Study on Quality Control in Sewing Section

Authors:

Said Alam Rafi1

Sujon Chandra Roy

Dept. of Textile Engineering

Daffodil International University, Dhaka, Bangladesh

Email: saidalamrafi@gmail.com1

ABSTRACT

This project is ‘Study on quality control of sewing section’ of “Millennium Textiles (Southern) Ltd”. Garment manufacturing is quite different from any other conventional manufacturing. It is not a continuous production method. Each style is a different product that requires a different type of fabric, color, buttons, thread, etc.. Sewing process is one of the most important stages in labor intensive ready-made clothing enterprises. Quality faults occurring during this process adversely affect the product quality and product efficiency, and also increase the production cost. The aim of this study is to investigate whether the woven production process is under control in a woven production enterprise and to detect the processes with the highest rates of sewing faults in sewing section and finally to make suggestions for improving the quality control. Also, the processes with highest amounts of sewing faults and the effects of these processes on fault rates were investigated. End of The Line Inspection Report on the 04 days we identify 325 pieces faults out of 1805 pieces inspected garments. Poor Trimming, Uneven stitches, Broken Stitches, Puckering, Point Up- Down, Uneven Stich, Down Stich, Button Stich etc.. faults are found by inspection of garments in the sewing section. Poor Trimming/Uncut Thread is the major problem in the sewing section. Average of Poor Trimming/Uncut Thread is 25.84%. Finally, we have found different types of sewing faults by Sewing machine and operator. We are also mentioning remedies for specific reasons which all are included in this project report. We also included some end line inspection report of “Millennium Textiles (Southern) Ltd.”.

INTRODUCTION

1.1 Background of the Study

The largest and the most important section in a garment industry is its sewing section. In this section, each and every sewing machine and jobs of machine operators should be inspected on a routine basis for identifying, correcting and controlling of faults and maintaining quality of products. To ensure the quality of the product, quality control personnel have to control quality in a different section in garment industry, which are directly or indirectly involved with production. Quality is the difference between products. It is the goodness or badness in a product. This definition holds true till this date. The Garment also plays a vital role in the society. For produce good garment we need to maintain quality and quality depends on sewing arrangement of garment.

1.2 Objectives of the Study

- To know how to analyze a garment effectively and efficiently.

- To identify the causes of sewing fault and solve this.

- To minimize sewing fault from garments.

- To improve quality of garments.

- To implement technical solutions toward thread defects.

- To show how technical know-how can increase production efficiency.

1.3 Importance of the Study

A Cost Saving Approach in Garments Production Unit. This article explains the causes of sewing faults in ready-made garments. Sewing faults is a problem widely faced by garment manufacturers. In spite of it being a very common problem, it is very difficult to get rid of it completely. Some aspects of the sewing fault formation, its causes, and determination and remedies are discussed in this article. The author notes that it is very difficult to eliminate faults completely. The questions whether the level of a fault is acceptable or not depends largely on the type of garment, location of the seam, appearance. Quality faults occurring during this process adversely affect the product quality and product efficiency, and also increase the production cost. The aim of the study is to investigate how to control quality in garment production and make suggestions for improving the quality control. By this study, we demonstrated that the investigation of each quality control process would make significant contribution to produce quality garment and prepare more effective the improvement plans.

However, reduction in sewing faults will always be welcomed and would be an important aspect in the international marketing of readymade garments.

1.4 Limitations of the Study

During the study I had faced the following limitation

- Shortage of secondary data sources: Publication of this field not available and there were no organization or department for maintaining proper information about the company.

- Respondent unwillingness: Some respondents were unwilling to respond due to maintaining secrecy about the company.

- Lack of accurate data: Respondents were unwilling to disclose their fault and quality check data. So, this types of data used in this report is not too proper.

- There is no special training department for study.

- Shortage of time: At least eight months required for completion of the final report, but we have given only three months. So to acquire a vast knowledge it is the most important limitation for me.

LITERATURE REVIEW

2.1 Quality:

The term quality refers the excellence of a product. When we say the quality of a product is good. We mean that the product is good for the purpose for which it has been made. Good Quality does not necessarily mean high quality. It means a predictable degree of uniformity and dependability at low cost, which suits to the market. Aristotle 2500 years ago defined quality as following:

- Quality is the difference between products.

- It is the goodness or badness in a product. This definition holds true till this date.

Quality is also referred to as “conformance of goods to buyers’ specifications”. ISO 9000: 2000 defines quality as “degree to which a set of inherent characteristics fulfill requirements”.

2.2 Objectives of Quality:

- To maximize the production of goods within the specified tolerances correctly the first time.

- To achieve a satisfactory design of the fabric or garment in relation to the level of choice in design, styles, colors, suitability of components and fitness of a product for the market.

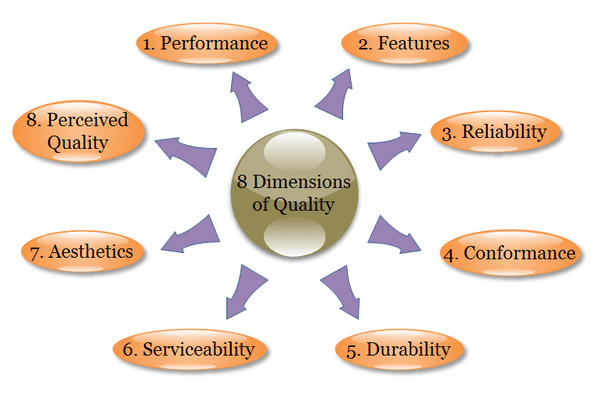

2.3 Dimensions of Quality:

2.4 Quality depends on:

Quality depends on two things. Such as given below:

- Form: It represents features of a product in terms of shape, size, style, design &measurements.

- Content: It represents features expressing internal quality, implying quality of raw materials & the value additions attached to it.

2.5 Importance of quality

- Every product must feature functional characteristics as well as some other aspects related to its shape, size & design. Consumers always demand following expectations of the purchased product:

- The product must satisfy the consumer in terms of beauty, attractiveness, taste, shape, design & longevity etc. depending on the type of product.

- A product devoid of quality has no demand among consumers & as such, has no salability. Most importantly, some criteria of customer satisfaction are negotiable but quality is such a factor that it is not at all bargain able.

2.6 Elements of cost of quality:

Quality means consistency in meeting customer expectation. The cost of quality is the cost of yarn that met those expectations, combined with the costs that result when you fail to meet them.

2.7 Sewing

Sewing is a process that involves stitching fabrics together either with a needle and thread by hand or with a machine. Joining the fabric by using needle & thread is called sewing. Sewing section is the biggest section in the garments industry. It is a universal & widely used method of joining fabrics. The purpose of sewing is to produce seam. A line along which two or more fabrics are joined by fusion, gluing, sewing, stapling or alternative method is termed as seam. Usually near edges of sewn fabrics pieces.

