What is Cut Edge Fabric?

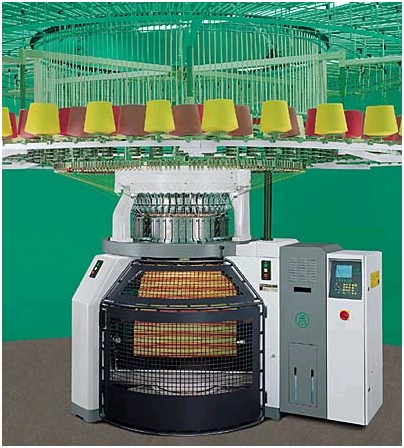

A cut edge fabric is usually produced by slitting open a tube of fabric knitted on a circular machine. A slit tube of a fabric from a 30 inch diameter machine will have a width of 94 inches (πD) at knitting and before relaxation.

In a word cut edge fabric means free of edge, so that it will be open. After cutting the tubular fabric we get our desire cut edge fabric. In modern knitting machine, there is device which cut the edges and rolls the fabric in taker-in roller automatically.

In the conventional finishing line a machine used to slit the tubular fabric called slitting machine. Now a day the demand of cut edge fabric is increased day by day, due to the finishing performance is quite higher than that of tubular finish.

You may also like: What is Selvedge Fabric | Working Principle and Importance of Selvedge Fabric

What is Tubular Fabric?

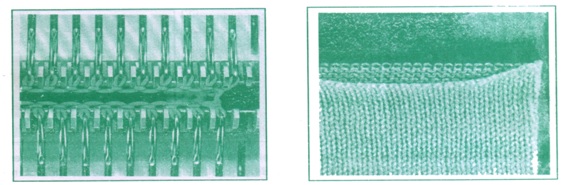

This is also called circular knitting. It can be made on circular machines with one needle-bed or on flat machines with two needle beds. In this latter case the tubular fabric knits a flat tube which takes its circular form after knitting. The following description gives tubular knitting made on flat machines with two needle-beds. The flat machines have, in regard to circular machines for instance, the important advantage of being able to produce tubular fabric of any diameter, due to the simple fact that one puts into action the needles on any width.

It can be interesting in certain cases, especially for trimmings– to not connect the selvedges of the fabric of the front to that of the back, thus producing tubular fabric open at one or both sides. To do this, knit two rows on the back needle–bed, then two rows on the front needle-bed, and so on. Now the liaison will only be affected at one side, at the right or the left, depending on whether the start has been done from the right or the left. To obtain circular knitting open both sides, one must naturally use two yarns carriers, one on the back knitting always with the back needle-bed and the other on the front feeding the front needles. In this manner the thread of each yarn carrier feeds always the needles of the same needle-bed and the two pieces of fabric are not joined to one another. The ordinary weft of an article is knitted generally with 2, 4, or 6 rows of tubular knitting, which ensures a sound edge.

The tubular fabric is composed of joining up of two pieces of knitting on one needle bed, one piece made on the front needle bed and the other on the back needle bed. They are connected one to the other by a common thread which passes from one needle bed to the other at the two selvedges. This liason is not visible in the fabric, the gap between the needle beds is designed so that the inter stitch at the selvedges is equal to the other inter- stitches.

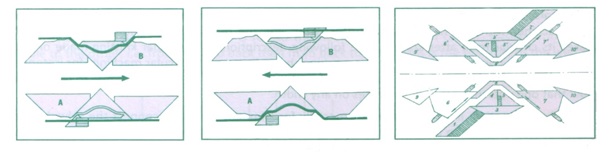

The followings figures illustrate the cam plates of a hand sweater knitting machine arranged for the production of tubular fabric. Two raising cams, one at the back, are out of action. Thus when the carriage travels from left to right, the back needles only will form a stitch. On the other hand, when the carriage goes from right to left, only the front needles form a stitch. In this manner, the lowering cams A and B are always inactive. They must therefore be fixed at a higher position than the other two so as to avoid any tension on the stitches. In the following right corner figure of cam-boxes the clearing or raising cam 1 and 2 set for tubular fabric.

What is Open Width Fabric?

Cut edges fabric is known as open width fabric in somewhere. The width of open width fabric is double of the width of tubular fabric.

Mathematically, width of tubular fabric = width of open fabric /2

The actual width of the fabric depends on the diameter of the machine and the stitch length.

You may also like: What is Knitting and Knitted Fabric | Features of Knitted Fabrics