Pattern making process:

The making of exact image of each part of a garment with flat hard board paper is called the pattern. The first step in apparel production is the creation of design and construction of patterns for the components of design. Besides, pattern making process is one of the most important task in garment manufacturing. Sketch is converted into garments by pattern making hence it is like a bridge between the design and production. Separate patterns are made for each of the parts of a garment. These patterns are used for drawing all the parts of a garment on fabric or on marker paper before the cutting of the fabric. If lining or interlining is used in the garment, then for that purpose also patterns are made.

For making garments patterns specialized knowledge and efficiency is required on skillness, technical knowledge, capacity of analysis of garments designs and on technology of garments making. The patterns used in garment industry are produced mainly in two stages which are called block pattern and garment pattern.

Block pattern:

Block pattern or basic pattern means the actual pattern which is fitted to a certain standard body structure but without any specific construction for enhancing beautification, design or style. Based on the average measurements of young, adults, tall etc. group of men’s and ladies, block patterns are made. Different block patterns are also made for the kids based on their age. Block patterns are made in two ways as described below:

A. Flat method:

The pattern of various parts of a garment, especially the body and sleeve are made through technical drawing. In case of technical drawing, the rules and their application procedure of body measurements and their proportionate rates are dependent on pattern maker. This type of patterns may also be made through computer. In case of basic pattern making process through computer, pattern making programs are saved in computer discs. Flat method has been evolved mainly from modeling system and in this system, patterns can be made rapidly.

B. Modeling:

For garments pattern making process, modeling is the first and actual system and in garments industry it is still widely used system. In this system, a block fitted with the standard body of a model is made, which is called the Toile. This toile is used in the body of the model and it is made maintaining adjustment and balance with the body of the model. Then the toile is removed from the body of the model and each of the parts of the toile is drawn separately on comparatively harder paper or board paper. Patterns made in this system become very accurate but it takes much time.

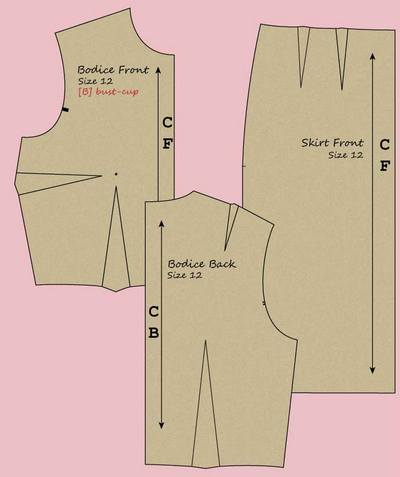

Garments Pattern / Working Pattern:

Block patterns are made in flat method or modeling system and garments patterns or working patterns are made based on basic block. Each block pattern is kept on board paper and its copy is made with the help of pencil. Then with the copy of this block pattern, sewing allowance, trimming allowance, center front line, center back line, button hole, button attaching position, dart, pleat, how much the garments will be loose, different or specific design of a particular part (if any) etc. are added. For facilitating the proper attaching of the patterns, “U” or “V” shaped notches are cut along the seam lines. For each part of a garment, separate working pattern or garment pattern is made. In order to show the direction of grain line or the warp yarn of fabrics, each pattern must be marked with arrow line. After finishing the drawing of the pattern, the working pattern or garments pattern will be separated from the board paper by cutting with sharp scissors or knife. Each pattern will be marked for size and part’s name. Sample garment is made with working pattern.

References:

- Patternmaking for Fashion Design by Helen Joseph Armstrong

- Garments & Technology by Prof. M. A. Kashem

- Garment Manufacturing Technology by Md. Shafiul Azam, Md. Abu Saleh & Khondokar Abu Nafiz

- Apparel Manufacturing Technology by T. Karthik, P. Ganesan, D. Gopalakrishnan

- Garment Manufacturing Technology Edited by Rajkishore Nayak and Rajiv Padhye