2.7.1 Types of sewing Machine:

- Mechanical Sewing Machines

- Electronic Sewing Machines

- Computerized Sewing Machines

2.8 History of Sewing & Sewing Machine

The first British patent for a mechanical device to aid the art of sewing, in 1755. His invention consisted of a double pointed needle with an eye at one end. In 1790, the English inventor Thomas Saint invented the first sewing machine design, but he did not successfully advertise or market his invention. In 1804, a sewing machine was built by the Englishmen Thomas Stone and James Henderson, and a machine for embroidering was constructed by John Duncan in Scotland. In 1807An Austrian tailor Josef Madersperger began developing his first sewing machine. In 1814 he presented his first working machine. The first practical and widely used sewing machine was invented by Barthélemy Thimonnier. In 1829 His machine sewed straight seams using chain stitch like Saint’s model. In 1830 he signed a contract with Auguste Ferrand, a mining engineer, who made the requisite drawings and submitted a patent application.

On 17 July 1830 and in the same year, he opened the first machine-based clothing manufacturing company in the world to create army uniforms for the French Army. In 1832 the first American lockstitch sewing machine was invented by Walter Hunt. In 1842, John Greenough patented the first sewing machine. John Fisher in 1844 for the processing of lace materials. His machine was substantially similar to the devices built by Isaac Merritt Singer and Elias Howe in the following years. In 1830 he signed a contract with August eFerrand, a mining engineer, who made the requisite drawings and submitted a patent application.

2.9 There are many types of Industrial Sewing Machines used in sewing section:

- Double chain stitch m/c (4-needle short)

- Double chain stitch m/c (4-needle elastic inserting m/c)

- Double chain stitch m/c(double needle with reserve feed)

- Feed of the arm (double chain stitch m/c, 3-needle)

- Interlock m/c (twin needle, 5-thread over lock m/c)

- Lock stitch m/c (1-niddle with vertical trimmer wiper & reverse feed)

- Lock stitch m/c (twin needle feed)

- Lock stitch m/c (single needle with variable top feed with automatic thread trimmer)

- Lock stitch m/c (single needle with automatic thread trimmer)

- Lock stitch m/c (single needle sewing m/c)

- Lock stitch m/c (2-needle with spilt needle bar sewing)

- Buttonhole m/c (for woven fabric)

- Bias tape cutting m/c

- Button hole sewing m/c (for knit fabric)

- Button sewing m/c

- Bar take m/c (with automatic thread trimmer)

- Button covering stitch belt loop making m/c (kansai m/c)

- Over lock m/c (twin needle, 4-thread m/c)

- Over lock m/c (1-needle, 3-thread)

- Lap seaming m/c ((for back tape attaching)

- Zigzag sewing m/c (1-needle)

- Linking m/c

- Top & bottom cover stitch flat bed m/c (3-needle)

- Label sewing m/c

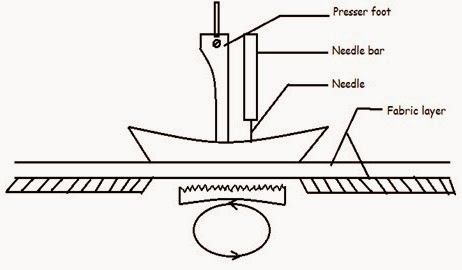

2.10 Main parts of Sewing machine:

- Throat plate/needle plate/feed plate

- Feed dog

- Pressure foot

2.10.1 Throat plate

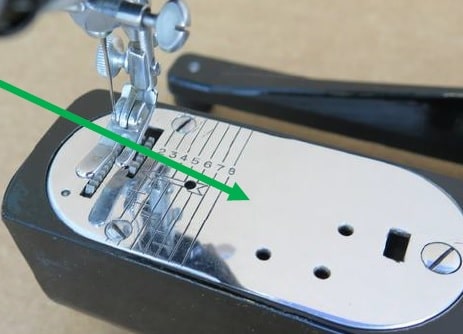

The part of the bed of the sewing machine which has openings for the needle and for feed dog penetrations and which provides localized support to the material. The openings vary in size and shape, depending on the sewing requirements. This is made of steel smooth. Due to the smooth surface fabric can be feed easily. It is also called needle plate. It has one or more slots through which feed dog can move forward and backward. It has a hole through which needle can move up &down with more than 30% of needle size. If it is, the fabric can be pushed into the hole with each penetration of the needle which is called Flagging. It is the type of sewn seam failure in which some yarn slip out of the seam.

2.10.2 Feed dog

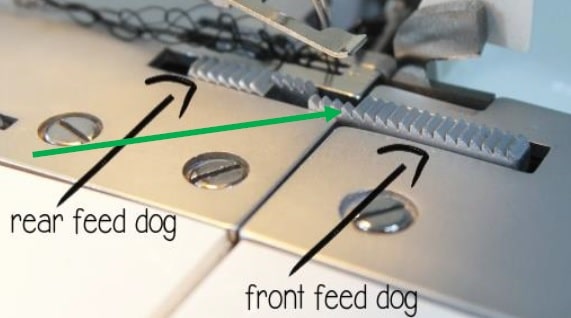

A toothed element which acts on the surface of the material is being sewn to move it in a controlled way during stitching. The action is normally on the lower surface of the material, but a mechanism which acts on the upper surface are also in use time, the operative motion is forward but in specific cases the motion is reversed. It is the most important part of feed mechanism. The main function of this part is to move sewn fabric after making individual stitch as predetermined length. Upper part of the feed dog is made toothed. The movement of the feed dog is lateral. Feed dog moves upward & comes upward through the slot of the throat plate, containing with the lower surface of the fabric, moves down again below the throat plate. In this way its lateral movement is completed. The up & down movement of the needle should be carefully handled. When fabric is moved forward the needle must be out of the action or to its maximum position.

2.10.3 Pressure foot

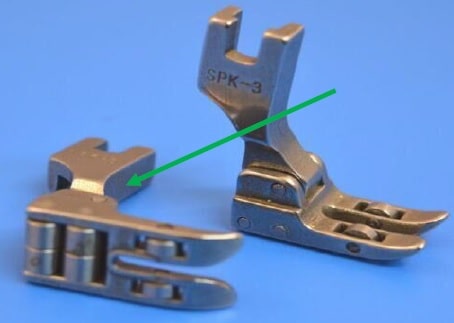

This is an element which is used to constrain the movement of the material during stitch formation by applying to it an adjustable downward pressure. It works in conjunction with the throat plate & feed dog to achieve controlled movement of the material &formation. Different designs of pressure foot are in use. The most common have a solid or hinged surface which controlled the material. It is used to give an adjustable downward pressure. Lower surface of the pressure foot is very smooth to fabric& pressure foot.

2.11 Sewing machine feed mechanism

The means of moving the materials or fabric being stitched from one stitch position to the next is called feed mechanism. This is a very important part of sewing machine. The following are the function of a sewing machine depends on the feed mechanism:

- Proper seam appearance.

- Proper stitching required.

- Controlling of SPI

- Move forward & backward of seam fabric.

- Sometimes crease effect is formed according to the design.

There are so many types of feed mechanisms are available according to the desired function & machine. But, common three parts are must whatever the type of feed mechanism is. The following three parts of a feed mechanism are given by heading to understand easily.

2.11.1 Drop feed mechanism

The drop feed mechanism is commonly found in domestic sewing machines and a majority of industrial sewing machines. Also known as regular feed mechanism, the drop feed mechanism involves the movement of serrated metal strips known as feed dogs, needle plate. This is the simplest & widely used feed mechanism. When two plies of fabrics are sewn by this mechanism, the feed dog moves backward & come up ward through the slot of the throat plate & contacted with lower surface of the fabric. Spring loaded pressure foot gives pressure on the upper side of the fabric. Then the fabric moves forward a step & then feed dog descends from the fabric & moves down again below the throat plate. Sometimes it is seen that, the lower of the fabric is more feed than the upper ply. This is called ply shifting or differential feeding pucker or feeding pucker. With the same reason, sometimes roping is occurred during making of hem. Those problems may be controlled by experienced operator.

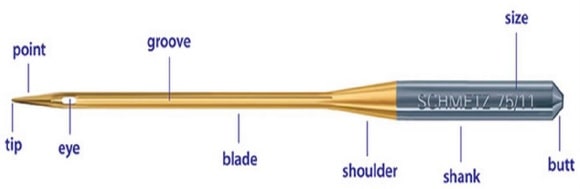

2.12 Sewing Needle

A sewing needle is a long slender tool with a pointed tip. The first needles were made of bone or wood; modern ones are manufactured from high carbon steel wire, nickel- or 18K gold plated for corrosion resistance. The highest quality embroidery needles are plated with two-thirds platinum and one-thirds titanium alloy. Traditionally, needles have been kept in needle books or needle cases which have become an object of adornment. Sewing needles can also be kept in an etui, a small box that held needles and other items such as scissors, pencils and tweezers.

2.12.1 The basic functions of a needle

- To create a passage in the material for the thread to pass through.

- To carry the needle thread through the material and form a loop which can be picked up by the hook or lopper mechanism.

- To pass the needle thread through the loop formed by the lopper mechanism on machines other than lockstitch.

2.12.2 Various parts of needle

- Butt

- Shank

- Shoulder

- Blade

- Long groove

- Short groove

- Eye

- Point

- Tip

2.12.3 Types of sewing needle

- Sharps needle

- Embroidery needle

- Milliner’s needle

- Universal needle

- Denim/jeans needle

- Metallic needles

- Ballpoints needle

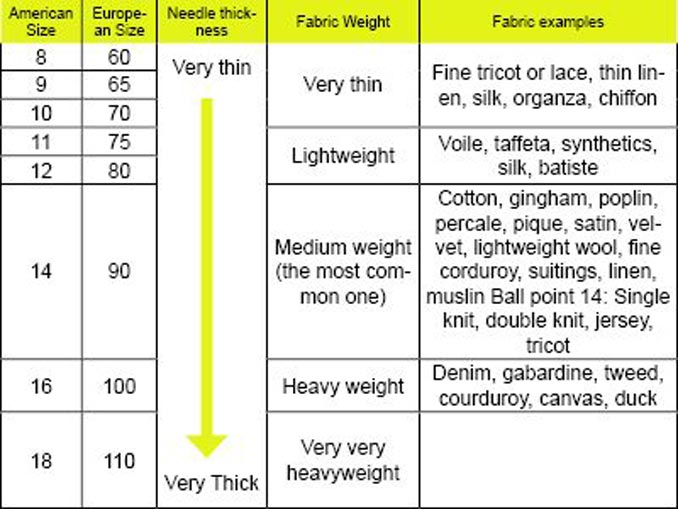

2.12.4 Effect of wrong needle selection

If the needle is finer then sewing thread:

- The thread cannot move easily through the needle eye.

- The thread will not take position perfectly at needle long groove.

- The result is more thread breakage & production loss.

If the thread is finer than needle:

- May produced slipped stitch as the needle cannot create perfect size or loop.

If the needle is coarse than required fabric:

- Fabric will be locked odd due to bigger hole.

- Seam pucker may be produced on woven fabric.

If the needle is finer than required fabric:

- During sewing needle will be deflect & become curve with the action of throat plate.

- This curve needle will produce slip stitch as the looper may not catch the loop needle thread.

2.12.5 Chart of Needle Size with Fabric Categories:

2.13 Sewing Threads

Sewing threads are special kinds of yarns that are engineered and designed to pass through a sewing machine rapidly. They form efficient stitches without breaking or becoming distorted during the useful life of the product. The basic function of a thread is to deliver aesthetics and performance in stitches and seams. Sewing thread is the main trims of the garment. Sewing thread is directly related to the quality of seam. Sewing threads are classified in following ways:

Linen:

Oldest thread & was used at a range for sewing threads during the making of garments. This type of thread has high strength & can make more strength of seam. But now it is most replaced by synthetic threads.

Silk thread:

This type of thread is made from booth continuous filament & broken filament silk. Comparatively, contains higher strength, extensive, lustrous & good qualities. This type of thread is expensive.

Cotton thread:

These types of sewing thread are widely used & productive, among the threads made from natural fibers. Generally made from better quality of cotton fibers. This is easy to sew fabrics by cotton thread, but has less frictional resistance compared with synthetic threads. This type of thread is generally three types; such as:

- Soft cotton thread.

- Mercerized cotton thread.

Viscose thread:

It may be made from continuous filament or staple fibers. The strength & durability are comparatively less but more brighten. Water can reduce viscose strength.

Polyester thread:

This type of thread is strong, low cost, good wash fastness & satisfactory elastic properties. It can be washed up to150c without any shrinkage. At present it is widely used in garments among the synthetic sewing threads.

Nylon thread:

These types of threads are made from hex methylenediamine & acetic acid. It may make seam pucker after sewing due to shrinkage. It may be used to sew knitted fabric, extensible seam & swimming wear.

Aramid thread:

Aramid threads are not use as a rate because of more expensive. It is used in special cases like firefighting garments. It is costly. Its commercial name is Nomex.

2.13.1 Factors affecting performance

Thread used in garments must be durable enough to withstand the abrasion and needle heat that occur while sewing, garment finishing, stretching and recovery during wear.

Thread performance in garments can be evaluated from its:

- Seam strength

- Abrasion resistance

- Elasticity

- Chemical resistance

- Flammability

2.13.2 The properties required of a sewing thread:

- Needle thread must pass freely through the small eye of the needle; consequently they must be uniform, knot-free, non-torque and fault free.

- Tensile strength/breaking strength is one of the essential properties of the thread.

- For good performance in a sewing machine moderate to low extension-at-break of the thread is usually preferred.

- The elasticity of the sewing thread must be uniform along its length.

- The forces that are developed in the sewing thread are mostly due to the friction between the thread and machine parts

- Good abrasion resistance is essential for good sewing performance.

- Good resistance to heat is a very important requirement of a sewing thread.

- The hairiness of sewing thread also affects the appearance of the seam.

- Color fastness is a general requirement for sewing thread.

- Good luster in the thread improves appearance of the seam

- Threads must be uniformly dyed in a good match to the materials.

- The ability of the thread to perform efficiently in the sewing machine is defined sew ability.

- The characteristics of properly constructed seam are strength, elasticity, durability, stability and appearance.

2.14 Defects

A defect is the characteristics of a product which impair the functional quality or its stability. A defect an unwanted feature in a product or absence of a feature or a feature existing in the distorted or the wrong way.

