Features of Water Jet Cutting Machine with Advantages and Disadvantages

Saiful Sabuz

Department of Textile Engineering

Ahsanullah University of Science and Technology (AUST)

Email: saifulsabuz.tex23@gmail.com

Water Jet Cutting Machine:

A water jet cutter is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of water or a mixture of water. The cutter is commonly connected to a high-pressure water pump where the water is then ejected from the nozzle, cutting through the material by spraying it with the jet of high-speed water. The features of water jet cutting machine is given below:

Features of Water Jet Cutting Machine:

- In water jet cutter, water or mixture of water is used to cut fabric which is controlled by computer.

- Special software is used to cut fabric.

- A very high velocity (60,000 lb/ square inch) and small diameter steam of water is created by a water jet intensifier pump.

- The high pressure jet acts as a solid tool and sharp knife which can easily cut the fabrics, lathers and plastic materials.

- As the jet penetrates successive plies in a spread, the momentum decreases and cutting ability is reduced. So, the lower lays of fabric cutting will be wide and less effective.

- The jet of water and loose fibers normally caught and drains away by a catcher when cut the fabric. It is in the bottom of the fabric lays and moves with the same speed and the same direction of water jet.

- To improve the cutting speed, it is needed to adjust the pressure and radius of the jet.

Working Principle of Automated Water-jet Cutting Systems:

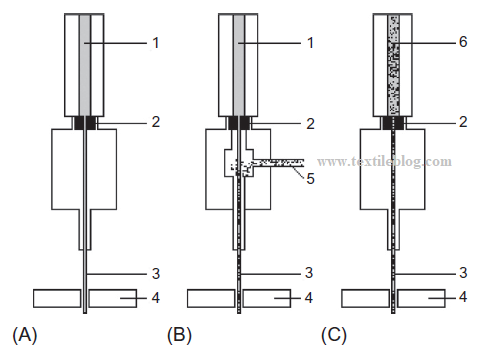

The cutting operation is performed by a very thin jet (3) of pure water (1) or water-abrasive mixture (6) that is forced at high speed through a tiny hole in an industrial sapphire or diamond (2) (see Figure-3). Two types of water-jet cutting methods are distinguished, pure water jet cutting and abrasive water-jet cutting.

The widely used ‘abrasive’ water-jet process is started in the same way as with a ‘pure’ water jet. The difference lies in the manner in which the abrasives are added to the water. An entrained system pressurizes water and pulls abrasive particles (5) into the rapidly moving stream at its exit. As the thin stream of water leaves the jewel, abrasive is added to the stream. The jet of water accelerates the abrasive particles, enabling them to cut through much harder materials (4). An abrasive slurry system mixes water and abrasive (6) before the water is pressurized. The abrasive jet stream works by particle erosion; therefore, it takes some time to cut through the material. Abrasive water-jet cutting gives good tolerances and surfaces but slightly conical cuts. The abrasive water jet is a well-established method and a good alternative/complement to laser and plasma cutting. The advantages of this type of system are the use of lower pressures, very high material removal rates, and less expensive equipment. The slurry system is less precise and therefore is more commonly used for rough cutting processes where a high rate of material removal and cool cutting is important.

Advantages of Water-jet Cutting Machine:

- Most effective to cut hard materials such as leather and plastic.

- Sound of cutting is less.

- Excess heat is not produce.

- Higher cutting speed.

- The table is not cut as catcher is used.

- Since there is no solid knife so, no sharpening is required.

Disadvantages of Water Jet Cutter:

- There is a danger of wet edges.

- Water spot may occur on fabric.

- High costly.

- Hard water causes rusting. So water must be filtered and de-ionized before use.

- As in the lower lay, water jet spreads out and then cut is wider and rough at the bottom of the spread.

- Not suitable for high lay of fabric.

- The sound of jet need to control.

Uses / Application of Water Jet Cutting Machine:

Water-jet machine is widely used to cut metal, composite, marble, granite, ceramic tile, glass, cloth, food, leather, rubber, nylon, wood, dynamite and so on. Water jet cutter is not suitable for cutting fabric but this cutter is under research to cut fabric.

References:

- Industrial Cutting of Textile Materials, 2nd Edition by Ineta Vilumsone-Nemes

- Garment and Technology-Prof. M.A. Kashem

- Garments Manufacturing Technology- Saiful Azam, Abu Saleh.

- http://en.wikipedia.org/wiki/Water_jet_cutter

- http://www.jetedge.com/

- http://www.wardjet.com/

You may also like:

- Garments Fabric Cutting: Definition, Requirements and Methods

- Fabric Cutting Machines with Advantages and Disadvantages

- CO2 Laser Galvo Systems for Laser Marking and Engraving on Denim & Jeans