Sewing Needle:

Needle is used for sewing fabric with thread. The speed of the sewing needle in the sewing machine is controlled by mechanical way. During sewing, the way in which the needle penetrates the fabric, has its relation with the strength of the seam, the appearance of the seam and the normal wearable life of the seam.

Functions of the Sewing Needle:

The functions of the needle of a sewing machine are as follows:

- Without damaging the fabric, a hole is made in the fabric, through which needle thread is entered.

- After entering the needle thread with needle into the fabric, to make a loop of the needle thread which will be picked up by the hook of the bobbin case or the looper.

- In other machines except the lockstitch, to pass the needle thread through the loop made by the looper.

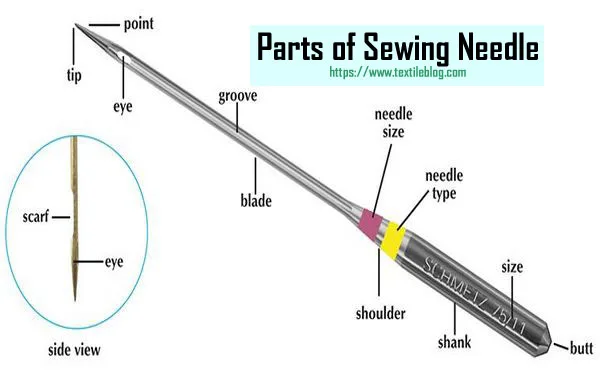

Parts of a Sewing Needle:

About the image of an ordinary needle, the names of the various parts of it and their role in making a satisfactory stitch are discussed below. In figure, the image of an ordinary needle has been shown.

1. Butt:

The very first portion or base of a needle which is made in a specific shape, by which the needle can be attached with the needle bar easily and fairly.

2. Shank:

This is the surface or part of a needle which is attached in the needle bar. A shank may be cylindrical or there may have a flat end in one side. This is thicker and stronger than the remaining part of the needle and it works as a support for the needle.

3. Shoulder:

The portion in between shank and blades is called the shoulder. When a needle penetrates into the fabric and reaches to its lowest bottom destination, then the shoulder also goes into the fabric, as a result, it helps to increase the hole made by the head of the needle. When the needle comes out of the fabric with needle thread, then there is less friction between needle and fabric due to the bigger hole, besides, the shoulder helps to strengthen the blade of the needle.

4. Blade:

The long portion of the needle extended from the eye to the shoulder is called the blade. This is the longest portion of a needle and most frictions with fabrics happen here.

5. Long groove:

There is a long and narrow slot in the blade extended from the shoulder to the eye of the needle which is called the long groove. When the needle penetrating into fabric goes downward with needle thread, then the needle thread stays at the gap of the long groove, as a result it helps to become comparatively less friction of thread and needle with fabric. Also less heat is generated in the needle due to less friction and the possibility of damaging of needle thread become less due to friction or temperature.

6. Short groove:

The short groove is placed at the same side at which the hook or the looper is placed in the needle. This is extended from a little above the needle eye to the bottom and it helps in the formation of needle thread loop.

7. Needle Eye:

There is a hole at the front of the needle which is called the eye. It is extended from long groove to the short groove. The inside shape of the needle is very important, especially it is related with being damaging or not of the needle thread when the needle penetrates into the fabric and it is also related with the correct loop formation of the needle thread. The parts of some needle eyes are much wider than the blade which are called buldged eye. The buldged eye acts like a shoulder but during sewing of fine fabrics, fabric may be damaged.

8. Scarf:

Just a little above the needle eye, there is a small slot which is called the scarf. This scarf helps for setting the looper or hook closer with the needle. As a result, the hook or looper can easily hold the needle thread loop.

9. Point:

The part extended from the needle eye to the tip of the needle is called the point. The needle point is made in such a way so that no harm is caused to the fabric during its penetration. If it is not determined properly that which needle will be used for which fabric, then during sewing of the fabric it (fabric) may be damaged by the needle.

10. Tip:

The last end of the needle point is called the tip. Tip is related with the efficiency of penetrating of fabric with needle.