Reject: A product is called reject when it’s functional or service qualities are impaired due to deflection of sewing or other work, due to imperfections of materials or due to any other type of defect. A product becomes a reject when it loses stability in the market. A single defect in the most visible area of a garment may make it a reject.

Types of defects:

There are two main types of defects:

- Non-Sewing Defects

- Sewing Defects

2.14.1 Sewing Defect

Defects may occur in garments industry produced on a mass scale. The sources of defects are given below:

- Defects due to problems of stitch formation.

- Defects due to fabric distortion or puckering.

- Defects due to fabric damage along stitch line.

2.14.2 Non-Sewing Defect

Defects may occur in garments industry produced on mass scale. The sources of defects are given below:

- Defects due to cutting of fabrics, lining, interlining by wrong pattern.

- Defects occurs due faulty raw material.

- Defects due to wrong marking, wrong spreading etc.

- Defects due to oil marks.

- Defects due to ironing, Folding, Packing, Packaging etc.

2.14.3 Types of Sewing faults/defects

Sewing defect can be classified as three groups:

- Problems of stitch formation.

- Damage of fabric on seam line.

- Problem of pucker.

2.15 Some Sewing faults in garments

Faults in garments are three types. These are:

- Major fault.

- Minor fault.

- Critical fault.

2.15.1 Major fault:

The faults which are present in garments may not lead the garments be rejected rather after removing this faults garments are executed for shipment is called major fault. Example:

- Uncut thread

- Spot in the front part.

- Skip stitch

- Seam puckering.

- Button too big for button hole

- Button hole is too big for button

- Slipped stitch.

- Joint stitch

- Open seam or hem

- Raw edge out

- Open stitch

- Reject or Damage

- Dirty spot

- Needle mark

- Bar tack missing

- Broken stitch

- Collar fullness or tightness of fabric

- Missing or wrong accessories

- Zipper puller self-lock not secure

- Zipper guider does not

- Zipper slider does not glide through the teeth smoothly

- Zipper slider does not glide through the teeth smoothly

- Snapping action too tight to close

- Napping action too loose to close adequately

- Missing collar bone

- Poorly attached hanger hook

- Poly bag / inner box too loose or too tight.

- Belt loop Missing/Incomplete

- Color shade variation within a box

2.15.2 Minor fault:

The faults which are present in the garments cannot lead the garments be rejected rather if small quantity of this fault are present in the garment, garments can be accepted for shipment. This type of fault is called minor fault.

Example:

- Spot in the under part.

- Sewing problem in the under part etc.

2.15.3 Critical fault:

The faults present in garments lead the garments to be rejected directly are called critical fault. This garment should not pass for shipment.

Example:

- Broken hanger resulting to sharp end/edge

- Brand name differs from PO/sample

- Hole in the garments.

- Styling mistake

- Print cracking

- Shade variation of the garments fabric

- Order number missing

- Broken needle in garments

- Two leg are uneven in same garments

- Mould problem

- On line order A poly sticker missing

- Children order name label missing

- Denim garments wash symbol missing

2.16 Defects due to fabric distortion or puckering

Puckering is wrinkle appearance along a seam line in a smooth fabric. It is one of the most frequently occurring defects. Puckering shows that as if there is too much fabric and not enough thread in the seam and as if the thread is drawing the seam in. this is the reason why sewing thread is often blamed for causing puckering though there are other factors as well for promotion of puckering. They are given below:

- Seam construction

- Needle size.

- Fabric structure.

- Wrong thread tension

- Unsuitable thread

- Material feeding problem.

Puckering may be visible as soon as sewing is complete but some appear later when the garment is ironed or washed. It is generally said that stitching on a fabric always leads to some amount of puckering or fabric distortion. Fabric from synthetic fibers generally has a tendency to show up puckering. A puckering is the most frequently occurring sewing seriously investigated by researchers who found five reasons of puckering.

2.17 Defects Due to Problems of Stitch & Seam Formation:

Defects may occur in garments industry produced of the sewing section. There are some defects names due to problems of stitch formation are given below:

- Uncut Thread

- Label displace

- Shade Problem

- Oil Spot

- Skipped Stitch

- Broken Stitch

- Open Seam

- Joint Uneven

- Thread Breakage

- Joint Stitch

- Uneven Stitch

- Raw edge problem

- Needle Mark

- Yarn Mark

- Measurement Discrepancy

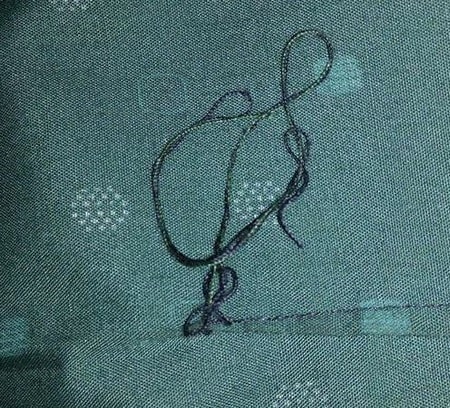

2.17.1 Poor Trimming/Uncut Thread:

If thread or loose thread on seam line then this fault is called uncut thread.

Cause:

- Due to improper trimming or finishing.

- In sewing process extra thread allowance.

Remedies:

- Sewing thread use properly.

- Garments finishing should be checked properly.

2.17.2 Open Seam:

If seam line is open or loose the seam and missing the stitch after sewing process that called Open seam. It’s a major sewing defect.

Cause:

- Improper handling of garments.

- Improper setting and timing between needle and looper.

- Failure of needle to enter loop.

- Needle deflection.

- Thread loop failure.

- Flagging of fabric due to poor presser foot control.

- Its mainly mechanical problem.

Remedies:

- Proper setting and timing between needle and looper

- Clear markings for stitch lin

- Worker training

- Threading, SPI and backtack settings should be checked oftenly

- Feed dog and hook set timing should be checked periodically.

2.17.3 Down Stitch / Fall Of Stitch

Where the stitch forming misses appropriate sewing direction and seam fall from fabric.

Causes:

- Insincerely work

- Adjustment of feed dog.

Remedies:

- Sewing operators must have the correct material handling techniques.

- Make sure the patterns/guide has been designed properly.

- Use ideal seam construction.

2.17.4 Raw-Edge

Causes:

- Not working the machine knife.

- Fault of machine.

- Uncarefully work.

Remedies:

- Check the machine before sewing.

- Machine’s knife check.

- Carefully sewing

2.17.5 Uneven Stitch/ Unbalance Stitch:

Causes:

- Improper thread tension.

- Unbalanced thread.

- Incorrect threading.

- Poor fabric feed control.

Remedies:

- Increase thread tension.

- Change to better quality thread with consistent quality.

- Increase presser foot pressure.

- Improve fabric feed mechanism

2.17.6 Shading:

It is the problem appeared when the two parts shade looks different in the garments

Causes:

- It is also may be a problem in cutting section where this parts made numbering mistake.

- For the lack of experience or concentration of worker and if different parts are mixed by the workers.

Remedies:

- Shade problem parts are separate and actual parts are attached

2.17.7 Skipped Stitch:

They occur when the bobbin or looped of the machine cannot pick up the loop in the needle thread.

Causes:

- Failure of hook or looper and needle to enter loop at correct time.

- Irregular thread tension on upper or lower loop.

- Due to needle deflection.

