Aerospace Textile:

From G-suit to space shuttle, textile could be used anywhere in the aerospace. Aerospace textile is one of the most important sectors which is aim to safe guard the life of an aerospace traveller or astronaut’s life. The development of these textiles is a great benediction to the present-day textile industry. Today, the era of technical textiles application, the aerospace industry is considered as one of the most important for engineering applications.

Space and Its Environment:

Learning about the space and its environmental conditions is a mandatory before entering into the topic aerospace textiles. The outer space environment is vacuum surrounds the upper most part of earth. In outer-space the pressure is zero whereas at the sea level in earth, the pressure is 101.325 kilopascals.

For the absence of this atmospheric pressure, it will rip apart fragile tissues such as eardrum, capillaries and so on. The atmospheric pressure helps human body to balance the internal pressure of our body fluids and gases.

Further lack of oxygen to the human brain leads to immediate unconsciousness in less than 15 seconds. The temperature range are found in outer-space provides a major hazard for humans. There is some major hazard like temperature range, electrically charged particle, ultraviolet radiation (UV radiation), and micrometeoroids, and so on.

Hence, there need a system development with the help of technical textile which can be encountered these outer-space environmental problems and also kept the astronauts alive in the space.

Application of Textile in the Aerospace Industry:

Based on the applications, aerospace textiles are broadly divided into two sections: A. Aircraft Textiles and B. Space Textiles.

A. Application area of aircraft textiles:

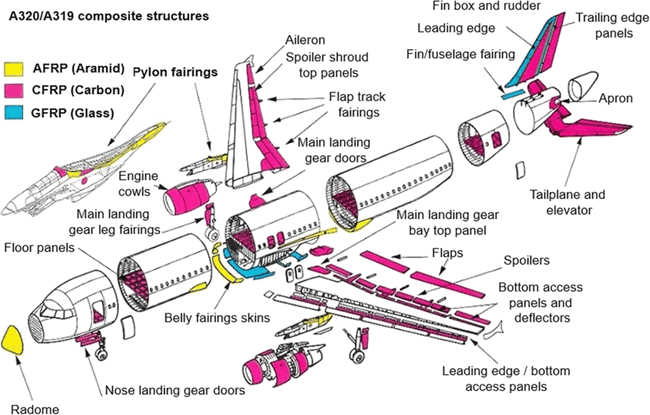

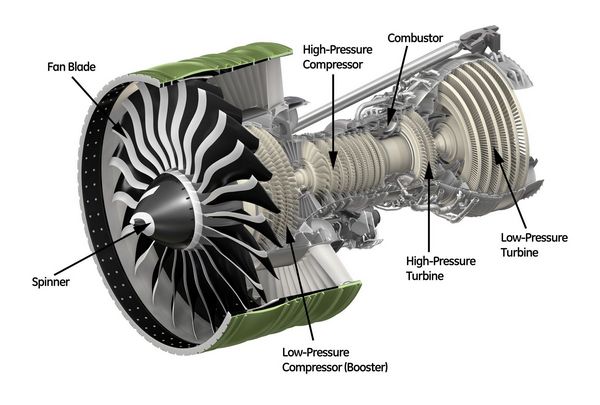

Various textile composites are used in aircrafts had predominantly increased, properties such as strength, resistance to heat, chemical and harmful radiations, specific modulus, etc. The main technical application in aerospace textiles for the textile technologist are safety and weight saving. Every 1 kg of weight saved in an aircraft, £150 per year is saved in fuel costs. Vital and statistics show that uses of flame retender composite reduced over 25% of deaths in aircraft accidents. Phase Chane Materials (PCM) also used in aerospace textile.

Application area of textiles in aerospace industry:

- Wings

- Body Parts

- Fuel Tanks

- Curtains

- Carpets

- Furnishing fabrics

- Technical fabrics

- Upholstery fabrics

- Aerodynamic fairings

- Wall covers

- Covering

- Seat Cover

- Fibre-reinforced composites

- Nylon tyre cord

- Rotor blades

- Circuit boards

- Webbing for aircraft

- Aircraft upholstery

- Head set

- Seat belt Webbing

- Air bags

- Parachute, etc.

Textile composites fibre used in aerospace industry:

| Composite Fibre | Application Area |

| Carbon/Epoxy | Primary structure and skin. |

| Kevlar/ Epoxy | Mostly used in military application, in primary structure and armour plating. |

| Glass fibre | Used as a structural and skin material. |

| Glass/Phenolic (GFRP) | Used in interior fittings, furnishing, Hood panel insulator and structures. |

| Poly Fibre | Can be rejuvenated after years of weathering. Poly fibre is only all vinyl systems in which bonds extremely well to polyester fabrics and remains flexible when its dries and does not support combustion. |

| Nylon | Steel cover slit sheet, Airline and headlines, Interior carpet. |

| PVC coated | Trunk cover. |

| Polypropylene | Shelf panel cover. |

| Polyester | Door trim panel padding. |

| PET, glass, nylon-6, Polyester, etc. | Tire cords. |

Textiles in aircraft manufacturing:

a) Rotor Blade:

Broken parts of rotor blade can act as projectile and from external effect. That’s why woven structure and material like: Kevlar, nylon, glass fibre metal resign, aromatic polyamide, and carbon/Epoxy composite structure used to low impact damage. These textile materials help flight surface and rotor inner side covering against ballistic impact in aircraft.

