Define Jute Fibre:

Jute is a long, soft, shiny important natural bast fibre that can be spun into coarse, strong threads. Jute fibre is basically lignocellulosic, biodegradable, and renewable. Owing to its high tenacity and low extensibility, it is traditionally being used for producing packaging material. It is also stiff and harsh. Taken from two varieties of the Corchorus plant, white jute and tossa jute which is softer, silkier, and stronger than white jute.

The plants grow to three metres high in sandy soil with a subtropical climate, and the fibres are removed from the stem using the retting process. Jute fibres are composed primarily of the plant materials cellulose (major component of plant fibre) and lignin (major components of wood fibre). It is thus a ligno-cellulosic fibre that is partially a textile fiber and partially wood. They are produced in and exported from India, Bangladesh and Pakistan mainly. It is an inexpensive fibre used primarily for ropes, packaging and backing carpets due to its coarseness. With the rise of synthetics in the 1960s, jute lost some of its market to polypropylene. Its breaking strength is comparable to that of steel wire. Jute can be mixed with cotton for casual garments.

Typical Properties of Jute Fibre:

| Property | Jute |

| Ultimate cell length, L (mm) | 0.8-6.0 |

| Ultimate cell breadth, B (mm) | 10-25 pm |

| Length/breadth (LB) ratio | 110 |

| Fineness (denier) | 15-35 |

| Tenacity (gm/denier) | 3-5 |

| Specific gravity (gm/cc) | 1.48 |

| Coefficient of static friction | 0.45-0.54 |

| Refractive index | 1.577 |

| Specific heat (Cal/g/t) | 0.324 |

| Thermal conductivity (cal/s/cm.°Q.cm2) | 0.91 x 10-4 |

| Thermal conductivity (M watt/m.kelvin) | 427.3 |

| Heat of combustion (Jules/g) | 17.5 |

| Ignition temperature (°C) | 193 |

| Elongation at break (%) | 1.0-1.8 |

| Density (gm/cc) | 1.46 |

| Degree of crystallinity (X-ray) | 55-60% |

| Angle of orientation (X-ray) | 7_90 |

| Initial modulus | 17-30 N/tex |

| Flexural rigidity (dynes.cm) | 3.0-5.0 |

| Moisture regain (%) at 65 % R.H. | 12.5 |

| Moisture regain (%) at 100% R.H. | 36 |

| Diameter swelling (%) at 100% RH | 20-22 |

(Source: Textile Engineering Department, IIT, Delhi & Indian Jute Industries’ Research Association, Kolkata)

Physical Properties of Jute Fibre:

1. Microscopic appearance:

Jute is a multicellular fibre. The individual fibre shows nodes and cross markings in longitudinal view and polygonal shapes in cross-section. Lumen is wider than the cell wall and shows remarkable constrictions (irregular thickness) in the cell wall. Lumen broadens at the end of the fibre making cell wall very thin. Externally fibre is smooth and lustrous.

2. Length and diameter:

A single jute fiber has average length of 0.1 inch and a mean diameter of 12µ (microns). The mean length/breadth ratio is around 90.

3. Density:

The density of fibre is 1.48-1.50 gm/cm3

4. Moisture regain:

Jute is highly hygroscopic in nature. Its moisture regain is 12-14% at standard condition.

5. Strength:

The tenacity of jute varies from 3.5-7 gm/denier.

6. Colour:

Varies from yellow to brown to grey depending upon condition of growth and retting etc.

7. Elongation:

Jute do not stretch to appreciable extent under tension. Its breaking elongation is 1-1.2% under normal atmospheric condition.

8. Composition:

Jute fibre contains cellulose (55-63%), hemicelulose (20-24%) and lignin (12-14%).

9. Conductivity:

It is very good insulator of heat and electricity.

10. Elasticity:

Jute has lower elasticity due to its stiffness and rigidity. This has advantages of jute to be used as bagging material as they retain their shape on loading.

