Stitch formation techniques:

Stitch formation or loop formation is a basic and principle tasks for all sewing machine. Stitch formation techniques are the mechanical components; with perfect synchronization between the parts they form stitches. Stitch forming technique includes a needle, a thread carrying looper & a retainer which enters the looper thread loop & operates to retain & hold the same during the retracting movement of the looper until the needle has entered the looper thread loop. There are some steps for loop formation; such as, Penetration, Loop formation, Conformation, Cast off, Stitch setting etc.

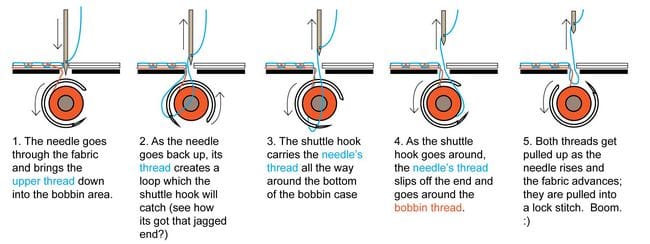

Stitch formation techniques of industrial lock stitch machine:

Lock stitch is the almost basic and simple stitch. This stitch is formed by the lock stitch sewing machine. Here needle thread comes from cone package and bobbin thread comes from bobbin case.

Stitch formation techniques of industrial three, four and five thread overlock machine:

In this machine, there are two types of thread, one is needle thread and another is looper thread, both this two groups is come from large package of cone and the stitch of formed by inter looping technique. Here one looper thread is in upper side of seam and another is in under side of the seam. And this two looper thread is interlaced over the edge of the fabric after cutting of that edge of the garments by upper and lower knife set. As both needle and looper thread comes from cone package so there is no problem for thread shortage in the time of stitching.

In case of four thread overlock machine, the inside needle thread is used to increase the seam so that is can be used as the side seam of a garment.

In case of five thread overlock machine, there is a double threaded chain stitch inside the seam so where this 5 thread overlock stitch is used there is not necessary to apply other stitch for joining of that end.

Stitch formation techniques of industrial bartack machine:

In this machine there are two source of thread, one is needle thread and another is bobbin thread. By interlacement of this two thread stitch is formed. Bobbin thread is stored in a bobbin which is placed under the needle bed of machine. The needle of this machine is move a little front and back to form stitch in a limited length of stitch in heavy dense stitch to increase the seam strength on that point.

Stitch formation techniques of industrial feed of the arm machine:

In this machine, there are two types of thread, one is needle thread and another is looper thread both this two groups is comes from large package of cone and the stitch is formed by inter looping technique. As both needle and looper thread comes from cone package so there is no problem for thread shortage in the time of stitching.

Stitch formation techniques of industrial flat lock machine:

In this machine, there are two types of thread, one is needle thread and another is looper thread both this two groups is comes from large package of cone and the stitch is formed by inter-looping technique. Here one looper thread is under side of the seam. Looper thread may also used one or two looper for both upper and lower side Zig-Zag shape. As both needle and looper thread comes from cone package so there is no problem for thread shortage in the time of stitching.

Stitch formation techniques of industrial button holing machine:

In this machine there are two source of thread, one is needle thread and another is bobbin thread. This is a one kind of bartack sewing machine here is makes two bartack in successive distance. After making two bartack stitch in successive position then it two ends join together and make a loop. After stitching the hole creates by a cutting knife which is operated form the top after the top after stitching. The length of the bottom hole may vary according to the requirements.