If anyone asked out about the bulletproof vests, armor, protection, space suits, or formula one helmet, the Kevlar name rings a bell for almost everyone. Cause, Kevlar fiber, which has changed the war industry as well as history. This fiber is widely used for manufacture protective clothing.

With the advancement of science, scientists are making continuous efforts to turn science-fiction into reality. In its continuity, new technologies are being invented; new modern equipments are being made. Defense and war industry are not exceptional. Just as new state-of-the-art weapons are being developed. So are various things that are resistant to weapons. The most versatile weapon resistance material is Kevlar.

What is Kevlar?

Kevlar is a special type of aramid fiber. It’s synthetic woven into textile materials which is extremely strong and lightweight, with resistance toward corrosion and heat also. It’s a plastic strong enough to prevent bullets and knives. Kevlar is usually described as being “five times stronger than steel on an equal weight basis.” Kevlar is used in vast applications such as war industry, body armor, bulletproof vests, car brakes, aerospace engineering, body of the aircraft and boats and so on.

Why the birth of the bulletproof vest and Kevlar?

People have been involved in warfare since ancient times. People have been using armor to defend themselves in these wars since ancient times. We will first talk about iron, bronze or other alloys as armor. But according to researchers, in the 11th century BC which was made of rhinoceros skin.

This armor of China is considered to be the oldest armor. Greek warriors of the time also used a kind of armor. It is known to be made of bronze and wax. It is difficult to say exactly when the use of iron armor started. Later, in medieval Europe, elite warriors used heavy armor made of thin tin sheets in self-defense. However, with the advancement of technology, armor made of easily portable steel was invented for warriors in the mid-fourteenth century, which provided protection from head to toe.

You may also like: Defense Textile

For years, scientists have been developing sophisticated, advanced, and powerful armor to survive the onslaught of these sophisticated weapons. In its succession, a new fiber was discovered called Kevlar. Which is usually known as being, “five times stronger than steel on an equal weight basis.”

How Kevlar fiber works within bulletproof armor together?

For example, have you ever seen a footballer scored a goal with a great speed shot? Football hits the net of the goal post at high speed. Even though football hits only one part of the net, the whole net absorbs the speed of the ball at this time. You can understand the matter more easily by giving the example of throwing stones in the pond.

You throw a rock at a point but the waves are spreading over a lot of places. The same thing would happen if you threw the rock on a wall. (But you can’t see the energy being absorbed by the naked eye). The same thing happens in the case of Kevlar armor. Kevlar fiber absorbs the power of the bullet after hitting the bullet. As a result, the bullet cannot penetrate it. If there is a ceramic ballistic plate, it also acts as an absorber. Kevlar may be combined usable with other fibers to produce hybrid composites.

History of Kevlar:

Kevlar invented by Stephanie Kwolek in 1965 at DuPont. She was experimenting with polymers combination with fabrics. The creation of Kevlar came about completely by accidentally in 1965, while analyzing molecule chains at low temperatures. She found a specific formation of molecule chains that was exceptionally strong and stiff. The solution was strange. It was cloudy and thin, unlike nylon polymers, which are clear and thick. The fibers created from this solution were the strongest, world had ever seen. This was the history of Kevlar.

A whole new war industry came about from her creation of Kevlar. It is the key material behind every bulletproof vest, which has saved countless lives. The high-strength material Kevlar was used first time commercially in the early 1970s as a replacement for steel in racing tires. Kevlar has many applications from bicycle tires to aerospace industry, spacecrafts, planes, boats, canoes, car brakes, shoes, and even the fiber optic cables that allow you to read this article on the internet.

Types of Kevlar:

- Kevlar – Tire cord yarn.

- Kevlar 29 – Multipurpose yarn.

- Kevlar 49 – High modulus yarn.

- Kevlar 68 – Moderate modulus yarn.

- Kevlar 100 – Coloured yarn.

- Kevlar 119 – High elongation yarn.

- Kevlar 129 – High tenacity yarn.

- Kevlar 149 – Ultra high modulus yarn.

Properties of kevlar fiber:

Kevlar has some unique and versatile properties, like high tensile strength, high toughness, and chemical stability at high temperatures in aromatic polyamides. Especially Kevlar has high tensile strength-to-weight ratio. That’s why it is 5 to 8 times stronger than steel. Kevlar is widely-used as a friction material in the war industry and a combustion protection material in the aerospace industry.

