Sewing Defects in Garments:

In order to get the correct appearance and good performance of seams, various considering factors, such as, stitch, seam, feed system, needle, thread, etc. Have to be correctly selected and adjusted. The sewing defects or problems that may arise during sewing, may be as follows and for detection and their solutions. The sewing defects can be classified in three groups, such as,

- Defects or Problems of stitch formation

- Puckering problems, and

- Fabric defects along the sewing line

Elaborate discussions are made below about the probable sewing defects under each group, the reasons of the problems and their probable solutions:

A. Problems of stitch formation:

Due to various reasons, the stitches may be in different shapes and appearances instead of being in the shapes and appearances that should have been. About the various types of sewing defects, probable reasons and the means of solutions are discussed below:

1. Slipped stitch:

There are successive stitches in a seam. Among the successive stitches, if one or more stitches fail in connecting the upper thread with the lower thread, then it is called the slipped stitch or skipped stitch. Slipped stitch is more harmful in case of chain stitch than in case of lockstitch. The probable reasons of slipped stitch and their probable solutions are given in diagram:

Slipped stitch

| Causes | Remedies |

| 1. If the hook or looper or needle cannot enter into the loop of the thread. |

|

| 2. If the size of the loop of the needle thread is small. |

|

| 3. If there is fabric flagging during sewing. |

|

| 4. If the needle bends or if there is needle deflection. |

|

| 5. If there is big maladjustment of tension of upper thread or lower thread. |

|

| 6. If the capacity of loop form of below standard. |

|

2. Staggered stitch:

Each stitch produced by needle should remain parallel to the sewing line. But if the stitches are produced in curve instead of parallel, then it is called staggered stitch. The probable reasons and the ways of their solutions are given in the below table:

Staggered stitch

| Causes | Remedies |

| 1. For needle trembling or deflection. |

|

| 2. Blunt needle point or wrong needle point. |

|

| 3. If the needle size and thread size are not adjusted properly. |

|

| 4. If the movement of the feed dog is defective. |

|

| 5. If the fabric is not controlled well in the feed mechanism. |

|

3. Unbalanced stitch:

This type of sewing defects are frequent specially in lockstitch. The interlacement of upper thread and lower thread is supposed to be just at the middle of the two layers of fabrics. For any reason, if this interlacement is placed at to some extent the upper position or lower position instead of the middle position, then it is called the unbalanced stitch. The possible reasons of unbalanced stitch and the remedies are given in the below diagram:

Unbalanced stitch

| Causes | Remedies |

| 1. If the tension of the sewing thread is not correct. |

|

| 2. If the thread is not passed through the guide properly. |

|

| 3. If there is needle thread snagging with bobbin case and position figure. |

|

| 4. If there is no lubrication in thread (imbalance of tension may happen). |

|

4. Variable stitch density:

The number of stitches per unit length should be uniform, but if it does not happen so for any reason, becomes plus or minus, then it is called variable stitch density. The main cause of variable stitch density is the insufficient pressure in the pressure foot, which causes that fabric cannot enter into the machine in uniform speed. This type of problem may be seen in drop feed mechanism, specially for sewing of smooth fabrics, the tendency of creating this type of problems occur much. For removing problem, good quality feed mechanism may be used and the pressure of the presser foot may be increased.

5. Frequent thread breakage:

The frequent thread breakage during sewing is the wastage of valuable time and it is harmful for production. Specially, it is very much troublesome and laborious task, if the sewing opens due to the breaking of thread, and it is required to open the stitches and then to re-stitching. The causes of frequent breaking of the needle threads and their remedies have been shown below diagram:

Needle thread breakage

| Causes | Remedies |

| 1. Thread is not coming out from the package properly. |

|

| 2. If the needle thread winds at the base of the thread package. |

|

| 3. If thread winds at the guide of the thread. |

|

| 4. If thread snarls up before tension disk. |

|

| 5. If tension is higher in threads. |

|

| 6. If the check spring is broken. |

|

| 7. If the edges of throat plate, hook point, needle guard, bobbin case, needle groove, needle eye etc. are sharp. |

|

| 8. If the twist of threads frays from the needle. |

|

| 9. If the needle temperature is too high. |

|

| 10. If the hook heats too much. |

|

| 11. If the sewing thread is of inferior quality. |

|

The cause of frequent breaking of the bobbin or looper threads and their remedies are shown below diagram:

Frequent bobbin thread breakage

| Causes | Remedies |

| 1. If threads are wound in bobbins defectively. |

|

| 2. If the tension of thread of the bobbin is very high or if the bobbin rotates much. |

|

| 3. If the edges of bobbin case, looper eye or the edge of the spring are very sharp. |

|

| 4. If the bobbin case fitting is not correct. |

|

Except the above mentioned reason, thread may break dew to shutdown of machines. Specially, during the time of sewing with 100% synthetic thread, due to the frictions among needle, fabric and thread, 300 degree centigrade or more temperature may be generated in needles. At this temperature, nylon or polyester threads melt easily. As a result, due to the shutdown of the sewing machine for a temporary period, thread may melt and break by the heat generated from the needle. In order to avoid such problem, core spun thread may be used or arrangement may be kept for keeping the needle cool or good quality needle may be used.

B. Problems of puckering:

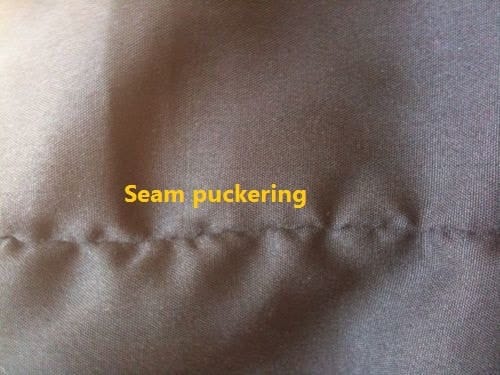

1. Unequal stretch on the plies of fabrics:

When two or more plies of fabrics are sewn together. Then the fabric of each of the ply is supposed to be fed at the same time and at the same speed. But for any reason, especially if there is unbalanced stretch among the plies of the fabrics, one ply of fabric will be more fed than the other, as a result, seam puckering is created along the sewing line. This type of puckering problem happens mainly due to the limitation of the feeding mechanism of the machine. For example, in ordinary drop feed machine, it is very difficult to remove the feed puckering problem.

If feed puckering is to remove, the feed mechanism of the sewing machine should be of good quality. In order to remove feed puckering in drop feed sewing machine, need skilled operator and fabric is to be handled in special mechanism.

2. Fabric dimensional stability:

When two or more types of fabrics are sewn together, later on, specially after the washing of the garments, if the shrinkage of one fabric is bigger than the other, then the differential puckering is created. Before sewing of the fabrics of two or more types together, need to know the properties of their shrinkage. If the shrinkage difference of the two fabrics is 2% or more than that, then if those fabrics are sewn together, puckering will be created.

3. Extension in sewing thread:

During sewing of fabrics, various types of tension happen on the sewing thread. Specially, the tension on the needle thread is bigger than the tension in under thread. Due to this tension, thread is extended to a great extent. After completion of sewing, the garments are removed from the machine, then due to the tension free condition, both fabric and thread, return to their normal volume after being shrinkage. If the shrinkage of both fabric and thread are same, then seam puckering problem does not occur. But, if the thread shrinks greater than fabric, then seam puckering will be created.

In case of puckering due to the extension of sewing thread, sewing arrangement is to be done using the tension of thread as less as possible and if possible, the problem can be solved also by changing the thread.

You may also like: Common Woven Fabric Defects with Pictures

4. Sewing thread shrinkage:

After sewing of the garments with sewing thread, for any reason, if the sewing thread shrinks, then seam puckering is created by gathering of the fabrics along the sewing line. This type of puckering is generally visible after washing and ironing of the garments.

Before sewing of any fabrics or garments, the shrinkage properties of fabric and sewing thread should be learnt. The shrinkage of synthetic sewing thread after washing is very little, because of this, in using this thread, there is no apprehension of such problems.

