous zippers are also used widely for making of garments for kids, ladies and men’s. In some zippers, there are two sliders, which are used in long coats or garments. Specially, in big suitcases, their use is wide spread.

Button:

Buttons is an essential trimmings in garments which is required in almost all types of garments. It is used in garments as a functional component or a decorative component, or for both the purpose at a time. Buttons are made from various materials. Buttons are made from natural material, such as bone, wood, pearl etc. But the prices of buttons made from those materials are high and their supply is limited also. The buttons which are made from synthetic (man-made) materials, such as polyester, nylon, acrylic, metal etc are comparatively cheap and easy available.

Buttons may be of various types, such as two holes, 4 holes or without holes, that is shank buttons. Whatever types of buttons they may be, they must have arrangements for attaching to the garments by sewing with machines. In garments manufacturing industries, buttons are generally attached to the garments by button attaching machines. In such machine, there is a clamp in which a button is held tightly and the needle of this machine attaches the button to the garment by sewing. The sewing machines used for attaching the button to the garments by sewing, are one needle chain stitch machine or one needle hand stitch machine or two thread lock stitch machine. Among these three types of machines, the price of the first one, that means, “one needle chain stitch machine”, is comparatively low and used most. But buttons attached by sewing with such type of machine, may be opened anytime, that means they are not secured. Buttons attached by the other two machines are not opened easily, that means they are secured, but the price of these machines are comparatively high.

For attaching the buttons to the garments by sewing, whatever machines or whatever processes are used, it is a must to keep observation so that the fabric or the button hole of the place where the button has been attached is not shrunk or crease marked and the button is not unfastened easily. Care should also be taken so that during washing or cleaning of the garment, buttons or their colors are not damaged.

Sewing thread:

For sewing of fabrics or garments, needle and thread are required first of all. Sewing thread is one the most important trimmings in garments. Sewing thread may be of various types, various colors and of various constructions. Before sewing of any fabrics or garments, during the time of thread selection, the various qualities of thread, specially strength, elasticity, shrinkage, size etc. should be examined properly so that the quality of garments is not hampered due to the cause of thread.

You may also like: Sewing Thread Consumption Guide for Professional

Interlining:

For strengthening some of the parts of a garment or for giving a desired shape and holding of this shape, additional one or more layer of material, belonging to the special class of fabric are used between two or more layers of fabrics, which is called interlining. Generally, interlinings are used in collar, cuff, facing, the front part of jacket and coat, waist band etc.

Interlining may be of various types, but fusible interlining is widely used in garments making. Because, fusible interlining has various advantages than sewn interlining.

Lining:

In the inside of some of the garments, separate to the main fabrics, different type of fabrics are joined by sewing and used which is called lining. In order to increase the shape, hang and comfort of garments, lining are used. It works as insulating to the garments and also helps for increasing the beauty of the inner side of the garments.

Lining fabric may be from both knitted fabric and woven fabric and generally, the lining fabrics are made from polyester, nylon, viscose, cotton, wool or their blended fibers. The lining fabric may be of slippery quality or it may also be brushed fabric. Generally, the brushed lining fabric is used in the body parts of a garment and the slippery lining is used in the sleeve parts of a garments. If slippery lining is used in sleeves, garments can easily be worn in body or put off from body.

Lining is generally joined in the garments by sewing and for this, sewing machine is used. But during joining of lining, adoption of special care and technique is required. Because of seam slippage, there is possibility of arising of defects at the edge of lining. The technique of joining is based on the types of the upper garments. It is widely used in making of jacket, coat, overcoat, rain coat, pocket, pocket flap, kids garments, ladies garments etc. Generally, the lining fabric is used in cheaper price than the main fabric of the garment.

Hook and Loop fastening:

This is a special type of trimming which can be used instead of chain or button. The hooks are set in lines on a nylon tape and the loops are placed in lines in another nylon tape. The hooks are comparatively strong. When the hook set tape is placed on the loop set tape with a pressure, then those two tapes are joined and cannot be opened by pulling them sideways but they can easily be separated if pulled upwards. In the parts of a garment where arrangement is made for closing by chain or by button, the loop set tape is joined by sewing to one of those parts and the hook set tape is joined to the other part and the functions of button or chain is made performed.

Hook and loop binding base is used in limited types of garments and in a limited amount. But in limited types of cases where the hook and loop binding is used, in that case, its necessity and effectiveness are very much important. The special advantage of this binding is that its use for the old, the disabled and the kids is very easy and comfortable. Specially, the disabled persons sometimes can wear or put off the garments with this type of binding by themselves without taking others help. Besides garments, this types of bindings are being used in various fields, such as, shoes, purse, moneybag, folder, bag, suitcase etc.

