Introduction:

The term circular covers all those weft knitting machines whose needle beds are arranged in circular fashion. Single jersey fabric is produced by the plain circular latch needle machine. In this machine only one set of latch needle is used. Here the cylinder and the sinker ring revolve through the stationary knitting cam system. Yarn feeders which are stationery, situated at the regular interval around the circumference of the cylinder. Yarn supplied from the cones. Sinker cam system is mounted outside on the needle circle. The center of the cylinder is open and the machine is perforated.

Objects:

- To acquire the knowledge of identification about the main parts of the single jersey circular knitting machine.

- To acquire the knowledge of their functions and uses.

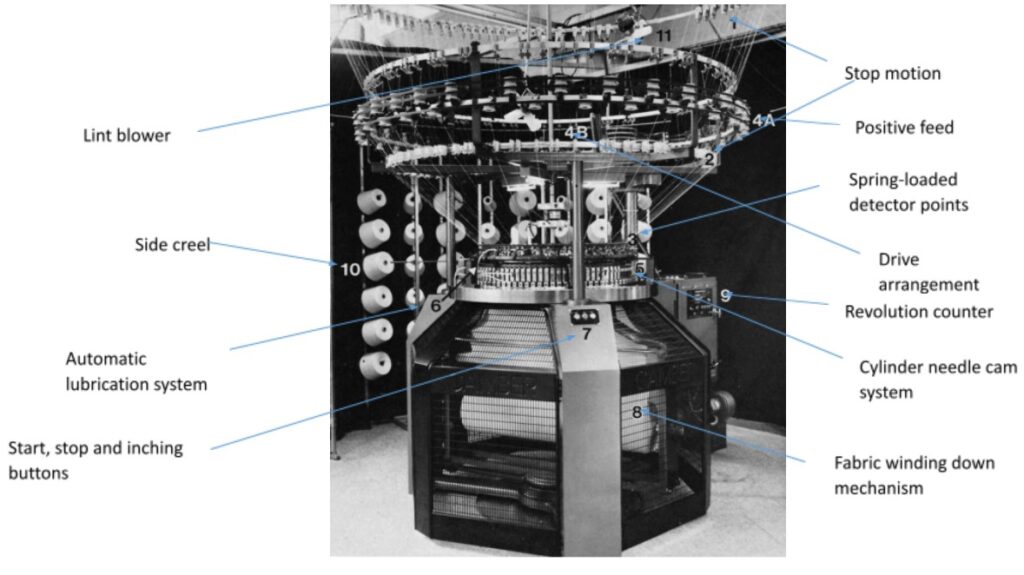

Machine description:

This is an electrically driven knitting machine. The machine possesses 36 feeders. The needle gauge is 24 i.e., the machine has 24 needles per inch and total number of needle is 1734 (this number is measured by using the formula πDG, where D means machine dia and G means machine gauge). The cylinder dia of the machine is 23 inch. This machine can produce only single jersey fabrics. The other specification of the machine is as follows:

Machine specification:

- Name – Single truck single jersey circular knitting machine.

- Model – TS

- Manufacturer – TS mechanical works private Ltd.

- Made in Ludhiana of India.

Identification:

- Top side is open.

- One set latch needle is used in the cylinder trick.

- One set sinker is used in the sinker plate.

- Cam box contain single cam, is known as single truck.

Different Parts and Functions of Single Jersey Circular Knitting Machine:

- Latch needle is used to produce loop

- Sinker is used to hold the new loop and out the old loop.

- Cam is used to raise the needle and cam box is used to hold the cam in the cam box.

- Sinker plate is used to hold the sinker and cam plate is used to hold cam.

- Feeder is used to supply the yarn in the proper way and feed the yarn in the needle.

- Cylinder gear and Bevel gear both are used to change the motion and bevel gear move the cylinder gear.

- Spreader is used to flat the fabric from round form.

- Take down roller is used to collect the fabric in proper tension from the cylinder.

- Batch roller is used to role the fabric.

- Crank shaft / Elbow lever is used to transfer the motion from take down roller to crank roller.

- Rachet pinion and pushing paw is used as a helping element to transfer the motion from take down roller to batch roller.

- Auto motion stopper is used to stop the machine automatically by clatch when the yarn breakage.

- Over head creel is used to hold the package and supply the yarn in proper way.

- High stand is the helping hand to open the yarn from the bobbin.

- Handle and clatch both are used to join the loose pulley and fast to drive the machine.

- Machine pulley is used to collect mechanical power by V-belt and transfer the motion in the bevel gear.

- Motor is used to convert the electric power to mechanical power and motor pulley is used to transfer the motion everywhere by V-belt.

Conclusion:

The single jersey circular knitting machine is a very commonly used machine in country to make knitted fabric. So this experiment has significance in our study life. In this experiment we acquire knowledge of identification about the main parts and action of the single jersey circular knitting machine. We also show the knitting action, cam system. We point out the various specification of the machine. So the experiment helps us to know more.

Above all the experiment is a successful one.

You may also like: Difference between Single Jersey and Interlock Circular Knitting Machine