- If needle thread loop size is too small.

- If sewing thread is unable to form loop.

Remedies:

- Examine the setting and timing between needle and hook or looper.

- Needle should be changed.

- Needle size and thread should be adjusted.

- Thread should be changed.

2.17.8 Point Up-Down:

Causes:

- Mismatching of body parts size.

- Mishandling of body parts.

Remedies:

- To match the body parts according to size and number and lot.

- Skilled operator used to handling the garment.

2.17.9 Button Stitch:

Some excess thread is visible on the top side of the button.

Causes:

- Quality of thread.

- Train operators.

Remedies:

- Use best quality sewing thread.

- Should use the lock stitch machine for attaching buttons.

EXPERIMENTAL DETAILS AND DATA COLLECTION

3.1 Attachment of sewing report

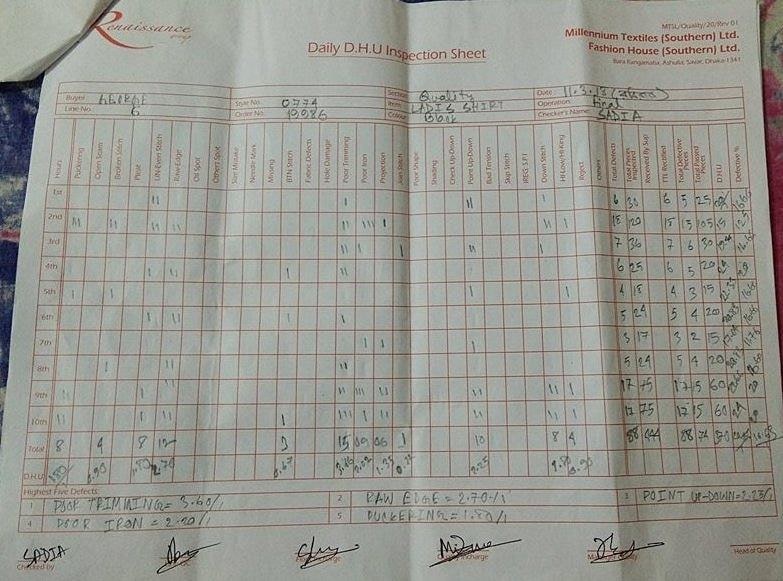

Line inspection report 1

This per hour End of The Line Inspection is done by the Q.C. & his assistants on a specific table for separating the faulty product in every each hour from a produced product of a specific line. We have inspected the End table Inspection on 10/03/18, 11/03/18, 12/03/18 & 13/03/18.

A copy of End of The End Line Inspection report is attached that we have collected from the factory

100% End of The Line Inspection Report in Sewing Section 1003/2018

Buyer: George

Date: 10-03-2018

Style No: 0774

Color: Black

Line: 6

Item: Ladies Shirt

| Hours | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th | Total Qty | D.H.U% | ||

| Total Pieces Inspected | 17 | 23 | 24 | 60 | 60 | 48 | 24 | 17 | 92 | 93 | 458 | 100% | ||

| Total Defects | 3 | 4 | 5 | 12 | 11 | 9 | 5 | 3 | 16 | 14 | 82 | 17.24% | ||

| Total Defective Pieces | 2 | 3 | 4 | 10 | 10 | 8 | 4 | 2 | 12 | 13 | 68 | 14.84% | ||

| Total Passed Pieces | 15 | 20 | 20 | 50 | 50 | 40 | 20 | 15 | 80 | 80 | 390 | 85.15% | ||

| Operation & Defect Description | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th | Total Qty | D.H.U% | ||

| Puckering | 2 | 1 | 2 | 1 | 1 | 2 | 1 | 10 | 2.18 | |||||

| Open Seam | ||||||||||||||

| Broken Stich | 1 | 1 | 1 | 1 | 4 | 0.87 | ||||||||

| Pleat | ||||||||||||||

| Uneven Stich | 1 | 1 | 1 | 2 | 2 | 2 | 3 | 1 | 1 | 2 | 16 | 3.49 | ||

| Raw-Edge | 1 | 1 | 1 | 2 | 1 | 6 | 1.31 | |||||||

| Oil Spot | ||||||||||||||

| Other Spot | 1 | 1 | 1 | 2 | 5 | 1.09 | ||||||||

| Size Mistake | ||||||||||||||

| Needle Mark | ||||||||||||||

| Missing | ||||||||||||||

| Button Stich | ||||||||||||||

| Fabric Defects | ||||||||||||||

| Hole Damage | ||||||||||||||

| Poor Trimming | 1 | 2 | 2 | 2 | 7 | 1.52 | ||||||||

| Poor Iron | 1 | 2 | 2 | 1 | 1 | 2 | 2 | 11 | 2.40 | |||||

| Projection | 2 | 2 | 0.43 | |||||||||||

| Join Stich | ||||||||||||||

| Poor Shape | ||||||||||||||

| Shading | ||||||||||||||

| Check Up-Down | ||||||||||||||

| Point Up-Down | 1 | 1 | 1 | 2 | 5 | 1.09 | ||||||||

| Bad Tension | 1 | 1 | 0.21 | |||||||||||

| Skip Stitch | ||||||||||||||

| IREG: S.P.I | ||||||||||||||

| Down Stich | 1 | 1 | 2 | 1 | 2 | 3 | 10 | 2.12 | ||||||

| HI-Low/HI-King | 1 | 1 | 1 | 1 | 4 | 0.87 | ||||||||

| Reject | 1 | 1 | 0.21 | |||||||||||

| Others | ||||||||||||||

| 1st Higest | Defect Qty | 2nd Higest | Defect Qty | 3rd higest | Defect Qty | |||||||||

| Uneven Stich | 16 | Poor Iron | 11 | Puckering | 10 | |||||||||

| Total check | 458 | |||||||||||||

| Defects | 82 | |||||||||||||

Total defects % = 17.24%

On this day I also found different types of faults the amount of faults are given below

Down Stitch: 10

Poor Trimming: 7

After check this fault they send to this operator to remove the faults.

3.2 Attachment of sewing report

Line inspection report 2

100% End of The Line Inspection Report in Sewing Section 11/03/2018

Buyer: George

Date: 11-03-2018

Style No: 0774

Color: Black

Line: 6

Item: Ladies Shirt

| Hours | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th | Total Qty | D.H.U% | ||

| Total Pieces Inspected | 30 | 120 | 36 | 25 | 18 | 24 | 17 | 24 | 75 | 75 | 444 | 100% | ||

| Total Defects | 6 | 18 | 7 | 6 | 4 | 5 | 3 | 5 | 17 | 17 | 88 | 20.04% | ||

| Total Defective Pieces | 5 | 15 | 6 | 5 | 3 | 4 | 2 | 4 | 15 | 15 | 74 | 16.66% | ||

| Total Passed Pieces | 25 | 105 | 30 | 20 | 15 | 20 | 15 | 20 | 60 | 60 | 370 | 83.33% | ||

| Operation & Defect Description | 1st | 2nd | 3r d | 4th | 5th | 6th | 7th | 8th | 9th | 10th | Total Qty | D.H.U% | ||