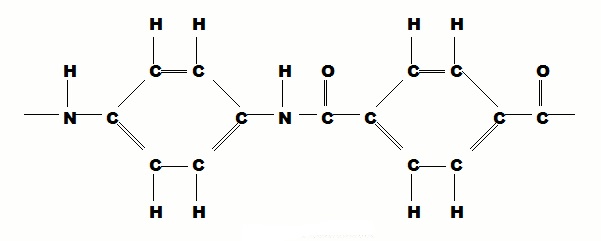

Kevlar’s chemical structure:

Mechanical properties of Kevlar fiber:

- Resistant to extreme temperatures

- Chemical resistant

- Hard to separate

- High tenacity

- High toughness (work-to-break).

- High modulus of rigidity.

- Low ductility.

- Low electrical conductivity.

- Low coefficient of thermal expansion.

- High chemical resistance.

- Excellent dimensional stability.

- Flame retardant.

- Self-extinguishing and so on.

Physical properties of Kevlar:

Table: Physical Properties of Kevlar

| Yarn properties | Kevlar & Kevlar 29 | Kevlar 49 | Kevlar 68 | Kevlar 119 | Kevlar 129 | Kevlar 149 |

| Tensile strength (gpA) | 23 | 23 | 23 | 24 | 26.5 | 18 |

| Initial modulus (gpA) | 550 | 950 | 780 | 430 | 750 | 1100 |

| Elongation (%) | 3.6 | 2.8 | 3.0 | 4.4 | 3.3 | 1.5 |

| Density (g/cm) | 1.44 | 1.45 | 1.44 | 1.44 | 1.45 | 1.47 |

| Moisture regain (%) | 6 | 4.3 | 4.3 | — | — | 1.5 |

Application of Kevlar fiber:

1. Armor:

Kevlar is used in the manufacturing of personal armor such as: bulletproof vests, combat helmets, ballistic face masks, ballistic vests etc. Kevlar fibers is very difficult to break, are placed creating layers. This way it can easily slow down the kinetic strength of the bullets and shrapnel shell until stopping it. Because of the high strength of this material, it is being made into body armor, bullet-proof vests and other forms of protection for military and other law enforcement agencies, or journalists covering war zones.

2. Protection Suit:

Kevlar has resistance against high temperatures, as well as against some chemicals. That makes it a very used material in Bomb Suit and PPEs. Kevlar is also Cut-resistant gloves, thermal insulation, flame retardant blankets or helmets and so on.

3. Motorsports:

Kevlar used in manufacturing formula one racing car. It is used also in the pilot’s helmets, construction of the engines and fuel tanks of the vehicles in automotive industry. It is widely used for reinforcements in motorbike suits. The abrasion resistance of the Kevlar fabrics make it a great ally against the injuries produced in elbows or knees.

4. Sports Industry:

The lightness of Kevlar, have made this fiber popular in sports equipment such as sports jacket and helmets. In water-sports industry Kevlar’s tenacity has makes the fiber perfect for boat sails, competition sailboats. It can also find it in climbing material such as boots or ropes. Recently Kevlar is often used in hockey helmets and lightweight tennis rackets.

5. Aerospace Industry:

High tenacity and lightweight are key properties in the aeronautic industry. That’s why Kevlar has been commonly used for the safe but low weight space suits. Kevlar has also been used as part of the landing system of the spacecraft. The combination technology of Kevlar used in the wings and even the anti-shrapnel protections the jet engines of the airplanes.

6. Fashion Industry:

Kevlar is even being used in the fashion industry. Versatility of Kevlar helps to use in manufacturing a variety of apparel, fashion accessories, and equipment to make them safer and more durable. Most of the time, Kevlar are used for security, not for style in fashion industry.

Conclusion:

While Kevlar is integral to fabric engineering and the war industry, it’s intriguing to future needs to innovate fiber. It may help the next revolutionary use of Kevlar, or another game-changing fabric to protect in extreme climate conditions.

References:

- S.M.M. Amir, M.T.H. Sultan, M.Jawaid and A. Hamdan “Nondestructive testing method for Kevlar and natural fiber and their hybrid composites“January 2019, DOI: 10.1016/B978-0-08-102290-0.00016-7

- https://textilelearner.net/kevlar-fiber-types-properties-manufacturing/

- http://www.edgeofyesterday.com/time-travelers/how-one-failure-changed-the-world-the-story-of-kevlar

- https://www.sciencedirect.com/topics/engineering/kevlar

- https://www.explainthatstuff.com/kevlar.html

- https://materials-today.com/kevlar-uses-properties-and-processing/

- https://en.wikipedia.org/wiki/Kevlar

Author of this Article:

Md. Mahedi Hasan

B.Sc. in Textile Engineering

Textile Engineering College, Noakhali.

Email: mh18.bd@gmail.com