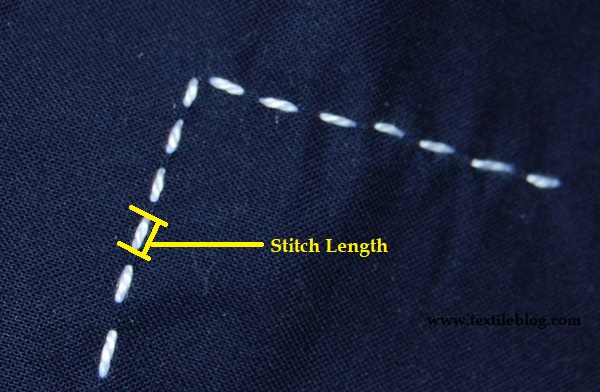

What is Stitch Length?

Basically stitch length is how long each stitch is sewn by sewing machine. Or, the distance between stitches in a seam. Stitch length measured by counting the number of stitches per inch (SPI) or measuring the length of each stitch in millimeters. Newer machines use millimeters and some older machines use SPI. To convert stitch length in millimeters to SPI the equation is 25.4/mm=SPI. In this equation 25.4 is the number of millimeters in one inch. For example if you wanted to convert a 2mm stitch length to SPI then the equation would be 25.4/2=12.7 so your answer is 12.7 SPI.

Already we know that Stitch length is measured in Millimeters or SPI (stitches per inch). Now I will discuss below.

Millimeters: This is the system used in most newer machines. If the stitch length setting on your machine is numbered from 1 to 5 then (or 1 to 6 or other low numbers) then your machine uses millimeters. In this case the stitch length in millimeters is simply measured. It is usually more accurate to measure 10 stitches and then divide that length by 10. If you need to be very accurate then measure 100 stitches and then divide the length by 100.

SPI (stitches per inch): This is the system used in most older machines. If the stitch length setting on your machine has numbers from 6 to 30 (or something in that area) then your machine uses SPI. The SPI numbers are inverse – longer stitch lengths have smaller numbers and shorter stitch lengths have larger numbers. For most general purpose machines a long stitch length is 6 or 8 SPI, a medium stitch length is 10 to 15 SPI and a short stitch length is 18 to 25 SPI. To measure the SPI you can hold a ruler parallel to the seam and count the number of stitches in a one inch long section. There is a stitch counter that you can buy that makes it easier to count the stitches.

You may also like: Different Types of Stitches with Pictures

Conversion:

Sometimes you may need to convert from SPI to millimeters or from millimeters to SPI. You can use the following equations:

Millimeters to SPI: To convert stitch length in millimeters to SPI the equation is 25.4/mm=SPI. In this equation 25.4 is the number of millimeters in one inch. For example if you wanted to convert a 2mm stitch length to SPI then the equation would be 25.4/2=12.7 so that is 12.7 SPI.

SPI to Millimeters: To convert stitch length in SPI to millimeters the equation is 25.4/SPI=mm. For example if you wanted to convert a 6 SPI stitch length to millimeters the equation would be 25.4/6=4.23 so that is 4.23 mm.

Selecting the Right Stitch Length:

There are a number of reasons for changing stitch length. Among them for basting, for sewing leather or vinyl, for top-stitching are important. Besides, finer threads need a shorter stitch and thick threads need a longer stitch. Short stitch length has better for smother curve than longer stitch length. Longer stitch length stitch can easily remove if you are planning on using your seam ripper. Besides, stitch of shorter stitch length make strong seam than longer length stitch.

For many types of sewing, seam strength is not an issue and stitch length can be selected on the basis of aesthetics alone. Some things to keep in mind are that really short stitch lengths will use more thread and your machine will run much slower and take longer to complete your seams. Short stitches are also harder to remove if you need to take out the stitching. Really long stitch lengths may not look good and will not be as strong.

You may also like: Stitch Formation Techniques of Various Sewing Machines

For most sewing a medium stitch length can be used such as 2mm or 2.5mm (12 SPI or 10 SPI). For stretchy fabric a shorter stitch length should be used or a zigzag stitch should be used to allow the stitch to stretch with the fabric, otherwise the thread may break.

When maximum seam strength is required you should sew several tests with different stitch lengths and stitch types and then test the seam strength by pulling the seams apart. When you pull apart the seam the failure will be one of two types; thread failure of fabric failure. If you experience thread failure you can use a thicker thread or decrease you stitch length. If you experience fabric failure you can try to increase the seam allowance or change the seam construction to a stronger type. You may need to test different thread types and stitch types as well.

References:

- The Sewing Machine Master Guide: From Basic to Expert by Clifford L. Blodget

- https://textilelearner.net/stitch-length-measurement-technique/

- https://threadistry.com