What is Sliver Lap Machine?

Sliver Lap Machine is an important textile machine used in the preparation of fibers for the combing process. This machine is part of the combing preparation. In the combing process, fibers are straightened and parallelized, and short fibers are removed. To prepare for combing, the fibers need to be in a uniform lap form. So, the Sliver Lap Machine creates lap from slivers. Though Sliver Lap Machine itself does not produce yarn, it plays a critical role in preparing high-quality fiber laps, which leads to superior yarn used in apparel manufacturing.

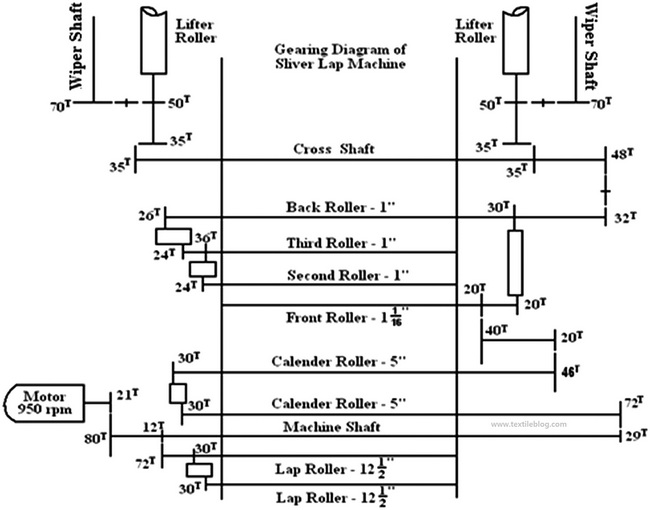

Gearing Diagram and Production Calculation of Sliver Lap Machine

The gearing of the machine is shown in Figure 2 below. The drive is initiated from the motor and it reaches the machine shaft. The machine shaft drives the lap rollers on one side and the calendar rollers on the other side. The front drafting roller gets its drive from the calendar roller, and in turn, passes it on to the back roller (B.R.), T.R. and S.R. The drive to the lifting rollers is given by the B.R.

Speeds:

……………………………950 x 21

1) Machine Shaft = ————————

………………………………80

= 249.37 rpm

……………………..249.37 x 12

2) Lap Roller = —————————

………………………….72

= 41.56

……………………………..249.37 x 29

3) Calender Roller = ————————-

…………………………………..72

= 100.44 rpm

………………………..100.44 x 46 x 40

4) Front Roller = ——————————-

…………………………….20 x 20

= 462.02 rpm

………………………..462.02 x 20

5) Back Roller = ————————

……………………………..30

= 308.01 rpm

………………………..308.01 x 26

6) Third Roller = ———————–

………………………………24

= 333.67 rpm

………………………….333.67 x 26

7) Second Roller = —————————-

……………………………….24

= 361.48 rpm

………………………..308.01 x 32 x 35

8) Lifter Roller = —————————–

……………………………..48 x 35

= 205.34 rpm

Surface Speeds:

……………………..41.56 x π x 12

1) Lap Roller = —————————- x 0.3048

……………………………12

= 41.45 m/min

[Note: 1 ft/min = 0.3048 m/min]

……………………………..100.44 x π x 5

2) Calender Roller = ————————— x 0.3048

…………………………………….12

= 40.07 m/min

………………………..462.02 x π x 1-1/16

3) Front Roller = ———————————– x 0.3048

…………………………………12

= 39.17 m/min

………………………..308.01 x π x 1

4) Back Roller = —————————- x 0.3048

………………………………12

= 24.57 m/min

………………………..333.67 x π x 1

5) Third Roller = ————————— x 0.3048

………………………………12

=26.62 m/min

……………………………361.48 x x 1

6) Second Roller = ————————— x 0.3048

………………………………….12

= 28.84 m/min

…………………………204.34 x x 1 -3/8

7) Lifter Roller = ——————————— x 0.3048

…………………………………12

= 22.42 m/min

Draft Between:

1) Lap Roller and Calender Roller = 41.45 / 40.07 = 1.03

2) Calender Roller and Front Roller = 40.07 / 39.17 = 1.02

3) Front Roller and Second Roller = 39.17 / 28.84 = 1.35

4) Second Roller and Third Roller = 28.84 / 26.62 = 1.08

5) Third roller and Back Roller = 26.62 / 24.57 = 1.08

6) Back Roller and Lifter Roller = 24.57 / 22.42 = 1.09

7) Total Draft = 1.03 × 1.02 × 1.35 × 1.08 × 1.08 × 1.09 = 1.80

This is also equal to – (41.45 / 22.42) = 1.8

Production Rates:

With a lap weight of 35 g/m (approximately 540 grains/yd), the production rate of the machine per shift of 8 hours would be:

….41.45 x 60 x 8 x 35

= ————————————-

………….1000

= 696.36 kg / shift

The production thus calculated is for 100% machine efficiency. There are always efficiency losses, owing to lap changes, breakdowns, etc. These may vary depending on the situation existing in the mill. The actual production, therefore would be the calculated production multiplied by the efficiency.

The total draft in the machine is usually very small. Whenever it is desired to vary this draft, it is the change pinion (C.P.) (see gearing, figure 2) which is changed. This changes the draft in the draw box between the front roller and back roller.

Thus, Draft Constant = Total Draft x Change Pinion = 1.8 x 30 = 54

[Note: Here the C.P. is a 30T wheel on the back roller and it is a driven wheel]

Conclusion:

Sliver Lap Machine bridges carding and combing, ensuring fibers are optimally prepared for refining. It converts multiple carded slivers into a compact lap for better feeding into the Ribbon Lap Machine or Comber Machine. I have discussed about gearing diagram and production calculation of sliver lap machine, if you have any query please let me know in comment section.

References:

[1] Khare, A. R. (2023). Principles of spinning: Combing in Spinning. CRC Press.

[2] Gokarneshan, N., Varadarajan, B., & Kumar, C. B. S. (2012). Mechanics and calculations of textile machinery. In Woodhead Publishing India Pvt. Ltd eBooks. https://doi.org/10.1533/9780857095527

[3] Kumar, R. S. (2014). Process management in spinning. CRC Press.