b) Aircraft Interior Designing:

In aircraft and spacecraft, different textile composites are used to interior designing. From aircraft automotive seat to floor covering every interior design has involved with textile composites. Advance technology like microfibres, nanotechnology, polymer, etc have revolutionized the application of textiles in the aircraft interiors designing.

c) Parachute:

Parachute is a type of aerospace textiles contributing in the space operations. It helps the safe decent of person or material from aerospace to ground surface. It can also be used for horizontal deceleration of fixed- wing aircraft. A parachute composes with thin lightweight fabric, supporting tapes and suspension cords. Nylon, polyester, Kevlar, Nomex, etc fabric used for parachute. Anti-gravity suits, space suits and parachutes are the few examples of aerospace textiles effectively serving the aerospace operations.

B. Application area of space textiles:

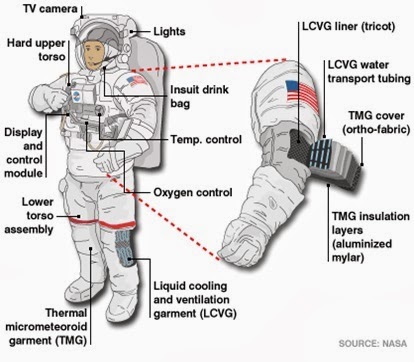

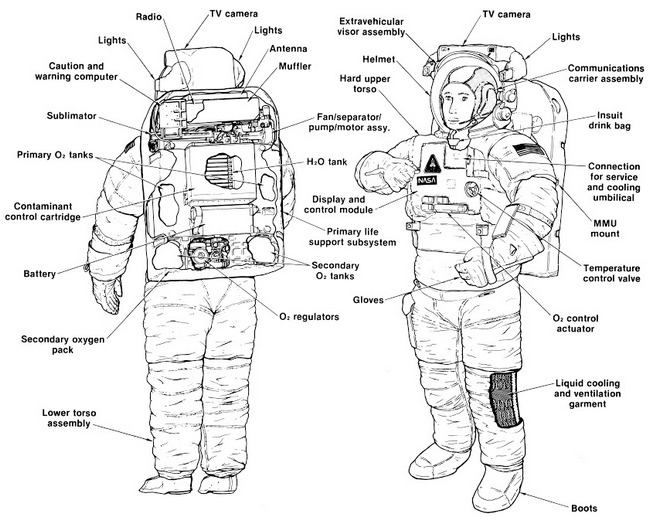

1. Astronauts Functional Clothing:

Astronauts functional clothing used by the astronauts during space shuttle missions represents the ultimate protective clothing. It protects the astronauts from heat, cold, chemical, micrometeoroids, pressure fluctuations and temperature extremes. Astronaut’s functional clothing should be also lightened. Every kg to be launched in a spacecraft increases fuel consumption and costs. That’s why, tough textile components are used to lighten the astronaut’s suits.

2. Design of an Extra Vehicular Mobility Unit (EMU):

In Space Shuttle, Extravehicular Mobility Unit may be described as a waist entry suit with a hard-upper torso and relatively softer mobility joints made of fabric. Extra Vehicular Mobility Unit was designed by the NASA Engineers have to work in zero gravity. It is influenced by the space-suit performance.

3. G- Suit:

Anti-g suit is a flight suit worn by aviators and astronauts who are subject to high levels of acceleration force (g). It containing air or liquid that can be pressurized using a g-sensitive valve and held firm to legs and abdomen under higher values of gravitational force. It is worn by fighter pilot, astronauts, and aviators to control the blood circulation at higher level of acceleration. G-suit is an interesting and significantly useful textile product in aerospace industry.

Properties of a Space Suit:

- High specific modulus & Strength.

- Lighter in weight.

- Flexible in handling.

- Resistant to chemicals and organic solvents.

- Good fatigue.

- Thermal insulated and thermal resistant.

- Impact and stress resistant.

- Modifiable in size and shape.

- Better dimensional stability & conformability.

- Low flammability & Non-sensitive to harmful radiations, etc.

Conclusion:

Textiles had always played a vital role in the optimizing aerospace industry. Low weight, high strength, cost efficiency, safety, etc parameters can be achieved by more and more research on the aerospace textile. There is huge scope for research and development in aerospace to save the life.

References:

- Textiles in Aerospace Applications by Dr. Faheem Uddin, Textile Department, School of Science of Technology, University of Management and Technology.

- Handbook of Technical Textiles Edited by A R Horrocks and S C Anand

- https://textilelearner.net/aerospace-textiles-raw-materials-and-applications/

- https://www.technicaltextile.net/articles/textiles-in-aerospace-applications-3566

- https://arts.eu/blog/textiles-in-industry-the-importance-of-modern-textiles-in-the-aerospace-industry

- https://www.slideshare.net/vigneshdhanabalan/textiles-in-aircraft

- https://www.wikipedia.org/

- https://textilelearner.net/components-for-space-suit/

Author of this Article:

Md. Mahedi Hasan

B.Sc. in Textile Engineering

Textile Engineering College, Noakhali.

Email: mh18.bd@gmail.com