Water pollution is one of the most environmental threats throughout the world. Water is an important asset for all living beings in the ecosystem. UNICEF and World Health Organization reports said that one in three people worldwide does not have access to safe drinking water, and the UN reports that around 1.5 million people die every year from contaminated drinking water. Textile Industry is the 2nd largest water polluter of worldwide. It produces almost 20% of the world’s wastewater. Effluent from the textile industry is the chief contribution to water pollution. To reduce water contamination, different sustainable methods have been employed in textile wastewater treatment in the wet processing industry.

Necessity of water treatment:

Textile industries consumes large amount of chemicals and water for garment manufacturing. After being the product is manufactured, untreated effluent from the textile industries is directly discharged into water streams.

These effluents are highly coloured. It contains variety of toxic contaminants like: suspended solids, dyes, acids, bases, salts, surfactants, chlorinated compounds, oxidizing, reducing agents, etc.

In wet processing ndustry, dye is considered to be the most troublesome components in textile wastewater treatment because of its complex chemical structure. Chemical additives in the textile effluent consist of a high concentration of organic and inorganic compounds. Standard amount of chemical effluent from the textile industry is below:

Standards for effluent from textile industry:

| Parameter | Standards |

| 1. PH | 5.5-9.0 |

| 2. Total suspended Solids | 100 mg/L |

| 3. Biochemical Oxygen Demand (BOD) | 30 mg/L |

| 4. Chemical Oxygen Demand (COD). | 250 mg/L |

| 5. Total chromium | 2mg/L |

| 6. Sulphide | 2mg/L |

| 7. Phenolic compounds | 1mg/L |

| 8. Oil and grease | 10mg/L |

From the table of standards for effluent from textile industry, you can easily understand the pollution of textile industry.

Therefore, the effluent must be treated before discharge from the industry. Because of these concerns about environmental pollution, the textile industry must develop on-site or in-plant treatment plants to treat effluents before their discharge into water.

Sustainable wastewater treatment process:

Sustainable wastewater treatment methods:

Textile effluent consists of a high concentration of organic chemical compounds. Effluent is discharged directly into water streams. It makes the water unusable for drinking purposes and other domestic uses. In textile effluent treatment, many methodologies have been employed to find an economic and effective way to treat wastewater.

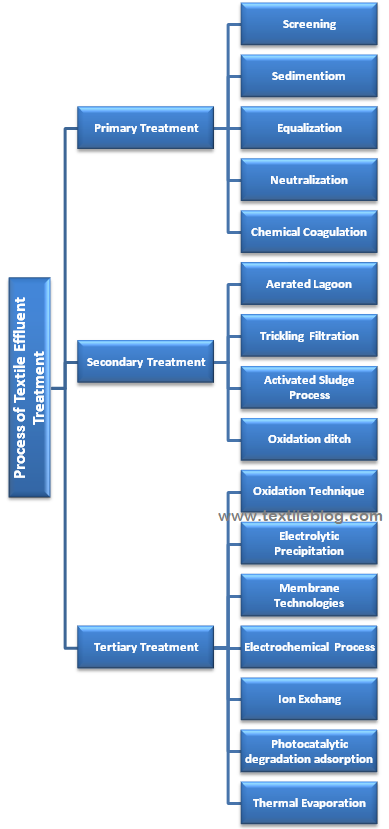

Water Treatment Methodologies are usually classified as:

- Physiochemical

- Biochemical

- Combined treatment process

Table: Sustainable Water Treatment Methodologies

| Methodologies | Process Name | Stage | Status | Performance | Limitations |

| Bio Degradation | 1. Activated sludge | Main treatment | Widely used | Bulk COD removal; partial nitrification | High residual COD, ammonia, colour. |

| 2. Sequential anaerobic–aerobic | Main treatment | Few reports of full-scale use | Better COD and colour removal than AS alone. | High residual COD, colour | |

| 3. Fixed bed | Main treatment | Pilot trials in China | Better COD and colour removal than AS. | Some residual colour. | |

| 4. Fungi/H2O2 | Main treatment | Bench-scale | Full decolourisation. | ||

| Physico-chemical treatment | 1. Coagulation-flocculation | Pre-, main or post-treatment | Extensive use | Almost full decolourisation, water reuse. | Unreliable performance, sludge disposal. |

| 2. Adsorption | Pre- or post-treatment | Bench- to full-scale depending on adsorbent | Water reuse with newer adsorbents. | Sludge disposal or adsorbent regeneration. | |

| 3. Membrane filtration

| Main or post-treatment | Extensive use in South Africa | Reliable performance, water reuse. | Concentrate management. | |

| Oxidation | 1. Ozonation | Post-treatment | Full-scale | Full decolourisation; water reuse | Expensive; aldehydes formed |

| 2. Fenton’s reagent | Pre-treatment | Several full-scale plant in South Africa | Full decolourisation | ||

| 3. Photo-catalysis | Post-treatment | Pilot-scale | Near complete colour removal | For final polishing only | |

| 4. Electrolysis | Pre-treatment | Pilot-scale | Full decolourisation | Foaming;limited electrode life |

Industrial textile wastewater treatment is an assortment of physical, chemical and biological processes. The application of micro-organisms in biological treatment is an attractive method and has considerable advantages. Biological treatment is affected by several parameters like: the pH, temperature, level of aeration and redox potential of the system. Different types of biodegradable organic matter such as polyvinyl alcohol slurry and new additives are added into the water environment, resulting in an increase in the concentration of BOD, COD and other organic complexes.