| Puckering | 3 | 1 | 2 | 2 | 8 | 1.80 | ||||||||

| Open Seam | ||||||||||||||

| Broken Stich | 2 | 1 | 1 | 4 | 0.90 | |||||||||

| Pleat | ||||||||||||||

| Uneven Stich | 2 | 2 | 1 | 1 | 1 | 1 | 8 | 1.80 | ||||||

| Raw-Edge | 2 | 2 | 2 | 2 | 2 | 2 | 12 | 2.70 | ||||||

| Oil Spot | ||||||||||||||

| Other Spot | ||||||||||||||

| Size Mistake | ||||||||||||||

| Needle Mark | ||||||||||||||

| Missing | ||||||||||||||

| Button Stich | 1 | 1 | 1 | 3 | 0.67 | |||||||||

| Fabric Defects | ||||||||||||||

| Hole Damage | ||||||||||||||

| Poor Trimming | 1 | 2 | 2 | 2 | 1 | 2 | 2 | 3 | 15 | 3.66 | ||||

| Poor Iron | 3 | 1 | 1 | 3 | 1 | 9 | 2.20 | |||||||

| Projection | 1 | 1 | 2 | 2 | 6 | 1.35 | ||||||||

| Join Stich | 1 | 1 | 0.22 | |||||||||||

| Poor Shape | ||||||||||||||

| Shading | ||||||||||||||

| Check Up-Down | ||||||||||||||

| Point Up-Down | 2 | 2 | 1 | 1 | 2 | 2 | 10 | 2.25 | ||||||

| Bad Tension | ||||||||||||||

| Skip Stitch | ||||||||||||||

| IREG: S.P.I | ||||||||||||||

| Down Stitch | 1 | 2 | 1 | 2 | 2 | 8 | 1.80 | |||||||

| HI-Low/HI-King | 1 | 1 | 1 | 1 | 4 | 0.90 | ||||||||

| Reject | ||||||||||||||

| Others | ||||||||||||||

| 1st highest | Defect Qty | 2nd highest | Defect Qty | 3rd highest | Defect Qty | |||||||||

| Poor Trimming | 16 | Raw- Edge | 12 | Point Up- Down | 10 | |||||||||

| Total check | 444 | |||||||||||||

| Defects | 88 | |||||||||||||

Total defects % = 20.64%

On this day I also found different types of faults the amount of faults are given below

Poor Iron: 9

Puckering: 8

Uneven Stitch: 8

Down Stitch: 8

After check this fault they send to this operator to remove the faults.

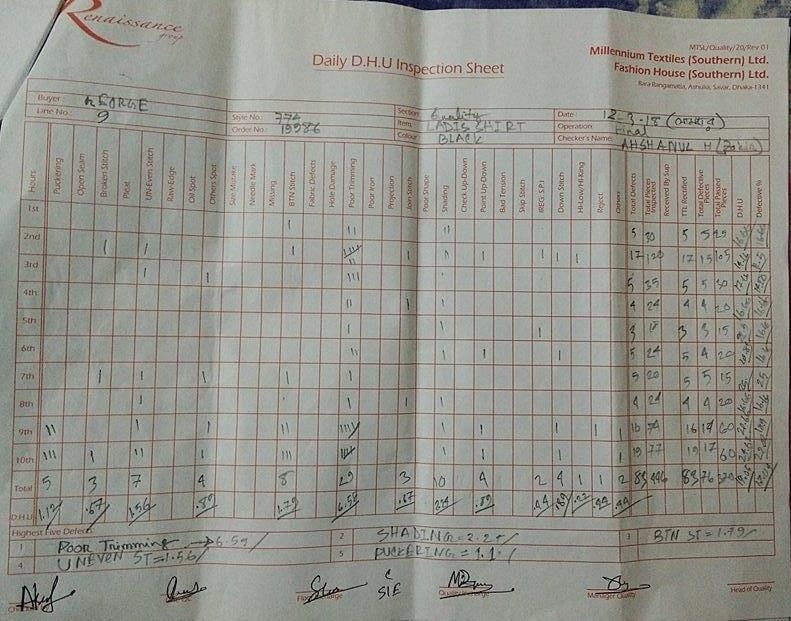

3.3 Attachment of sewing report

Line inspection report 3

100% End of The Line Inspection Report in Sewing Section 12/0/20178

Buyer: George

Date: 12-03-2018

Style No: 0774

Color: Black

Line: 9

Item: Ladies Shirt

| Hours | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th | Total Qty | D.H.U | ||

| Total Pieces Inspected | 30 | 120 | 35 | 24 | 18 | 24 | 20 | 24 | 74 | 77 | 446 | 100 | ||

| Total Defects | 5 | 17 | 5 | 4 | 3 | 5 | 5 | 4 | 16 | 19 | 83 | 19.05 | ||

| Total Defective Pieces | 5 | 15 | 5 | 4 | 3 | 4 | 5 | 4 | 14 | 17 | 76 | 17.04 | ||

| Total Passed Pieces | 25 | 105 | 30 | 20 | 15 | 20 | 15 | 20 | 60 | 60 | 370 | 82.95 | ||

| Operation & Defect Description | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th | Total Qty | D.H.U | ||

| Puckering | 2 | 3 | 5 | 1.12 | ||||||||||

| Open Seam | ||||||||||||||

| Broken Stitch | 1 | 1 | 1 | 3 | 0.67 | |||||||||

| Pleat | ||||||||||||||

| Uneven Stitch | 1 | 1 | 1 | 1 | 1 | 2 | 7 | 1.56 | ||||||

| Raw-Edge | ||||||||||||||

| Oil Spot | ||||||||||||||

| Other Spot | 1 | 1 | 1 | 1 | 4 | 0.89 | ||||||||

| Size Mistake | ||||||||||||||

| Needle Mark | ||||||||||||||

| Missing | ||||||||||||||

| Button Stitch | 1 | 1 | 1 | 2 | 3 | 8 | 1.79 | |||||||

| Fabric Defects | ||||||||||||||

| Hole Damage | ||||||||||||||

| Poor Trimming | 2 | 7 | 3 | 2 | 1 | 2 | 1 | 1 | 5 | 5 | 29 | 6.58 | ||

| Poor Iron | ||||||||||||||

| Projection | ||||||||||||||

| Join Stitch | 1 | 1 | 1 | 3 | 0.67 | |||||||||

| Poor Shape | ||||||||||||||

| Shading | 2 | 2 | 1 | 1 | 1 | 1 | 1 | 1 | 10 | 2.24 | ||||

| Check Up-Down | ||||||||||||||

| Point Up-Down | 1 | 1 | 1 | 1 | 4 | 0.89 | ||||||||

| Bad Tension | ||||||||||||||

| Skip Stitch | ||||||||||||||

| IREG: S.P.I | 1 | 1 | 2 | 0.44 | ||||||||||

| Down Stitch | 1 | 1 | 1 | 1 | 4 | 0.89 | ||||||||

| HI-Low/HI-King | 1 | 1 | 0.22 | |||||||||||

| Reject | 1 | 1 | 0.22 | |||||||||||

| Others | 1 | 1 | 2 | 0.44 | ||||||||||

| 1st Highest | Defect Qty | 2nd Highest | Defect Qty | 3rd higest | Defect Qty | |||||||||

| Poor Trimming | 29 | Shading | 10 | Button Stitch | 8 | |||||||||

| Total check | 446 | |||||||||||||

| Defects | 83 | |||||||||||||

Total defects % = 19.05%

On this day I also found different types of faults the amount of faults are given below

Uneven Stitch: 7

Puckering: 5

Point Up-Down: 4

After check this fault they send to this operator to remove the faults.

