What is Uster HVI 1000?

HVI means high volume instrument. USTER HVI 1000 is manufactured by world famous USTER Company. Uster HVI 1000 provides the most accurate and repeatable test results for the efficient classification of cotton quality (and high-throughput requirements for spinning mills). It rapidly provides full reports on 11 important quality characteristics describing the length, strength, fineness, color and moisture content of the fiber.

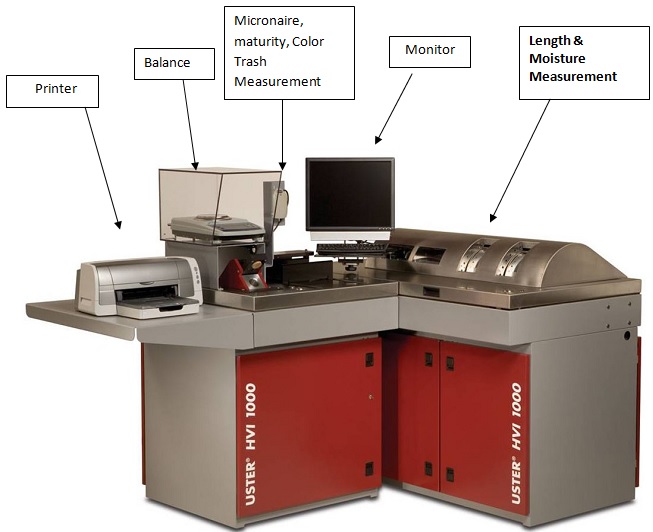

Components of Uster HVI 1000:

- Balance

- Micronaire

- Monitor

- Keyboard

- Printer and

- Printer table

- Barcode Reader

Main Equipment:

Computer Software:

The USTER® HVI 1000 is a menu driven design that allows quick access and selection of testing, setup, calibration, and data management. These features include:

- Windows XP operating system with icon-based software

- Simple user interface

- Error messages for troubleshooting

- Network capabilities

Computer Hardware:

- Computer system with 2.8 GHz PC with 512 MB RAM, P&P Sound Card, DVD-R drive, 1.44 MB (3.5-inch) Floppy Disk Drive, 60 GB or better hard drive, and Pentium P4 processor

- Keyboard with Integrated Touchpad

- 17” High Resolution Flat Panel LCD Monitor with Integrated Sound Bar

- Balance

- Printer

- Integrated Bar Code Scanner

Available Options:

- Barcode Reader (M700)

- UPS – Uninterrupted Power Supply device.

- UV Module

- NEP Module

Application Range:

100% cotton samples in the form of bale or opened and cleaned material (card mat).

Measurements and Calculations of Uster HVI 1000:

- Micronaire

- Maturity Index

- UHML – Upper Half Mean Length

- UI – Uniformity Index

- SFI – Short Fiber Index

- Fiber Strength in g/Tex

- Elongation

- Moisture Content

- Color (Reflectance Rd, Yellowness +b) & Color Grade (USDA Upland, Pima, or regional customized color chart)

- Trash (% Area, Trash Count) & Trash Grade (USDA)

Above parameters are described below:

1. Micronaire: Micronaire Reading Measured by relating airflow resistance to the specific surface of fibers.

2. Maturity: Maturity Ratio Calculated using a sophisticated algorithm based on several HVI™ measurements.

3. Length: Upper Half Mean Length, Uniformity Index, Short Fiber Index Measured optically in a tapered fiber beard which is automatically prepared, carded, and brushed.

4. Strength: Strength is measured physically by clamping a fiber bundle between 2 pairs of clamps at known distance. The second pair of clamps pulls away from the first pair at a constant speed until the fiber bundle breaks. The distance it travels, extending the fiber bundle before breakage, is reported as elongation.

5. Moisture: Moisture content of the cotton sample at the time of testing, using conductive moisture probe.

6. Color: Rd (Whiteness), +b (Yellowness), Color Grade measured optically by different color filters, converted to USDA Upland or Pima Color Grades or regional customized color chart.

7. Trash: Particle Count, % Surface Area Covered by Trash, Trash Code measured optically by utilizing a digital camera, and converted to USDA trash grades or customized regional trash standards.

