What is Sewing Thread?

Sewing thread is a type of yarn used for stitching fabrics, leather, or other materials together. It is a basic raw material for giving desired shape to a garment. External appearance and qualities of a seam are directly concerned with the sewing thread. Specially, the quality of a garment also depends on the selection that what sort of sewing thread will be used for the sewing of the garment. The construction of sewing thread, the fiber types in the thread and the finishing material in the thread etc influence on the external appearance of the seam and its qualities. There are various types and of various sizes of sewing threads but specific thread is to use for specific fabric and specific thread size should be used for specific needle size.

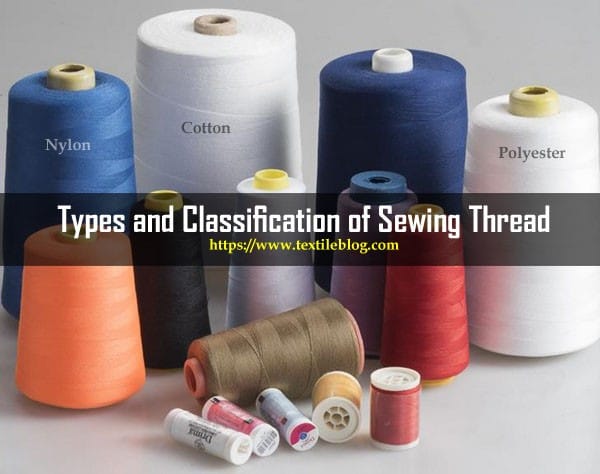

Types and Classification of Sewing Thread:

Threads may be of various types and they may be classified in various ways but internationally, sewing threads are classified in the following three ways, such as,

- Fiber types

- Thread construction

- Thread finishing

A. Fiber Types:

Depending on the classification of fibers in the thread, such as, natural fiber, synthetic fiber or their blends, the classification of sewing thread is determined.

The sewing thread produced from natural fibers:

The various types of sewing threads produced from the natural fibers are discussed below:

Linen:

The linen thread is very ancient and once it was used for sewing of garments on a large scale. Linen thread is very strong and to some extent it is stiff, once used on a large scale for making comparatively more stronger seams like tents, canvas, shoe making and button attaching but presently the use of linen thread is about an extinct because of synthetic thread.

Silk thread:

Silk thread is made from both continuous filament and broken filament silk. The silk thread is comparatively stronger and stretchable. It is lustrous and of good quality. But its use is limited for making costly garments.

Cotton thread:

Among the threads produced from natural fibers, cotton thread is produced and used most. Generally, cotton thread is produced from good cotton fiber. Sewing of fabrics with cotton thread is easier and suitable but its strength and abrasion resistance is comparatively lower than synthetic thread. During sewing temperature produced by needle, cotton thread is not damaged. Cotton thread is generally of three types, such as:

Soft cotton thread:

Among these cotton thread, bleaching and dyeing is done and sometimes lubricants are used for becoming less friction. If this type of thread is wet in water, they shrink and due to this, there is a possibility of puckering of seams after washing of the fabric in water.

Mercerized cotton thread:

These cotton threads are finished in caustic solution in full stretched condition. As a result the fibers in the thread become rounded, resulting in the increase of both strength and glaze of the thread.

Glazed cotton thread:

Glazed cotton thread is made by applying the surface coating on the soft cotton thread. As a result, this type of thread becomes to some extent stiff and smooth and increases the abrasion resistance.

You may also like: Functional and Aesthetic Properties of Sewing Thread

Presently the price of cotton thread is higher than the price of synthetic thread. The strength of the same count of synthetic thread is comparatively higher than that of cotton thread. Cotton thread can easily be rotten for which the use of cotton thread has decreased to a great extent in garments industries. But the use of cotton thread is increasing for sewing of those garments which are dyed after making of the garments.

Viscose thread:

It is made from continuous filament or staple fiber produced from re-generated cellulose. Both the strength and the durability of viscose thread are comparatively low, but they are highly lustrous. For these reasons, the demand for viscose thread is very low for sewing thread but it is being used on a large scale for embroidery purpose. The garments where the use of viscose thread is much, those garments should be less washed in water.

The sewing thread produced from synthetic fibers:

There are various types of synthetic fiber but polyester and nylon fibers are mostly used in making synthetic sewing threads. Without this, Aramid and PTFE fibers are also used in some small quantities for making of synthetic sewing threads. Continuous filament and staple fibers, this means from both of these fibers, sewing thread is made. Generally, the synthetic thread is not easily damaged by mildew or bacteria and it is not easily rotten. The strength and durability of these are very high. Specially, the abrasion resistance is four times higher than that of cotton thread. About the synthetic threads, which are used for sewing works, are discussed below:

Polyester thread:

The sewing thread made from polyester fiber are strong enough, cheaper in price, good elasticity property and excellent colorfastness resulting in using on a large scale in garments sewing. Presently, the use of polyester thread is maximum among the use of synthetic sewing threads. If it is washed in water or boiled up to 150 degree centigrade temperature, it does not shrink.

Nylon thread:

The use of nylon thread for sewing of garments is very much limited. But due to its high extensibility, nylon thread is used in sewing of swim wear and some knitted fabrics.

Aramid thread:

The use of this type of thread is very much limited, because it is a very costly thread. The aramid thread such as Nomex is used as a sewing thread in those garments which are flame resistant.

PTFE sewing thread:

This type of thread is also very costly and its use is very much limited. The PTFE sewing thread is used in sewing of those garments only which are fully resistant, melting resistant and having the quality of chemical reaction prevention.