Chemical Properties of Jute Fibre:

In chemical composition jute is different from linen and cotton as it is composed of a modified form of cellulose called lignocellulose, a compound of lignin and cellulose.

1. Action of alkalies:

Strong alkalies degrade its strength. Jute loses its weight when it is boiled with dilute caustic soda. The loss is mainly due to the removal of hemicellulose.

2. Action of oxidising agents:

Ordinary oxidising agents have no action on jute.

3. Action of acids:

Organic acids like oxalic acid, formic acid, mineral acids like sulphuric acid and hydrochloric acid in dilute condition has no reaction at ordinary or cold conditions. With strong acids at boiling condition hydrocellulose is formed.

4. Action of microorganisms:

Jute is more resistant to microbiological attack than grey cotton or flax. If it is slightly scoured it has excellent resistant owing to protective effect of lignin. Sometimes jute fabrics are treated with cuprammonium solution and then dried so that a film of green colour is produced on the material which makes it more or less rot proof.

5. Action of sunlight:

When jute is exposed to sunlight it gradually assumes a yellowish tinge. This is due to colour changes within the fibre connected with lignin molecules.

6. Action of heat:

Jute like other textile fibres may not be degraded by heat. However, prolonged heating operation degrade the fibre.

Mechanical Properties of Jute Fibre:

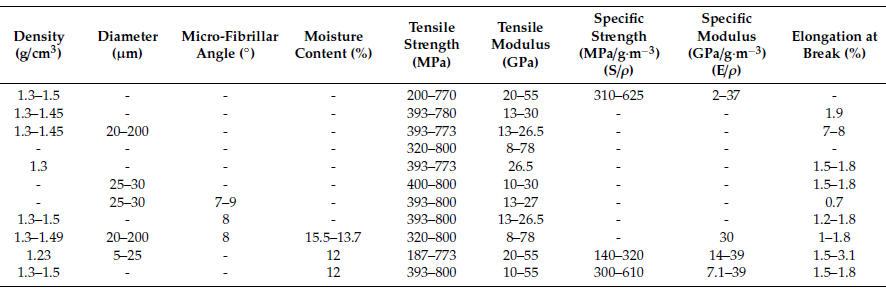

Jute fibre is considered to be one of the most important fibres for the production of bio-composites and bio-plastics. Much research can be found studying the different mechanical properties of jute fibre, which have acceptable mechanical properties like tensile properties, specific strength, and modulus, hence increasing its potential use in different applications. The values of the different mechanical properties of jute fibre reported by researchers are listed below in Table.

Table: Mechanical properties of jute fiber

Top 5 Jute Producing Countries in the World:

- India ——–>55.1%

- Bangladesh –>41.9%

- China ———>1.3%

- Uzbekistan —->0.57%

- Nepal ———->0.41%

Uses of Jute Fibre:

Jute fibres are an environmental friendly natural fiber which can be used as good alternatives in the reinforcement of composite materials. Besides also used in hessian, scrim, canvases, packaging, ropes, carpet backing, clothing fabrics, bags, floor coverings, wall coverings, upholstery and geotextiles. Knitted jute decomposes around plants as they grow, providing natural mulch. Jute contains cellulose and wood fibre, and it has been developed for use within the automobile, paper and bedding industries as non-woven, technical and composite fabric.

You may also like:

- Viscose Rayon Fibre – An Overview

- Properties, Production and Uses of Viscose Fiber

- Sisal Fiber: Properties, Production Process and Uses

- Properties, Processing and Uses of Kenaf Fiber

- Milkweed Fiber: Properties, Processing and Applications

- Kapok Fiber: Properties, Processing and Applications

- Hemp Fiber: Properties, Processing and Uses

- Properties, Extraction and Uses of Pineapple Leaf Fiber

- Kenaf Fiber: Properties, Cultivation, Production, Uses and Advantages