The textile & apparel is a series of interrelated activities which originates with the manufacture of fibre & culminates in the delivery of a product into the hands of the consumer. The textile and apparel industry is a major contributor to several national economies, including both small & large scale processes globally. Garment manufacturing is labor intensive, which is characterized by low fixed capital investment; a wide range of product designs and hence input materials; variable production volumes; high competitiveness and often high demand on product quality. Although the manufacturing process is associated mainly with apparel & household linens, it is also used in a variety of industries and crafts such as upholstery, shoe-making, sail-making, bookbinding and the production of varieties of sporting goods. Sewing is the fundamental process, with ramifications into a variety of textile arts and crafts, including tapestry, quilting, embroidery, appliqué and patchwork. Further, it is a sector where comparatively modern technologies could be implemented even in poor countries at moderately low investment costs.

With concern to the employment as well as production, the textile sector is one of the prime industries in the world.

The textile and garment sector also has the high potential market segment for value added products where design and research and development (R&D) are key competitive factors. The luxury fashion industry utilizes higher labor in design and marketing segments. The same applies to market sectors like sportswear where both design and material technology are vital. In this article I will discuss structure of textile and apparel industry.

Structure of the Textile and Apparel Industry

The clothing or garment industry is a labor-oriented, low wage industry but a vibrant, innovative sector, depending on the type of market segments upon which the industry focuses. The high-end fashion sector is considered modern technology, with comparatively well-paid workers and designers and a high degree of flexibility. There are wide varieties of garment types that the apparel manufacturers have to handle, which can be broadly divided into two categories: outer garments and inner garments.

The core operations of industries servicing this market sector are mostly situated in developed nations and often in certain geographical locations within these nations. The other kind of major market sector is bulk production of standard products like t-shirts, uniforms, underwear, etc.

Manufacturers for this type of standard product market sector are mostly seen in developing countries. For lower- to medium-priced products in the market, the responsibility of the retailer has become more and more important in the organization of the supply chain. The retail market sector has turned out to be more intense, leaving more market power to multinational retailers.

Textiles are responsible for the key raw material input to the garment industry, developing vertical supply chain relationships between the two containing sales and distribution functions. The textile and apparel sectors involve:

- Acquiring and processing raw materials, that is, the preparation and production of textile fibers.

- Manufacturing of textile yarns and fabrics.

- Dyeing and finishing of textile materials, which provide visual, physical and aesthetic properties that consumers demand, such as bleaching, printing, dyeing and coating.

- Conversion of textiles into garments that can be either fashion or functional garments.

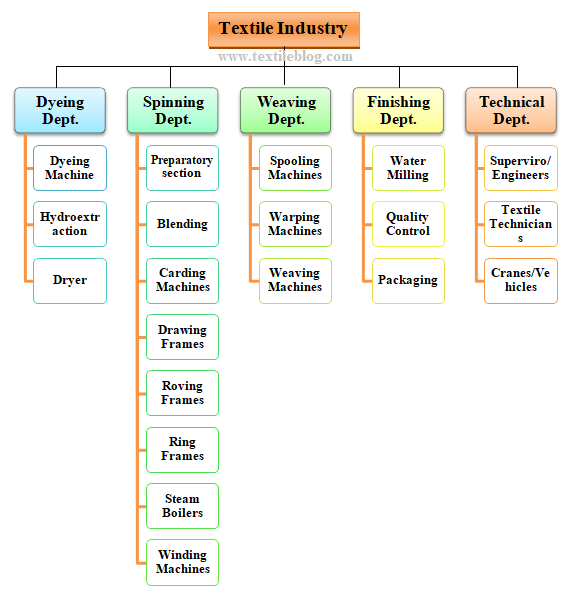

Textiles industry:

The textile industry is primarily concerned with the design and production of yarn, cloth, clothing, and their distribution. So in the textile business generally needs more investment compared to the garment sector and it is an extremely automated area. It comprises yarn manufacturing, fabric manufacturing and dyeing and finishing, and these three functions could be carried out in integrated plants. On the other hand, the textile sector suffers from the higher lead time as well as high investment cost, which results in relatively large minimum orders.

