Basic Concept of Wool Fiber:

Wool belongs to the animal fibers together with the fine and coarse animal hairs. The best quality of wool is obtained from the shoulders and back of the sheep and the poorest wool is obtained from the lower legs. Wool is mainly used as a minor blend (up to 10%) with cotton to introduce special properties to the terry fabric. Raw wool contains a wide variety of impurities, which can account for between 30% and 70% of the total mass. The impurities consist of wool grease, secreted from the sebaceous glands in the skin; suint, produced from the sweat gland; dirt and sand. Wool grease consists chiefly of esters, formed from a combination of sterols and aliphatic alcohols with fatty acids. Suints consist primarily of the potassium salts of organic acids. The most important breeds of sheep for fiber production are Merino, Crossbred and Comeback, the most important producing countries are Australia (fine fibers) and New Zealand (coarse wool, mainly for carpets).

Wool is the fiber derived from the specialized skin cells, called follicles, of animals in the Caprinae family, principally sheep, but the hair of certain species of other mammals such as goats, llamas and rabbits may also be called for wool. Wool has several qualities that distinguish it from hair or fur: it is crimped; it has a different texture or handle; it is elastic; and it grows in staples (clusters).

Wool’s scaling and crimp make it easier to spin the fleece. They help the individual fibers attach to each other so that they stay together. Because of the crimp, wool fabrics have a greater bulk than other textiles and retain air, which causes the product to retain heat.

Wool is a keratinous type protein base staple fiber. Keratin fibers are subdivided into three categories, viz.

- Wool fibers which are grown by sheep.

- Hair fibers which are grown by animals other than sheep.

- Fur fibers which are grown by rabbit, mink, etc.

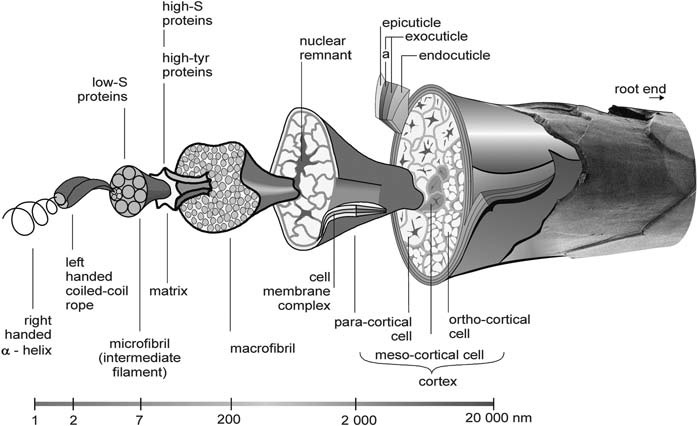

Wool comprises about 33% keratin, 26% dirt, 26% suint (usually salts of sodium, potassium or fatty acids), 10% wool fats and 5% mineral impurities. Keratin consists of more than 20 different types of amino acids. The morphology of wool fibers is complex. A schematic diagram showing the morphology of fine wool is shown in below Figure. There are essentially two main categories of cell: cortical cells, which account for 90% of each fiber, and cuticular cells, which are present at the fiber surface. The cuticle is separated from the underlying cortex by a cell membrane complex, which also holds adjacent cortical cells together. The cell membrane complex is, therefore, the only continuous phase in a wool fiber. Coarser wool fibers often contain a medulla as well. The medulla comprises a central core of cells, continuous or intermittent, arranged along the fiber axis between the cortical cells.

The surface properties of wool are dependent on the structure of the cuticle. Each cuticular cell approximates to a rectangular sheet of length 30 μm, breadth 20 μm and thickness 0.5 μm. The scaly type of fiber surface is the results of a considerable overlap of adjacent cuticular cells. One consequence of this arrangement is the so-called directional frictional effect: the coefficient of friction from the root to the tip is considerably less than that from the tip to the root. The directional frictional effect is responsible for the innate ability of wool to felt, a unique property amongst textile fibers. The cuticle accounts for 10% of the fiber and consists of three layers: the epicuticle, the exocuticle and the endocuticle. The epicuticle is identified as a thin surface membrane, containing predominantly keratin chains with a small proportion of lipid.

Although it is traditionally considered as an individual component of the cuticle, it is now realised that it is part of the resistant membrane that surrounds all cuticular and cortical cells. The exocuticle, 0.3 μm thick, comprises 60% or so of each cuticular cell. There are two subcomponents of the exocuticle, although neither is well defined. The cortex comprises over 85% of a wool fiber, and is the main component governing its mechanical properties. It is extremely complex structurally and consists of spindle shaped cells, generally 100 μm long and 3–6 μm wide, aligned along the fiber axis. There are two principal types of cortical cell: the orthocortex and the paracortex. They are distinguished from each other by the distribution of nonkeratinous material within each cell. The proportion of orthocortex is 66% and that of paracortex is 30%. The bilateral segmentation of the two types of cortical cell is considered to give rise to the natural crimp of fine wool fibers. The orthocortex is oriented towards the outside of the curl of the crimp. In coarser wools, as in Lincoln wool for example, the orthocortex is surrounded by the paracortex.