3.4 Attachment of sewing report

Line inspection report 4

100% End of The Line Inspection Report in Sewing Section 15/07/2017

Buyer: George

Date: 13-03-2018

Style No: 0774

Color: Black

Line: 9

Item: Ladies Shirt

| Hours | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th | Total Qty | D.H.U | ||

| Total Pieces Inspected | 18 | 25 | 24 | 58 | 56 | 47 | 23 | 15 | 93 | 95 | 457 | 100 | ||

| Total Defects | 4 | 5 | 4 | 10 | 7 | 8 | 4 | 3 | 15 | 17 | 77 | 16.84 | ||

| Total Defective Pieces | 3 | 5 | 4 | 8 | 6 | 7 | 3 | 3 | 13 | 15 | 67 | 14.66 | ||

| Total Passed Pieces | 15 | 20 | 20 | 50 | 50 | 40 | 20 | 15 | 80 | 80 | 390 | 85.33 | ||

| Operation & Defect Description | 1st | 2nd | 3rd | 4th | 5t h | 6th | 7th | 8th | 9t h | 10th | Total Qty | D.H.U | ||

| Puckering | 1 | 1 | 1 | 1 | 1 | 5 | 1.09 | |||||||

| Open Seam | ||||||||||||||

| Broken Stich | 1 | 1 | 1 | 3 | 0.65 | |||||||||

| Pleat | ||||||||||||||

| Uneven Stich | 1 | 1 | 1 | 1 | 1 | 6 | 1.31 | |||||||

| Raw-Edge | ||||||||||||||

| Oil Spot | ||||||||||||||

| Other Spot | 1 | 1 | 1 | 2 | 5 | 1.09 | ||||||||

| Size Mistake | ||||||||||||||

| Needle Mark | ||||||||||||||

| Missing | ||||||||||||||

| Button Stich | 1 | 1 | 1 | 1 | 2 | 6 | 1.09 | |||||||

| Fabric Defects | ||||||||||||||

| Hole Damage | ||||||||||||||

| Poor Trimming | 2 | 1 | 2 | 4 | 2 | 3 | 2 | 1 | 7 | 9 | 33 | 1.31 | ||

| Poor Iron | ||||||||||||||

| Projection | ||||||||||||||

| Join Stich | 1 | 1 | 1 | 3 | 0.65 | |||||||||

| Poor Shape | ||||||||||||||

| Shading | 2 | 1 | 1 | 1 | 5 | 1.09 | ||||||||

| Check Up-Down | ||||||||||||||

| Point Up-Down | 1 | 1 | 1 | 1 | 1 | 5 | 1.09 | |||||||

| Bad Tension | ||||||||||||||

| Skip Stitch | ||||||||||||||

| IREG: S.P.I | ||||||||||||||

| Down Stich | 2 | 2 | 1 | 5 | 1.09 | |||||||||

| HI-Low/HI-King | ||||||||||||||

| Reject | ||||||||||||||

| Others | 1 | 1 | 0.21 | |||||||||||

| 1st Highest | Defect Qty | 2nd Highest | Defect Qty | 3rd highest | Defect Qty | |||||||||

| Poor Trimming | 33 | Button Stich | 6 | Uneven Stich | 18 | |||||||||

| Total check | 457 | Total defects % = 16.84% | ||||||||||||

| Defects | 77 | |||||||||||||

On this day I also found different types of faults the amount of faults is given below

Puckering: 5

Shading: 5

Uneven Stich: 6

Point Up-Down: 5

After check this fault they send to this operator to remove the faults.

RESULT AND DISCUSSION

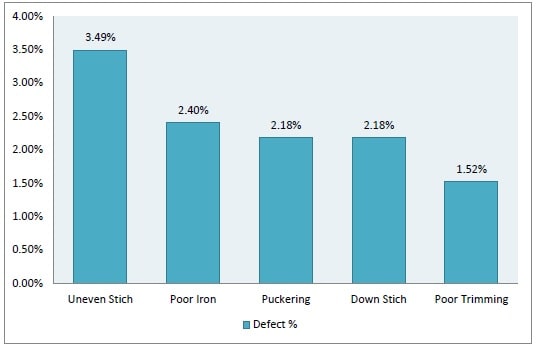

4.1 Analysis Data Collection

We have analyzed on the sewing section floor in “Millennium Textiles (Southern) Ltd.”. And we found different types of frequently occurs Poor Trimming, Down stitch, oil mark, Raw- Edge, dust mark, Poor Iron, Uneven Stich etc. we found that Poor Trimming which is comparatively higher than other defects.

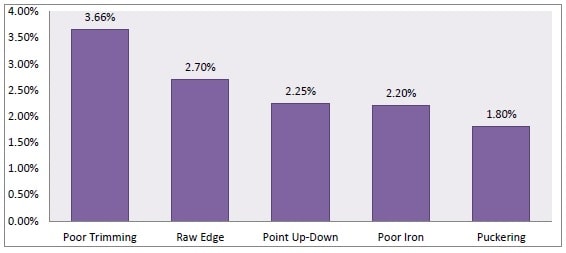

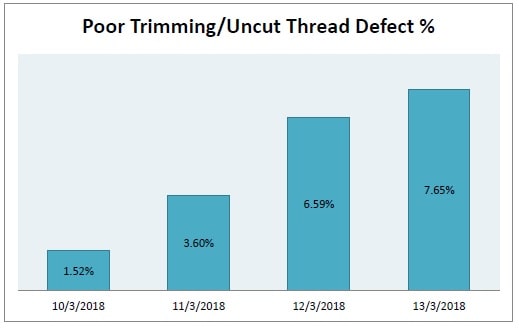

Graph 4.1.1 Table 3.1 End Of The Line Inspection report of sewing section 1 (10/03/2018)

After observation 3.1 we found Uneven Stitch faults. We observed 10th hour’s production and found 16 Uneven Stitch sewing fault pcs but all pieces are altering and no rejecting pieces found. Maximum Uneven Stitch sewing fault occur 4-6th hour production time. Average fault occur in hours is maximum 1.6 pieces. For this sewing fault of the Shirt, We have taken lot of information from Q.A.D for actual causes and remedies of this type of fault. This fault actually happened for the fabric is being pulled while sewing. Another cause for uneven stitches is the old or inferior thread. When sewing it is important to remember to never pull the fabric – allow the fabric to be taken up by the sewing machine.

Graph 4.1.2 Table 3.2 End Of The Line Inspection report of sewing section 2 (11/03/2018)

After observation 3.2 we found Uneven Stitch faults. We observed 10th hour’s production and found 15 Uneven Stitches sewing fault pieces, but all pieces are altering and no rejecting pieces found. Maximum Uneven Stitch sewing fault occur 4-6th hour production time. Average fault occurs in the hours is maximum 1.6 pieces. For this sewing fault of the Shirt, We have taken lots of information from Q.A.D for actual causes and remedies of this type of fault. This fault actually happened to untrained operators.