Maintenance of Uster HVI 1000:

The Operator is obligated to maintain & operate the HVI is proper and undamaged condition. The maintenance intervals specified in

- Lint/ waste box → Daily

- Excess cotton fiber carding place → as a required

- Comb track assembly → Daily

- Rails → Daily

- Inter filter of water → Daily

- Computer cooling fan filter → Weekly

- Combing → Weekly

Additional Features of Uster HVI 1000:

- Safety interlocks to prevent injury from un-authorized entry to the instrument

- Relative humidity and temperature probe

- Moisture measurement

- Easily accessible Lint Waste Box with two separate access doors

- Computer System easily removed for service

- Configuration can be straight line configuration or “L” configuration

- Industrial brushed stainless steel top and work surfaces

- Single point adjustable brush pressure

- Integrated air enclosure around balance to eliminate influences of air turbulence

- Password protected operational software

- Complete Operator Manual included

Dimensions:

The USTER® HVI 1000 can be installed in an In-Line (straight) or an L-shaped configuration and requires only one operator. The following is a breakdown of the individual cabinets for each instrument.

The Length/Strength cabinet physically occupies a space of 53.5 inches (136 cm) wide by 30 inches (76.2 cm) deep. The working surface is 38 inches (96.5 cm) from the floor. The Length/Strength cabinet weighs approximately 765 pounds (347 kg) (M1000) and 725 pound (329kg) (M700).

The Micronaire, Color and Trash cabinet is 28 inches (71 cm) wide; it is the same height and depth as the Length/Strength cabinet and weighs approximately 335 pounds (152 kg).

Power:

The following power requirements apply to both North American and European-type systems.

- Voltage (nominal): 220 AC ±15%

- Current: <15 Amperes

- Frequency: 50 – 60 Hertz

- Harmonic distortion: <5%

- Wire size: Sufficient to have <5% drop from no load to full load

- Electrical interference: Free of transient voltages from other equipment

Uninterruptible Power Supplies (UPS):

If you expect to have frequent power shutdowns, USTER Technologies recommends that an Uninterrupted Power Supply (UPS) device be used to prevent loss of data or other related problems. The input for the UPS, which powers the computer and monitor only, is located on the back of the main cabinet beside the power entry connector.

Requirements for UPS to Support the Entire USTER® HVI 1000 System (except vacuum blower).

Superior Electric #SLI1000XR (recommended) or equivalent with the following characteristics:

- “Line Interactive” design for maximum protection against line transients

- Minimum output power rating of 1000 VA (900 Watts) at 230 volts 50 or 60 Hz

- Input voltage of 154 – 288 volts, 50 or 60 Hz (single phase)

- Must be TÜV certified or bear the CE mark for European countries and be UL listed for North America

- Run time of 10 minutes or greater

UPS is not required for the computer/monitor if UPS is used for the entire system.

Compressed Air:

The air supplied to the instrument should comply with ISO8573.1 Quality Class 3 as follows:

- DIRT Particle Size: <5 microns

- WATER Pressure Dew Point: <-4° F @ 100 PSIG (128 ppm by volume)

- OIL (including vapor): <1.0 ppm

- Air Pressure: 100-150 PSIG (700-1034 kPA)

- Air Volume: The instrument requires at least three SCFM (85 liters/min) supplied by a 10-mm (3/8 inch) line.

- Laboratory Temperature: These specifications are for the ambient conditions referenced below. If the air line will be subjected to temperatures that could promote condensation, a water filter attached to the air line inside the lab is recommended to remove any condensation that may occur.

Ambient Conditions:

According to ISO 139, the following ambient conditions must be maintained in the laboratory in order to get repeatable and comparable test results:

- Temperature: 20±2°C; 65 °F to 72 °F

- Relative Humidity: 65±2%

For consistent test results, fiber samples should be conditioned in the laboratory environment with the above-mentioned ambient conditions for 24 hours. Samples should be laid out openly in the laboratory, and taken out of plastic bags, in order for the cotton to fully condition to the environment.

Uster Technologies has made all possible efforts to ensure that all information is accurate at the time of publication. Hereby it is declared that alterations to the product may be possible at any time. In these cases the information contained in this technical datasheet is subject to change without notice.

You may also like:

- List of Spinning Machines with Manufacturers Name

- Recent Development of Carding Machine in Yarn Spinning