Properties of Wool Fiber:

Wool is a luxury fiber with an excellent feel and touch. It is soft and natural hand feel. Generally wool is wrinkle-resistant. It is light weight and durable. Wool absorbs moisture. It retains shape. Wool has a good drape and fall. Basic properties of wool fiber is summarized below:

a) Absorbency:

Wool is hygroscopic; water droplets will remain on the surface due to the natural oils that are retained within the fabric. However, after a period of time, moisture will seep through. The wool can absorb about 20% of its weight in water, but it will not feel damp. Although it is absorbent, it will not allow wicking. As it is highly absorbent it can be dyed easily.

b) Resiliency and Elasticity:

Wool has great resilience and elasticity, which means that it has excellent draping qualities, good shape retention and creases will disappear after a period of time. A fiber can be stretched by 25% times its original length without breaking which makes it less likely to tear and giving freedom of movement to the wearer. This property arises due to the ease of slippage of the scale structure and the natural crimp of the fiber.

c) Strength:

Wool is the weakest of the natural fibers and the durability will be determined by the grade of wool; the more durable the wool the less resilience and texture the fabric will have. Wool can be strengthened by using a tight twist in the spinning process or plied yarns.

d) Conductivity:

Wool fibers do not conduct heat because the gaps between scales trap the air to maintain the temperature. A yarn that has a low twist will increase the warmth of the product.

e) Non-Flammable:

Wool is flame resistant. If fibers or fabric are lit they will smoulder for a short period of time before self extinguishing.

f) Susceptible:

Wool is easily attacked by the larvae of moths and carpet beetles; the hatched grubs feed off the fibers and leave holes in the fabric. Wool fibers are also weakened by perspiration, strong alkalis, and strong sunlight, but there the fiber possesses some degree of UV protection. Wool is very susceptible to shrinkage – more so in woollen than worsted products; the looser construction of woollen yarns causes such shrinkage. Also, wool can be itchy and cause allergic reactions in people with sensitive skin.

g) Sustainable:

Wool is a renewable, sustainable resource. It is also biodegradable and excellent for recycling; garments are sold to specialist firms that reclaim the fibers and use them to make yarns and fabrics.

Below table will also clarify about properties of wool fiber.

| Property | Value |

| Specific gravity | 1.32 |

| Tenacity | 9–15 cN/Tex (dry), 7–14 cN/Tex (wet) |

| Elongation at break | 25–30% (dry), 25–50% (wet) |

| Elastic recovery | 50% recovery from 10% stretch |

| Resilience | Very high |

| Abrasion resistance | Apparel wool: quite low. Carpet wool: high |

| Moisture regain | 14–18% |

| Launderability | Wool garments need to be washed with care—normally at 40°C. Severe mechanical agitation in washing machines and tumble driers can induce felting |

Wool Quality Number:

Wool quality number is nominally intended to indicate the highest worsted count to which it can be spun. It is probably more accurately interpreted as implying a certain fineness of fiber. This has arisen owing to the importance of fineness as a factor affecting the spinning quality, and to the consequent stress which is laid upon it by the wool classers.

From the foregoing discussion, and from the fact already mentioned that a single fleece varies considerably within, it will be realized that at least, so far as raw wool is concerned, quality number should be taken as being only general indications of probable spinning performance.

In the trade, a series of numbers called quality numbers is, therefore, used to indicate the difference in standards. The highest quality number is given to the finest wool, the lowest to the coarsest wools. The normal range of commercial wool is from 80s quality down to 28s quality, the numbers being apportioned to conform to easily distinguishable differences in standard, particularly fineness. The numbers are not regularly progressive or spaced but the full range as 90, 80, 70, 64, 60, 58, 56, 54, 52, 50, 48, 46, 44, 40, 36, 32 and 28s. These numbers should not be confused with those used for the gauge or thickness of a yarn. In yarn processing, such numbers are known as yarn count or spinning count. This yarn number is one which can be absolutely defined and determined, whereas quality fineness number of fiber cannot be defined and determined. But quality fineness number cannot so accurately be related to the mathematical measurement of the diameter of the fibers, e.g. from 64s quality maximum of 48s and minimum 30s yarn count can be spun.

Different types of wool quality number:

1. Fine wool:

Merino sheep, generally Australian merino, Rambouillet, American merino breeds produce fine wool. The quality (designated as wool quality number) varies from 60s upward length of fiber varies from 4 cm to 12 cm for one year growth. These fibers are non-medullated and the diameter of fiber is below 24 μm.

2. Medium wool:

Some breeds of sheep such as Hampshire, Southdown, Cheviot, produce medium quality wool. Wool quality varies from 48s to 60s. Length of fiber varies from 5 to 10 cm for one year growth. Diameter varies from 24 to 32.5 μm. These fibers are slightly medullated.

3. Coarse wool:

Most of the Asiatic breeds of sheep produce coarse wools which are invariably medullated. They are mostly of quality below 48s, and their length varies from 6 cm to 15 cm for one year growth. Diameter ranges from 32.5 μm and above. Since these wools are used mainly in carpets, they are often known as carpet wools.

In addition to the above mentioned varieties of wool there are two other important varieties namely, long wool and cross-breed wool.

4. Long wool:

Breeds such as Cotswool, Romneymarsh, Lincoln, etc., which are generally regarded as mutton type of sheep, which produce medium to coarse wools which are very long, i.e. about 12 cm–40 cm for one year growth. These wools may be medullated and their quality usually will be in the range of 36s–50s and their diameter ranges from 30 to 40 μm.

5. Cross-breed wool:

These are not pure breeds. These breeds are produced from two different breeds of sheep. Depending upon the parent breeds of sheep, the characteristics of the cross-breed will vary.

Corriedale and Polwarth are typical examples of cross-bred sheep. Their quality varies from 48s to 64s. Their length varies from 6 cm to 17 cm for one year growth, and the diameter ranges from 22 to 32.5μm.

The wool fibers are obtained by shearing or clipping the sheep in such a manner that the coat of hair or fleece remains in one piece. Shearing may take place once or twice a year.

References:

- Introduction to Textile fibers by H. V. Sreenivasa Murthy

- Fibres to Fabrics by Bev Ashford

- Handbook of Worsted Wool and Blended Suiting Process by R. S. Tomar

- Woven Terry Fabrics: Manufacturing and Quality Management by Jitendra Pratap Singh and Swadesh Verma