Therefore, the combined physiochemical and biological process has a better role in removing new synthetic dyes and organic complexes from effluents. In the different kinds of treatment techniques, some of the methods have been used effectively.

Sustainable Water Treatment process are described below:

a. Adsorption:

Adsorption is a surface phenomenon used to remove soluble organic pollutants that are present in solution using a suitable interface. The most commonly used adsorbent for effluent treatment is activated carbon.It’s prepared from carbonaceous materials such as sawdust, coconut husks, cellulosic materials, palm kernel husks, coffee-tea waste, etc. Activated carbon is very effective in adsorbing metal ions, dyes, cations and mordants.

b. Coagulation:

Coagulation is a widely used method for sustainable textile wastewater treatment. Different co-polymers (penta-ethylene, hexamine and ethylidene dichloride, etc) and different coagulant agents (ferric chloride, ferrous sulphate, aluminium sulphate, ferric sulphate, copper sulphate, calcium chloride, etc) are used to form flocs with contaminants. Then the clustered impurities are separated by sedimentation and filtration.

c. Membrane separation:

Membrane separation is a sustainable technology used to treat textile dyeing effluent. The membrane filter is used in this process for filtration. It consists of micropores that separates organic substances.

d. Flotation:

In flotation, suspended organic compounds attach to the air bubbles that are generated. These air bubbles are less dense than water and make the cluster of suspended particles rise to the surface of the feed water. However, flotation has several disadvantages like: higher energy consumption, operational cost, intense mechanical operations.

e. Ozonation:

Among these effluent treatment techniques, ozonation has some special advantages for textile dyeing treatment. Commercially available oxidizers like sodium hypochlorite can break down organic molecules, detergents and phenols into smaller compounds by ozonation.

f. Ion exchange:

Ion exchange is widely used to remove inorganic salts and organic anionic components. Ion exchange materials are capable to exchange soluble cations and ions with electrolyte solutions. Its transferring them into sludge.

g. Evaporation:

In the evaporation process, concentrated liquid is allowed to pass through the multiple evaporator system. At the same time, steam is applied to the evaporator. During evaporation, the liquid is recirculated until it attains the desired concentration of salt or the specific density. The vapor and steam collect in the condenser. The temperature of evaporator may vary based on the length of the tubes.

h. Crystallization:

Crystallization is used effectively for solid–liquid separation. It refers to the formation of solid crystals from a homogeneous solution. In this technique, crystallizers can be used to remove chemicals such as calcium sulphate, sodium sulphate, sodium chloride and calcium chloride.

Advances of sustainable wastewater treatment process:

| Methodologies | Advantages |

| 1. Adsorption | High efficiency of metal ion removal, fast kinetics, extensive range of target pollutants. |

| 2. Coagulation | Dewatering characteristics |

| 3. Membrane separation | Metal dye selective, small space requirements. |

| 4. Flotation | Low retention time. |

| 5. Ozonation | Constant pressure performance, no disposal of concentrates or solids. |

| 6. Ion exchange | Selective removal of metal ion, lower number of metal ions removed. |

| 7. Evaporation | Simple and cheap to construct, easy to use, clean and maintain. |

| 8. Crystallization | Products are relatively pure; crystal size can be controlled. |

Conclusion:

The textile industry is one of the largest industrial segments worldwide. But it is also responsible for environmental water pollution. Therefore, based on environmental safety, sustainable effluent treatment methodologies are mostly expected. Unfortunately, no particular treatment methodology is appropriate for textile effluents. Consequently, a combination of different treatment methods is the best solution for the textile effluent. This combination treatment process should consist of physical, chemical and biological methods which will effectively treat wastewater based on the pollution load. Therefore, suitable treatment methodologies (combined treatment plants) can be used and made fit for recycling and the reuse of treated effluent from the textile industry.

References:

- Sustainable Fibres and Textiles by Subramanian Senthilkannan Muthu

- Sustainable Innovations in Apparel Production by Subramanian Senthilkannan Muthu

- S.K. Ramamoorthy, A.P. Periyasamy, S. Rwahwire, Y. Zhao “Sustainable Wastewater Treatment Methods for Textile Industry” DOI: 10.1007/978-981-10-8591-8_2

- Madhav, A. Ahamad, P. Singh, P.K. Mishra “A review of textile industry: Wet processing, environmental impacts, and effluent treatment methods” March 2018, Environmental Quality Management 27(3):31-41, DOI: 10.1002/tqem.21538

- https://textilelearner.net/reduction-of-etp-load-wastewater-segregation/

- https://textilelearner.net/implementation-of-effluent-treatment-plants-for-wastewater/

- https://www.who.int/news-room/detail/18-06-2019-1-in-3-people-globally-do-not-have-access-to-safe-drinking-water-unicef-who

- https://www.fibre2fashion.com/industry-article/3451/effluent-treatment-in-textile-wet-processing-technology-option-and-effluent-treatment-plant

Author of this Article:

Md. Mahedi Hasan

B.Sc. in Textile Engineering

Textile Engineering College, Noakhali.

Email: mh18.bd@gmail.com