What is Smart Textile?

Smart textile, e-textiles, intelligent or multifunctional textiles: many names are used to designate these textiles which do a little more than the others. But basically, what distinguishes intelligent textiles from more traditional textiles, and what are the trends in this area? Back on nearly thirty years of innovations, from MIT to our wardrobes.

Generally, an object is qualified as intelligent when it is able to adapt to a situation that is to say to detect and react to a stimulus (electrical signal, but also temperature variation, stress mechanical or chemical information). There are different levels, with:

- Passive intelligent structures capable of detecting a stimulus

- Active intelligent structures capable of reacting to it in a pre-programmed manner

- And finally adaptive intelligent structures, with a learning capacity capable of adapting to the situation

Textiles and in particular clothing offer choice supports for innovation and numerous experiments have been carried out since the end of the 20th century, with more or less success, to transform traditional textiles into intelligent passive, active or adaptive structures.

How to make a connected textile?

A textile is a multi-layer material formed from intertwining threads. Each thread is formed from several fibers of one or more materials. To be connected, a textile needs to be equipped with several onboard systems with a local decision. First, it requires a source of energy. It is either directly supplied by a cell or battery, or by a local energy recovery system (photovoltaic, wind, dynamo, etc.). Intelligent textiles also require sensors that make it possible to obtain the desired information on the wearer or his environment: heart rate, temperature, etc.

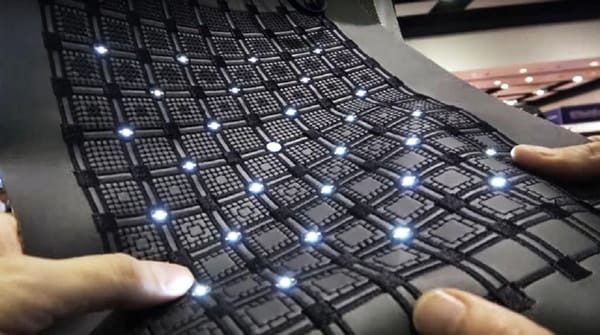

To be functional, a connected textile requires an actuator. The latter allows interaction with the carrier and the environment. It is, for example, a motor that changes the shape of the textile or an LED which modifies its color. Such a fabric also requires a microprocessor with an algorithm and a database for signal processing. And sometimes outside communication to communicate with a smartphone using Bluetooth, a computer or the cloud. Finally, to connect the various previous elements, we need conduction and energy or data transfer systems and connectors.

“In ten years, we will have pure electronic textiles by nature and no longer by addition,” projects Guillaume Tartare, a researcher at the GEMTEX research laboratory at the Roubaix school of textile engineers (ENSAIT). The future ambition of the electronic textile is that there are no more electronic components and that the textile itself becomes electronic”.

Fiber innovations

The smart textile trend is towards the development of connected fibers. For example, the Grenoble-based startup Primo1D is developing the RFID e-thread. The latter incorporates an RFID chip inside the wire. The European Power Weave project is developing a wire that collects and stores electrical energy in its fibrous matrix. He works on the connection between battery fibers and photovoltaic fibers. The objective is to meet the need for an easily storable and transportable power supply. “You almost plug your phone into your t-shirt and it is he who will recharge your battery, “raves Guillaume Tartare.

A lot of work is being done on the different ways of recovering energy locally. Researchers are working on photovoltaics or textile wind power, on heat recovery in the form of electrical energy. On the other hand, they are still struggling to obtain stable electricity production. This still remains most often incompatible with the use of sensors or microcontrollers. “Researchers must find a method to store this intermittent energy and transform it, “says Guillaume Tartare. In the meantime, most of the solutions on the market simply use batteries recharged from the mains.

Process innovations

Textile processes are also evolving. The challenge is to use textile fibers to directly produce electronic components. The German company ZSK, for example, sells machines that incorporate electronic chips when embroidering fabrics. The transition is already underway. There are textile transistors on the market which do not require any additional electronic components. “Simply, it is the textile that becomes transistor”, specifies Guillaume Tartare. Soon, the fibers will directly embed the data and it will be possible to print the sensor directly on the textile. Fibers become intrinsically communicating, matter and the flow of information is completely merged.

On this point, the P-Tronics project, led by the CNRS and the University of Lorraine is particularly innovative. Thanks to functional plastics, it allows 3D printing of flexible sensors, actuators and complete objects with integrated electronics. “This allows for example to print connected soles and personalized portable sensors”, confides Mehdi Ammi, lecturer and researcher at the Laboratory of Computer Science for Mechanics and Engineering Sciences (LIMSI-CNRS) of the University of Paris -Saclay. The laboratory is actively seeking an industrial partner to transfer its technology.

What connected clothing today?

Many of connected smart textile and materials are already available on some top markets. Their google allows them to use the application for cloth but many fake materials are now in the market so that is a risk. The geo-location function of the jeans allows, by vibration on the right or left side, to indicate the direction to take when a trip is programmed. The swimsuits have a sensor that measures the UV dose in the sun and invites its user to put on sunscreen.

References:

- https://www.researchgate.net/publication/286459263_Smart_Textiles-New_Possibilities_in_Textile_Engineering

- https://www.elsevier.com/books/smart-textile-coatings-and-laminates/smith/978-0-08-102428-7

- https://smarttextiles.se/en/

- https://stdl.se/

- https://www.ugent.be/ea/match/textiles/en/research/researchtopics/smart-textiles

Author of this Article:

Md. Raisul Islam Rifat

Dept. of Textile Engineering

Daffodil International University, Dhaka

Email: ririfat750@gmail.com