B. Thread Construction:

Sewing thread is made both from staple fiber and continuous filament fiber. Initially, single thread is made from staple fiber with S twist and then a number of single threads together are given Z twist and the sewing thread is made. Z twist sewing thread is used mostly, but in some cases for example, in flatlock machines, S twist sewing thread is used. In case of filament, sewing thread is made by twisting one or more than one filament. Based on the construction of threads, the types of sewing threads are described below:

Monofilament:

Generally, this type of sewing thread is made with a continuous filament and there is no twist in the thread. As a filament itself is used as sewing thread, so it becomes stiff and thick than the other filaments. Moreover, the cutting end of the thread prickles in the body. The gripping capacity of its seam is very low and the stitches in the seam open very easily. As the filament is transparent, no problem of shade matching arise in sewing with any color of fabrics. Generally, monofilament thread is used for sewing low priced garments, upholstery garments and in sewing of fabrics for household use.

You may also like: Sewing Thread Consumption Guide for Professional

Multi-filament:

This thread is made by twisting together a multiple continuous filaments and in the form of single, or plied or corded. In case of making of flexible threads, the thread made from filament is twisted, dyed and lubricated. Synthetic polymer is applied on plied thread for having the highest quality and abrasion resistant thread. As a result, polymer bond is created between each filament and thread. Such produced thread from polyester filament is very stronger and they are obtained comparatively in cheap price. The thread produced in this system is comparatively fine, so thread of a longer length can be wound in a thread cone. The most abrasion resistant and strongest sewing thread is obtained from poly amide that means nylon filament in bonded process. This type of thread is being used on a large scale in leather or shoe making factories. If multifilament thread is used in sewing works, the stitches at the beginning of the sewing and at the ending of the sewing must be required to secure, otherwise sewing may start opening from an end.

Textured thread:

Texturing means, modification of threads by applying crease in threads in various ways. Generally, this type of thread is made by texturing together a number of continuous filaments. Folds or crimps are created in filaments by texturing. This can be done in various ways, such as, false twisting, air jet, edge crimping etc. Based on the desired use, the amount of crimps are increased or decreased. This type of sewing thread is felt soft in touch for which they are used as under thread and edge finishing on a large scale.

Textured thread is made both from polyester or nylon filament, but the crimp rigidly is higher in nylon than polyester. The seam locking capacity of the textured thread is better than monofilament or multifilament. Generally, it is much used as looper thread.

Core spun thread:

This type of sewing thread is made in combination of continuous filament and staple fiber. Continuous filament stays at the center of single thread and generally cotton fiber is wound around it during twisting. This way, by twisting two or three single threads together, the sewing thread is made. Generally, polyester filament is used as core and cotton fiber is used as staple. The most remarkable suitable property of this type of thread is that the strength equal to synthetic thread is obtained and the qualities of cotton fiber is obtained. In addition to that, it is suitable in stitch formation and if any lubricant is applied in thread, it remains easily preserved for a long time by cotton fiber. Without this, the shrinkage of this type of thread is low. During sewing in high speed, the needle is heated due to friction. There is no possibility of damage to this type of thread due to the high temperature created by the needle. But this type of thread is dyed in two times, so the dyeing cost is high.

Now a days, the core spun thread is being produced in combination of polyester filament and polyester staple fiber. Very fine sewing thread can be made in core spun system, by which very fine fabric can be easily and fairly sewn. The use of this type of thread, specially the use of polyester or cotton core spun thread, is gradually increasing for making of high class garments.

C. Thread Finish:

Various types of finishing material are used on threads for the interest of sewing easily and fairly. Specially, by applying finishing material on sewing threads, some special properties are inserted in them. Lubricant is one of the finishing materials that are used in threads.

The main cause of the use of lubricant in threads is that if lubricant is used, the frictions of needle and fabrics with the thread will be less and specially the possibility of damaging of synthetic thread by the temperature of the needle will reduce. Lubricant has to be used in threads skillfully and in required quantity, otherwise seams may be damaged and the problem of frequent breaking of thread may happen. There are various types of lubricant available for thread lubrication. The qualities which should be present in good lubricants are as follows:

- Will not close the needle eye in combination with dirt.

- Will not create any stain in needle.

- Will not create any problem to open thread from the package.

- Will help to reduce the friction between machine and thread.

- Will not cause any harm due to excessive heat.

- Will be applicable to thread easily.

- Will be comparatively cheap.

Various types of lubricant can be used in sewing thread based on the types of the fiber that means natural or synthetic fiber. Again, the quantity of lubricants vary based on the fields of the use of the threads.

In hot and wet weather, synthetic thread is generally rot and mildew resistant, but cotton thread is not. In order to make rot and mildew preventive to the cotton thread, special type of finishing material is applied in the thread. This type of thread is not used in normal use instead of some specific cases.

You may also like: Various Factors Influence Sewing Thread Consumption

The garments which are rain or water proof for making those garments also the sewing thread should be water proof. By applying special type of finishing in threads, the water proof sewing thread is made. If lubricating finish is to apply in water proof sewing thread, care should be taken so that the lubricant does not damage the water proof quality of the thread.

There are some garments which are flame retardant. The sewing thread required for sewing those garments should also have the properties of flame retardant. By using special type of fiber or by finishing the sewing thread with some special chemicals, the flame retardant sewing thread can be made. Due to the wearing of garments and for repeated washing, this special properties of thread can be damaged.

Based on the types of finishing, the threads, on which discussion has been made here, are not always directly available. So for procuring these threads, the manufacturers or suppliers should be ordered beforehand.