Abbreviation of ERP is Enterprise Resource Planning. Like other industry, ERP has been used in textile and apparel industry for quite a long time. It is a revolutionary innovation in the modern textile and apparel industry. ERP software provides a great contribution to earn maximum profit in various sectors of textile and apparel industry. As the competition is increasing in global clothing market and margins and timelines are being reduced, textile and apparel industry people have started realizing that need for cost control & utilizing the enterprise wide resources to the maximum have become essential. ERP comes as a rescue tool to all these issues. Various modules of ERP are used in various department in textile and apparel industry.

Textile and Apparel ERP Modules:

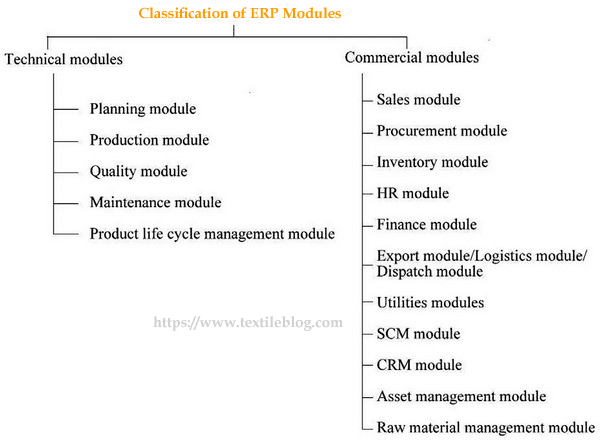

ERP modules can be classified in two ways; as technical modules and commercial modules. Technical modules execute transactions in relation to technical functions like production, quality, maintenance, and planning. Commercial modules perform commercial functions like selling, marketing, purchasing, storing, exporting, logistics, HRM, and finance. The various modules are showed in below figure.

In this article I will explain different ERP modules uses in textile and apparel industry in detail. The functions carried out in each module like production, planning, sales, procurement, inventory, and so on will be described so that it helps to know the specific activities carried out in textile and apparel vertical.

Technical Modules of ERP Uses in Textile and Apparel Industry:

Functions of planning module:

Planning module executes the following functions:

- Production operations are defined.

- Production capacity, efficiency and utilization are analyzed of each machine.

- T&A (time and action) activities are detailed.

- It also involves activities of IE (Industrial Engineering) department whose job is to reduce the SAM (Standard Allowed Minute) value of operations and improving ergonomics to benefit workers.

- An order plan is created based on the delivery date according to the machine availability.

- In case of sewing department, based on the skill inventory, sewers are planned for each line & operation.

- In the case of spinning, count-wise plan is created & based on the availability of ring frame, the start dates of previous processes are planned.

Functions of production module:

The production module in garment ERP performs the following functions:

- Creation of production order.

- Inputting the production data of each machine either through machine integration or through manual entry

- Stoppage data of each machine, including reason for stoppage & machine down time

- Details of employee operating the machine

- Provides data on deviation from what was planned for production

- Utilization & efficiency of each machine

- Creating batches for production (batch for processing industry)

- Preparing job card

- Moving material between processes

- Providing work-in-progress (WIP) data in the production process

- Getting materials from stores to start production

- Returning excess material to store after production

- Reprocessing material if required (e.g., shade variation in dyeing)

- Job order & subcontract reconciliation

- Creating identification for each finished material & sending material for inspection (Doff numbers in weaving)

Functions of quality module:

We know that quality module is a very important module in ERP, as it helps to check the quality aspects of products. Quality module performs the following functions:

- Test results of each material done in different instruments are available.

- Inspection report of the fabric or garment inspected is available.

- All quality-related data are entered in the system and are made available.

- Various quality studies like ring frame-end breakage study and process studies can be obtained using data retrieved from the quality module.

- Raw material inspection can be done and products falling short of standards can be sent back to the vendor.

- It helps in vendor evaluation by providing sufficient data.

- Captures data from each testing instrument automatically, processes the same, and provides detailed information to the user.

- Gives data on the quality of product produced by each machine.

