What is Operation Breakdown and SMV?

A breakdown is a list of the elements that comprise the content of a job. A garment is manufactured by a number of sewing jobs and non-sewing jobs. Jobs or activity involved in making a garment is known as operations. When you breakdown a garment, you are writing down all of the parts and all of the operations one after another, lying with the whole garment and following the process sequence. So we can say, the method of preparing operations’ list in a sequence is called as operation breakdown.

SMV means Standard Minute Value. It is a predetermined time measurement used to estimate the time required to perform a specific operation or task. SMV is a common tool between fashion brands and manufacturers for discussions on cost, time and floor capacity.

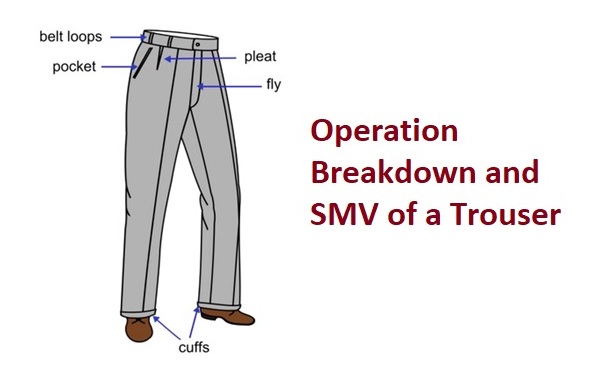

A trouser, also commonly known as pant, is a garment that covers the lower part of the body, specifically the waist to the ankles. It is worn by both men and women. Trouser is a very commonly manufacturing product in knit garments. Generally, it is made by fleece fabric or single jersey, popular clothing in this generation. In this article I will explain operation breakdown and smv of a trouser with proper data.

Operation Breakdown and SMV of a Trouser:

| SL No. | Operation Description | M/C Type | SMV |

| Front | |||

| 1 | Facing OL | 013 | 0.350 |

| 2 | Facing attachment to pocket bag | SN | 0.450 |

| 3 | Pocket bag close | SN | 0.550 |

| 4 | Turn and top stitch on pocket bag | SN | 0.500 |

| 5 | Pocket bag mark and attachment front | SN | 0.600 |

| 6 | Trim and turn | HLP | 0.400 |

| 7 | Top stitch | DN | 0.550 |

| 8 | Dummy stitch | SN | 0.500 |

| 9 | Inside fly run and ready | 013 | 0.350 |

| 10 | Zip attachment to fly | SN | 0.450 |

| 11 | Inside fly attachment | SN | 0.400 |

| 12 | Zip finish | SN | 0.450 |

| 13 | J fly attachment and top stitch | SN | 0.550 |

| 14 | J stitch | DN | 0.450 |

| 15 | Front rise attachment | 015 | 0.400 |

| 16 | Bar tack fly | BARTACK | 0.100 |

| 17 | FR trim and inspection | HLP | 0.450 |

| W/B | |||

| 18 | W/B joint | SN | 0.350 |

| 19 | WB iron | HLP | 0.450 |

| 20 | WB run stitch | SN | 0.600 |

| 21 | Trim and turn | HLP | 0.400 |

| 22 | Loop ready | FL | 0.350 |

| 23 | Mark and trim | HLP | 0.450 |

| Back | |||

| 24 | Dart stitch | SN | 0.450 |

| 25 | Welt attachment | DN | 0.500 |

| 26 | Pocket bag attachment | SN | 0.450 |

| 27 | Notch and turn | HLP | 0.60 |

| 28 | Side tacking | SN | 0.65 |

| 29 | Welt close | SN | 0.45 |

| 30 | Bottom edge stitch | SN | 0.65 |

| 31 | Pocket bag close | SN | 0.60 |

| 32 | Bag top stitch | SN | 0.55 |

| 33 | Welt top edge stitch | SN | 0.650 |

| 34 | BK rise | 01.5 | 0.45 |

| 35 | Trim and inspect | HLP | 0.45 |

| Assembly | |||

| 36 | FR and BK attachment (side) | 01.5 | 0.750 |

| 37 | Inseam | 01.5 | 0.700 |

| 38 | Loop attachment | SN | 0.650 |

| 39 | WB and body no set | HLP | 0.450 |

| 40 | WB attachment | SN | 0.600 |

| 41 | WB finish | SN | 1.000 |

| 42 | Loop finish | SN | 0.700 |

| 43 | Bar tack on loop | BARTACK | 1.10 |

| 44 | Bottom hem | SN | 0.800 |

| 45 | Hook and eye attachment | Special | 0.500 |

| 46 | Back pocket button attachment | BS | 0.260 |

| 47 | Button hole sew | BH | 0.260 |

| 48 | Trimming and checking | HLP | 2.00 |

References:

- Apparel Manufacturing Technology by T. Karthik, P. Ganesan, and D. Gopalakrishnan

- Practice of Garments Merchandising and Management by Engr. Md. Faruk Hosen

- Industrial Engineering in Apparel Production By V. Ramesh Babu

You may also like: