Quality Parameters of Woven Fabric

Authors:

Md. Samiul Haq1

Afifa Sultana

Dept. of Textile Engineering

Daffodil International University, Dhaka, Bangladesh

Email: samiul23-4561@diu.edu.bd1

ABSTRACT

The fundamental motivation behind this task is to discover the fabric quality by following diverse test which is done in textile industry. This postulation work will assist us with finding out the variety of woven fabric quality as indicated by the development just as synthesis. We have determined numerous quality parameters, for example, GSM, tear quality, elasticity, skewness test, bowing test, shrinkage test, pilling test, crimp percentage test which are legitimately or by implication relies upon fabric quality. Previously, every test we have checked epi and ppi of the woven fabric and deliberately saw the construction of the fabric. Throughout the information assortment process, we have kept up the standard of ISO. During the information assortment time we were earnest and steadfast. What’s more, we constantly attempted to complete a few tests for getting the genuine outcome. Our endeavors were to build up a trustworthy way so one can without much of a stretch imagine the quality parameters of sewed fabric with required setup. We unequivocally accept that, hypothetical information that we assembled in the class and viable information that we have gotten the hang of during the internship period help us to play out the task flawlessly.

INTRODUCTION

Fabric is a get together of yarn which is made by interlacing or interloping. knitting and woven are the two fundamental class of fabric. We will discuss the woven fabric quality parameter which alludes diverse test method of fabric, for example, EPI and PPI tally, GSM, quality and so forth.

Quality means, the standard of something as measured against other things of a similar kind; the degree of excellence of something. Quality issues are the main factor for an industry to sustain. It can hinder the growth of the industry. Because, no buyer will buy quality less product. Here, one thing should be cleared that, quality in textile or garments sector means buyer requirement.

The quality issues that we will be discussed in thesis are:

- EPI & PPI

- GSM

- Shrinkage

- Skewness

- Bowing

- Tensile strength test

- Tear strength test

- Pilling test

- Elongation & Recovery

These issues are must be maintained in a product and a quality person must be concentrate on these matters. During an order processed a fabric merchandiser have to check these issues must. So, it is cleared that, the aim of this project; clarify the test procedure with meaningful comparison between construction of fabric.

So, in a word we worked with woven fabric quality parameters which are must be followed in a textile industry to find the quality issues of a fabric. It will also show the variation of quality value when the procedure is different.

Objectives

- To know about the production procedure of some major commercial single wovenstructures e. Plain, Twill, Oxford, Dobby etc.

- To determine and evaluate quality of the produced. Structures that were interlacedwith cotton & cotton/polyester blended yarns maintaining similar major woven variables, e. yarn count and stitch length.

- To observe the variation in quality parameters performance of the produced fabrics.

- To analyze the obtained data statistically to find out qualitative/quantitative influence of weaving.

- To know details about quality parameters of woven fabrics and their importance.

LITERATURE REVIEW

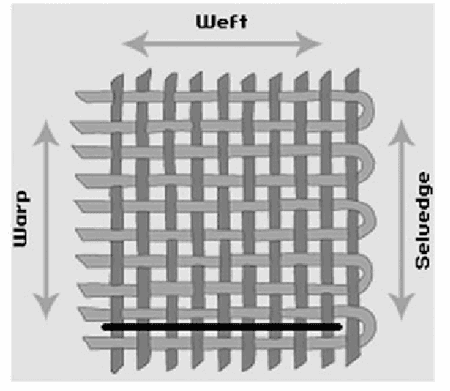

Woven fabrics are made on looms. They consist of two sets of yarns that are interlaced and lie at right angles to each other. The threads that run along the length of the fabric are known as warp (ends) and the threads that run from one side to the other side of the fabric, are weft (picks). In triaxial and in three-dimensional fabrics yarns are arranged differently.

Basic of Woven Fabric

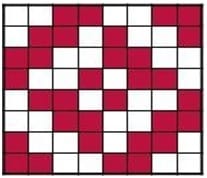

The form of interlacing of warp and weft yarns can be divided basically into three categories- plain, twill and satin/sateen weave. These three kinds of forms are called basic weaves.

Plain Weave:

The simplest of all weaves is the plain weave. Each filling yarn passes alternately over and under one warp yarn. Each warp yarn passes alternately over and under each filling yarn. Some examples of plain-weave fabric are crepe, taffeta, organdy, and muslin. This have some categories as follows:

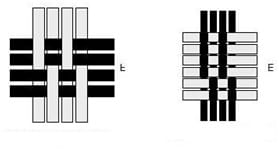

Warp rib weave:

Warp rib weaves may be described as plain weave in which two or more picks are inserted in the same shed. Warp rib weaves are normally used in warp faced constructions. The warp cover factor and the warp crimp are substantially higher than the weft cover factor and the weft crimp. The intention is to produce fabrics with prominent weft- way rib formed by the crowns of the warp threads.

Weft rib weave:

Weft rib may be described as plain weave in which two or more ends weave together as one. It is difficult to achieve very high weft cover factors in weft faced plain- weave cloths. By using two finer ends weaving as one, it becomes possible to achieve higher weft cover factor. Such cloths are expensive to weave and not very common.

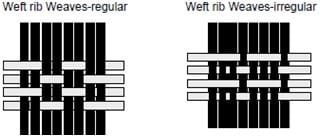

Basket, matt or hopsack weave- In matt, basket or hopsack weaves two or more ends and two or more picks weave as one. The simplest and commonest of these weaves is 2/2 matt.

Twill Weave:

A weave that repeats on 3 or more ends and picks & produces diagonal lines on the face of the fabric. A twill weave is characterized by diagonal rib (twill lines) on the face of the fabric. These twill lines are produced by letting all warp ends interlace in the same way but displacing the interlacing points of each end by one pick relative to that of the previous end. In twill weave line moves sinisterly (Right – Left, Z twill) and dextrally (Left – Right, S twill). Common derivatives of twill weave are as follows:

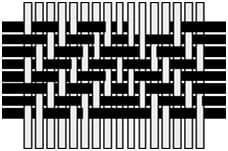

Zigzag weave:

If the direction of the diagonal in a twill fabric is reversed periodically across the width, a zigzag effect is produced. Zigzag weave is achieved by simply combining two S and Z twill weaves of equal repeat.

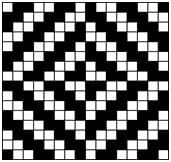

Diamond weave:

Diamond weaves are achieved by combining two symmetrical zigzag weaves of equal repeat. Diamond designs are vertically and horizontally symmetrical.

Herringbone weave:

In Herringbone weave also the twill direction is reversed periodically like zigzag weave but at the point of reversal the order of interlacement is also reversed and then twill line commence as usual.

Diaper weave:

Diaper weaves are produced when we combine two Herringbone designs. Diaper designs are diagonally symmetrical.

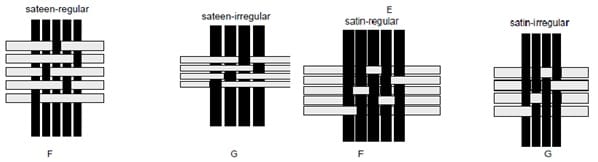

Satin/sateen Weave:

The satin weave is characterized by floating yarns used to produce a high luster on one side of a fabric. Warp yarns of low twist float or pass over four or more filling yarns. The low twist and the floating of the warp yarns, together with the fiber content, give a high degree of light reflection. Weights of satin fabrics range from chiffon satin to heavy duchesse satin. The sateen weave is similar to a satin construction except that in the sateen weave, the filling yarns float and are visible on the surface of fabric. Examples: cotton sateen, and damask.

Woven fabrics are manufactured on any of the weaving machines as per their applications. Their strength, thickness, extensibility, porosity and durability can be varied and depend on weave used, thread spacing (that is the number of threads per centimeter), raw materials, structure (filament or staple), linear density (or count) and twist factors of the warp and weft yarns. Higher strengths and greater stability can be obtained from woven fabrics than from any other fabric structure using interlaced yarns.

Not need to say that in the competitive market, quality of finished product plays a vital role. So, there are many customers which are ready to pay more for ‘quality’ which ensures the better performance of the product.

Therefore, it becomes necessary to control the quality of the product manufactured. For this purpose, many test methods and testing instruments are developed. By testing the product we obtain values of quality related variables of the textile product.

Analyzing these values with standard norms, we can control the quality. In case of woven fabric, there are various methods by which we can easily control the quality of the fabric.

Though textile testing and quality control is a costly process, it is necessary to test textile product for their quality. As far as quality is the concern, we have to test the material first and so that testing process starts from the raw material itself.

Initially, standards of certain quality are fixed for the particular end product and the accordingly, the product is manufactured. During manufacturing product is testing is done and obtained values are compared with standards and quality control is done.

By testing and controlling the quality of the textile product we can reduce the cost of production, as we are reducing variation in manufactured product, reducing the waste and rework, improving efficiency and increase productivity. Testing is the process or procedure to determine the quality of a product.

A particular standard of product which satisfies the customers need is nothing but the “QUALITY” of the product. Fabric quality mainly consists of two components:

- Fabric properties

- Fabric faults/defects

There are many customers who ready to pay more for ‘quality’ which ensures the better performance of the product. Therefore, it becomes necessary to control the quality of the fabric manufactured.

Quality Control

As we know that particular standard of product which satisfies the costumers need is nothing but the “QUALITY” of the product. Testing of the product is done and parameters of that product are verified.

Maintaining these parameters in given tolerance limit of standards, this process is called as “Quality Control”.

There are many customers ready to pay more for ‘quality’ which ensures the better performance of the product. Therefore, it is become necessary to control the quality of the product manufactured.

Objects of Quality Control

- To manufacture the required quality

- To fulfill customer’s

- To reduce the cost of

- To reduce

- To make more profit at minimum

Quality Control Process

Quality control is not a single step procedure, it is a multi-step procedure in which following steps are carried out.

- Testing of material.

- Analysis of

- Corrective action according to results from the

To obtain a quality end product these steps must be carried out on the woven fabric which is to be processed.

You may also like: Basic Concepts of Quality and Quality Control in Textile

Defects of woven fabric:

Bad selvedge

Inappropriate shuttle wire strain, twisted shuttle jaw, shuttle split, increasingly pressure on selvedge yarns, late shedding bringing about scouring of shuttle to the selvedge and ill- advised determination of selvedge weave for the fabric being woven are the primary explanations behind bad selvedge.

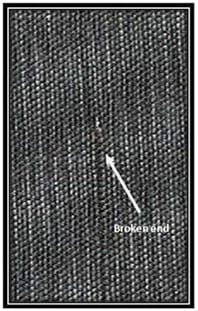

Broken end

This problem is raised in warp direction when the warp yarn broke in a place of fabric. This problem could be raised during weaving or finishing.

Broken weft

High weft pressure, ill-advised form of pirn, knots at the nose or pursue of pirns, back fastens in cones bolstered as weft in shuttle less weavers, and harmed surface of pirns, shuttle tongue not in level, harsh places inside the van, harmed nylon circles, sloughing off or approximately fabricated weft bundle, transport eye chipped or broken, weft caught in the crate, selvedge closes cutting the weft, weft fork too far through the mesh, unpleasant box fronts or shuttle guides, inappropriate arrangement of cone in weft feeder, lower curve in weft bringing about weft opening out in air-fly weavers, missing the picks, ill-advised tying of last parts, and harsh treatment of cones are the principle explanations behind higher weft breaks.

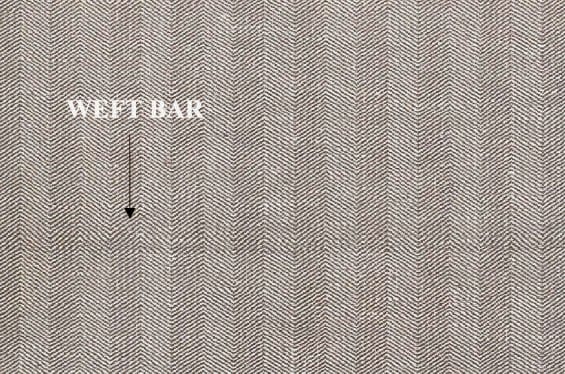

Weft bar

At the point when count of yarn changes starting with one cone then onto the next cone then a bar of weft will be showed up in fabric subsequent to weaving.

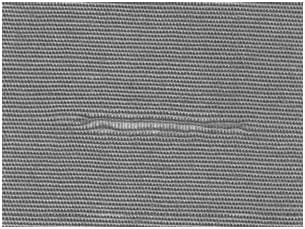

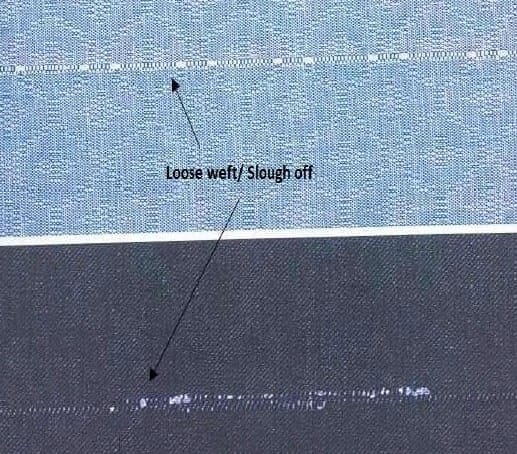

Loose weft or Slough off or Snarl

When a bunch of or coil of yarn slips from the pirn during weaving then thick yarn bunches or coils appear on the fabric.

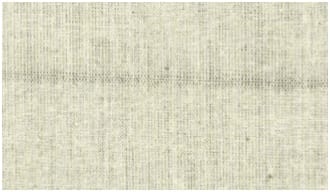

Starting Marks

Thick or thin places occurring in fabric due to pick density variation when starting the loom, causing starting marks.

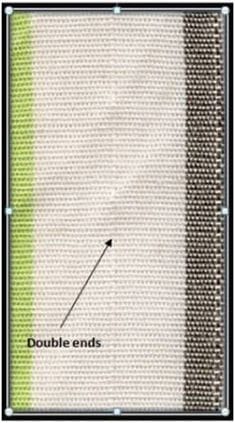

Double end

This sort of issue is created in woven fabrics when the two parts of the warp get together subsequent to sizing.

Knots or slubs in the warp or weft yarns

Knots or slubs in a portion of the weft or warp yarns are viewed as flaws when they are obvious to an accomplished individual and when they ruin the presence of the fabrics. This visual evaluation is adequate to test whether the shortcomings would be unsuitable in an article of clothing and no resilience is allowed for flaws recognized utilizing this technique for control.

Oil spot or stain

Staining on a neighborhood a substrate that might be impervious to expel by washing or cleaning. It happens during turning, weaving or wrapping up. It is additionally frequently found in the woven fabric. It is likewise created in woven fabric if an excessive amount of oiling has done on the loom parts.

METHODOLOGY

Area of experiment: Woven fabric quality parameter

Will be discussed here: Counting of EPI & PPI, GSM, Shrinkage, Skewness, Bowing, Tear & Tensile strength, Abrasion resistance test, Pilling test.

All the materials and machineries are used from Mahmud Fabrics and Finishing Ltd.

Machine used:

There are several machines used during the experimental work had processed. Weaving machine, counting glass, GSM cutter machine, seizer, shrinkage scale, shrinkage board, washing machine, pilling cutter, tear and tensile strength measuring machine, weighting machine.

Weaving machine:

Machine specification:

| Brand Name | PICANOL (Rapier Loom) |

| Model No | Optimax |

| Origin | Belgium |

| M/C Speed | 850 rpm |

| Heald Frame | 16 |

| Dope Wire | 6 |

| No. of cutter | 2 |

| Let off motion | Electrical |

| Take up motion | Electrical |

Counting glass:

Washing machine:

GSM cutter:

Tear strength testing machine:

Tensile strength testing machine:

Abrasion & pilling testing machine:

EPI & PPI calculation:

EPI and PPI are the exceptionally normal word in the textile business. In woven fabric EPI and PPI is estimated to the quantity of yarn on a fabric. Regularly, EPI is the quantity of wrap yarns per inch of fabric and PPI is the quantity of weft yarns of per inch of fabric. After read this article we can without much of a stretch comprehend EPI and PPI in material attire.

EPI:

EPI signifies “Ends Per Inch” is the mainstream word in the articles of clothing and textile industry. Number of yarns in twist bearing is estimated by EPI. Typically, closes per Inch are the quantity of wrap yarns. It is the speak to vertical yarns of the fabric. It is known as the wrap yarn.

PPI:

PPI signifies “Picks Per Inch” is additionally the most prominent word in the textile and pieces of clothing industry. Number of Weft yarn in fabric is estimated by PPI. Picks per inch is the quantity of weft yarns of the fabric. It is speaking to the flat yarns. It is the called weft yarn.

There are two techniques to discover EPI and PPI:

- Testing technique in Lab.

- Without testing technique or manual.

1. Testing technique in Lab

On the off chance that you need to know EPI and PPI in the fabric, at that point send fabric test to the testing lab. Subsequent to checking the fabric test they will educate you what number of Ends Per Inch and Picks per inch on the fabric.

2. Without Testing Lab or Manual

Ordinarily, it he the straightforward strategy to path discovers the EPI and PPI on the fabric. Also, most extreme fabric EPI yarn is the higher than PPI yarn. On the off chance that you need to know EPI and PPI, at that point you ought to follow in the beneath system.

Gather the fabric swatch. Put the fabric swatch on the plain table. And furthermore, checks wrap and weft bearing of the fabric.

Imprint 1X1 inch on the fabric test.

Vertical or wrap yarn check individually. Also, discover what number of wrap yarns. And furthermore, flat or weft yarn check individually. Discover what number of weft yarns.

Along these lines, utilizing this technique we can without much of a stretch comprehend and discover one-inch fabric yarns tally of length and Width.

GSM calculation

We measured GSM for three times for same fabric. One is before wash; another is after wash (Dried in dryer) and the last one is also after wash(Dried in open air).

Procedure of calculation:

- At first, we cut the fabric with GSM cutter; the knife was sharp so it cut so easily; there must not loss any single yarn from the cutting part and we were very much careful about it.

- Then we weighted the fabric in an electric balance and before weighing we set the balance in gm unit and neutralize it.

Shrinkage calculation

Shrinkage (in fabric) is a parameter of testing fabric to quantify changes long and width in the wake of washing. Shrinkage bombing materials are dimensionally flimsy and they can cause disfiguring of the pieces of clothing or items made out of those materials.

Procedure of calculation:

- At first need to mark two length in warp and weft direction of the fabric. Marking is done through using We did it very carefully. Before making mark, we were concern about the straightness of the fabric. This task is done before washing as the shrinkage happen after wash.

- Then next procedure will carry out after washing. Following the procedure, the marked length will be measured again by shrinkage scale. Increases of length will express in positive sign and decreases of length will express in negative sign.

For calculate shrinkage percentage,

Shrinkage% = {(length before wash – length after wash) / length before wash} × 100

Tear strength calculation

Tear strength is the quality required to begin or proceed with the tear in a fabric under explicit condition and tearing power is the required to proceed with a tear recently began in a fabric. The tear obstruction test on fabrics or tear quality is estimated to check how the material can withstand the impacts of tearing or cuts when in strain. The tear quality is estimated according to the ASTM D412 standard test technique, which is likewise used to quantify ductile and extension.

Procedure of calculation:

- At first need to cut the sample for testing. During cutting sample for warp and weft test a rule should be followed that during cutting warp, short length of template (10mm) should remain in warp wise. And same rule for weft sample cutting.

- Then the cutting sample should set on the clamp of tear testing machine and cut a slit through using knife switch.

- Then the operation switch should be In James Heal tear testing machine two switch are operated this action.

- After tearing completed, the result will show in a monitor of the machine. 3 or 5 tests can be And we do 5 tests of every sample.

- At last need to take the average value from the screen.

Tensile strength calculation

Tensile strength of any material is the power at which example breaks. in the event that if fabrics it is the most extreme recorded power required to tear a fabric. Elastic testing of fabric includes different test (Strip test, snatch test, tearing test, and so on) which can invigorate a thought regarding the tensile strength of fabric.

Procedure of calculation:

- Need to cut sample at (2-inchX 8-inch) parameters for both warp and weft side.

- Then need to set the sample at the clamp.

- Then need to give command form the computer to start the operation.

- Through graph method the procedure will give result. After 3 test the average value will show on screen of the computer.

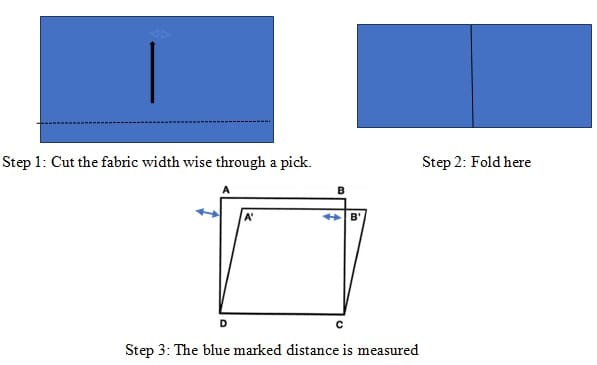

Skewness calculation

Skewness is an imperfection happens in a fabric. It is a condition coming about when filling yarns or sewed courses are precise uprooted from a line opposite to the edge or side of the fabric because of uneven appropriation of pressure.

Procedure of calculation:

- Take a sample of fabric of full width and a minimum length.

- Cut the sample width wise and must follow same pick during cutting.

- Fold width wise after cutting and there will some parts which will not match.

- Measure that parts and that’s the skewness value.

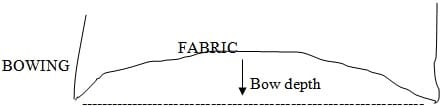

Bowing calculation

Bowing is a condition in woven textiles where filling yarns are displaced from a line perpendicular to the selvages and lie in an arc across the width of the fabric. Bowing appears as rows of courses or yarn-dyed stripes forming a bow shaped curvature along the fabric width.

Procedure of calculation:

- At first need to cut a sample fabric along the width and a pick should be followed during the cutting.

- Then the fabric should be fold length wise and from the cutting side bow depth will show.

- Measure the depth length from bow portion top position to level position of other fold length.

For calculation bowing percentage,

Bowing percentage = (Bowing depth/fabric width) ×100

Abrasion resistance calculation

Abrasion is a kind of wear in which rubbing away of component fibers and yarns of the fabric takes place. During abrasion, a series of repeated applications of stress takes place.

Procedure of calculation:

- At first need to cut the sample by pilling or abrasion cutter.

- Set the sample to the clamp with backing felt. There must be same fabric sample in upper and lower position of the spinle.

- Set the required no. of cycle to rub. We set it at 2000 cycles.

- After completing the cycles, the sample will be examined under light box.

Pilling resistance calculation

A pill, colloquially known as a bobble, fuzz ball, or lint ball is a small ball of fibers that forms on a piece of cloth. Pilling is a surface defect of textiles caused by wear and is considered unsightly to some. It happens when washing and wearing of fabrics cause loose fibers to begin to push out from the surface of the cloth, and, over time, abrasion causes the fibers to develop into small spherical bundles, anchored to the surface of the fabric by protruding fibers that haven’t broken. These fiber balls are called Pills.

Pilling is also done as the same procedure as abrasion resistance calculation.

Elongation and recovery calculation

Elongation is indicated as a level of the beginning length. The versatile lengthening is of definitive significance since fabric items without flexibility would scarcely be useable. They should have the option to twist and furthermore come back to shape.

Recovery or elasticity is the aftereffect of extending a fabric to the most extreme without being disfigured. The flexibility is estimated as a percent for each meter or inch. The fabric versatility can be estimated wide-wise, long-wise, or over the predisposition of the fabric. It can likewise be estimated over a few faculties simultaneously; with the possibility their measure is extraordinary.

Procedure of calculation: [Experiment carry out in Titan 5 machine form James Heal]

- Cut the sample length/width wise (according to requirement) at 2 inch × 8 inch length.

- Set it on the clamp of the machine.

- Set the test method and required no. of cycle of applying force.

- After completing cycle remove the sample immediately and measure the length of the sample.

- After 3 tests, average value needs to calculate.

