What is Yarn Twist?

Twist is the spiral arrangement of the fibers around the axis of the yarn. The twist binds the fibers together and also contributes to the strength of the yarn. The amount of twist inserted in a yarn defines the appearance and the strength of the yarn. The number of twists is referred to as turns per inch.

The amount of twist added into a yarn will determine the property of the yarn in terms of durability, flexibility, resilience and strength. A high-twist yarn may offer a hard and relatively stiff yarn, whereas a low-twist may give a weak yarn that is more flexible. Finer yarns have more twists in them than coarser ones, and warp yarns have more twists in them than weft yarns. Fabrics with a soft surface, e.g. peach effect, have a slack twist called soft twist, which allows fiber ends to be pulled to the surface. Fabrics with smooth surfaces have a higher amount of twist, which offers extra strength and some crease resistance, whereas textured surface fabrics, such as crêpe, are given a maximum twist.

There are different definitions given to twist of the yarn. Some of the definitions given are as follows:

Yarn twist is defined as the spiral deposition of the components of a twist is the measure of the spiral turns given to a yarn in order to hold the constituent fibers or threads together – Skinkle.

When a strand is twisted the component fibers tend to take on a spiral formation, the geometric perfection of which depends on their original formation – Morton.

Twist may be defined as the rotation about the yarn axis of any line drawn on the yarn which was originally, before twisting parallel to the yarn axis – Wool Res. Vol. 3.

Twist may also be defined as thread which is usually the result of relative rotation of the two ends.

Twist Direction:

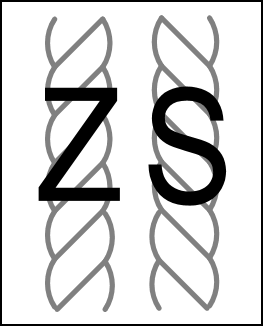

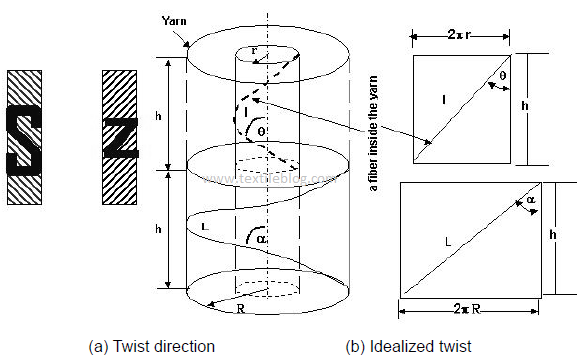

The direction of the twist at each stage of manufacture is indicated by the use of letters S or Z in accordance with the following convention. Twist may be performed in the following two directions (see Figure 2).

S direction: A single yarn has ‘S’ twist (clockwise) if, when it is held in the vertical position, the fibers inclined to the axis of the yarn conform in direction of slope to the central portion of the letter S.

Z direction: A single yarn has ‘Z’ twist (anticlockwise) if, when it is held in the vertical position, the fibers inclined to the axis of the yarn conform in direction of slope to the central portion of the letter Z.

As can be seen from the diagram (Figure 1), by holding the yarn upright, the slope of the middle of the yarn should flow in the same direction as the slope of the middle of the letters S or Z. The majority of single yarns are Z, but the direction does not really affect the property of the yarn. However, in a plied yarn, the direction is important because the single yarn should be in one direction but when two yarns are combined to make the ply it is running in the opposite direction; this ensures that the yarn holds together.

For example, 2 x S single yarn + Z ply = stable, smooth, firm, tight and durable yarn suitable for weaving; worsted yarns often possess a high-angled twist.

2 x Z single yarn+ S ply = stable, soft, bulky yarn suitable for knitting. It often has a low-angled twist.

2 x S single yarns + S ply = an unstable yarn that will snag and curl.

2 x Z single yarns + Z ply = unstable yarn that will snag and curl.

Twist Level / The Amount of Twist:

The amount of twist in the yarn is commonly expressed by the number of turns per unit length. In B.S. 946: 1952 it is stated that the amount of twist in a thread at each stage of manufacture is denoted by a figure giving the number of turns of twist per unit length at that stage. It affects the characteristics and properties of a yarn including appearance, behavior and durability.

The amount of twist is an important factor in finished consumer goods. It determines the appearance as well as the durability and serviceability of a fabric. Fine yarns require more twist than coarser yarns. Warp yarns, which are used for the length wise threads in a woven fabric, are given more twist than filling yarn which is used for cross wise threads.

The amount of twist also depends upon the type of the fabric to be woven:

- Yarns intended for soft surfaced fabric are given slack twist. They are called as soft twisted yarns.

- Yarns intended for smooth surfaced fabrics are given optimum twists. Such twisted yarns contribute strength, smoothness and elasticity.

- Yarns intended for crepe fabrics are given maximum amount of twists.

Types of Twist:

- S-twist

- Z-twist

Twist Principle:

One end will be fixed and another end will be turned this is the twist principle.

You may also like: