Single Guide Bar Fabrics:

Single guide bar fabrics are the simplest warp knitted fabrics, produced from one guide bar, usually by full threading. All yarns in such fabrics have the same orientation, and the forces in the loop heads are often come in equilibrium after deformation of the structure, so the loops can have different angles. Single guide bar fabrics can be interpreted as the basic element, which is used for the design of more complex structures and multiple bar structures. The multi bar structures are a combination of several single bar structures, but not all pattern and threading of single guide bars produce stable structures.

Characteristics of Single Guide Bar Fabrics:

Warp knit fabrics produced by single guide bar alone have the following drawback:

1. Poor Dimensional Stability: Like a loosely knitted single jersey in weft knitting.

2. Lower Patterning potential: One of the main fabric design elements on warp knit is the use of guide bars. The modern raschel machines have expanded from 48 guide bars to 76 just for the purpose of increasing the pattern potential.

3. Poor Cover: In knitting the regular structures, the number of yarns used to form a loop is directly proportional to the number of guide bar. For single bar fabrics, most loops are composed of one yarn only and consequently the cover is not as good as 2 or 3 guide bar.

4. Loop distortion: The loops of each course tend to deflect to the same direction as the guide bar overlap. This problem is not so serious in those two or more bar fabrics, simply because the guide bars usually move in a direction opposite to each other.

5. Edge curling: All single bar fabrics are made of unbalanced structures and fabrics will curl to one side.

Different Types of Single Guide Bar Fabrics:

- Pillar stitch chains

- Cord stitch fabrics

- Tricot stitch fabrics

- Satin and velvet fabrics

- Atlas fabrics

- Combined stitches

Above single guide bar fabrics are described below.

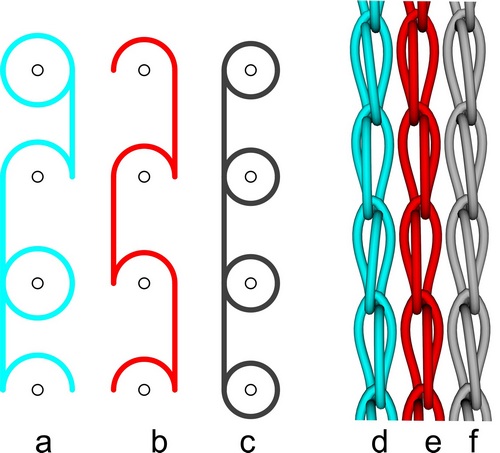

1. Pillar stitch chains:

Pillar stitches are built when the yarn guide produces lapping around one and the same needle. Such motion leads to production of vertical courses, which are not connected into fabrics. These are used mainly often as a ropes, or as a basic element in meshes and as a ground for structures, connected by weft yarns or other loops. All three types of the pillar stitches can be used – the open, closed and open-closed (Figure 1).

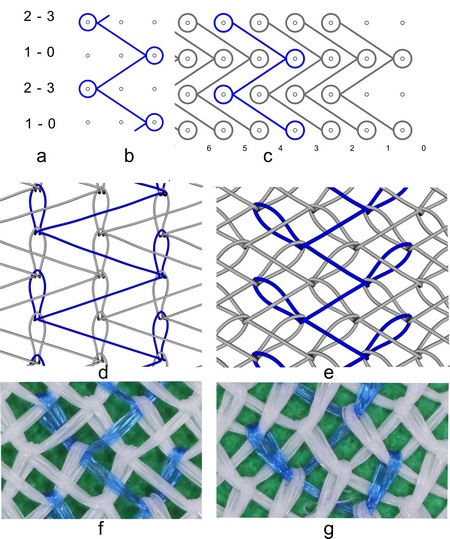

2. Cord stitch fabrics:

Cord stitch fabrics at full threading can be recognized through the underlap behind one loop. The configuration with closed loops in simulated and photographic images is represented in Figure 2. The underlaps determine the optics of the technical face side Figure 2. f), while on the technical back the loop faces are visible Figure 2 g). The loops in the relaxed stay are more declined to the horizontal side in comparison to the loops of the tricot stitch, because of the larger paths to left and right.

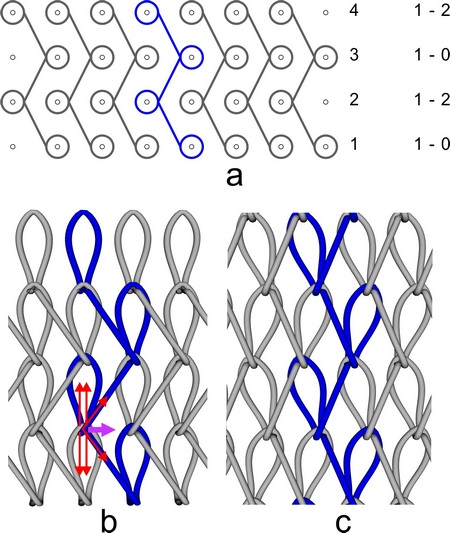

3. Tricot stitch fabrics:

Tricot fabrics are the simplest plain fabrics, where the individual chains are connected at every course. The example structure with closed lap is demonstrated in Figure 3 as idealized simulation Figure 3 b), with adjusted vertical orientation of the loops Figure 3 c).

4. Satin and velvet fabrics:

For the structures, where longer oatings of the yarns are needed, the satin (under 3 over 1) and velvet (4 – 1 or under 4 over 1) lapping in full threading are used. These structure have more shine and a smooth technical face because of the longer underlaps. Using partial threading – 1 in 2 out or (A..) for satin or 1 in 3 out (A…) for velvet can be used as well for production of tricot fabrics with lower density. Using velvet with 1 in 1 out (A.) leads to a cord fabrics with lower density.

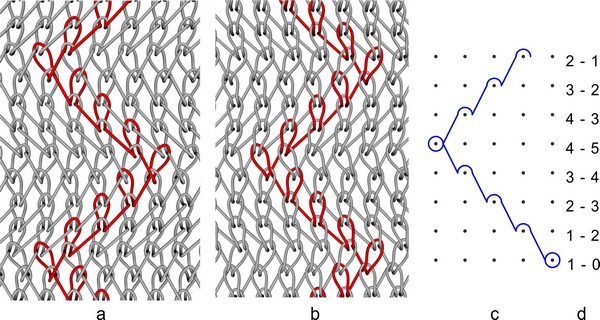

5. Atlas fabrics:

The atlas lapping can be used for the production of the lightest fabrics. The technical back of the open atlas (Figure 4) looks very similar to horizontal stripes of weft knitted fabrics, where the stripe width depends on the number of the courses of the atlas. These structures have the lowest weight per unit surface as they are built with the shortest yarn length per course, because there are practically no underloops there. Closed atlas fabrics are similar, but built of closed loops. The loops of single guide bar atlas fabrics do not remain vertical and are tilted to one or other side because of the assymetric loading from the yarns of their previous and following loops.

6. Combined stitches:

All basic stitch types can be combined in a sequence for the building of more complex lapping. Such combinations are used normally for fabrics of two or more bars (multibar technique), but in some cases they can be applied as well on single guide bar structures. One such example is the combination of lock stitch and tricot for the building of a simple mesh structure. The length of the part with lock-stitch determines the length of the mesh elements.

Conclusions:

Tricot, cord, velvet, satin and atlas laps applied on single guide bar with full threading leads to production of warp knitted fabrics. The lock stitch produces only vertical chains, which are not connected together into wider fabrics. All laps over two needles (including lock stitch 0-2/0-2//) produce fabrics; they can be used as well with full and half threading. The laps with longer underlaps (cord, velvet, satin) and the back lapped atlas can be applied with partial threading of the guide bar for production of fabrics with lower density on the same machine. Single guide bar fabrics are very light structures, whose loops change their vertical orientation during the relaxation process.

References:

- Warp Knitted Fabrics Construction By Yordan Kyosev

- Knitting Technology by David J Spencer

- Reference Book for Knitting By Carmine Mazza and Paola Zonda

- https://studylib.net

You may also like:

- What is Knitting and Knitted Fabric | Features of Knitted Fabrics

- Derivatives of Single Jersey and Double Jersey Weft Knitted Structures with Cam and Needle Arrangement

- 100 Different Types of Fabric and Their Uses