Indigo is probably the most important single textile dye worldwide. The demand for indigo depends greatly on fashion. In comparison with other dyes, indigo occupies a special position because it is used almost exclusively for dyeing warp yarn in the production of blue denim. Being identical to the natural material, indigo leads to environmentally friendly clothing.

Denim continues to be popular with men and women of all ages and social classes. Jeans are worn by both male and female. Much of the popularity of denim is mainly attributable to the attractiveness of its blue color and the finishing effects that develop when the fabric is laundered repeatedly. The blue color characteristic of denim fabric is related to cotton warp yarns that are dyed traditionally by indigo. The dyeing of cotton warp yarns with indigo is usually seen as key to the denim fabric manufacturing process. The use of indigo as coloring matter for textile materials can be traced to ancient times when natural plants and animal derivatives were the only known sources of dyes. Various methods of indigo dyeing that have been used in the past and others that are currently used for indigo dyeing are examined.

Indigo Dyeing Techniques:

Indigo is available as a powder, granulate, or liquid preparation. The dyeing technique has not changed over the years and, like vat dyeing, involves the following: (1) dissolving of the dye by reduction in alkaline medium, (2) dyeing in the vat, and (3) oxidation on exposure to air.

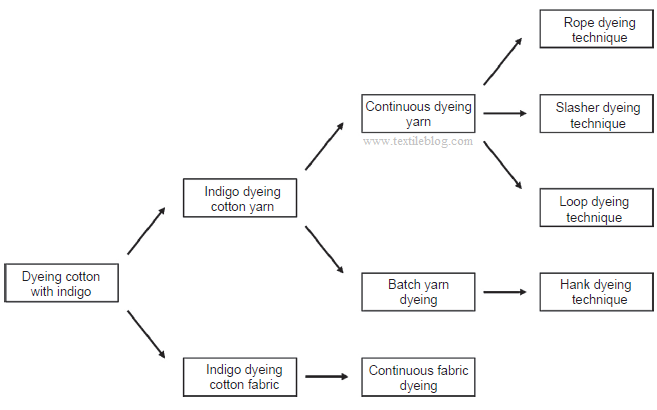

The main techniques used for cotton dyeing with indigo can be illustrated in the schematic diagram of Figure 1.

Indigo is dyed continuously on rope dyeing machines and slashers. In rope dyeing machines, 300-400 warp threads are combined into a rope and, in this form, passed through the dyeing system. Slashers were developed in the 1970s from sizing machines. In these machines, the warp threads are dyed side by side, parallel to each other. Both types of machines have advantages and disadvantages and should be assessed according to the specific requirements (e.g., small or large batches, required fastness of dyeing). In this article I will discuss different cotton dyeing techniques with indigo.

Batch Dyeing Techniques:

Until 1915, most indigo dyeing was conducted using the batch dyeing technique, which is also called skein or hank dyeing. The batch dyeing technique can be carried out artisanally in pots on gas burners or in specialized machinery. These machines are generally classic machines of cotton hank dyeing that were modified by artisans in order to be more adaptable for the specificity of indigo dyeing. With this technique, dyeing occurs in skeins or hanks generally 110 m in length, which may be suspended in the dye machine. Every skein is first looped over a hook and washed in water, opening the fibers in order to receive the dye. Then it is dipped into the dyeing bath. After dipping, it is exposed to the air for oxidation. It is possible to dip the skeins up to 20 times in order to reach a deep shade.

This technique is a laborious and time consuming process. However, it achieves a good and rich color penetration. Furthermore, this dyeing technique is less deteriorating to the textile material, and the yarns retain a softer and loftier feel.

On the other hand, contrary to other yarn dyeing techniques (rope dyeing, slasher dyeing and loop dyeing), which provide a ring dyeing effect (a characteristic of indigo dyeing whereby only the outer ring of the fibers in the yarn are indigo dyed, while the inner core remains white), hank dyeing produces a core dyeing effect.

Skein dyeing of indigo is still the useful method of dyeing with indigo on very fine yarns for delicate high fashion fabrics. Recently, it has been largely applied for dyeing organic denim with natural indigo.

Continuous Dyeing Techniques:

Continuous Yarn Dyeing Techniques:

