What is Stone Washing?

Stone washed garments, generally cotton, show a characteristics well worn look and are very popular with young people. Stone washing means washing garments specially denim garments with special stones (generally pumice stones) so that garments achieve a very strong washed effect. Mainly for bringing fading effect on denim garments stone washing is done. To get a faded look on the garment surface, white stones are used with enzymes during washing. During washing, the fabric comes in contact with stones and the color fades by the rubbing action. Stone wash also helps to increase the softness and flexibility of otherwise stiff and rigid fabrics such as canvas and denim. This process could result in color-fading of jeans and there is added usage of water for the washing.

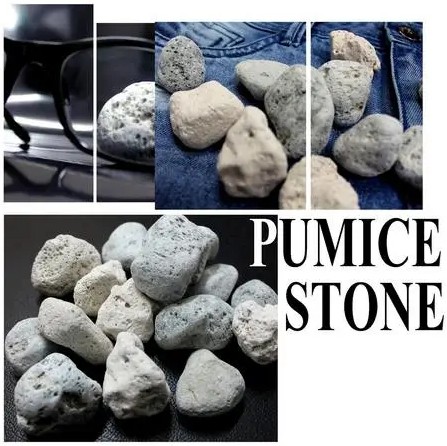

Volcanic rocks or pumice stones (Figure-2) are added during washing as abradants. The color fading is more apparent but less uniform. The degree of colour fading depends on the washing time (60–120 min), stone ratio (weight of stones relative to weight of the garment) (0.5: 1–3:1), size of stones (diameter: 1–7 cm), liquor ratio (∼10:1) and garment load. The world’s major pumice stone supplying countries include the USA, Turkey, Italy, Germany, Iceland, New Zealand, Japan, Indonesia and Philippines.

Flow Chart of Stone Washing Process:

Stone washing process flow chart for any garments is in the following-

Garments loading with stone

↓

De-size

↓

Rinse (Two times)

↓

Stone wash

↓

Rinse (Two times)

↓

Softener

↓

Unload the garments

↓

Extracting

↓

Drying

Stone washing process of denim fabric gives ‘used’ or ‘vintage’ look on the garments. This is due to the varying degree of abrasion in the garment. Traditionally, stone washing of denim garments is carried out with pumice stones to achieve a soft hand and desirable look. The pumice stones having an oval and round shape with a rough surface work as an abradant in washing cycle. The variations in shape, composition, hardness and porosity result in different washing effects in the denim fabric. During washing, these stones scrape off dye particles from the surface of the yarn of the denim fabric which shows a faded, worn out and brilliance effect in the denim fabric. From ring dyeing of denim fabric and heavy abrasion during stone washing, the fading is more apparent but less uniform. Stone washing makes the denim garments more supple so that they fit comfortably. To get the desired washed effect, the stone should be of proper hardness, shape and size. For heavy weight denim fabric, large and hard stones are suitable and also last longer. Similarly, smaller and softer stones are suitable for lightweight denim fabrics.

Procedure of Stone Washing:

Stone washing process is as follows:

- Load stones into the machine.

- Load garments into the machine (the ratio is usually 0.5–3.0 part weight stones to 1 part weight garments).

- Desize with α-amylase enzyme and detergent. The liquor ratio is approximately 5–8:1.

- Rinse.

- Refill and tumble with stones for 30–90 min, depending on the desired effect. The Liquor ratio is 5–8:1 at 50–70°C. Scouring additives can also be used.

- Drain. Separate garments from stones (garments can be transferred to another machine).

- Rinse.

- Apply a softener (garments can be transferred to another machine for softening).

- Extract and unload.

- Destone and tumble dry.

- Press, if required.

Softeners and lubricants can be added during Steps 3 and 5 to reduce the potential for creasing. Sometimes, bleach is added to the wash so that the color fades in a more pronounced manner. This is done to turn navy blue jeans into a more faded light blue color. Such a wash requires a lot of skill, experience, workmanship and expertise so that desired results are achieved.

In stone washing, the following points should be carefully checked:

Effect of stone ratio:

Stone ratio effects on color fading. When the stone ratio below 0.5 : 1, no significant color fading effect in the denim garments. When the stone ratio is high, the color fading effect becomes enhanced. However, too high a stone ratio may cause severe abrasion leading to fabric damage.

Effect of stone size:

There is also effect of stone size on the color fading effect in denim garments. It is noted that the smaller the stone size, the better is the color fading effect. In addition, small stones can provide an even and uniform abrasion effect, but the color contrast produced is not good when compared with large stones. Stones should be selected based on the required abrasion affect as well as the type of fabric of the garments. Larger stones may damage comparatively lightweight fabric.

Effect of stone washing time:

Color fading effect on denim garments also depends on stone washing time. It is shown that after 90 min, there is no further increase in the color fading in denim garments.

Effect of quantity of the bleach:

Use of more bleach can shorten wash time, leading to more productivity. Bleach, however, cannot be used indiscriminately. Disproportionate amount of bleach may lead to loss of the desired blue/white contrast on the fabric. To get better results, one should cut a balance between the quantity of bleach, stone size and the amount of stone. Sometimes, one needs to use a normal quantity of stone and longer washing time to achieve the color standard requirements.

Disadvantages and limitations of stone washing process:

Stone washing of denim fabric with pumice stones has some disadvantages and limitations, such as:

- Stones may cause wear and tear of the fabric and may damage the washing machine from abrasion of the stone with fabric or machinery parts.

- It may also create the problem of environmental disposition of waste of the grit produced by the stones.

- Increase the labor cost required to remove stone dust from finished garments. Denim garments are required to be washed several times for complete removal of the stones.

- The stone washing process may cause back staining and redeposition.

- The process is non selective.

- Metal buttons and rivets in the garments as well as the drum of the washing machine sometimes get abraded which substantially reduces the quality of the garment and the life of the equipment.

References:

- Denim : Manufacture, Finishing and Applications. Edited by Roshan Paul

- Sustainability in Denim. Editors: Subramanian Muthu

- Handbook of Value Addition Processes for Fabrics By B. Purushothama

- Chemical Technology in the Pre-Treatment Processes of Textiles by S. R. Karmakar

You may also like:

- Tinting Process of Denim Garments

- Step by Step Bleach Wash Process in Garments

- Acid Washing Process of Denim Jeans