Study on Sewing Fault and Measurement Variation for Short Sleeve T-Shirt

Authors:

Md. Nawaz Morshed1

Md. Sajuman Al Sajjad

Md. NazimUddin

Dept. of Textile Engineering

Daffodil International University, Dhaka, Bangladesh

Email: nawazmorshedbd@gmail.com1

ABSTRACT

This project presents the different types of sewing fault for bulk production of knit garments. Actually this project made by specific product and style of sewing fault for short sleeve t-shirt . This work is done in TEXEUROP (BD) ltd. During making several garments defects are ascend in multifarious types of knit garments. Major and minor defects are founded such as skip stitch, open seam, broken stitch, stitch gathering, down stitch and dirty oil spot etc. Actually this project giving idea about how many defects present and which types of defects are present. It also giving idea about how to reduce or solution garments defects in better way. Overall this project will be helped for producing better quality knit garments.

INTRODUCTION

1.1 Objectives

- To way to reduce fabric faults;

- To analysis the cutting, sewing and finishing fault data;

- How many time required repairing them;

- Economical effect due to cutting, sewing & finishing faults.

- To analysis the percentage of fabric faults in textile sector for specific products.

1.2 Outcome:

Sewing process is one of the most important stages in labor intensive ready-made clothing enterprises. Quality faults occurring during this process adversely affect the product quality and product efficiency, and also increase the production cost. The aim of this study is to investigate whether the knitwear production process is under control in a knitwear production enterprise and to detect the processes with highest rates of sewing fault in sewing department and finally to make suggestions for improving the quality control.

1.3 Limitation:

During our thesis period we have faced some problem. Those are given below:

- We can’t collect all data due to some restriction

- Without permission of higher authority, we can’t bring some necessary papers.

- Time is also a limitation.

- Gathering information during working was a tough job.

LITERATURE REVIEW

2.1. What is Short Sleeve T-Shirt?

Short sleeve t-shirt is made from various type of fabric for both mens and womens casual wear in daily life. The evolution of the classic t-shirt has been impressive, to say the least. From the first prototype of the union suits developed in the US in the late 1800’s, it has undergone several transformations to emerge as the one of the most versatile men’s garment of clothing. Its 100-year-long tradition that began as a work wear staple to its current role as an ultimate style statement, it is a quintessential garment that has found a place in every man’s heart and wardrobe.

Classification of Short Sleeve T-Shirt:

Short sleeve t-shirt can be classified according to collar into five types. These are given below:

1. Crew-neck style.

Fashion Tip: Probably, the most ubiquitous t-shirt that you will encounter on men is the crew neck t-shirt. It is characterized by a round, circular neckline that fits snugly at the neck and works best on men with long, narrow faces and sloped shoulders to create a well-rounded silhouette. For a timeless look, nothing beats the crew neck t-shirt.

2. V-neck style.

Fashion Tip: As the name suggests, this type of t-shirt forms a V shape at the neck. Guys with round faces and broad shoulders can take advantage of this neckline as it flatters their body type giving them a slimmer look. It can be paired with an unbuttoned shirt wherein the V neckline doesn’t show from underneath the shirt.

3. The Henley y-neck style.

Fashion Tip: The Henley or Y-neck t-shirt is best described as a hybrid between the crew and the V necklines. It comes with a buttoning placket that runs several inches deep and fits perfectly over a well-built, muscular chest. The addition of buttons increases its aesthetic appeal while maintaining an elusive kind of machismo.

4. Polo t-shirt Collar style.

Fashion Tip: Polo t-shirts are made famous by golfers and the collared variety adorned with buttons adds a sense of formality to the look. Men with a lean frame can take the most advantage of this t-shirt type.

5. The Scoop Neck Style

Fashion Tip: Unlike other types of sweater, the gilet can be worn on formal occasions paired with blazer and tie instead of the vest pocket.

2.2 Fabric Used for Short Sleeve T-Shirt

Different types of fabric are used to make short sleeve t-shirt. These are described below:

Cotton

Cotton is the most popular fabric for T-shirts. Cotton is soft, sturdy, and breathable. It is also very affordable. Cotton does wrinkle, so remove from the dryer immediately to prevent this. Cotton is ideal for everyday wear and is casual. Several types of cotton are used in apparel, and each one slightly differs.

Combed Cotton

Slightly more expensive than basic cotton, combed cotton is extremely soft. It is made by specially treating the cotton fibres before spinning them into yarn. To do this, fine brushes are used to get rid of short strands and straighten fibres. The outcome is a stronger, smoother fabric.

Organic Cotton

Organic cotton is grown using methods that do not greatly impact the environment. For example, organic cotton production maintains soil fertility and reduces the need for fertilizers and pesticides. Because of the strict growing methods, organic cotton is more expensive than regular cotton; however, it is very soft to the touch.

Pima/Supima Cotton

Considered the highest quality cotton available, pima cotton is made from extra longfibres. These long fibres make the cotton extremely soft and durable. Supima cotton is the same as pima cotton in texture; it just refers to 100 per cent American grown pima cotton. These cottons resist pilling, fading, and stretching, even after multiple washings. In fact, with each washing, the cotton becomes softer.

Slub Cotton

Slub cotton appears to have slight lumps in the fabric. This is due to the process prior to weaving the cotton where the cotton is twisted, creating irregular twists. The result is a unique fabric with texture to it. Slub T-shirts are light and airy and do not cling to the body. Because the fabric naturally looks textured, there is no need to iron, because it is not designed to look flat.

Linen

T-shirts are also made from linen. Linen is made from the flax plant and has a textured weave. It is lightweight, breathable, and moisture-wicking, making it a good choice for summer wear. By the very nature of the fabric, it is stronger when damp. With repeated washings, it gets softer and softer. The only downside to choosing a linen T-shirt is that it wrinkles easily and often requires ironing.

Lycra

Shoppers often hear the term lycra; however, this is the brand name for the material known as spandex. Spandex, or lycra, is a stretchy material that is often added to T-shirts to give them a little more “give”. This material is most often found in athletic apparel since it allows for easy movement.

Polyester

Polyester is an extremely strong fabric that has many advantages. It is quick drying, does not mould or mildew, and is very easy to machine wash and dry. After repeated wear and washings, it retains its shape and resists shrinking or stretching. Thus, it is an excellent material often seen in athletic apparel.

Rayon

Created as a more affordable alternative to silk, rayon is a man-made fibre created from trees, cotton, and plants. It is woven or knitted into a silky, breathable fabric, and is often found in athletic wear. It drapes easily, is simple to dye, and is extremely absorbent. However, it does not hold up well over prolonged wear; it tends to become yellowed and pilly. Rayon also wrinkles easily.

Modal

A form of rayon made from beech wood plant fibers, it has a beautiful drape and a slinky feel. Modal is soft and breathable. It is cool to the touch and dries quickly when wet, making it perfect for summer wear. It is shrink-resistant and fade-resistant. It stays soft and does not pill quickly, in contrast to regular rayon.

Blends

Often, T-shirts are a combination of two or three materials. A very popular example is a cotton and polyester blend. By combining these two fabrics, the best qualities from both result. This blend remains cool and lights from the cotton fibres, yet it also has the strength and wrinkle-resistance of polyester.

2.3 Sewing Fault of Short Sleeve T-Shirt

A. Skip Stitch

Stitches in the seam are present in a regular wise. If the interloping or interlacing between top & bottom thread of stitch is not take place or missed is known as skipped stitch. This is more harmful in case of chain stitch than lock stitch.

Causes:

- Failure of hook or looper and needle to enter loop at correct time

- Irregular thread tension on upper or lower loop

- Due to needle deflection

- If needle thread loop size is too small.

- If sewing thread is unable to form loop.

Remedies:

- Examine the setting and timing between needle and hook or lopper

- The tension of thread should be adjusted.

- Needle should be changed.

- Needle size and thread should be adjusted.

- Thread should be changed

B. Unbalanced Stitch

Thread tensions generally cause unbalanced stitches and give poor appearance.

Causes:

- Thread tension

- Thread passes through wrong path

- Bobbin case and positioning finger snagging

- If the threads are not lubricated

- Incorrect adjustment of needle thread path.

- Used incorrect thread path.

Remedies:

- Control thread tension

- Control thread twisting

- Make bobbin case smooth and reset positioning finger

- Better qualities of Lubricate threads must be used

C. Slipped Stitch

Missing of interloping or interlacing top and bottom.

Causes:

- Hook or needle failing to enter thread loops at the correct time

- Thread loop failure caused by incorrect needle size.

- Flagging of fabric due to large throat plate hole

- Incorrect sewing tension in the needle

Remedies:

- Machine clearances and timings should be checked

- Check if the needle is inserted and aligned correctly

- Needle size should be changed.

- The hole of throat plate & needle size must be adjusted.

D. Seam Puckering

When the smooth fabric appearance turned wrinkled by the way of seam is called Pucker. It is generally happened when there is too much fabric and not enough thread in the seam. Pucker is one of the most repeatedly occurring sewing defects on fabric. Seam puckering in garments is the combination of many causes. Generally seam puckering in cloth is seen after sewing and washing.

Causes:

- Higher thread tension

- Improper thread balance

- Incorrect thread type.

Remedies:

- Bobbin tension should be kept as low as possible.

- Proper thread balance should be ensured between top and bottom thread.

- Have to maintain tension guides properly.

E. Staggered Stitch

If the stitches produced by needle are not parallel or become curvy to sewing line is known as staggered stitch.

Causes:

- Needle vibration or deflection

- Incorrect or blunt needle point.

- Feed dog away.

- Poor fabric control, presser foot bounce

- Wrong adjustment of needle & thread size.

Remedies:

- Increase needle size or change to a reinforced or tapered needle.

- Change the needle.

- Tighten the feed dog.

- Reset the presser foot. Change the feed mechanism.

- Needle size & thread size to be changed.

F. Unbalanced Stitch

Improper interlacement of thread especially in lock stitch machine.

Causes:

- Wrong tension of sewing thread.

- Used wrong thread path.

- Wrong adjustment of needle thread path

- If the threads are not lubricated.

- Snagging of needle with bobbin case & positioning finger.

Remedies:

- Setting of proper tension to the sewing threads

- Use of right thread path

- Improper thread balance

G. Variable stitch density:

When number of stitch per unit length is not equal.

Causes:

- Improper unwinding of thread from package during sewing

- Twisting of needle thread in the bottom of thread package

- Twisting of thread in the thread guide

- Snarling of thread before tension disk

- More tension to the thread

Remedies:

- The position of thread guide must be 2.5 times higher than the position of thread package

- Foam pad must be used to the bottom of thread package

- Proper threading of sewing thread during sewing

- The edges must be smooth, and needle must be changed as needed

- Finer threads must be used or to be used heavy needle.

H. Frequent Thread Breakage

This is the breakage of thread again & again during sewing. And also there needs more time and which is harmful for production. Specially, when there needs to open out of sewing to solve the problem.

Causes:

- Wrong winding of threads on to the bobbin

- More tension to the bobbin threads

- If the edges bobbin case, lopper eye and so on are more sharpened

- Wrong fitting of bobbin case

Remedies:

- Proper winding of threads on to the bobbin

- The tension must be adjusted to the bobbin threads

- The edges to be smooth

- Examine the size & type of bobbin.

I. Broken Stitch

Section of the garment that has not been covered by sewing thread that is broken or open seam.

Causes:

- This problem due to improper handling of the parts of garments, improper setting and timing between needle and lopper or hook etc.

Remedies:

- Clear markings for stitch line

- Fine quality or D-core thread must be used

- Pattern needs to be correct

- Perfect setting and timing between needle and looper or hook

- Proper handling of the parts of garments

J. Oil spot

Causes:

For various purpose sewing machine parts may be jammed or in need of cleaning or maintenance. The machine should be oiled or lubricated. Sewing machine needle also be lubricated by oil for reducing friction. If the machine at that time, there might be get an oil mark. For this, need to run a test thread and fabric through the machine to remove excess oil.

Remedies:

At first, pretreated with the pre-wash stain remover, liquid laundry detergent. After that, launder the garments by using hottest water safe for fabric.

K. Mechanical damage:

It is happened due to wrong needle selection or needle damage. But it may be happened in case of new or fine needles

The followings are the steps to be taken to keep the fabrics free from this type of defect:

- By using perfect size & shape of the needle & needle point without any defect.

- By reducing the speed of sewing machine

- By using lubricant.

- By testing sew ability before sewing fabrics.

L. Needle heating damage:

The damage of fabric due to friction occurred between the needle & fabrics. The fabric can be damaged with that temperature. There is a less possibility of damaging in case of fabrics made from natural fibers.

You may also like: Sewing Defects Causes and Remedies in Apparel Industry

The following are the steps to be taken to keep the fabrics free from this type of defect:

- By changing needle Size & shape so that there is less generating of heat to the needle.

- By sewing smaller length at higher speed.

- By using lubricant to the needle.

- By using Teflon coated needle.

2.4 Measurement of Short Sleeve T-Shirt

Garment measurement techniques have been designed to show how and where to measure a wide variety of different measurement points on finishing garments across all product areas. Garment measurement guidelines should be used when reviewing size specifications, measuring garments and also creating sample product. Measurements of garments can also contribute to minimize production time and reduce production cost. Every reputed garment manufacturing industry has a garments measurement department. They use some essential key points of measurement to get a perfect pattern and get a perfect sample.[4]

Preparation for Measuring Garments:

- Smooth and flat surface table must be used.

- Garment must be buttoned and zipped unless otherwise specified

- Garment with non-closure must be overlapped as specified

- Carefully remove all folds, wrinkles or creases on garment without any distort.

How to take garment measurement:

Certain rules or guidelines should be followed in making measurements of garments so that all concerned use the same measurement methods or technique. A company should have the guidelines in writing and as a part of quality policy. Correctly measuring garments is essential to achieve the high quality garment.

How to measure a basic T-Shirt:

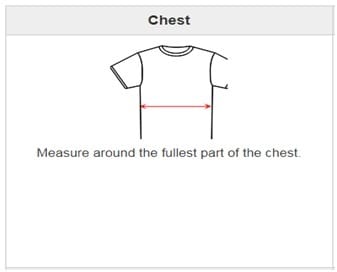

Chest: Measure around the fullest part of the chest

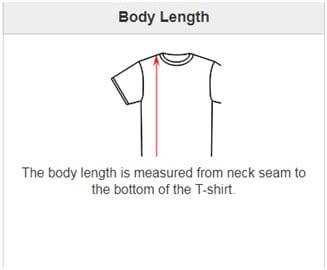

Body Length: The body is measured from neck

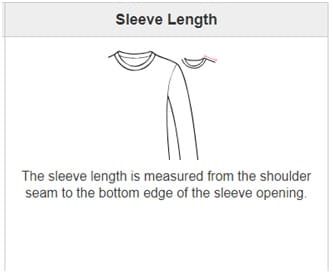

Sleeve Length: The sleeve length is measurement from the shoulder seam to the bottom edge of the sleeve opening.

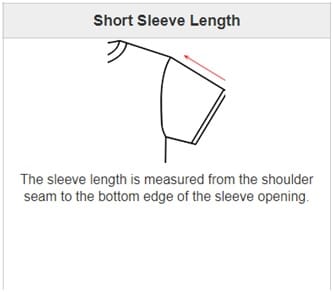

Short sleeve length: The sleeve length is measurement from the shoulder seam to the bottom edge of the sleeve opening.

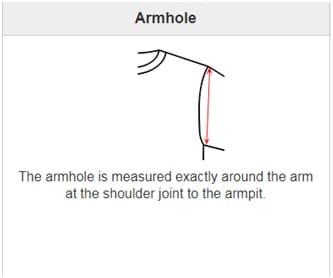

Arm Hole: The arm hole is measured exactly around the arm at the shoulder joint to the armpit.

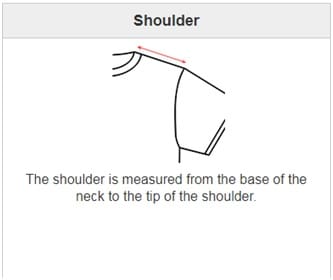

Shoulder: The shoulder is measured from the base of the neck to the tip of the shoulder.

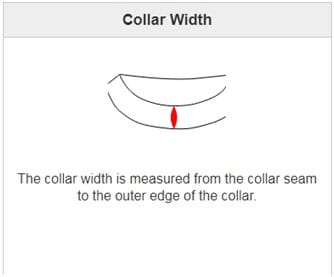

Collar Width: The collar width is measured from the collar seam to the outer edge of the collar.

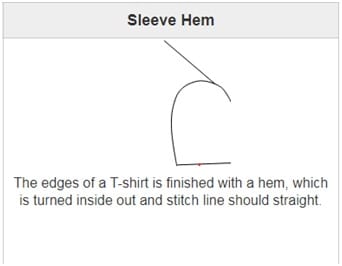

Sleeve Hem: The edges of a T-shirt is finished with a hem, which is turned inside out and stitch line should straight.

2.5 Machine Layout of a Short Sleeve T-Shirt

| Operation Name | Machine name |

| Shoulder Join | Overlock m/c |

| Care Label | Plain m/c |

| Sleeve Join | Overlock m/c |

| Neck Rib Join | Overlock m/c |

| Neck Stich Open | Helper |

| Neck End Tack | Plain m/c |

| Neck Close | Overlock m/c |

| Loop Join | Plain m/c |

| Back Neck Piping | Flat lock m/c |

| Back Tack & Scissoring | Plain m/c |

| Front Neck Top Stitch | Flat Lock m/c |

| Back Neck Top Stitch | Flat Lock m/c |

| Side Join | Overlock m/c |

| Bottom Hem | Flat Lock m/c |

| Sleeve Hem | Flat Lock m/c |

EXPERIMENTAL DETAILS

3.1 Garments Picture

Fig 3.1

Buyer: Poly concept

Style no: 38024

Description: Short sleeve T-Shirt

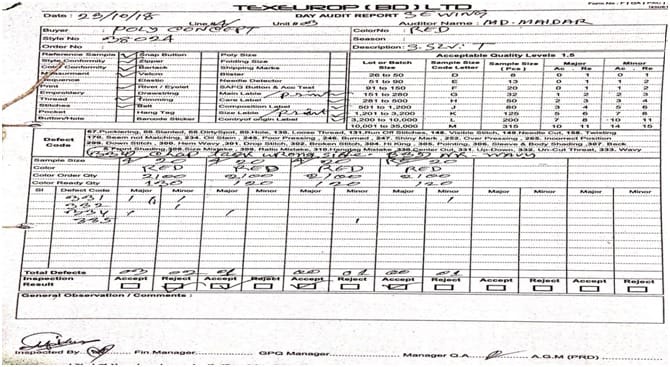

3.2 Scan Data of Sewing Fault

3.2.1 Summery Analysis

| Sample size | 4/20 | 4/20 | 4/20 | 4/20 | ||||

| Color | Red | Red | Red | Red | ||||

| Color order Qty | 2100 | 2100 | 2100 | 2100 | ||||

| Color Ready Qty | 130 | 120 | 120 | 120 | ||||

| Detect Name | Major | Minor | Major | Minor | Major | Minor | Major | Minor |

| Up-Down | 1 | 1 | 1 | |||||

| Un-cut Thread | 1 | 1 | ||||||

| Chap tack wrong side | 1 | 1 | ||||||

| Neck wavy | 1 | |||||||

| Total Defects | 03 | 02 | 01 | 01 | 01 | |||

| Inspection Result | Reject | Accept | Accept | Accept | ||||

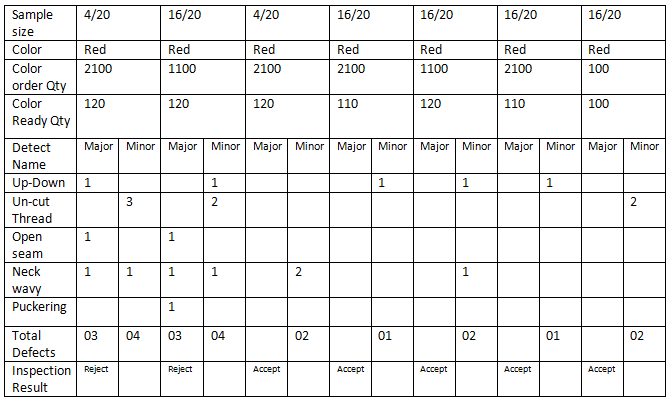

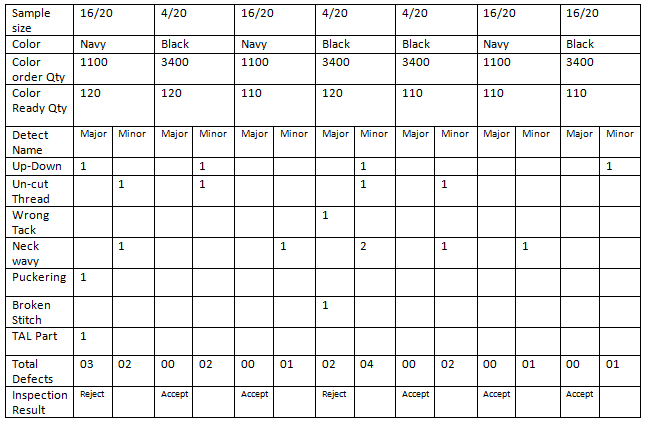

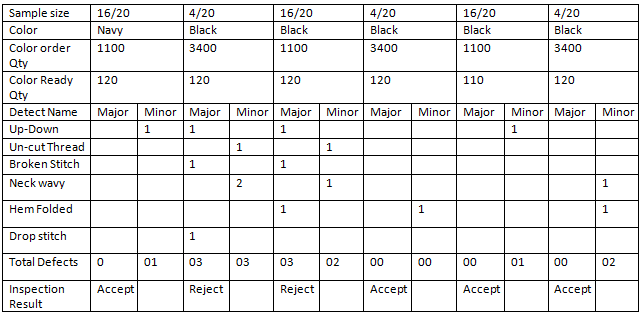

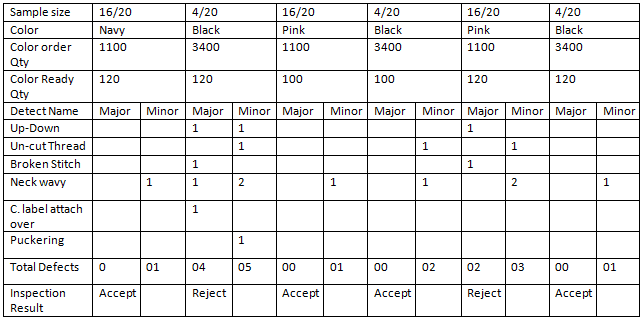

3.2.2 Summery Analysis

3.2.3 Summery Analysis

| Sample size | 16/20 | 4/20 | 16/20 | 4/20 | 16/20 | |||||

| Color | Grey | Red | Grey | Red | Grey | |||||

| Color order Qty | 1100 | 2100 | 1100 | 2100 | 1100 | |||||

| Color Ready Qty | 120 | 120 | 120 | 130 | 120 | |||||

| Detect Name | Major | Minor | Major | Minor | Major | Minor | Major | Minor | Major | Minor |

| Up-Down | 1 | 1 | 1 | |||||||

| Un-cut Thread | 2 | 1 | 1 | 1 | ||||||

| Open Seam | 1 | 2 | ||||||||

| Neck wavy | 2 | 2 | 1 | |||||||

| Total Defects | 02 | 04 | 00 | 02 | 00 | 01 | 03 | 03 | 00 | 01 |

| Inspection Result | Reject | Accept | Accept | Reject | ||||||

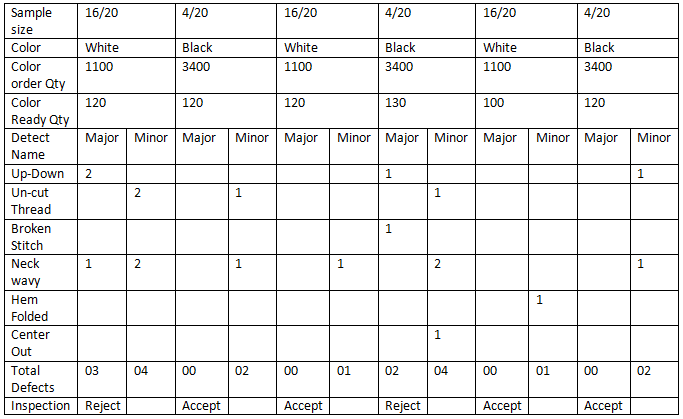

3.2.4 Summery Analysis

3.2.5 Summery Analysis

3.2.6 Summery Analysis

3.2.7 Summery Analysis

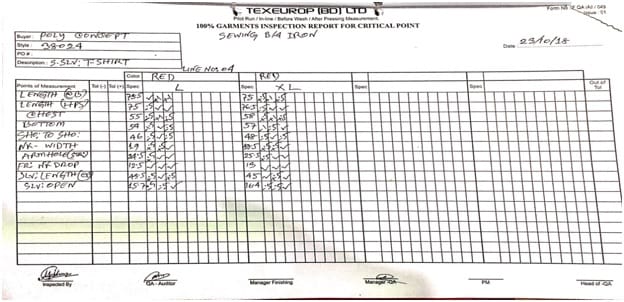

3.3 Scan Data of Measurement

3.3.1 Summery Analysis

| Point of measurement | Spcf. | L/Red | Spcf. | XL/Red | Line 04 | ||||

| Length (CB) | 73.5 | ü | +1 | +1 | 75 | +0.5 | +1 | +0.5 | |

| Length (HPS) | 75 | -0.5 | ü | ü | 76.5 | -0.5 | ü | ü | |

| Chest | 55 | -0.5 | +1 | +0.5 | 58 | +0.5 | +1 | +0.5 | |

| Bottom | 54 | -1.5 | ü | -0.5 | 57 | -1 | -0.5 | ü | |

| Shoulder to Shoulder | 46 | -0.5 | ü | -0.5 | 48 | -0.5 | ü | -0.5 | |

| Neck Width | 19 | +0.5 | +0.5 | ü | 19.5 | +0.5 | +0.5 | ü | |

| Arm Hole Straight | 24.5 | +0.5 | ü | ü | 25.5 | +0.5 | ü | ü | |

| Front neck drop | 12.5 | ü | ü | ü | 13 | ü | ü | ü | |

| Sleeve Length | 43.5 | +0.5 | ü | +0.5 | 45 | ü | +0.5 | ü | |

| Sleeve Open | 15.7 | -0.5 | -0.5 | ü | 16.4 | -0.5 | -0.5 | ü | |

3.3.2 Summery Analysis

| Point of measurement | Spcf. | M/Red | Spcf. | XL/Red | Line 16 | ||||

| Length (CB) | 62 | +1.5 | +1.5 | +2 | 67 | +2 | +1.5 | +1.5 | |

| Length (HPS) | 63.5 | +1 | +1.5 | +2 | 68.5 | +1.5 | +1.5 | +1.5 | |

| Chest | 46 | +0.5 | +1 | +1 | 52 | +1.5 | +1 | +1.5 | |

| Waist | 39 | +1 | +1 | +1 | 45 | +1 | +1 | +1 | |

| Bottom | 46 | +0.5 | ü | ü | 52 | ü | ü | ü | |

| Shoulder to Shoulder | 38 | +1 | +1 | +0.5 | 42 | +1 | +1 | +1 | |

| Neck Width | 18.5 | +2.5 | +1 | +1 | 19.5 | +1.5 | +1 | +1.5 | |

| Arm Hole Straight | 22.5 | -1 | -0.5 | ü | 24.5 | ü | ü | ü | |

| Front neck drop | 12.5 | ü | ü | ü | 13.5 | -0.5 | -0.5 | ü | |

| Sleeve Length | 38 | ü | ü | ü | 41 | +0.5 | ü | ü | |

| Sleeve Open | 15 | ü | ü | ü | 16 | ü | ü | ü | |

3.3.3 Summery Analysis

| Point of measurement | Spcf. | M/Grey | Spcf. | XL/Red | Line 16 | ||||

| Length (CB) | 62 | +1 | -0.5 | +0.5 | 67 | +1 | +.5 | +1 | |

| Length (HPS) | 63.5 | +0.5 | -1 | +1 | 68.5 | +1 | +1 | +1 | |

| Chest | 46 | +2 | -1 | +1 | 52 | +0.5 | ü | +.5 | |

| Waist | 39 | +2 | ü | +2 | 45 | +2 | ü | +0.5 | |

| Bottom | 46 | +1 | ü | +0.5 | 52 | ü | ü | ü | |

| Shoulder to Shoulder | 38 | +1.5 | +1 | +1 | 42 | +0.5 | ü | +0.5 | |

| Neck Width | 18.5 | +1 | +1.5 | +1 | 19.5 | ü | ü | ü | |

| Arm Hole Straight | 22.5 | ü | ü | ü | 24.5 | ü | ü | ü | |

| Front neck drop | 12.5 | ü | ü | ü | 13.5 | ü | ü | ü | |

| Sleeve Length | 38 | ü | ü | ü | 41 | ü | ü | ü | |

| Sleeve Open | 15 | ü | ü | ü | 16 | ü | ü | ü | |

3.3.4 Summery Analysis

| Point of measurement | Spcf. | L/White | Spcf. | XL/Black | Line 04/16 | ||||

| Length (CB) | 64.5 | +1 | +1 | +1 | 78 | +0.5 | +1 | +0.5 | |

| Length (HPS) | 66 | +1.5 | +1 | +1 | 79.5 | -0.5 | +0.5 | +1 | |

| Chest | 49 | +1 | +2 | +1.5 | 64 | +1 | +1 | +1 | |

| Waist | 42 | +1.5 | 2 | +1.5 | —- | —- | —- | —- | |

| Bottom | 49 | -0.5 | -0.5 | ü | 63 | -1 | -1 | -0.5 | |

| Shoulder to Shoulder | 40 | +0.5 | +1.5 | +1 | 52 | -1 | -0.5 | ||

| Neck Width | 19 | +1.5 | +1 | +1.5 | 20.5 | +1.5 | +0.5 | +1.5 | |

| Arm Hole Straight | 23.5 | ü | ü | ü | 27.5 | +0.5 | ü | +0.5 | |

| Front neck drop | 13 | -0.5 | ü | ü | 14 | ü | ü | ü | |

| Sleeve Length | 39.5 | ü | ü | ü | 48 | -0.5 | -0.5 | _1 | |

| Sleeve Open | 15.5 | ü | ü | ü | 17.5 | +0.5 | +0.5 | ü | |

3.3.5 Summery Analysis

| Point of measurement | Spcf. | M/Grey | Spcf. | XL/Red | Line 16 | ||||

| Length (CB) | 62 | +1.5 | +2 | +1.5 | 67 | +1.5 | +1 | +1 | |

| Length (HPS) | 63.5 | +1 | +1.5 | +1 | 68.5 | +1.5 | +1 | +1 | |

| Chest | 46 | +0.5 | -0.5 | +0.5 | 52 | +1 | +0.5 | +1 | |

| Bottom | 46 | ü | -1 | -0.5 | 52 | -0.5 | -0.5 | ü | |

| Shoulder to Shoulder | 38 | -1 | -0.5 | -1 | 42 | ü | ü | ü | |

| Neck Width | 18.5 | +0.5 | +0.5 | +0.5 | 19.5 | +1.5 | +1 | +1.5 | |

| Arm Hole Straight | 22.5 | ü | ü | ü | 24.5 | -0.5 | ü | -0.5 | |

| Front neck drop | 12.5 | ü | ü | ü | 13.5 | ü | ü | ü | |

| Sleeve Length | 38 | -1 | -0.5 | -0.5 | 41 | ü | ü | ü | |

| Sleeve Open | 15 | ü | ü | ü | 16 | -0.5 | ü | -0.5 | |

3.3.6 Summery Analysis

| Point of measurement | Spcf. | M/Red | Spcf. | XL/Red | Line 16 | ||||

| Length (CB) | 67 | +2 | +2 | +1.5 | 62 | +2 | +1.5 | +1 | |

| Length (HPS) | 68.5 | +2 | +1.5 | +1 | 63.5 | +1.5 | +1 | +1 | |

| Chest | 52 | +0.5 | ü | ü | 46 | ü | +0.5 | ü | |

| Waist | 45 | +1 | +1 | +0.5 | 39 | +1 | +0.5 | +1 | |

| Bottom | 52 | +0.5 | -1 | -1 | 46 | -1 | -0.5 | -0.5 | |

| Shoulder to Shoulder | 42 | ü | ü | -0.5 | 38 | -0.5 | ü | -0.5 | |

| Neck Width | 19.5 | +0.5 | +0.5 | ü | 18.5 | +0.5 | ü | +0.5 | |

| Arm Hole Straight | 24.5 | +0.5 | +1 | +0.5 | 22.5 | +0.5 | ü | +0.5 | |

| Front neck drop | 13.5 | ü | ü | ü | 12.5 | ü | ü | ü | |

| Sleeve Length | 41 | -1 | -0.5 | -1 | 38 | -0.5 | -1 | +0.5 | |

| Sleeve Open | 16 | ü | ü | ü | 15 | ü | ü | ü | |

3.4 Summary of Sewing Fault:

| Date | Color | Defect | Result | Lot to be Recheck | |

| Major | Minor | ||||

| 23/10/18 | Red | 4 | 4 | Recheck | 1st lot |

| 24/10/18 | Red | 6 | 16 | Recheck | 1st& 2nd lot |

| 25/10/18 | Red + Grey | 3 (Red) 2 (Grey) | 5 (Red) 6 (Grey) | Recheck | 1st lot (Grey) 4th lot (Red) |

| 27/10/18 | White + Black | 3 (White) 2 (Black) | 6 (white) 8 (Black) | Recheck | 1st lot (White) 4th lot (Black) |

| 28/10/18 | Navy + Black | 3 (Navy) 2 (Black) | 4 (Navy) 9 (Black) | Recheck | 1st lot (Navy) 4th lot (Black) |

| 29/10/18 | Navy + Black | 0 (Navy) 6 (Black) | 1 (Navy) 8 (Black) | Recheck | 2nd& 3rd lot (Black) |

| 30/10/18 | Navy+ Black+ Pink | 0 (Navy) 4 (Black) 2 (Pink) | 1 (Navy) 8 (Black) 4 (Pink) | Recheck | 2nd (Black) 5th (Pink) |

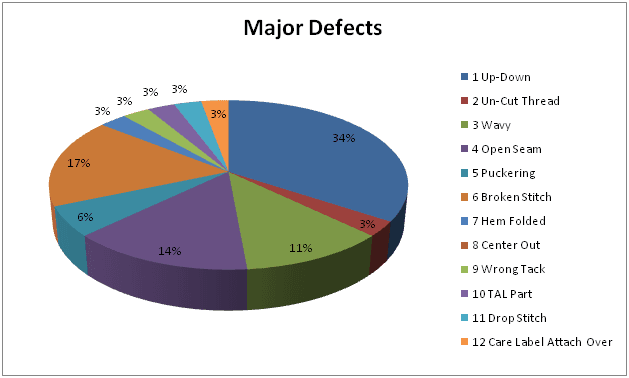

3.4.1 Sewing fault found in total style

| SL no. | Defect Name | Total Major Defects |

| 1 | Up-Down | 12 |

| 2 | Un-Cut Thread | 1 |

| 3 | Wavy | 4 |

| 4 | Open Seam | 5 |

| 5 | Puckering | 2 |

| 6 | Broken Stitch | 6 |

| 7 | Hem Folded | 1 |

| 8 | Center Out | 0 |

| 9 | Wrong Tack | 1 |

| 10 | TAL Part | 1 |

| 11 | Drop Stitch | 1 |

| 12 | Care Label Attach Over | 1 |

3.4.2 Graphical Analysis

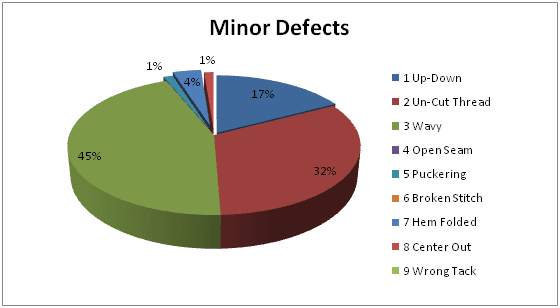

3.4.3 Sewing fault found in total style:

| SL no. | Defect Name | Total Minor Defects |

| 1 | Up-Down | 14 |

| 2 | Un-Cut Thread | 26 |

| 3 | Wavy | 36 |

| 4 | Open Seam | 0 |

| 5 | Puckering | 1 |

| 6 | Broken Stitch | 0 |

| 7 | Hem Folded | 3 |

| 8 | Center Out | 1 |

| 9 | Wrong Tack | 0 |

| 10 | TAL Part | 0 |

| 11 | Drop Stitch | 0 |

| 12 | Care Label Attach Over | 0 |

3.4.4 Graphical Analysis

DISCUSSION

4.1 Discussion on Sewing Fault

According to ‘Acceptable Quality Levels 1.5’ here we inspect 20 sample pcs from 90-150 pcs lot. Here we inspect the sewing fault from these samples. The acceptance or recheck of the lot may vary by the presence of sewing fault. Here we define the fault variation by mention by:

- Major Fault

- Minor Fault

Major fault is one that is likely to create failure of the sewing.

Minor fault is a discrepancy from the standards but not likely to affect the usability of sewing.

Here we found some major fault in sewing:

| Defect Name | Total Major | Total Minor |

| Up-Down | 12 | 14 |

| Un-Cut Thread | 1 | 26 |

| Wavy | 4 | 36 |

| Open Seam | 5 | 0 |

| Puckering | 2 | 1 |

| Broken Stitch | 6 | 0 |

| Hem Folded | 1 | 3 |

| Center Out | 0 | 1 |

| Wrong Tack | 1 | 0 |

| TAL Part | 1 | 0 |

| Drop Stitch | 1 | 0 |

| Care Label Attach Over | 1 | 0 |

The tolerance of this garments is‘1 major and 2 minor’ defects from a lot samples. Otherwise if we found 2 major or 3 minor defects or more from a lots sample then the whole lot must be recheck and rectify these defects.

Here is some reason to create these kinds of defects:

- Operator awareness

- Mechanism fault

- Fabric fault

- Lack of operator skills.

4.2 Discussion on Measurement Variation

After get clearance from sewing inspection, the garments are inspected in measurement section.

Here 3 sample are collecting from every color and every size. After collecting the samples, these are checked that the sample measurement is fulfilled the buyer requirement or not.

The tolerance of buyers requirement is maximum ±2 cm.

If we found the variation of measurement over or less than ± 2cm then the lot must be recheck and rectify the problem.

Causes of Measurement variation:

- Operator awareness

- Cutting problem detect

- Mechanism problem of sewing machine.

5. CONCLUSION

In this project we discuss about different types of sewing fault for bulk production of knit garments. Actually in this project we made some specific product and style of sewing fault for short sleeve t-shirt .We done this project by the help of employee of TEXEUROP (BD) ltd’. During making several garments defects are ascend in multifarious types of knit garments. In this project we found some major and minor defects are founded such as up-down, thread un-cut, neck wavy, skip stitch, open seam, broken stitch, stitch gathering, down stitch and dirty oil spot etc. Actually this project giving us the idea about how many defects present and which types of defects are present.It also giving us the idea about how to reduce or solution garments defects in better way. We also found the variation measurement. Overall this project will be helped for producing better quality knit garments.

6. References:

- Garments Technology by Prof. M. A. Kashem

- Garment Manufacturing Technology by Md. Shafiul Azam, Md. Abu Saleh & Khondokar Abu Nafiz

- http://www.garmentsmerchandising.com/8-sewing-faults-with-causes-and-remedies/

- https://textilelearner.net/causes-and-remedies-of-sewing-problems/

- http://fashion2apparel.blogspot.com/2016/12/defects-stitch-formation-apparel.html

- https://www.apparelnbags.com/how-to/measuring-t-shirt.htm

- http://fashion2apparel.blogspot.com/2017/11/garment-measurement-guidelines.html