5. Fabric construction:

During sewing of very densely woven fabrics, that means the large number of warp and weft threads per inch, the threads of the fabrics being displaced around, creates the space for sewing thread. As a result, seam puckering is created by gathering of the fabrics along the holes created by needles. This type of puckering happens for the densely woven fabrics and no appreciable solution is possible by mechanical adjustment of the sewing machine. If puckering is created due to the densely woven fabrics, then it is very difficult to remove it totally. But for reducing the rate of puckering, at least to some extent, steps that can be taken are discussed below:

- The amount of puckering will be reduced if relatively fine thread and fine needles are used.

- If the stitch density per inch is reduced, then also the amount of puckering will be lower, to some extent.

- If possible, fabric is to be cut to some extent bias (15 to 20 degree) and then sewing, then puckering may be less.

- If possible, chain stitch has to be used instead of lockstitch, then problem may be less.

- If possible then fabric itself should be changed.

6. Mismatched patterns:

If two unequal patterns are joined together, then one will be joined with the other with a gathering resulting in a puckering of seam. For this type of problem, mainly the designer is responsible. But sometimes this type of problems also occur due to the joining of wrong patterns.

C. The problems of fabric damage along the sewing line:

During of fabrics, fabric yarn damage or yarn breaking along the sewing line is an unacceptable defect. This type of sewing defects happen mainly due to the needles, specially, if the sewing is done with stanted, bunt or damages needles, then fabric may be damaged. During sewing of fabric, if the fabric is damaged, then strength of the sewing will be weak, if the fabric damage is on a large scale, then there also be fabric tearing along the sewing line may occur.

If the fabric is sewn by damaged needle, then it is natural that there will be fabric damage. But during the sewing of fabric with new and good needle also fabric damage may happen, if the new needle size or needle points are selected wrong. If the fabric is damaged by needle, then the damage may not be visible instantly, but generally, during wearing of that garments after washing, that type of sewing defects are detected. The fabric damage done by needles are of two types, which are discussed below:

1. Mechanical damage:

The damage in fibers or yarns in fabric caused by needle is under mechanical damage. For protecting of fabric from this type of defect, the steps that can be adopted are listed below:

- Need to use the needle in correct sizes and of correct points. Specially, the needle must have to be damage free.

- If the magnitude of the problem is big, then the speed of the sewing machine may be reduced.

- Just before the sewing, lubricant may be used in fabrics along the sewing line.

- Before the sewing of any kind of fabrics, necessary measures may be taken by doing “sewability test”.

2. Needle heating damage:

During sewing of fabrics, friction happens between fabric and needle, heat is generated in needle due to that friction. The amount of this temperature in needle may be from 300 to 350 degree celcious. At this temperature, damage may happen to needle thread or fabric or both. The possibility of this type of damage may be less in case of the fabrics or garments made from natural fiber, but the finishing or coating in fabrics may be damaged.

You may also like: Various Parts of a Sewing Needle with Functions

In case of fabric or garments produced from synthetic fibres, the heat generated from needle, melts the fibers in the fabric which adheres with the needle, resulting the blockage of the groove and eye of the needle. As a result, sewing becomes inconvenient and the produced seam becomes defective and harsh. The damages in sewing and in fabrics that are produced from the defects in the needle and the steps which can be adopted for their remedies are discussed below:

- If the speed of the sewing is reduced, then the heat generated in the needle will be less resulting the reduction of the problems. But if the speed is reduced, then production may be reduced, for this reason, this remedial action may not always be acceptable.

- The friction between fabric and needle may be reduced by changing the size and shape of the needle, as a result, the possibility of fabric damage also reduces.

- Instead of sewing of long length in high speed, if the sewing is done in short length, then less amount of heat will be generated in needle and in consequence of it, the problem will also be small.

- It is possible to bring down the temperature of needle at 70 degree centigrade by blowing cold air on the needle during running of the sewing. But for the cause of saving money and reducing sound, it is necessary to keep arrangement so that the supply of air should remain active only when the needle will be in high speed and it (air supply) should be stopped just the moment of stopping of the speed of the needle.

- The needle or the fabric along the sewing line, or both can be lubricated. But need to be cautious so that no stain happens in the fabric.

- Special type of coated sewing needle, such as, Teflon coated needle may be used.