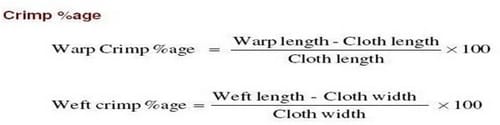

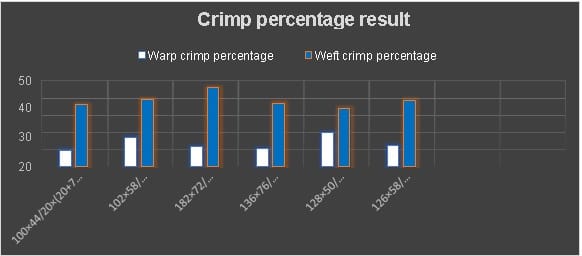

Crimp percentage calculation

At the point when warp and weft yarns join in fabric, they pursue a wavy or layered way. Crimp percentage is a proportion of this waviness in yarns.

Procedure of calculation:

- At first need to identify the warp and weft way of a sample.

- Then need to measure the fabric sample length and width.

- Following that, remove yarn from warp and weft side and measure the extended length of those yarn.

- Then following the below formula crimp percentage is measured

Data Table

Table 1: Data table for GSM

| Fabric type | Construction | GSM | |

| Before Wash | After Wash | ||

| ‘Z’ Twill | 96×72/40×(40+40D) | 212.35 | 232 |

| ‘Z’ Twill | 120×80/30×{20+(20+70D)} | 199.74 | 270.56 |

| Dobby | 84×78/ (30+21) × (30+21) | 169.48 | 178 |

| Plain | 110×50/40×32/2 | 142.35 | 144.4 |

| ‘S’ Twill | 90×62/30/2×16+70D | 244.64 | 322.21 |

| Plain | 88×74/40×40 | 225.32 | 237.43 |

| Dobby | 102×58/ 20× (20+40D) | 227.65 | 261.34 |

| Dobby | 120×80/ 30×(20+(20+70D)) | 235 | 270.35 |

| ‘S’ Twill | 110×50/40×32/2 | 143.23 | 146.7 |

| ‘Z’ Twill | 100×72/20×(20+40D) | 226.65 | 266.09 |

| ‘S’ Twill | 90×80/30×30 | 143.56 | 147.87 |

| Dobby | 94×60/40/2×{20+(20+40D)} | 208.31 | 287.76 |

| ’Z’Twill | 62×52/20×20 | 158.43 | 166.32 |

| ‘S’ Twill | 96×66/21×21cl | 192.34 | 203 |

| Plain | 112×67/ 40×40 | 108.5 | 119.23 |

| ‘Z’ Twill | 80×50/ 10×10 | 255 | 276 |

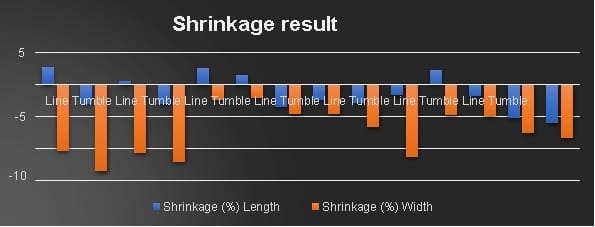

Table 2: Data table for Shrinkage

| Fabric construction | Drying | Shrinkage (%) | |

| Length wise | Width wise | ||

| 120×80/ 30×(20+(20+70D)) | Line | +2.85 | -10.32 |

| Tumble | -3.0 | -13.5 | |

| 100×60/16×(16+40D) | Line | +0.54 | -10.64 |

| Tumble | -3.00 | -12.05 | |

| 90×80/30×30 | Line | +2.65 | -2.36 |

| Tumble | +1.54 | -2.07 | |

| 94×60/40/2×{20+(20+40D)} | Line | -3.42 | -4.47 |

| Tumble | -2.34 | -4.5 | |

| 68×50/ 21cl×(20+70D) | Line | -2.84 | -6.54 |

| Tumble | -1.65 | -11.25 | |

| 92×64/21cl×(20+70D) | Line | +2.35 | -4.65 |

| Tumble | -1.76 | -4.87 | |

| 110×50/40×32/2 | Line | -5.11 | -7.58 |

| Tumble | -6.00 | -8.29 | |

Table 3: Data table for tear strength

| Fabric construction | Tear strength of Warp Yarn (N) | Tear strength for weft yarn (N) |

| 120×80/ 30×(20+(20+70D)) | 23.99 | 16.17 |

| 68×50/ 21cl×(20+70D) | 28.87 | 23.94 |

| 90×80/30×30 | 21.51 | 17.63 |

| 94×60/40/2×{20+(20+40D)} | 33.16 | 29.07 |

| 100×60/16×(16+40D) | 42.90 | 28.74 |

| 92×64/21cl×(20+70D) | 34.67 | 29.76 |

| 110×50/40×32/2 | 27.54 | 19.47 |

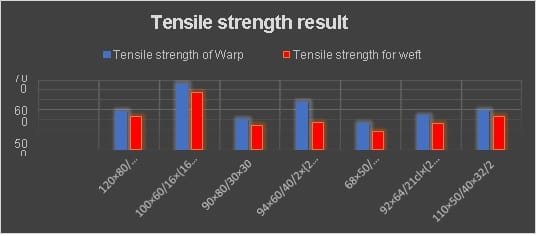

Table 4: Data table for tensile strength

| Fabric construction | Tensile strength of Warp Yarn | Tensile strength for weft yarn |