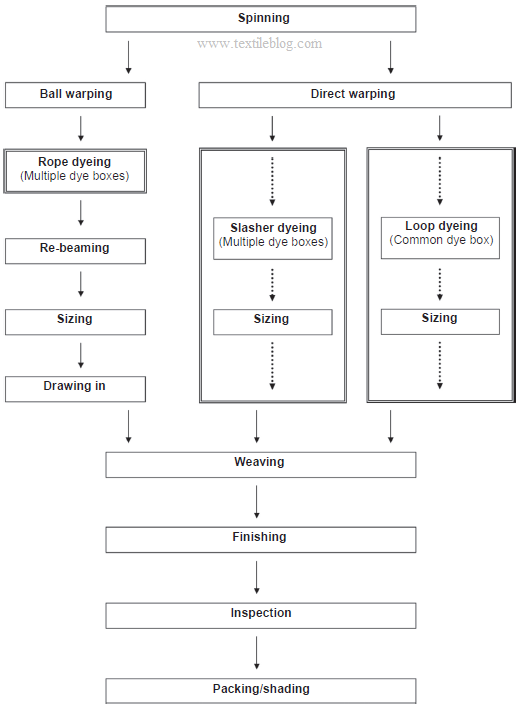

The continuous dyeing techniques of cotton yarns by indigo are mostly used for producing denim products. Denim fabrics are 100% cotton with blue face and white back. Traditionally, they are a 3 × 1 twill woven structure where the warp yarns are indigo dyed and the weft yarns are non dyed cotton. The dyeing of warp yarns is done continuously using three major methods: rope dyeing, slasher dyeing and loop dyeing. Figure-2 shows a schematic diagram that clearly represents the position of the steps of these dyeing methods in the manufacturing process of denim fabrics.

Rope dyeing:

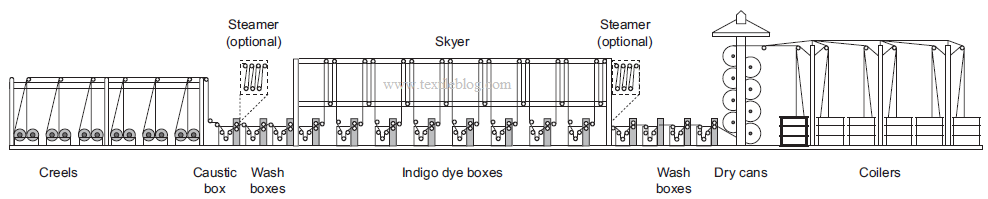

This dyeing technique dates from 1915, when the first rope dyeing machine appeared. A typical example of a rope dyeing range is shown in Figure-3. With the rope dyeing technique, 350–400 warp threads are bound on the ball-warper machine to very thick cables of 10,000–15,000 m in length (sometimes the length of cables may exceed 25,000 m). Generally 12–36 cables are first fed into one or more scouring baths containing wetting agents, detergents and sodium hydroxide. The scouring baths are used to remove naturally occurring impurities found in cotton fibers such as dirt, minerals, ash, pectin and naturally occurring waxes. It is very important to remove these substances in order to achieve uniform wetting and uniform dyeing. Then, the cables are fed into one or more water rinsing baths.

After that, the cables are dipped into a bath of leuco indigo with an immersion time of 12–20 s, and then are squeezed to give 70%–80% wet pick-up after each dip, followed by exposure to air for oxidation, multiple times. The oxidation time takes at least 80 s. Generally, four to eight dyeing vats are used for dipping. This results in the fine layer of indigo on the surface of yarn. The cables of yarn are washed in various water baths to eliminate the non-fixed dye. Next they pass through a softener box, which assists in obtaining a better opening of the cables in the long chain beamer. Finally, they are dried on Teflon covered cylinders and coiled into large cans.

Slasher dyeing:

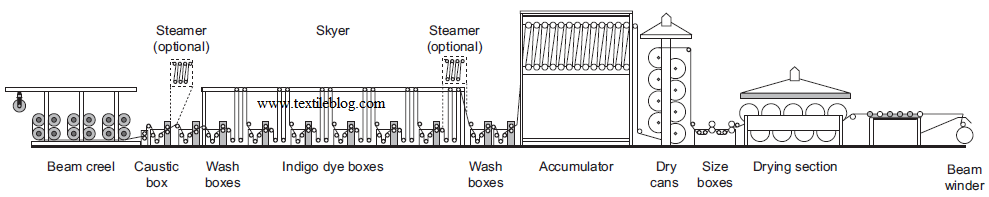

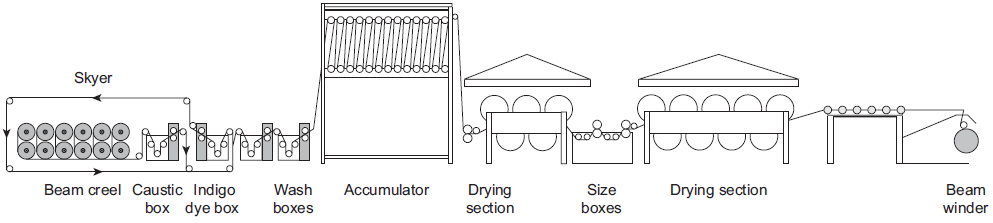

Slasher dyeing was introduced in 1970 to be more rapid and flexible in response to changes on the denim market. This kind of dyeing works well, especially with lightweight denims, and the corresponding dyeing machines require less floor space and enable smaller production runs. Basically, in slasher dyeing, direct warping beams are employed instead of the ball warping logs used in the rope dyeing technique. A schematic diagram of a typical slasher dyeing unit is shown in Figure-4. During slasher dyeing, section beams of warp yarn are forced into a sheet of yarns (approximately 4000 yarns), which is first fed into a scouring section to remove natural impurities as in rope dyeing. Then the sheet passes through the multi-dip/nip indigo dyeing section with an immersion time of 4–15 s in order to achieve fairly deep shades. The oxidation time takes at least 45 s. Some slasher dyeing ranges do not allow for multiple dip/nip applications, and so only light and medium shades can be obtained from indigo in this case.