Apparel industry:

Garment industry starting with the textile industry (producers of cotton, wool, fur, and synthetic fiber) via fashion industry to fashion retailers. The fundamental manufacturing process of the apparel industry has not undergone much change over the past century, and is considered by the progressive bundle system. Work or operation is planned in a manner that each operator is specialized in one or a few operations. The fabric is first cut into various garment panels and then grouped by components of the garment, tied into bundles and sent to an assembling (sewing) section for making a garment. An operator receives a bundle of cut garment panels and executes his or her single operation and keeps the bundle in a buffer. A buffer of about one day’s work is common at each operation. It takes about 40 operations to finish a pair of pants, which entails about 40 days of in-process inventory.

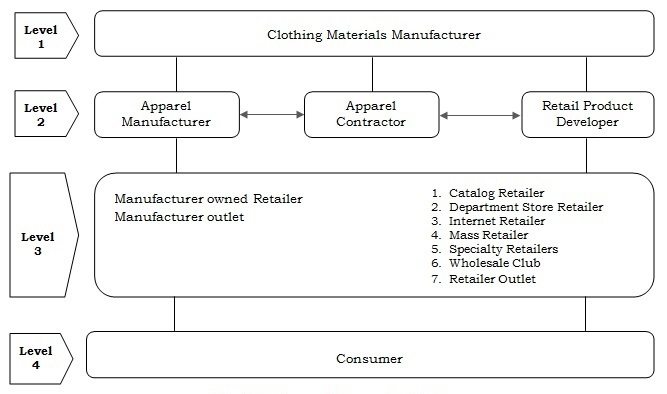

Supply chain of apparel industry is as following:

Level 1: Textiles and finding manufacturers (Mill Level)

↓

Level 2: Garment manufacturers, contractors, retail product development (Garment Manufacturing Level)

↓

Level 3: Manufacturer-owned retailers, outlets, catalog retailers, warehouse

↓

Level 4: Consumers

You can see in below image with details,

Though numerous advances in the industrial engineering segment for systematizing the operations and reducing the production time of each individual operation have taken place over a period of time, the basic method has remained the same. However, the apparel industry, especially sewing technology has remained significantly less automated compared to many other manufacturing industries.

The new technologies, systems and innovations in the clothing sector have improved efficiency at each production stage and enhanced the harmonization between stages and provided a more seamless interface between them. The major breakthrough innovation was the use of computers in apparel manufacturing in areas like pattern making, marker planning and computerized automatic cutting machine.

This machine has made it possible to cut increasingly thick layers of cloth accurately. These advancements are mainly associated with the preassembly phase of production, where technological developments have been more important than at the assembly stage.

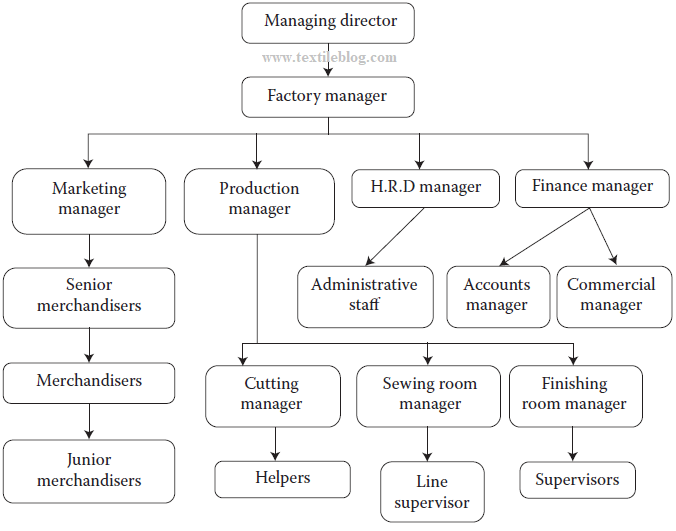

The organization structure of a medium-sized garment industry is shown in figure:

References:

- https://en.wikipedia.org/wiki/Clothing_industry

- https://en.wikipedia.org/wiki/Textile_industry

- Apparel Manufacturing Technology by T. Karthik, P. Ganesan, D. Gopalakrishnan

- Garment Manufacturing Technology Edited by Rajkishore Nayak and Rajiv Padhye

- The Apparel Industry by Richard M. Jones