- Provisions are available to track the faults related to particular orders against which customer has raised complaints. It helps to find out the person who has tested the product, the person who has manufactured the product, and results for each process so that the location or process where the defect has occurred can be found out.

- It also gives details about quality standards to be maintained, and notifies the concerned stakeholders about any deviation from the standards.

Functions of maintenance module:

The maintenance module is useful for entering and taking care of all the maintenance activities of the machines. The various functions of maintenance module are given as follows::

- The preventive maintenance schedule is prepared automatically based on the master data.

- The machine maintenance details are maintained correctly.

- Data on parts change, repair & replacement are tracked correctly.

- Breakdown reasons & time are noted $ can be used for analysis.

- The reason for machine outage can be found out by proper recording of data.

- Critical activities related to maintenance can be found out.

- Maintenance of critical spare parts in stock is made easy.

- Preparing an accurate budget for maintenance & exercising proper control over the budget is possible.

- Cost of maintenance, including employee cost, can be captured.

- Value of the machinery can be ascertained using the maintenance module.

Commercial Modules in Textile and Garment ERP:

Functions of sales module:

The sales module is known as merchandising module in the case of apparel industry or as marketing module; many times it encompasses activities such as marketing, sales, sampling, and costing. Sales module performs the following functions:

- Creation of sales order and quotation

- Preparing costing for the buyer order in liaison with planning department

- Finalizing the price of the order & executing samples if needed by linking the order with sampling department

- Marketing & getting orders from the customer

- Maintaining customer relations

- Sourcing material in case of accessories

- Ensuring smooth processing of order from creation till dispatch

- Overseeing order status

Functions of procurement module:

Procurement module takes care of all purchase activities. The list of functions enabled via procurement module is given as follows:

- Checking material stock availability & verifying the procurement requisition created by planning or production.

- Getting RFQ from vendors.

- Vendor evaluation & vendor rating.

- Selecting a vendor & creating a PO (Purchase Order).

- Creating various POs for various purposes, including for job work, subcontract, process PO & so on.

- Creating vendor invoice after receipt of approval from inventory department that does a quality check on the material & confirms its quality to be good.

- Based on vendor invoice, a debit note is raised in the procurement module; alternatively, vendor invoice is sent through workflow to finance to initiate payment process.

Functions of inventory module:

The functions of inventory module are as follows:

- Checking for material availability in stock

- Allocating available stock against work order or production order

- Creating GRN for the material received

- Quality checking of material received by quality team

- Once quality check is carried out and material quality is approved, material is updated in stock and the stock is allocated to its corresponding production order

- Issue note made on store indent received from production

- Material returned through a return note is updated in the stock and sent back to vendor if needed by creating a delivery challan

- Maintaining stock of all items & transferring stock between units

- Calculating total value of stock available with the company

- Using inventory techniques like EOQ, VED & ABC to maintain optimum stock.

Functions of dispatch/logistics/export module:

Dispatch module performs the following functions:

- Creating packing list

- Creating dispatch advice based on packing list

- Preparation of delivery challan

- Invoice preparation

- Preparing all statutory requirement documents for central excise, sales tax & so on

- Preparing export documents in case of export & booking container, vehicle for transportation & making appropriate entries to record transactions in ERP

- Preparing all export banking-related documents

Functions of raw material management module:

Raw material management module is mainly used in spinning mills to manage bales for obtaining optimum mixing. The various functions of the raw material management module are listed as follows:

- Getting data from the fiber testing instrument used for checking the quality of cotton bales produced

- All information related to bale quality is obtained

- Either standard distribution, normal distribution, or moving standard method is used to identify bales to be mixed for optimum mixing

- Various mixing codes can be generated with preset configurations and required quality

- Based on the code selected, bales will be identified by the module

- Bale details are fed into the module

- The module selects the correct mix and allocates bales for mixing to the mixing department

- It provides the logic of bale-laying for mixing

References:

- ERP for Textiles and Apparel Industry by K. J. Vishnu Vardhini, R. Rathinamoorthy, and R. Surjit

- https://www.fibre2fashion.com

- https://garmentsmerchandising.com