After rinsing, the sheet is dried on cylinder dryers. Next, the sheet passes through the size box containing the sizing agent. The yarns pick up the required quantity of size solution and the excess size is removed by squeezing. Then, the sheet is dried on cylinder dryers using hot steam rolls. In the end, the yarns are wound onto a loom beam for weaving. Using slasher dyeing, it can be seen that the handling of yarns is minimized since the warp sheet is directly processed and then sent to the weaving section for its conversion to fabric. A slasher dyeing range may consist of either the indigo dyeing range alone or a continuous indigo dyeing range with an integrated sizing range. It is possible to simultaneously treat two or more layers of warp sheet using this technique.

Loop dyeing:

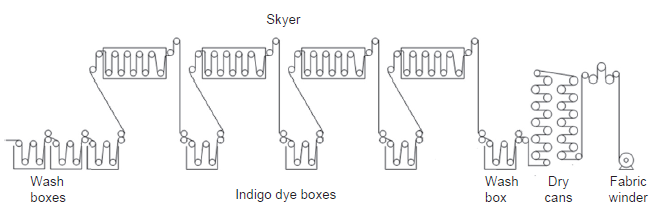

This dyeing technique, known as ‘Loopdye one for six’, was developed in 1980 by Eckhardt Godau and his company Looptex in order to solve many problems associated with both slasher and rope dyeing. A typical example of a loop dyeing range is shown in Figure-5. In comparison with the other indigo dyeing methods with six or eight dye baths, in the loop dyeing process, the yarns are dyed in only a single bath with one squeezing unit, after passing through the pre-treatment boxes. When the yarns exit the dyeing bath, instead of moving forward, the yarns are carried to the rear of the machine, around the top and rear of the yarn creel from where they started, to pass under the yarn creel, where they return to the indigo dye bath for another dye passage. This continuous passage of yarns that occurs between the yarn creel and the dye box represents a ‘loop’ form.

According to the desired shade, the yarns can make multiple loops through the indigo dye bath. Next, they are conducted through the wash boxes and then onto the drying cylinders. After drying, the indigo dyed yarns pass directly to the sizing unit. It can be seen that loop dyeing has various advantages in terms of handling, rapidity and flexibility of process, floor space and investment cost. To further clarify the difference between rope dyeing, slasher dyeing and loop dyeing, a comparative study between both the performance and the limitations of these continuous dyeing techniques is summarized in Table.

Table: Advantages and limitations of rope, slasher and loop dyeing

| Rope dyeing | Slasher dyeing | Loop dyeing | |

| Advantages |

|

|

|

| Limitations |

|

|

|

Bottoming and Topping:

The additional processes of bottoming and topping were included in the dyeing of denim fabrics especially due to fashion effects. Bottoming dyeing is applied before dyeing by indigo. In fact, after scouring, the yarns are fed originally into a bath of a reduced sulphur dye. The purpose of bottoming is to produce a much deeper and darker shade with less indigo for lower cost, or to slightly change the shade of the blue yarn in order to make it unique. Now, the bottom dye range is expanded to other classes of dyes like reactive and vat dyes in order to produce new shades.

On the other hand, topping dyeing is a process in which the warp yarns are dyed first with indigo and then they are washed and dyed generally with sulphur dye. Although the sulphur dye will migrate towards the core of the fiber/yarn, the sulphur top gives a different type of yarn color performance when the garment is washed than a sulphur bottom. Similar to the bottom dyeing process, it is possible to use other dyes for topping such as reactive and vat dyes. Another process called ‘bottoming indigo topping’ is also used in denim dyeing. In this case, the warp yarns are first dyed with bottom dye. After washing, they are dyed with indigo, followed by washing and a second dyeing with another dye such as sulphur dye.

Continuous Fabric Dyeing Techniques:

The continuous fabric dyeing technique consists of passing the fabric through successive baths of leuco indigo (Figure-6). After each dipping, the fabric is squeezed between rollers followed by exposure to air for oxidation, multiple times. Then the fabric is washed, passes to the drying section and wraps as a roll. This technique is not common industrially, probably for technical reasons. In fact, taking into account the specificity of indigo dyeing, it will be extremely difficult to achieve in practice a good level of dyeing and a good depth of shade as well as acceptable dyeing fastnesses when using this technique.

References:

- Denim: Manufacture, Finishing and Applications Edited by Roshan Paul

- Industrial Dyes: Chemistry, Properties, Applications Edited by Klaus Hunger

- Sustainability in Denim Edited by Subramanian Senthilkannan Muthu

You may also like:

- General Dyeing Procedure of Cotton Fabric with Recipe

- Different Types of Dyeing Methods

- Various Classification of Dyes | Different Types of Dyes

- Principal Classes of Synthetic Dyes and Their Characteristics

- Sustainability in Textile Dyeing and Finishing