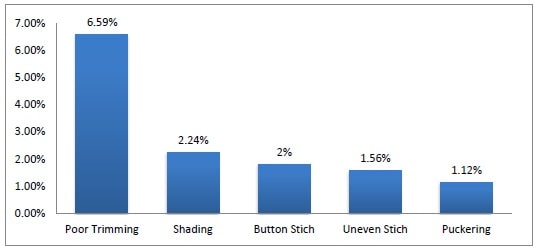

Graph 4.1.3 Table 3.3 End Of The Line Inspection report of sewing section 3 (12/03/2018)

After observation 3.3 we found Uneven Stitch faults. We observed 10th hour’s production and found 29 Poor Trimming sewing fault where 28 pieces are altering and 1 rejecting pieces found. Maximum Uneven Stitch sewing fault occur at9,10th hour production time. Average fault occur in hours is maximum 2.9 pieces. For this sewing fault of the Shirt, We have taken lot of information from Q.A.D for actual causes and remedies of this type of fault. This fault actually happened for improper trimming or finishing. To preventing this fault it is important to train the operators properly.

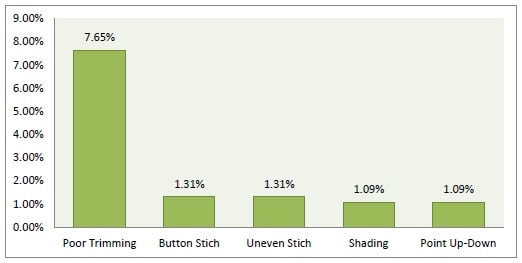

Graph 4.1.4 Table 3.4 End Of The Line Inspection report of sewing section 4 (13/03/2018)

After observation 3.4 we found Uneven Stitch faults. We observed 10th hour’s production and found 33Poor Trimming sewing fault pcs but all pieces are altering and no rejecting pieces found. Maximum Uneven Stitch sewing fault occur at9,10th hour production time. Average fault occur in hours is maximum 3.3 pieces. For this sewing fault of the Shirt, We have taken lot of information from Q.A.D for actual causes and remedies of this type of fault. This fault actually happened for improper trimming or finishing. To preventing this fault it is important to train the operators properly.

4.2 Comment

End Of The Line inspected 04 Days Report 1805 pieces of sewing Shirts and finally we got the followings faults which are more occurs than other faults.

- Poor Trimming: 84

- Puckering: 28

- Broken Stitch: 14

- Uneven Stitch: 37

- Raw-Edge: 18

- Other Spot: 14

- Button Stitch: 17

- Poor Iron: 20

- Projection:8

- Join Stitch: 7

- Shading: 15

- Point Up-Down: 24

- Bad Tension: 1

- IREG: S.P.I: 2

- Down Stitch: 27

- HI-Low/HI-King: 9

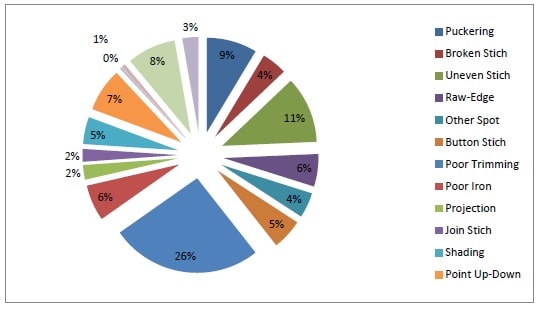

End of the line inspected 04 Days Report 325 faults.

Major problem of this report is Poor Trimming, which End Of The Line inspected 04 Days Report got 325 pieces out of 1805 piece garments.

4.2.1 Sewing Defects Percentage Measurement

| Defect name | Defect Number | Defect % |

| Puckering | 28 | 8.61 |

| Broken Stitch | 14 | 4.31 |

| Uneven Stitch | 37 | 11.39 |

| Raw-Edge | 18 | 5.54 |

| Other Spot | 14 | 4.30 |

| Button Stitch | 17 | 5.24 |

| Poor Trimming | 84 | 25.84 |

| Poor Iron | 20 | 6.15 |

| Projection | 8 | 2.47 |

| Join Stitch | 7 | 2.16 |

| Shading | 15 | 4.62 |

| Point Up-Down | 24 | 7.39 |

| Bad Tension | 1 | 0.30 |

| IREG: S.P.I | 2 | 0.61 |

| Down Stitch | 27 | 8.31 |

| HI-Low/HI-King | 9 | 2.73 |

| Total | 325 | 100 % |

Table 4.2.1: Sewing defects percentage

4.2.2 Different Sewing defects in sewing section are show in pie chart

4.2.3 Major problems occur in the sewing section

4.3 Result and Discussion

In sewing section we found many types of sewing defects. Such as Thread breakage, Skipped Stitches, Measurement Discrepancy, Uneven stitches, Open Seams, Broken Stitches, Needle Hole, Seam puckering, Joint Uneven, Label Displace etc. There are major and non- major problem. We analysis every type of sewing defects and we saw how to remove that type of defects at garments industry. But only fabric faults like as fabric hole or cut end of the fabric are created by sewing machine or hook then this type of defects call reject. Otherwise, all normal defects are called alter that removed or minimized by different methods.

Conclusion

Finally, we have completed our thesis after lots of inspection, experiment & discussion. We have gathered a large experience about this project. We have increased our knowledge about how sewing is done for making a Shirt, problems of sewing & how those problems are minimized. This thesis used a variety of garment samples which were grouped according to the end product categories. This study on quality control in woven (Shirt) sewing process in a ready-made clothing Enterprise, the reasons increasing quality faults and the priorities were determined for the improvement studies. To enable a good quality system in enterprises, there should be an adequate number of quality staff and the quality consciousness of workers should be increased. Material quality should be controlled by performing input controls, while the production quality should be provided by intermediary controls during production in sewing section. Quality level should be constantly improved and for this purpose, regular trainings should be prepared in the enterprise.

References:

- Information gathered from Millennium Textiles (Southern) Ltd.

- Garments Technology by Prof. M. A. Kashem

- Garment Manufacturing Technology by Md. Shafiul Azam, Md. Abu Saleh & Khondokar Abu Nafiz

- http://www.renaissance.com.bd/woven/

- Apparels express limited

- http://www.garmentsmerchandising.com/8-sewing-faults-with-causes-and-remedies/

- article.sapub.org/10.5923.j.clothing.20170401.01.html

- http://www.coatsindustrial.com/en/information-hub/apparel-expertise/solutions-to-sewing-problems

- https://www.slideshare.net/Mdabdullahalfaruk/production-and-faults-in-cutting- sewing-finishing-in-a-knit-garment-industry

- http://sewing.about.com/library/weekly/blsuperior.htm

- http://www.brothersewing.co.uk/en_GB/fixing-common-sewing-machine-problems;jsessionid=7420EBBE81D4E70FFA3A2020BBEA068B

- https://www.thespruce.com/sewing-machine-troubleshooting-2978277

- https://www.ebay.com/gds/Six-Common-Sewing-Machine-Problems-Solved/10000000177631751/g.html