| 120×80/ 30×(20+(20+70D)) | 385.7 | 329.71 |

| 100×60/16×(16+40D) | 658.51 | 577.25 |

| 90×80/30×30 | 298.42 | 242.80 |

| 94×60/40/2×{20+(20+40D)} | 478.69 | 269.47 |

| 68×50/ 21cl×(20+70D) | 259.13 | 181.66 |

| 92×64/21cl×(20+70D) | 337.41 | 263.85 |

| 110×50/40×32/2 | 390.54 | 333.27 |

Table 5: Data table for elongation and recovery percentages

| Fabric construction | Elongation (%) | Recovery (%) |

| 120×80/ 30×(20+(20+70D)) | 29.16 | 94 |

| 100×60/16×(16+40D) | 23.81 | 92 |

| 90×80/30×30 | 17.32 | 95 |

| 94×60/40/2×{20+(20+40D)} | 22.68 | 93 |

| 100×60/16×(16+40D) | 23.81 | 94 |

| 92×64/21cl×(20+70D) | 21.67 | 94 |

| 110×50/40×32/2 | 25.44 | 94 |

Table 6: Data table for Pilling resistance

| Fabric construction | Fabric Weave | Pilling test result |

| 120×80/ 30×(20+(20+70D)) | Dobby | 2/3 |

| 100×60/16×(16+40D) | 2/2 ‘Z’ Twill | 1/2 |

| 90×80/30×30 | 2/2 ‘S’ Twill | 2/3 |

| 94×60/40/2×{20+(20+40D)} | Dobby | 2/3 |

| 100×60/16×(16+40D) | 2/2 ‘Z’ Twill | 2 |

| 92×64/21cl×(20+70D) | 2/2 ‘Z’ Twill | 2/3 |

| 110×50/40×32/2 | Plain | 2/3 |

Table 7: Data table for crimp percentage

| Fabric construction | Warp crimp percentage (%) | Weft crimp percentage (%) |

| 100×44/20×(20+70D) | 9.73 | 36.19 |

| 102×58/ 20×(20+70D) | 16.98 | 39.08 |

| 182×72/ 30×(20+70D) | 11.88 | 46.2 |

| 136×76/ 30×(20+70D) | 10.63 | 37.08 |

| 128×50/ 20×(16+70D) | 19.99 | 34.14 |

| 126×58/ 20×(16+70D) | 12.35 | 38.85 |

Analysis of some collected sample

Sample 1:

| Weave | Plain | |

| Construction | 104×84/40×40 | |

| GSM | Before wash | 204 |

| After wash | 306 | |

| Tear strength | Warp wise | 29.45 N |

| Weft wise | 23.54 N | |

| Tensile strength | Warp wise | 395.23 N |

| Weft wise | 337.23 N | |

| Shrinkage | Warp wise | -2% |

| Weft Wise | 3.5%- | |

| Crimp percentage | Warp wise | 17.45 % |

| Weft wise | 40.45% | |

Sample 2:

| Weave | Twill | |

| Construction | 80×50/10×10 | |

| GSM | Before wash | 204 |

| After wash | 306 | |

| Tear strength | Warp wise | 43.87 N |

| Weft wise | 27.65 N | |

| Tensile strength | Warp wise | 330.54 N |

| Weft wise | 297.35 N | |

| Shrinkage | Warp wise | -1%- |

| Weft Wise | -2.5% | |

| Crimp percentage | Warp wise | 15.42% |

| Weft wise | 35.67% | |

Sample 3:

| Weave | Dobby | |

| Construction | 102×58/20×920+40D) | |

| GSM | Before wash | 227 |

| After wash | 261 | |

| Tear strength | Warp wise | 45.67 N |

| Weft wise | 27.25 N | |

| Tensile strength | Warp wise | 478.36 N |

| Weft wise | 276.34 N | |

| Shrinkage | Warp wise | 1%- |

| Weft wise | -14% | |

| Crimp percentage | Warp wise | 16.98% |

| Weft wise | 39.08% | |

Sample 4:

| Weave | Twill | |

| Construction | 92×64/20×(20+70D) | |

| GSM | Before wash | 240 |

| After wash | 261 | |

| Tear strength | Warp wise | 16.94 N |

| Weft wise | 43.76 N | |

| Tensile strength | Warp wise | 456.75 N |

| Weft wise | 267.45 N | |

| Shrinkage | Warp wise | -3.5% |

| Weft wise | -9.5% | |

| Crimp percentage | Warp wise | 20.34 % |

| Weft wise | 47.43 % | |

Sample 5:

| Weave | Twill | |

| Construction | 136×76/30×(20+70D) | |

| GSM | Before wash | 223 |

| After wash | 242 | |

| Tear strength | Warp wise | 27.97 N |

| Weft wise | 23.25 N | |

| Tensile strength | Warp wise | 398.7 N |

| Weft wise | 378.7 N | |

| Shrinkage | Warp wise | -2% |

| Weft wise | -9% | |

| Crimp percentage | Warp wise | 10.63 % |

| Weft wise | 37.08 % | |

Sample 6:

| Weave | Twill | |

| Construction | 96×66/21×21cl | |

| GSM | Before wash | 193 |

| After wash | 200 | |

| Tear strength | Warp wise | 37.67 N |

| Weft wise | 32.67 N | |

| Tensile strength | Warp wise | 288.42 N |

| Weft wise | 238.42 N | |

| Shrinkage | Warp wise | -4.5% |

| Weft wise | -1.5% | |

| Crimp percentage | Warp wise | 13.68 % |

| Weft wise | 43.53 % | |

RESULT & DISCUSSION

Graph presentation

Graph 1: GSM result analysis

Here, total 15 constructions of fabrics are examined. The constructed fabrics are Twill, Plain, Dobby. All the GSM has been taken at room temperature. From the graph of the results it can be said that the difference between the GSM of same fabric for before wash and after wash is very little. But, 1,3,6 and 16 no. of fabric from the graph shows different picture.

Graph 2: Shrinkage result analysis

Here total no. of fabric is seven and all are different construction. The shrinkage is measured on the basis of 2 types of drying process on is line drying and another is tumble drying. The graph of the results shows that, the shrinkage is higher for tumble drying process. It also shows that, length wise shrinkage is higher compare with width wise direction.

Graph 3: Tear strength result analysis

Here total no. of examined fabric is 7. And all the fabric is differently constructed. The results from the graph shows that all time warp tear strength is higher than the weft yarn.

Graph 4: Tensile strength result analysis

Here total no. of examined fabric is 7. And all the fabric is differently constructed. The results from the graph shows that all time warp tensile strength is higher than the weft yarn. And from tear and tensile strength graph it is also clear that the fabric which tear strength is higher its tensile strength is also higher than other fabric.

Graph 5: Crimp percentage result analysis

Here total no. of fabric is 6. And the construction of each fabric is different. But the EPI and PPI of 1 & 2, 3 & 4, 5 & 6 no fabrics are same. But these similarities don’t affect the result of crimp percentage.

CONCLUSION

Major finding of our project works are followings:

The creation of weaved fabric is likewise determined in length. The “length” of a sewed fabric for the most part relied upon two elements, in particular the epi and ppi and the yarn count.

- GSM is a significant quality parameter of sewed woven fabric. It very well may be tried by GSM shaper or a few conditions that we talked about previously. From the graph of the results it can be said that the difference between the GSM of same woven fabric for before wash and after wash is very little.

- The graph of the results shows that, the shrinkage is higher for tumble drying process. It also shows that, length wise shrinkage is higher compare with width wise direction.

- Tear and tensile strength are always higher in warp direction. And it is not depending only count but is GSM and EPI, PPI also.

- Fabric recovery after elongation relies between (90-95) % And it should be measured during the production of garments.

- Same counted fabric having different EPI, PPI shows different crimp percentage. Crimp percentage in weft direction is higher because the wavy form of weft yarn.

- Skewness happens when weft yarns are uprooted from their vertical position and warps are dislodged from their flat Adequate scope of skewness is 2%.

- Fabrics quality parameters means and how to measure different quality parameters.

Limitations:

- Limited no. of variation of fabric in case of composition and construction made the working experience tough.

- Maintaining standard climate couldn’t be conceivable during the molding of the woven fabric.

- Due to absence of accessible yarn it was unrealistic to check quality parameters on different mix proportion.

- In time of estimating count of yarn ”check variety” was happened.

- Due to absence of creation verities we can’t break down the quality parameters of all verities of sewed woven fabric.

- Due to absence of lab officers all trial of value parameters wasn’t possible.

Conclusion:

By the finesse of Almighty, we complete our thesis effectively.

Nature of an item resembles blood of human body. For keeping up legitimate nature of an item its basic to keep up all the quality parameters.

By our undertaking work we can learn insights concerning quality parameters of woven fabrics like Fabric EPI & PPI, Fabric width, Dimensional security, Skewness, Bowing, Fabric Strength, Crimp percentage, Fabric GSM, Yarn count, Elongation, Recovery etc.

The present investigation along these lines might be considered as a rule to become familiar with this quality issue on an essential down to earth way.

REFERENCES

- Dictionary of Textile by Books Fair Publication

- Textile Terms & Definitions by – J E Mclintyre

- Understanding Textiles for a Merchandiser by Shah Alimuzzaman Belal

- https://shodhganga.inflibnet.ac.in/bitstream/10603/127368/11/11_chapter2.pdf

- https://www.textilemates.com/quality-control-weaving/

- https://www.testextextile.com/what-is-pilling-in-fabric/