The hook and loop binding have a number of disadvantages, such as, due to the heavy of its thickness, its use is not suitable for lightweight garments. If dust or fiber particles are deposited in hook or loop, the effectiveness of binding is weaken, this type of problem may be created specially during washing of garments. There are also possibilities of damaging of the fabrics of the garments by hooks. Due to the poor flexibility of hooks and loops, use is also not comfortable.

Lace braid and Elastic:

Lace and braid are generally narrow and long. It is made from natural or synthetic, that means from both types of fibers. But elastic is generally made from rubber or elastan. Lace, braid and elastic are used for increasing decoration or as functional part or for both the purpose.

Laces of various measurements, designs and construction are made from yarn in weaving or in knitting methods. To increase the beauty of garments is the main purpose of using of lace. Lace is joined in the garments by sewing but the type of sewing or stitching depend on the type of lace and the desired design of the garments. The lace, supplied in rolls, can easily and beautifully be joined in the garments with the help of rack guide.

Braid is made by diagonally inter lacing of yarns. The shape of a braid may flat and like a narrow tape and also it may be round and in narrow tubular shaped. In most of the cases, braids are used in garments mainly for increase of the beauty of the garments. Braids are made from various types of fibers and braids are joined in the garments by sewing.

The materials which are extended or increased in lengths in applying force and return to its previous state soon after the withdrawal of force, those materials are called elastics. In the field of making of garments, rubber or elastan is used as elastic. Elastics are generally in the shapes of round, flat or narrow tape. Elastic is used in various types of garments. The use of elastic is high specially in undergarments or in kids garments. Elastic is joined in the garments by using various types of seams and stitches.

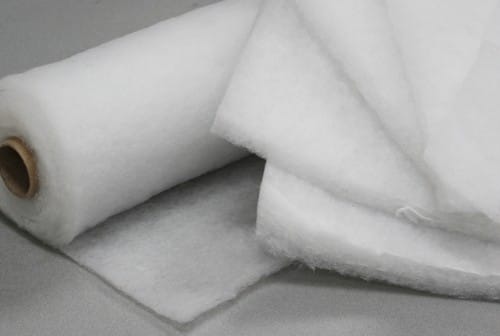

Wadding:

Various types of filling materials are made in different thickness and in the form of sheets, in non-woven method, from synthetic fibers, which is called wadding or batting. Wadding is used in those garments where the garment should posses the worm quality but the weight of the garments should not be high. There are a number of advantages in use of wading, such as, it can easily be washed and dried, thickness is high but the weight is very light, the price is also comparatively very cheap.

Various types of synthetic fibers are used for making wadding, but polyester and poly propylene are used most. The fibers may be of various thickness and constructions, specially hollow fibers may also be used. Wadding or batting is joined in the garments in such a way so that the fibers in the wadding cannot move or shift during the use of the garments. In both sides of wadding, that means the fabrics of the garments in the upper side and the lining fabric in the lower side are used, and small, medium and large sizes of rectangles are made by sewing so that wadding is not deposited in one place during using. Various types of problems may arise, if special type of sewing machine with feed mechanism is not used for sewing of wadding. In this case, if the sewing machine with compound feed mechanism is used, no such problems arise.

Care should be taken in the fabric selection of those garments where wadding will be used, so that fabric is closely woven. If no, the edges of the fibers in the wadding may come out from the gaps of the yarns in the fabric, which looks bad and may prickle in the body during use of the garments. If wadding is used in making of shower proof garments, it is better to attach the wadding without sewing, because water may penetrate through the sewing hole, if wadding is used with sewing, in this case, wadding can be joined in the garments by ultrasonic welding.

Shoulder pad:

The use of shoulder pad in making garments of men’s and ladies has been running since long. Sometimes shoulder pads are used as functional parts of garments. Again, sometimes they are used as decorative parts. Shoulder pads may be of various sizes, thicknesses, constructions and qualities. Shoulder pads are made from various materials but foam-made shoulder pads are comparatively cheap and cleaning is also suitable that means they can be washed with water.

Generally shoulder pads are available ready-made in required sizes and shapes, shoulder pads in required sizes and shapes can also be got by making. Linings are used on the upper and lower sides of shoulder pads, as a result they look good, become comfortable in use and also lasts for a long time. Shoulder pads are used by sewing in garments, but adhesive or fusing systems can also be used in these cases. In whatever ways the shoulder pads are joined in the garments, they have to be joined in the right places and accurately.