Hand Socks Circular Knitting Machine:

We know that there are variety of product of knitting item, hosiery and socks is one of them. Socks are manufactured by hand socks knitting machine. Hand socks circular knitting machine is a hand driven manual machine for sock production. Hand socks machine are used to make socks from single feed system. It is very simple mechanism. The principles of socks knitting machines are like circular knitting. Good quality products can be produced only when stop-motion and yarn-feeding functions are set properly. In circular weft knitting, needles knit one after the other in sequence, and loops are formed horizontally by needles knitting around the cylinder, forming a tube.

Objects:

- To acquire the knowledge of identification about the main parts of the hand socks circular knitting machine.

- To acquire the knowledge of their functions and uses.

- To know about the loop formation mechanism.

- To produce socks.

Machine specification:

- Name: Hand socks knitting machine.

- Model no: IR 130

- Machine dia: 5 inch

- Machine gauge: 6

- No of needle: πdg =3.1416×5×6=94.25≈94

- No of feeder: 1

- Manufacturer: IR Engineering Works Pvt LTD.

- Origin: Made in Bangladesh

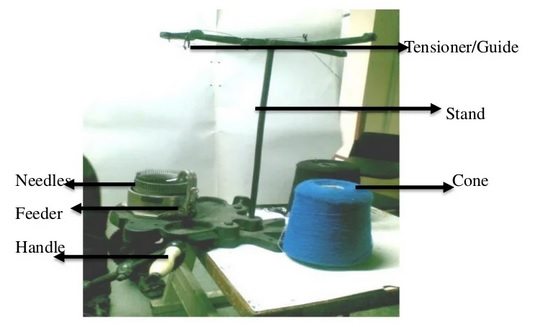

Main Parts of Hand Socks Circular Knitting Machine:

- Latch needle

- Cylinder

- Cylinder gear

- Bevel gear

- Handle

- Feeder

- Knit cam

- Yarn carrier

Loop Formation of Hand Socks Circular Knitting Machine:

Loop formation of latch needle is performed by the following 10 steps.

- Clearing

- Yarn laying

- Under lapping

- Pressing

- Landing

- Joining

- Casting off

- Loop forming

- Sinking

- Loop draw off.

Above steps are described below:

1. Clearing:

The process of loop formation is started by clearing operation in latch needle. Its aim to draw down the old loops below the latch. Sinker is constant during clearing. Clearing operation is performed when the needle reaches in optimum condition.

2. Yarn lying:

In the course of needle downward motion, the hook takes hold of yarn coming from the yarn guide. The new feed yarn is below the hook.

3. Under lapping:

The yarn is entered below the hook when needle comes down and draws in yarn.

4. Pressing:

The aim of pressing is to close the needle hook with the new feed yarn. When needle lowers, the old loop comes in contact of latch and the old loop presses the latch.

5. Landing:

Landing is defined as the placement of old loop on closed latch. The landing operation in latch machine begins simultaneously with pressing.

6. Joining:

A joining new yarn comes in contact with the old loop. Joining is accomplished simultaneously with the begging of casting off.

7. Casting off:

Falling of old loop on new loop from needle hook is casting off.

8 & 9. Loop forming and sinking:

In this stage, two processes are performed simultaneously. The old loop comes to the head of knitted yarn and loop is produced due to lowering of needle. Sinking is performed in lowering movement of needle at a finite distance.

10. Loop draw-off:

A new course is made by new loop to horizontal. Produce course is drawn downward by take down mechanism. Then the loop formation starts again from the first stage.

Conclusion:

In this experiment we learn about the yarn path diagram, total number of needles and machine parts of hand sock circular knitting machine. We learn about the machine parts and their operation during knitting action. This experiment has significance in our study life. We point out the various specification of the machine. So the experiment helps us to know more. This is the simplest machine for hosiery production so we should have gathered the idea properly about this machine. Above all the experiment is a successful one.

You may also like:

- What is Knitting and Knitted Fabric | Features of Knitted Fabrics

- Electronic Interlock Circular Knitting Machine: Parts, Knitting Action & Cam System